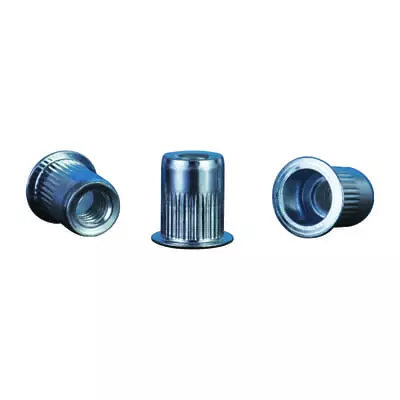

Home » Shop Steel Rivet Nut Inserts Online

Shop Steel Rivet Nut Inserts Online

Steel rivet nut inserts are a reliable and high-strength fastening solution designed to provide secure, load-bearing threads in metal and other hard materials. Known for their excellent tensile and shear strength, they are widely used in industries such as automotive, heavy machinery, construction, and industrial equipment manufacturing.

For businesses or procurement specialists looking to buy steel rivet nuts in bulk, these fasteners offer both durability and cost-efficiency. Whether you’re sourcing for production lines, assembly plants, or large-scale projects, steel rivet nuts in wholesale quantities ensure consistent performance and fast installation with minimal tooling requirements.

At Rivetfix, we supply a full range of steel rivet nuts in various thread sizes and head types (flat head, countersunk head, hex, knurled, and more) to suit diverse application needs. Get in touch today to discuss your requirements and request a quote for your steel rivet nut inserts bulk order.

Related Products

Get a Free Quote Now!

custom rivet and rivet nut manufacturer

M4 Steel Rivet Nut Inserts

M5 Steel Rivet Nut Inserts

M6 Steel Rivet Nut Inserts

M8 Steel Rivet Nut Inserts

M10 Steel Rivet Nut Inserts

M12 Steel Rivet Nut Inserts

Hex Steel Rivet Nut Inserts

Round Steel Rivet Nut Inserts

Knurled Steel Rivet Nut Inserts

Countersunk Head Steel Rivet Nut Inserts

Flat Head Steel Rivet Nut Inserts

Reduced Head Steel Rivet Nut Inserts

Applications of Steel Rivet Nuts

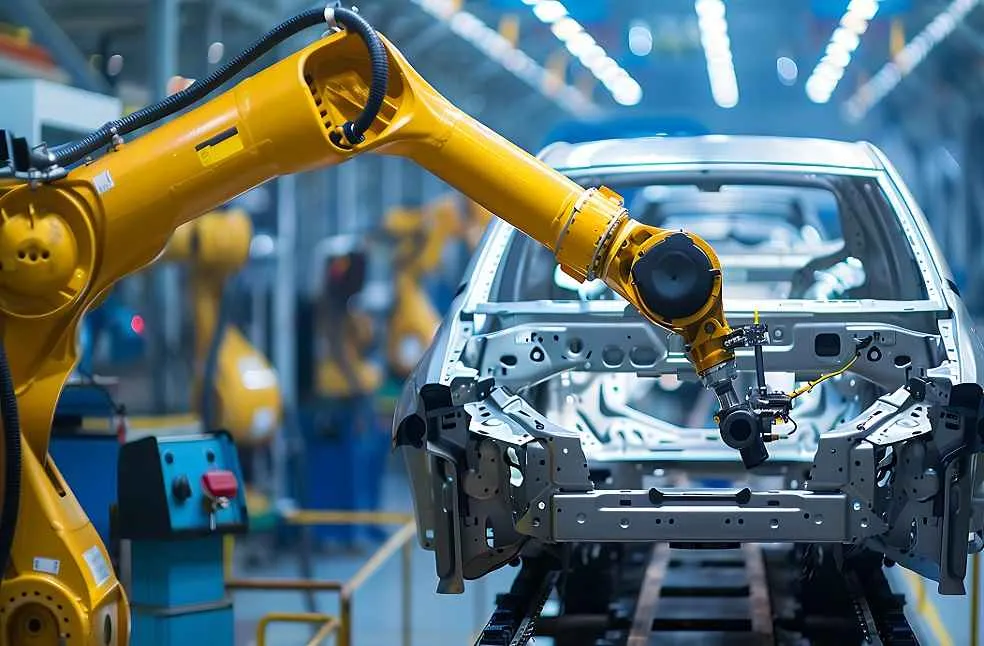

Automotive Industry

Steel rivet nuts are widely used in vehicle body structures, chassis, engine covers, and seat mounting due to their excellent tensile and shear strength. Their one-sided installation feature makes them especially suitable for space-constrained automotive assembly applications.

Heavy Machinery

In sectors such as construction machinery, agricultural equipment, and mining machines, steel rivet nuts are used to connect large metal structural parts. They can withstand high loads and constant vibration, ensuring structural stability and long service life.

Construction and Steel Structures

Steel rivet nuts are commonly used in curtain wall systems, metal brackets, industrial platforms, and steel frame structures. Compared to traditional welding methods, steel rivet nuts offer easier, more reliable, and maintenance-friendly installation.

Electrical and Cabinet Equipment

In electrical cabinets, distribution boxes, and industrial control panels, steel rivet nuts are used to mount fans, locks, cable clamps, and other components, ensuring secure connections that resist loosening.

Rail and Transportation

Steel rivet nuts are suitable for connecting rail vehicle structures, passenger seats, and lighting systems. Their vibration and fatigue resistance ensures safety during operation.

Furniture Manufacturing

Used in high-strength connections for items like office desks, metal cabinets, and industrial workbenches, steel rivet nuts provide a clean, reliable, and flush-mounted fastening solution.

Related Articles

What Is the Difference Between Keensert and Threaded Insert?

What Is the Differen

FAQs About Steel Rivet Nuts

What are steel rivet nuts used for?

They are used to create strong, load-bearing threads in thin or soft materials where conventional tapping is not feasible.

What types of steel are used in rivet nuts?

Common types include carbon steel, zinc-plated steel, and galvanized steel, each offering different levels of strength and corrosion resistance.

How do steel rivet nuts compare to stainless steel rivet nuts?

1. Material Composition

- Steel Rivet Nuts: Typically made from carbon steel, with surface treatments such as zinc plating, electroplating, phosphating, or hot-dip galvanizing to improve corrosion resistance and appearance.

- Stainless Steel Rivet Nuts: Made from 304 or 316 stainless steel, which provides natural corrosion resistance without relying on external coatings.

2. Corrosion Resistance

- Steel Rivet Nuts: Do not inherently resist rust and require surface treatment to improve corrosion resistance. However, they may still rust over time when exposed to humid or salt-laden environments.

- Stainless Steel Rivet Nuts: Offer excellent natural rust resistance, especially 316 stainless steel, which is ideal for marine, chemical, and harsh outdoor environments.

3. Mechanical Strength

- Steel Rivet Nuts: Generally offer higher strength than stainless steel, especially in tensile and shear loads, making them suitable for applications with high structural demands.

- Stainless Steel Rivet Nuts: Though slightly lower in strength compared to carbon steel, they meet the needs of most industrial applications and excel in corrosion resistance and service life.

4. Cost and Cost-Effectiveness

- Steel Rivet Nuts: Lower cost, making them suitable for cost-sensitive applications in dry or indoor environments.

- Stainless Steel Rivet Nuts: Higher initial cost, but better value over time due to longer service life, greater reliability, and superior corrosion resistance.

5. Typical Applications

- Steel Rivet Nuts: Ideal for use in indoor equipment, mechanical components, furniture, and electrical enclosures in general industrial settings.

- Stainless Steel Rivet Nuts: Better suited for outdoor equipment, marine structures, offshore engineering, food processing, and medical devices, where high corrosion resistance is required.

Final Recommendations:

- When strength and cost are primary concerns, steel rivet nuts are a good choice—but make sure proper surface coating is applied.

- When corrosion resistance and long-term durability are critical, stainless steel rivet nuts are the preferred option, especially in moist or corrosive environments.

Are steel rivet nuts suitable for outdoor use?

Steel rivet nuts can be used in outdoor environments under certain conditions, but proper corrosion protection is essential. Below is a detailed explanation:

1. Carbon Steel Itself Lacks Corrosion Resistance

Raw carbon steel, when exposed to air, moisture, or salt in outdoor environments, is prone to oxidation and rust, which can weaken structural strength and compromise connection stability.

2. Surface Treatment Determines Weather Resistance

To improve outdoor suitability, steel rivet nuts are typically treated with one or more of the following coatings:

Zinc Plating:

Provides basic rust protection and is suitable for mild outdoor conditions, but may still corrode in high humidity or salt spray environments.

Hot-Dip Galvanizing:

Offers a much thicker coating and higher corrosion resistance than standard zinc plating, making it suitable for exposure to rain or general outdoor use.

Dacromet Coating or Zinc-Chromium Coating:

Delivers excellent corrosion resistance and is commonly used in automotive and heavy-duty engineering applications requiring mid-to-high level outdoor protection.

3. Suitable Outdoor Applications (With Corrosion Treatment)

- Steel structure connectors in buildings

- Outdoor electrical enclosures and support brackets

- Traffic infrastructure and guardrails

- Agricultural machinery and gardening equipment

- Temporary steel structures

4. Bare Steel Is Not Recommended for Direct Outdoor Exposure

If steel rivet nuts are not treated with any protective coating, they are not recommended for outdoor use, as they can rust severely in a short time, leading to connection failure.

5. Alternative Recommendation

For long-term outdoor exposure or environments with high corrosion risk (such as coastal or humid areas), it is strongly recommended to use stainless steel rivet nuts (e.g., 304 or 316) to ensure durability and reliability of the fastening.

Do steel rivet nuts offer vibration resistance?

When properly installed, steel rivet nuts offer a certain level of vibration resistance. This is because, once riveted, the nut forms a stable mechanical lock with the base material, making it less likely to loosen due to vibration. In structural applications, the inherent strength and rigidity of steel help maintain fastening integrity under long-term vibration loads, making steel rivet nuts particularly effective in environments with medium to high vibration intensity, such as heavy machinery, automotive chassis, and engineering equipment.

However, it is important to note that steel rivet nuts themselves do not have anti-loosening features, such as locking threads or serrations. Therefore, in applications subject to frequent or intense vibrations, it is recommended to use additional anti-loosening methods—such as nylon-insert lock nuts, spring washers, or thread-locking adhesives—to further improve vibration resistance.