Home » Shop Countersunk Head Rivet Nut Inserts Online

Shop Countersunk Head Rivet Nut Inserts Online

Looking for a sleek and secure fastening solution? Our countersunk head rivet nut inserts are engineered for applications requiring a flush surface finish while maintaining strong thread performance. Made from premium materials, they are ideal for thin-walled materials where space and aesthetics matter. Whether you’re working in automotive, aerospace, electronics, or general fabrication, these inserts provide dependable load-bearing capabilities and corrosion resistance.

Upgrade your assembly process with our versatile and easy-to-install countersunk head rivet nut inserts. Designed to deliver precision and durability, they’re available in various sizes and finishes to meet your specific project needs. Shop now and enjoy a perfect blend of function and form—your next high-performance fastening solution starts here!

Related Products

Get a Free Quote Now!

custom rivet and rivet nut manufacturer

M3 Countersunk Head Rivet Nut Inserts

M4 Countersunk Head Rivet Nut Inserts

M5 Countersunk Head Rivet Nut Inserts

M6 Countersunk Head Rivet Nut Inserts

M8 Countersunk Head Rivet Nut Inserts

M10 Countersunk Head Rivet Nut Inserts

M12 Countersunk Head Rivet Nut Inserts

Countersunk Head Round Rivet Nut Inserts

Countersunk Head Knurled Rivet Nut Inserts

Applications of Countersunk Head Rivet Nuts

Sheet Metal Fabrication

Ideal for thin sheet metal where a flush surface is required after installation, ensuring a clean, professional look.

Automotive Industry

Used in body panels, dashboards, and structural components where a low-profile, strong thread is needed without access to the back side.

Aerospace Components

Commonly used in lightweight assemblies and interior panels where flush installation improves aerodynamics and appearance.

Furniture and Appliances

Perfect for joining metal, plastic, or composite parts where visible screw heads are undesirable.

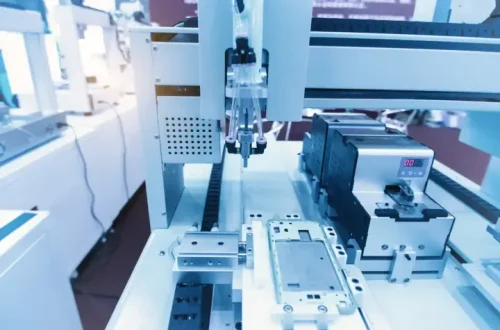

Electronics Enclosures

Ensure flat surfaces for circuit board mounting and enclosures requiring precision and a clean finish.

Architectural Fixtures

Used in railings, panels, and claddings for a secure, aesthetic connection that doesn't protrude.

Related Articles

What Is the Difference Between Keensert and Threaded Insert?

What Is the Differen

FAQs About Countersunk Head Rivet Nuts

1. What is a countersunk head rivet nut?

A countersunk head rivet nut is a type of threaded insert with a tapered, conical head designed to sit flush with the surface of the material it is installed into. It is commonly used to provide strong, reliable internal threads in thin sheet materials or hollow structures. Key features include:

- Structural Characteristics: The rivet nut features a countersunk (flat, conical) head that allows it to be installed flush with the surface. Its body may be round, hexagonal, or knurled to enhance anti-rotation performance. The internal threading allows for secure fastener engagement.

- Functional Use: Installed from one side using a rivet nut tool, the tail end expands behind the material, creating a permanent mechanical lock. It’s ideal for applications where traditional bolts and nuts cannot be used, such as thin sheets, tubing, or aluminum profiles.

2. What materials are commonly used for countersunk head rivet nuts?

These rivet nuts are commonly made from materials such as steel, stainless steel, aluminum, and brass. The material choice depends on the mechanical strength, corrosion resistance, and compatibility required by the application environment.

3. What are the advantages of countersunk head rivet nuts?

- Flush and clean surface after installation: The countersunk design allows the rivet nut to sit flush with the workpiece surface, providing a sleek and neat appearance. This is especially beneficial for applications with high aesthetic requirements, such as electronic enclosures and furniture panels.

- Space-saving installation: Since the head is embedded into the material, it doesn’t take up additional space on the surface, making it ideal for confined or edge-limited areas.

- Blind installation capability: Countersunk head rivet nuts can be installed from one side of the workpiece without access to the rear, which is perfect for closed profiles, tubing, or box structures.

- Stronger engagement with the material: The countersunk head increases contact area with the surface, which can enhance both pull-out and shear strength, resulting in a more secure connection.

- Versatile material compatibility: Suitable for use with metal, plastic, and composite materials, making them widely used across industries such as automotive, electronics, machinery, and aerospace.

4. Can countersunk head rivet nuts be used for thick materials?

Countersunk head rivet nuts are typically used for thinner materials. However, with the correct size and installation tool, they can also be used for thicker materials, though the hole diameter must be carefully chosen to ensure proper installation and effective load distribution.

5. Are countersunk head rivet nuts reusable?

In general, countersunk head rivet nuts are not designed for reuse. Once installed, they provide a strong, permanent thread insert. However, in some cases, if installed correctly and not under excessive stress, they may be removed and replaced, though this could compromise their holding power.