Rivet Nut Gun Near Me

Leading Rivet Nut Manufacturer and Supplier in China

Looking for a rivet nut gun near me? Whether you’re working in automotive repair, sheet metal fabrication, or DIY home projects, having the right rivet nut installation tool on hand is essential for creating strong, reliable threaded connections. In this guide, we’ll explore where to find rivet nut guns locally and online, how to choose the right model for your needs, and what to consider before making a purchase — helping you save time and get the job done right.

Table of Contents

What Is a Rivet Nut Gun and Why You Might Need One?

The Rivet Nut Gun is a specialized tool for installing rivet nuts (also known as nut rivets, pulling caps, and nutsets). It is through the rivet nut to apply tension, so that its tail in the thin plate, pipe and other structural components to produce deformation, and thus firmly fixed, the formation of threaded joints. The emergence of the rivet nut gun solves the problem of the inability to use ordinary nuts and bolts in the scenarios of single-sided operation, thin plate connection, and unthreaded foundation.

Common rivet nut gun types include:

- Manual Rivet Nut Gun: suitable for small batch or maintenance use, simple structure, low cost;

- Pneumatic rivet nut gun: driven by compressed air, fast speed, suitable for production line operation;

- Electric/servo rivet nut gun: suitable for automated assembly scenarios with high precision and traceability requirements.

Common application scenarios of rivet nut gun:

1. Automobile manufacturing and repair

- Installation of bumpers, wheel covers, interior panels and other parts that need to be fixed on one side

- No need to weld during the assembly of sheet metal parts to improve assembly efficiency and maintenance convenience

2. Sheet metal processing industry

- Rapid formation of threaded holes in thin sheet metal structures such as cabinets, electrical boxes, server housings, etc.

- Ensure structural integrity while facilitating subsequent disassembly and maintenance

3. Assembly of home appliances

- Widely used in the assembly of washing machines, air conditioners, refrigerators and other shells.

- Avoid high temperature welding, improve production safety and appearance consistency

4. Furniture and light industry

- Commonly used in metal frame furniture, display racks, showcases and other components that require removable threaded connections.

What Types of Rivet Nut Guns Near You?

Depending on the type of drive and the scenario in which they are used, Rivet Nut Guns are divided into three main categories: manual, pneumatic and electric. Which model to choose depends on your usage frequency, workload and budget.

1. Manual Rivet Nut Gun

Hand Rivet Nut Tools is one of the most basic and common rivet nut installation tools, usually consisting of a lever structure or screw structure, relying on manual force to tighten and shape the rivet nut. It is suitable for small and medium-sized rivet nuts (e.g. M3~M6), and is a common choice for repairers, DIY users and startups.

Major Advantages:

- Economic and practical: low price, low entry threshold, suitable for small projects with limited budget.

- Simple structure: no need for power or gas source, easy to carry, suitable for field or non-standard scene operation.

- Operation Flexibility: Suitable for intermittent, small batch installation tasks, such as equipment maintenance or non-assembly line assembly.

Limitations exist:

- Low efficiency: Completely dependent on human labor, not suitable for long time and high frequency operation.

- Easy to fatigue: prolonged use may cause hand fatigue and affect assembly consistency.

- Limited scope of application: Not suitable for installing larger size rivet nuts or high strength requirement scenarios.

Recommended usage scenarios:

- Simple repair or toolkit spare

- Temporary addition of threaded holes (e.g. exhibition construction, emergency equipment reinforcement)

- Small batch sample assembly, handmade projects

2. Pneumatic Rivet Nut Gun

Pneumatic Rivet Nut Gun utilizes compressed air as the power source to stretch and form the rivet nut by pneumatically driving the pull rod. Compared with the manual rivet nut gun, it has higher efficiency and stability, and is a common tool used in medium and large manufacturing enterprises and professional assembly lines.

Key Benefits:

- High Efficiency: One-button operation, complete installation in seconds, greatly enhancing the assembly beat;

- Good labor-saving: Relying on pneumatic pressure drive, it significantly reduces the physical burden of operators and is suitable for long-time use;

- Strong adaptability: can install a variety of specifications and materials of rivet nuts, suitable for metal, plastic, composite materials and other substrates;

- High Repeatability: the installation process is stable, which can ensure the consistency of riveting quality.

Limitations exist:

- Reliance on air source: It must be used with an air compressor, which limits the flexibility of the equipment;

- Large operating noise: Pneumatic tools may generate high noise when working, and need to be operated in an appropriate environment;

- Higher maintenance requirements: Pneumatic systems require regular maintenance and lubrication to ensure long-term stable operation.

Recommended usage scenario:

- Medium and large volume production lines: such as automotive parts, home appliance assembly, and electric control cabinet production;

- Sheet metal processing workshop: suitable for repetitive operations and intensive assembly workstation use;

- Light industrial manufacturing: such as lamps, elevators, furniture and hardware industry specialized assembly process.

3. Electric Rivet Nut Gun

Electric Rivet Nut Gun is a highly efficient tool that utilizes a motor-driven pull rod to complete the installation of rivets and nuts, and is widely used in production environments that require high quality, efficiency and consistency of installation. Some high-end models also support torque control, tension setting and data acquisition functions, making them ideal for use in intelligent manufacturing.

Applicable Scenarios:

- Automated production line: such as automobile assembly line, home appliance assembly, intelligent equipment production, suitable for long time continuous operation;

- Precision assembly operation: such as avionics, medical equipment, communication equipment and other industries that require high assembly precision;

- Factory lean production: production processes that require digital control and strong traceability, such as the application scenario of servo-electric rivet and nut guns;

- High-mix, low-batch manufacturing scenarios: flexible operation, convenient switching specifications, adapting to the needs of multi-species production.

Main Advantages:

- High precision control: some electric models are equipped with functions such as torque feedback and tension setting, effectively avoiding over-pulling or under-riveting;

- Strong automation compatibility: Adaptable to robots, automatic feeders, data recording systems, easy to integrate the whole line;

- Operator friendly: low noise, low vibration, labor-saving operation, in line with the ergonomic requirements of modern workstations;

- Low maintenance cost: more airtight structure and longer maintenance cycle compared to pneumatic tools.

Limitations:

- Higher initial investment: High-end models are more expensive, suitable for medium and large enterprises or customers pursuing long-term cost-effectiveness;

- Stable power supply is required: There are certain requirements for working voltage and power supply environment;

- Part of the equipment is heavy in weight: it is recommended to be used with a stand or fixed workstation to reduce operating fatigue.

Where to Buy a Rivet Nut Gun Near Me?

①. How to Buy from Local Channels

The most common channels to buy a Rivet Nut Gun locally include:

Hardware Stores and Specialty Tool Stores

Many large hardware chains or specialty tool stores stock rivet nut guns, especially in industrial parks or areas where manufacturing is concentrated. You can visit local hardware markets, tool towns, and other brick-and-mortar stores to view the product in person for a convenient understanding of the physical feel and operation.

Specialized industrial tool stores and distributors

Distributors specializing in industrial tools usually offer multi-brand and multi-model rivet nut guns and can provide after-sales support and maintenance services, which are suitable for enterprises or customers with professional needs.

Authorized Agents & Manufacturers' Direct Sales Outlets

Some famous brands will have authorized agents or service centers around the world, so you can get genuine product guarantee and professional technical guidance when purchasing.

②. How to Use Google Maps / Yelp / Store Navigation to Find

Quickly locate nearby rivet nut gun outlets with the help of your smartphone and web mapping tools:

Google Maps

Open Google Maps and enter keywords such as “Rivet Nut Gun Store” or “Industrial Tools”, the map will show relevant stores nearby. Combine user reviews and opening hours to choose the right store.

Yelp or Local Life Platforms

Search for “Rivet Nut Gun” or “Industrial Tools” on Yelp, Dianping and other local life platforms, check user reviews, store photos and contact information to judge service quality.

Store official website and navigation function

Focus on the official website of the target brand or distributor, get the authorized store address, and then directly through the navigation function.

③. Keyword search techniques

In order to more accurately find local points of sale, it is recommended to search in conjunction with geographic location:

- For example search keywords:

- “rivet nut gun in Chicago”

- “rivet nut gun in New York”.

- “industrial rivet nut tools near me”

- You can also use your voice assistant to directly ask “Where can I buy a rivet nut gun near me?” and the system will recommend nearby stores in relation to your location.

- The system will recommend nearby stores based on their location.

④. Other Buying Suggestions

- Call ahead to inquire about stock and model number to avoid a wasted trip;

- Ask if the store provides trial or demo to confirm the tool performance meets the requirement;

- Understand the after-sales service policy, especially warranty and maintenance support;

- For bulk purchases, give preference to manufacturers or large dealers for preferential pricing and customized services.

Online Alternatives When Local Options Are Limited

1. Trusted online sourcing platforms

When there is a lack of suitable local suppliers of Rivet Nut Gun, choosing online procurement has become a priority for many enterprises and individual users. Online platforms not only have a complete range of products, but also have a convenient purchasing process and fast delivery speed, which greatly improves the purchasing efficiency. The following are a few types of major and trusted online procurement channels:

As one of the world’s largest e-commerce platforms, Amazon has a rich assortment of industrial tools and rivet nut guns. Its platform supports fast ordering and diversified delivery options, which can meet the needs of individual users and small and medium-volume purchases. The buyer evaluation system is more complete, which can help users refer to the experience of other buyers, so as to make more informed purchasing decisions. In addition, Amazon usually supports 7 days return without reason and a certain period of after-sale protection, which enhances the security of shopping.

b. Alibaba and AliExpress

Alibaba platform gathers a large number of rivet nut gun manufacturers and wholesale suppliers, which is especially suitable for enterprise customers to make large-volume purchasing and customization needs. The platform provides detailed supplier information, including factory certification, product certification and buyer feedback, making it easy for users to identify high-quality suppliers, while AliExpress is geared towards the global retail market and is suitable for small and medium-sized enterprises (SMEs) or individual users to purchase products in smaller quantities. In terms of price, Alibaba and AliExpress are usually more competitive, suitable for limited budget but quality-assured purchasing needs.

c. Brand official website and authorized e-commerce

Many famous rivet and nut tool manufacturers (such as Rivetfix, GESIPA, etc.) have official websites or officially authorized e-commerce platforms. Direct purchase through the official website not only ensures that you can buy genuine products, but also enjoy the professional technical support and perfect after-sales service provided by the manufacturer. The official website usually also releases the latest product information and promotional activities, users can be the first time to get industry news and offers. Authorized distributors are also a safe and reliable purchasing channel, especially for customers who need technical advice, training or customized services.

2. Advantages of buying online

Complete models and various choices

The online platform brings together global suppliers with products covering a wide range of manual, electric, pneumatic and hydraulic rivet nut guns, so users can easily compare multiple models and brands.

Quick price comparison, saving purchasing time

Online stores usually provide detailed parameters and user reviews, making it easy for buyers to make quick judgments and purchases.

Support bulk purchasing and customization service

E-commerce platforms often support bulk orders and OEM customization to meet the different scales and individual needs of enterprises.

Convenient logistics and distribution service

Many platforms support cross-border direct mail and fast delivery, solving the purchasing problems caused by geographical restrictions.

3. How to choose a reliable seller?

Choosing a reliable seller is the key to ensure that you buy a high quality rivet nut gun and get good after-sales service. The following points can help you make a wise choice:

Check the seller's qualification and certification

Choose a seller with a formal business license and relevant quality certifications (such as ISO, CE certification, etc.) to ensure that the quality of the product meets industry standards.

Refer to user reviews and feedback

Carefully read the reviews and ratings of other buyers, paying particular attention to product durability, installation results and after-sales service experience to avoid encountering merchants with poor quality or poor service.

Confirm after-sales service policy

Choose sellers that offer reasonable return and exchange guarantees, warranty periods and technical support so that you can get timely help and support when you encounter problems during use.

Evaluate the seller's response speed and professionalism

Communicate with the seller’s customer service to test their responsiveness and level of expertise. Professional and timely communication can guarantee a smooth purchasing process and reduce misunderstandings and delays.

Prefer brand official or authorized distributors

Brand official stores or authorized dealers are usually more reliable, guaranteeing genuine products and after-sales protection to avoid buying fake or inferior products.

What to Consider When Choosing a Rivet Nut Gun?

I. Adaptable thread specifications, tension range, material compatibility

1. Thread Size Matching

- The cap puller gun should have the ability to replace threaded tie rods to fit a wide range of thread sizes (e.g. M3~M12 or even larger) to ensure applicability across your product range.

- Be aware of the distinction between Metric and UNC/UNF threading systems, as some equipment can only be adapted to one or the other.

- For special pitches (e.g., fine thread nuts) or customized products, check in advance to see if the equipment manufacturer offers custom fixtures or adapters.

- In continuous production scenarios, a quick-change configuration should be preferred to minimize downtime for replacing tie rods or work heads.

| Thread Size | Typical Base Material Thickness | Recommended Stroke Length | Suggested Tool Type |

|---|---|---|---|

| M3 | 0.5mm – 2.0mm | 4 – 6 mm | Manual / Pneumatic |

| M4 | 0.5mm – 2.5mm | 5 – 7 mm | Pneumatic / Electric |

| M5 | 0.8mm – 3.0mm | 6 – 8 mm | Pneumatic / Servo-Electric |

| M6 | 1.0mm – 3.5mm | 7 – 9 mm | Pneumo-Hydraulic / Servo |

| M8 | 1.2mm – 4.0mm | 9 – 11 mm | Pneumo-Hydraulic / Servo |

| M10 | 1.5mm – 5.0mm | 10 – 13 mm | Hydraulic / Servo |

2. Tension range matching

- The cap puller must have a sufficient maximum tension output to cope with the tensile requirements of Typical Base Material Thickness and rivet nuts.

- For example, a thin sheet aluminum part may only require 5kN while a steel part may require 15kN or more.

- Electric servo or hydraulic guns often have adjustable tension settings to suit different product standards to ensure a strong and consistent rivet joint.

- If the tension is not sufficient, common problems include:

- Rivet nuts idling in the parent material;

- Incomplete rivet set resulting in dislodgement;

- Deformation or stress concentration in the base material during riveting.

| Rivet Nut Size | Nut Material | Break-Off Force (Approx.) | Recommended Minimum Pull Force Output |

|---|---|---|---|

| M4 | Aluminum | ≈ 5.0 kN | ≥ 6.0 kN |

| M5 | Steel | ≈ 7.0 kN | ≥ 8.5 kN |

| M6 | Stainless Steel | ≈ 12.0 kN | ≥ 13.5 kN |

| M8 | Stainless Steel | ≈ 18.0 kN | ≥ 20.0 kN |

| M10 | Steel | ≈ 22.0 kN | ≥ 25.0 kN |

3. Material compatibility

- Common rivet nut materials and characteristics are as follows:

- Steel: high strength, suitable for structural parts connection;

- Stainless steel (e.g. 304/316): high corrosion resistance, high hardness, high requirements for gun tool tension and structure;

- Aluminum alloy: lightweight, suitable for thin plates and non-structural parts;

- Copper/Brass: good conductivity, commonly used in electrical connection parts.

- If using stainless steel or special alloy nuts, it is recommended to choose to have:

- High strength bearing structure (to avoid excessive wear);

- Automatic pressure relief function (to prevent the gun tool from jamming);

- Enhanced power system (pneumatic-hydraulic pressurization, electric servo, etc.).

- In a batch operation environment, inferior equipment is prone to failures due to incompatible materials, such as:

- Tie rod breakage;

- Tooth head slippage;

- Pull caps jammed and unable to exit.

If you want to know more about rivet nut material and substrate compatibility, read the blog best material for rivet nuts.

II. Frequency of use, operating comfort, ease of maintenance

Frequency of use:

- Low frequency: manual cap pulling guns are economical and practical.

- Medium to high frequency: pneumatic or electric tools are recommended to reduce manual fatigue and improve efficiency.

Operating comfort:

Ergonomic design, grip, non-slip handle, trigger strength and other factors affect the worker’s operating experience, especially more important in long-time operation scenarios.

Maintenance and parts availability:

- Simple structure, easy to disassemble and clean the equipment is more convenient to maintain.

- After-sales support, parts replacement cycle and accessibility of branded equipment are also critical.

III. Does it support automation or batch assembly

Auto-Feed System:

If used in automated production lines or mass production environments, it is recommended to select a cap puller gun that supports the Auto-Feed function to enhance beat efficiency.

Interface Compatibility:

Industrial applications, the device should be able to be integrated into robots, riveting platforms or CNC workstations, which need to support standard interfaces or communication protocols.

Operation consistency and quality control:

High-end models can set tension, stroke, and even record riveting data to help with quality traceability and process control.

Do You Have Any Questions?

Let Us Solve Your Problem

Why Rivetfix Is a Reliable Choice for Rivet Nut Tools?

Rivetfix is recognized as a professional fastener and rivet nut and rivet nut tooling solutions provider with high quality products, extensive model coverage and attentive customer service across a wide range of industries worldwide. Here are the core reasons why we are your ideal partner:

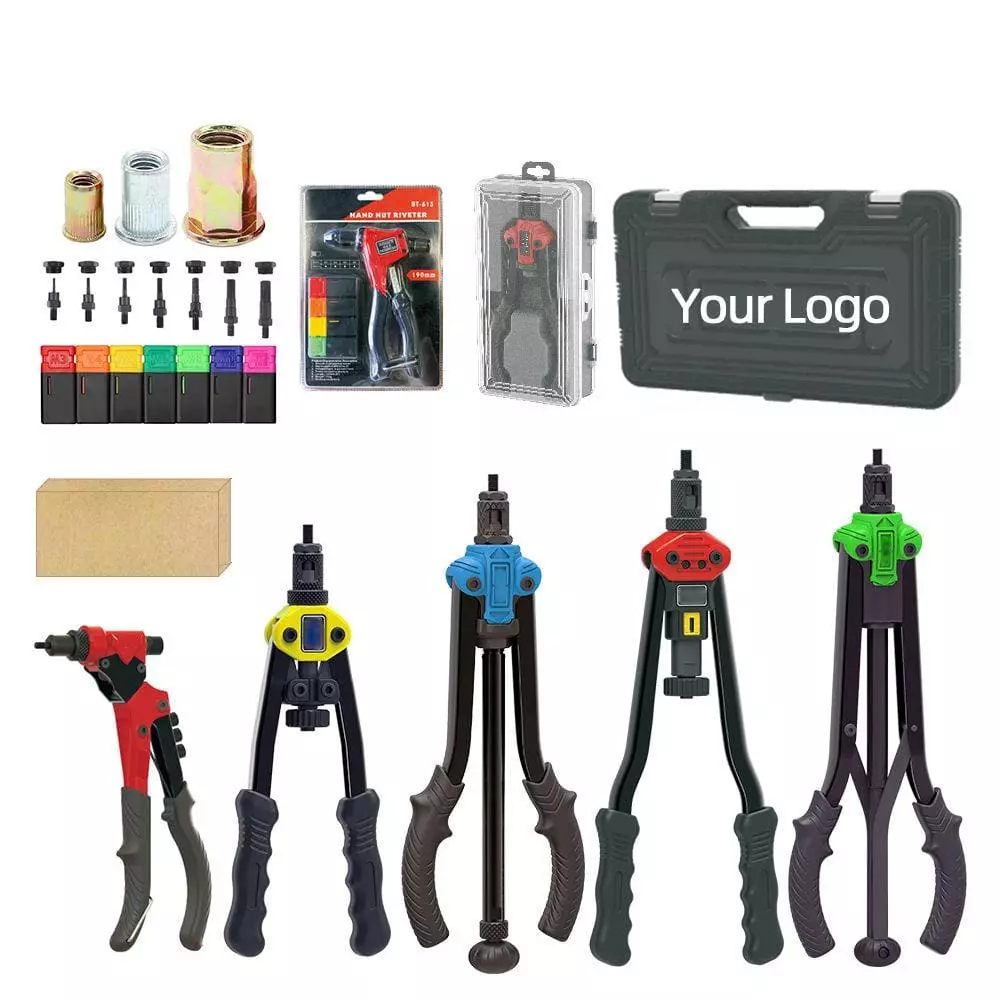

✅ Comprehensive range of products and models

Rivetfix offers a full range of manual, electric, pneumatic and hydraulic rivet guns for all rivet sizes from M3 to M12, suitable for a wide range of applications and materials (e.g. steel, stainless steel, aluminum, plastics, etc.). Whether you are doing sheet metal assembly, small batch repair, or automated production line batch riveting, you can find the right tool for the job.

✅ Support global shipping and customization service

Rivetfix has a mature international logistics and export system, supporting shipment to UK, Europe, America, Australia, Southeast Asia and many other countries and regions around the world. At the same time, we provide OEM customization service and one-on-one technical selection support, can be customized according to customer needs exclusive tool appearance, structure or functional configuration, to meet the enterprise branding or special application scenarios demand.

✅ Strong pre-sales and after-sales technical support

Our experienced technical engineering team can provide customers with selection advice, process evaluation and remote guidance services to ensure that each tool can efficiently match the actual working conditions. After-sales service, Rivetfix provides video tutorials, manual support, maintenance parts supply and other multi-dimensional protection, to truly achieve the “pre-purchase peace of mind, use of peace of mind, after-sales peace of mind”.

🔗 To learn more or to get a quote

Please visit our website https://rivetfix.com/, technical information and global service network.

Choosing Rivetfix is not just about choosing a reliable rivet nut tool, it’s about choosing a long-term stable partner. We are committed to providing efficient, safe and sustainable fastening solutions to users worldwide.

Customer FAQs About Rivet Nut Guns Near Me

Q1: How do I know which Rivet Nut Gun model is right for me?

Choosing the right Rivet Nut Gun requires a combination of the following core elements:

- Nut specification size: Confirm the size of the rivet nut you are using (e.g. M4, M5, M6, etc.), different models of tools support different range of threads;

- Riveting material and strength: If the material is steel or stainless steel, it is recommended to use pneumatic, electric or hydraulic models, manual tools may not be able to provide sufficient tension;

- Working scenarios:

- Small batch or maintenance work: manual models are recommended;

- Medium frequency use: electric or pneumatic models recommended;

- High-volume assembly/automated production lines: electro-hydraulic type or integrated system is recommended;

- Budget and Maintenance Costs: Different types of tools differ in purchase price and ease of maintenance, so you can choose flexibly according to your project budget.

It is recommended to contact specialized suppliers (e.g. Rivetfix) to provide usage scenarios and riveting requirements, and technicians will recommend suitable models.

Q2: Where can I find the maintenance service of rivet nut gun?

As a high-frequency use tool, rivet nut guns may require tie rod replacement, lubrication maintenance, or repair of components after prolonged use.

Common ways to obtain repairs include:

- Original factory after-sales service center or authorized repair point: if purchased from Rivetfix, after-sales application can be submitted by mail or official website;

- Industrial tool franchise stores or large hardware platforms: if certain local distributors have basic maintenance services;

- DIY maintenance: some problems (e.g. tie rod replacement, head replacement) can be done by yourself according to the instructions.

Rivetfix offers complete repair kits, online technical support with video tutorials to assist customers in quickly getting their equipment back in service.

Q3: Does Rivetfix support bulk orders and corporate purchasing?

Yes, Rivetfix fully supports B2B Bulk Order and Enterprise Customized Purchasing Services, the main services include:

- Bulk pricing discounts: customizable stepped pricing by purchase quantity and frequency;

- Exclusive sales consultants and technical engineers docking: guarantee efficient matching of product recommendations and delivery schedules;

- Commercial invoices can be issued and cross-border payment methods (e.g. TT, PayPal, etc.) are supported;

- Global logistics support: can be shipped to many markets such as Europe, America, Southeast Asia, Middle East, Australia, etc., with controllable timeliness;

- Branding customization service (OEM/ODM): provide product appearance, packaging, LOGO customization service for brand owners, equipment integrators and so on.

For enterprise quotation or cooperation intention, you can get in touch with us through the official website form. We will provide customized procurement solutions within 24 hours.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.