The Ultimate Guide to Clinch Nut Dimensions

Leading Self-Clinching Fasteners Manufacturer and Supplier in China

When it comes to creating strong, reliable threaded connections in sheet metal and other thin materials, clinch nuts are a go-to solution for engineers and manufacturers. However, choosing the right clinch nut isn’t just about material or thread size—clinch nut dimensions play a critical role in ensuring a secure fit, proper load distribution, and long-term performance. In this ultimate guide, we’ll break down everything you need to know about clinch nut sizes, from hole preparation to grip range and installation tolerances, helping you make the best choice for your application.

Table of Contents

A Clinch Nut, also known as a self-clinching nuts or pem nuts, is an internal threaded fastener designed specifically for sheet metal structures. It is installed in thin sheets or soft materials using a cold press fitting method, providing a stable threaded connection. Its installation process does not require welding or tapping, making it quick and suitable for large-scale automated production.

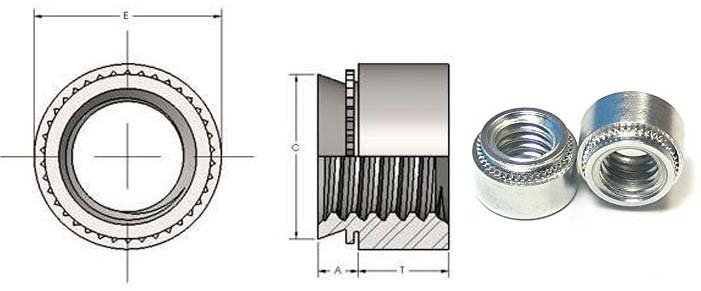

Structural Features

Clinch Nuts are typically made of carbon steel or stainless steel and have the following key structural characteristics:

- Cylindrical or Hexagonal Body: Facilitates alignment and prevents rotation.

- Bottom with Serrations or Knurled Design (Reverse Hook Design): Engages with the metal sheet during the pressing process, preventing loosening and rotation.

- Pre-formed Internal Thread Hole: For subsequent screw assembly, offering high precision and secure installation.

Compared to weld nuts, Clinch Nuts do not produce a heat-affected zone. Compared to rivet nuts, they are better suited for tight spaces or applications that require higher strength.

Common Applications

Clinch Nuts are widely used in the following industries and scenarios, primarily to integrate threaded structures into metal or composite material panels:

- Automotive Industry: Installed in sheet metal parts such as car doors, dashboard brackets, and chassis components to provide reliable internal threaded connections.

- Electronics and Electrical Equipment: Used in server enclosures, power supply housings, displays, and more, facilitating maintenance and disassembly.

- Industrial Equipment and Machinery Manufacturing: Ideal for sheet metal frames, control boxes, and mechanical housings.

- Aerospace and Rail Transport: One of the preferred fastening methods for high-strength, vibration-resistant applications.

- Home Appliances and Consumer Goods Manufacturing: Used in metal parts for items like microwave ovens and refrigerator housings.

How Clinch Nuts Work?

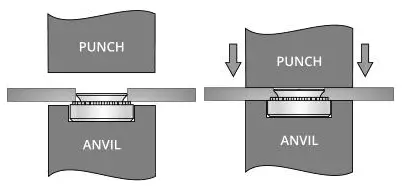

You fix a Clinch Nut into metal plates or soft materials by using a cold press fitting method—no welding or tapping required. During installation, you apply pressure to embed the locking structure at the bottom of the nut into the sheet material, creating a strong mechanical connection.

How Is It Fixed to the Sheet Material by Pressure?

The installation principle of a Clinch Nut involves using special press-fit equipment (such as a press machine or pneumatic tool) to apply axial pressure to the nut, pressing it into the metal sheet. The main steps of the fastening process are as follows:

Step1. Pre-drilled Installation Hole

- A hole slightly larger than the outer diameter of the Clinch Nut is punched in the sheet metal. The hole diameter must match the nut’s requirements to avoid loosening or improper press fitting.

Step2. Place the Nut in the Hole

- Insert the bottom part of the Clinch Nut into the hole, keeping it vertically aligned and centered.

Step3. Apply Vertical Pressure

- The press-fit equipment applies pressure from above, forcing the nut’s reverse hook structure or knurled ring to embed into the surrounding sheet material.

Step4. Material Deformation and Embedding into the Groove

- High pressure squeezes the metal sheet into the groove at the bottom of the nut, creating a mechanical lock.

Step5. Completion of Fixing

- After installation, the Clinch Nut is resistant to rotation or loosening, providing excellent pull-out and torsion resistance.

Advantages of the Clinch Nut Locking Mechanism

- Strong Anti-Rotation Performance: The hexagonal or knurled design, once embedded, prevents rotation.

- Fast Installation: No need for welding or tapping, significantly improving assembly efficiency.

- Suitable for Thin Sheets: Can achieve a firm connection even on metal sheets as thin as 0.5mm.

- High Thread Accuracy: Pre-formed threads ensure stable screw installation in subsequent assembly.

Key Dimensions of Clinch Nuts

1. Thread Size

The thread size determines the screw size that the Clinch Nut can accommodate and is one of the most fundamental parameters in the selection process.

- Metric Threads: Common sizes include M3, M4, M5, M6, M8, M10, M12, etc. For example, M5 means the outer diameter of the thread is approximately 5 millimeters, with a pitch typically of 0.8mm.

- Inch Threads: Common sizes include #4-40, #6-32, #8-32, #10-24, 1/4-20, etc. For example, #8-32 means the outer diameter is approximately 0.164 inches, with a pitch of 32 threads per inch.

Technical Standards

- DIN Standard: German industrial standard, known for high precision.

- ISO Standard: International Organization for Standardization, widely adaptable.

- PEM Standard: PennEngineering’s industry standard for clinch nuts, commonly referenced.

Engineers must confirm each thread size against specific parameter charts, as it corresponds to a complete set of structural dimensions—including installation hole size, flange diameter, and overall height.

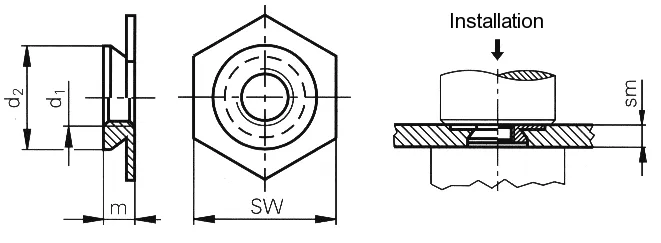

2. Flange Diameter

The flange is the top edge of the Clinch Nut, and its size directly impacts the tensile strength and stability of the connection.

- Larger Flange: Provides a larger contact area, suitable for withstanding greater loads.

- Hexagonal Flanges: For structures requiring higher anti-rotation features, hexagonal flanges (Hex Clinch Nut) can be selected to prevent slippage.

- Limited Space: In confined spaces, smaller flanges or concealed flange designs may be required.

Example:

- M4 Clinch Nut flange diameter is about 7.9mm;

- M8 Clinch Nut flange diameter is about 13.5mm.

During design, ensure that the flange does not interfere with surrounding components or conductive paths (such as when used on PCB boards).

3. Overall Height

Overall height (also called “assembly height” or “total length”) refers to the complete height of the Clinch Nut from the top flange to the bottom end.

- It determines whether the nut will protrude on the back of the sheet, affecting the overall space design of the assembly.

- Some products require a flush assembly surface, for which a flat-top Clinch Nut can be selected.

- To avoid screw penetration through the bottom, a closed-end design may be chosen.

Practical Application:

- In metal enclosures where a nut is to be installed without affecting the layout of internal electronic components, a “low-profile” or “embedded” structure should be selected.

4. Installation Hole Size

Engineers must strictly control the installation hole size within standard tolerances, as it determines whether the Clinch Nut can be correctly pressed into place.

- Hole Too Small: The nut will not press in properly or may deform improperly after pressing.

- Hole Too Large: The nut may rotate or fall out, resulting in an unstable connection.

- It is recommended to use a punching machine or CNC laser cutting to ensure the verticality and smoothness of the hole.

- Manual drilling should be avoided, as it can result in imprecise hole diameters and rough edges.

Reference Data:

| Thread Size | Recommended Installation Hole Size (mm) |

| M3 | 4.25 |

| M4 | 5.40 |

| M5 | 7.15 |

| M6 | 8.75 |

| M8 | 11.10 |

5. Material Thickness

The material thickness must meet the minimum requirements of the Clinch Nut, or it may lead to an unstable fixation or detachment risk. Engineers should confirm before design whether the sheet metal thickness falls within the allowed range for press-fit nuts.

- Each model has a “Minimum Sheet Thickness” requirement, typically ranging from 0.8mm to 3.0mm.

- If the sheet is too thick, it may affect the press fitting quality, which is why some brands also specify a “Maximum Sheet Thickness.”

- Some products are designed for thin or ultra-thin materials, such as floating nuts or reinforced designs.

6. Grip Range

Grip Range refers to the thickness range of materials that the nut can accommodate or fasten, especially useful in multi-layer materials or scenarios where the thickness is inconsistent.

- Although Grip Range is more commonly used in blind rivet nuts, some Clinch Nuts will also indicate this in their technical parameters.

- If there is significant variation in material thickness (e.g., aluminum covering steel plates), selecting a nut with a Grip Range can help avoid installation failure.

- For applications requiring high structural reliability, it’s advisable to choose the “middle value” rather than the extreme limits during design.

Example: A specific model may indicate a Grip Range of 1.0–1.8mm, meaning the nut can firmly secure materials within this thickness range.

1. What to do if the Clinch Nut becomes loose or rotates after installation?

- Cause: This could be due to an oversized hole, insufficient installation pressure, or incorrect selection of the Clinch Nut.

- Solution:

- Ensure the installation hole size matches the Clinch Nut, avoiding overly large holes.

- Increase the installation pressure to ensure the Clinch Nut is fully embedded and securely fastened.

- Choose a Clinch Nut with an anti-rotation design or use specialized installation tools to ensure precise alignment.

2. What is the impact of hole diameter deviation on performance?

- Cause: Hole diameter deviation can prevent the Clinch Nut from being properly installed, leading to looseness, failure, or insufficient load-bearing capacity.

- Solution:

- Precisely control the hole diameter, avoiding too large or too small deviations, keeping the tolerance between 0.1-0.2mm.

- Use appropriate tools for hole processing to ensure hole accuracy.

3. How to handle installation challenges with different materials?

- Cause: Different materials may affect the fastening effectiveness of the Clinch Nut, especially harder or thinner materials.

- Solution:

- For harder materials, use high-strength Clinch Nuts and ensure the tools can provide enough pressure.

- For thinner materials, use Clinch Nuts with lower tensile strength to avoid damaging the material.

- Use appropriate installation tools and molds to ensure even pressure distribution, avoiding material deformation.

4. What to do if the Clinch Nut gets stuck or cannot be removed during installation?

- Cause: This could be due to tool or mandrel jamming, or unstable air pressure causing issues with the removal process.

- Solution:

- Inspect the installation tools to ensure the mandrel is not damaged or worn. Lubricate or replace the mandrel if necessary.

- Check the air source and pressure to ensure the operating air pressure meets the tool’s requirements.

5. What to do if the Clinch Nut cannot bear the expected load after installation?

- Cause: This could be due to improper size, incorrect installation, or mismatched materials, leading to insufficient load-bearing capacity.

- Solution:

- Check the size and load rating of the Clinch Nut to ensure it is suitable for the required working conditions.

- Ensure the hole size and precision match the Clinch Nut and use the appropriate tools and installation methods.

- If higher load requirements are needed, consider using a higher strength Clinch Nut or switching to a different type of fastening solution.

Clinch Nuts vs. Other Fasteners

Advantages and Disadvantages of Weld Nuts:

Advantages:

- Strong Connection: Weld nuts are securely attached to the base material through welding, providing a strong connection, suitable for high-load applications.

- High-Temperature Resistance: Due to the welding process, weld nuts can withstand high temperatures, making them suitable for high-temperature environments.

Disadvantages:

- Complex Process: Welding requires additional equipment and skilled technicians, which increases cost.

- Non-Removable: Once welded, the nut cannot be removed, and removing it may damage the base material.

- Limited Applicability: Not suitable for thinner materials or applications requiring quick assembly.

Advantages of Clinch Nuts:

Advantages:

- Easy Installation: Clinch nuts are secured by pressure, eliminating the need for welding, resulting in faster installation, ideal for mass production.

- Removable: Clinch nuts provide removable threaded connections, making maintenance and disassembly easy.

- Wide Applicability: Suitable for different material thicknesses and types.

Ideal Scenarios:

- Choose Clinch Nuts when you need quick installation and disassembly, and high temperature or heavy load strength isn’t a priority.

- Opt for weld nuts when the application requires resistance to high temperatures or long-term heavy loads, and disassembly isn’t necessary.

Advantages and Disadvantages of Rivet Nuts:

- Wide Applicability: Rivet nuts can be used on thicker metal sheets and come in various sizes and materials, offering broad compatibility.

- Strong Load Capacity: Rivet nuts secure the threads to the material through riveting, allowing them to bear high tensile forces.

Disadvantages:

- Slower Installation: Compared to Clinch Nuts, the installation process for rivet nuts is more complex, requiring specialized tools for riveting, resulting in lower production efficiency.

- Non-Reusable: Once riveted, the rivet nut becomes firmly attached to the base material and cannot be reused, making maintenance more difficult.

Advantages of Clinch Nuts:

Advantages:

- Fast Installation: Clinch nuts are pressed into place, requiring no riveting, enabling faster installation and higher production efficiency.

- Removable: Clinch nuts offer threaded connections that can be repeatedly removed and reused, making them convenient for later maintenance or replacement.

- Strong Adaptability: Suitable for various materials and thicknesses, especially for thin sheet metals.

- Choose Clinch Nuts if you require high production efficiency and removable connections, as they are a better option than rivet nuts.

- Opt for rivet nuts if you need stronger fixation and don’t require disassembly.

3. Studs vs. Clinch Nuts

Advantages and Disadvantages of Studs:

Advantages:

- High Strength Connection: Studs provide very strong connections, making them ideal for high-load applications.

- Suitable for Various Environments: Studs can withstand large tensile forces, making them widely used in demanding industries such as automotive and aerospace.

Disadvantages:

- Complex Installation: Installing studs requires specialized tools and a more complicated process.

- Non-Adjustable: Once installed, the position of the stud is fixed, making it difficult to adjust or change.

Advantages of Clinch Nuts:

Advantages:

- Simple and Fast Installation: Clinch nuts are quickly secured with pressure, requiring no specialized tools or complicated procedures.

- Adjustable: Clinch nuts provide removable threaded connections, suitable for applications that require adjustments or replacements.

Ideal Scenarios:

- Choose studs if you need a high-strength connection and don’t require disassembly.

- Opt for Clinch Nuts if you need faster installation, removability, and adaptability.

When to Prioritize Clinch Nuts

- High Production Efficiency: In mass production, Clinch Nuts are ideal due to their fast installation and strong removability, which significantly increase efficiency.

- Thin Sheet Metal Applications: Clinch Nuts are well-suited for thin sheet metals and soft materials, particularly in situations where traditional riveting methods are not applicable.

- Applications Requiring Removable Connections: If future disassembly or bolt replacement is needed, Clinch Nuts are the ideal solution.

- Limited Installation Space: Clinch Nuts are perfect for tight spaces where large tools or equipment are not feasible.

Do You Have Any Questions?

Let Us Solve Your Problem

With over 15 years of expertise in fastener manufacturing, Rivetfix has become a trusted global supplier. Our team of 200+ skilled workers and 40+ sales professionals ensures reliable service and consistent supply.

Partnering with Rivetfix means access to top-quality fasteners, cost-saving solutions, and custom designs. We focus on boosting your efficiency, enhancing product durability, and providing on-time delivery. Count on our expert support and continuous innovation for your fastening needs. Choose Rivetfix for premium clinch fasteners and more!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.