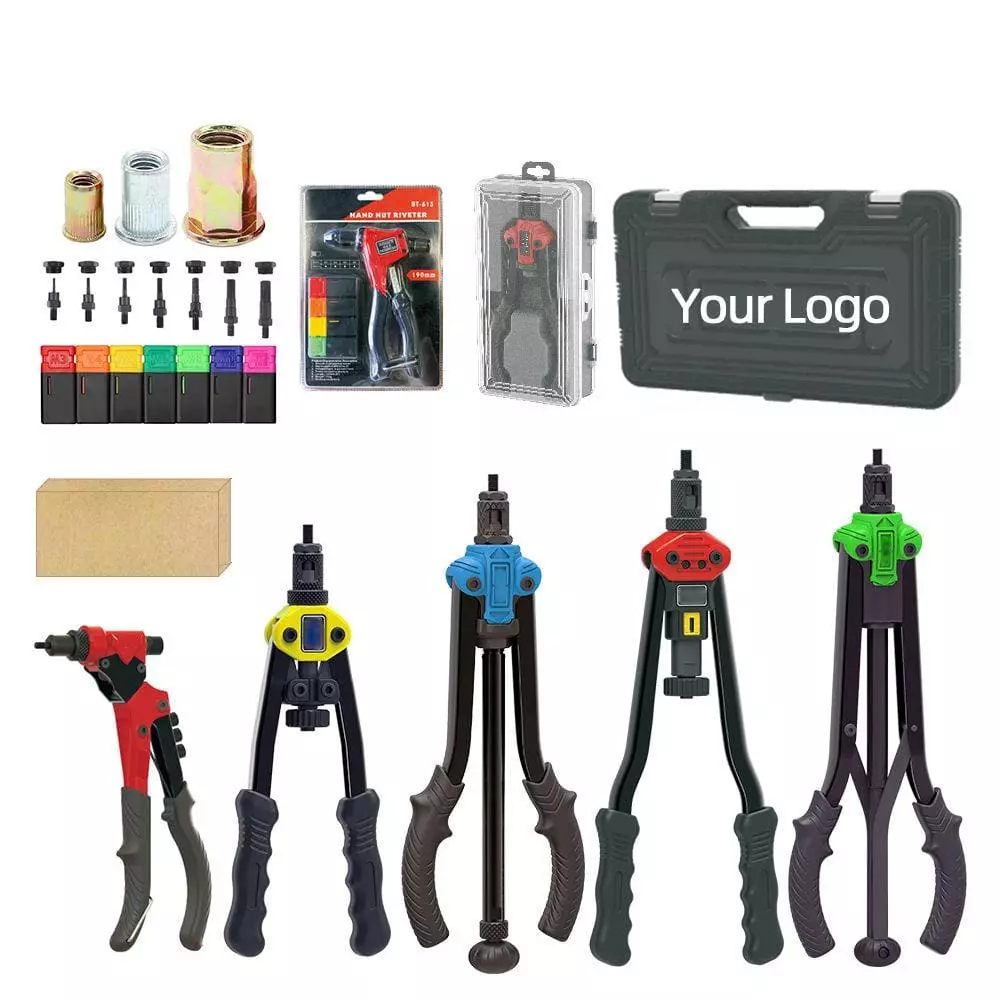

Popular Rivet Nut Gun Price Comparison 2025

Leading Rivet Nut Manufacturer and Supplier in China

When considering a rivet nut gun for your needs in 2025, it’s essential to compare the rivet nut gun price across various models and types. This guide will help you navigate the pricing landscape, ensuring you find the right tool that balances cost, quality, and performance.

Table of Contents

What Affects Rivet Nut Gun Price?

1. Drive Type

The drive type of a rivet nut gun directly affects its price. Different drive mechanisms are suitable for various work environments:

- The most affordable option, suitable for light-duty or occasional use.

- Operated manually, requiring significant effort, making it unsuitable for large-scale production.

- Ideal for small repairs, DIY projects, and home use.

- Powered by compressed air, suitable for industrial environments.

- Mid-range price, ideal for medium-scale production and improved efficiency.

- Requires an external air compressor, increasing the overall cost.

- Motor-driven for easy operation, suitable for high-intensity work.

- More expensive than manual and pneumatic types, often used in continuous production lines.

- Requires a power source or battery, and some models may not be suitable for high-strength metal materials.

Hydraulic Rivet Nut Gun

- Uses a hydraulic system for greater torque, ideal for heavy-duty industrial applications.

- The most expensive option, often used in aerospace, automotive manufacturing, and other precision industries.

- High equipment cost but provides more stable and efficient riveting results.

2. Supported Rivet Nut Sizes

The price of a rivet nut gun is influenced by the range of rivet nut sizes it supports:

- Single-size rivet nut guns (e.g., M6 only) are generally more affordable.

- Multi-size compatible guns (e.g., M3-M12 or larger) come with interchangeable mandrels and nosepieces, making them more versatile but also more expensive.

- Larger rivet nuts (M10 and above) require higher torque and stronger tools, which increases the cost.

3. Brand and Quality

The price of rivet nut guns can vary significantly between brands due to:

- Well-known brands (such as AVDEL, GESIPA, POP, RIVKLE) being more expensive but offering better quality, longer lifespan, and superior after-sales service.

- Domestic or lesser-known brands being more affordable, though quality may vary, making it essential to check material specifications, craftsmanship, and customer reviews.

- Premium brands using high-durability materials (such as high-strength steel or stainless steel) and featuring precision control systems, leading to higher prices.

4. Material and Manufacturing Process

The material and craftsmanship of a rivet nut gun directly affect its durability and performance, impacting its price:

- Standard carbon steel or alloy steel: More affordable but may wear out faster with prolonged use.

- High-strength steel or stainless steel: More wear-resistant and durable, costing more but suitable for professional and industrial applications.

- Aerospace-grade aluminum alloy: Found in some high-end models, offering lightweight durability and better handling at a higher cost.

Additionally, surface treatments (such as electroplating, powder coating, and anti-corrosion coatings) influence pricing. High-end products generally provide superior corrosion resistance and longer service life.

5. Additional Features and Accessories

The price of a rivet nut gun is also affected by its extra features and included accessories, such as:

- Automatic rivet nut removal: Premium models feature automatic nut removal, improving efficiency and reducing manual labor.

- Adjustable torque settings: Some electric or hydraulic rivet nut guns allow torque adjustments for different materials and rivet nut sizes.

- LCD display and smart controls: Industrial-grade rivet nut guns may include intelligent control systems for precise monitoring, increasing the price.

- Spare mandrels and interchangeable heads: Models that support multiple thread sizes often come with additional mandrels, making them more expensive.

3 Popular Rivet Nut Gun Price Comparison

Rivet nut guns are mainly divided into pneumatic, manual, and electric types. Each type has its own advantages and disadvantages, with prices varying based on brand, performance, application range, and market demand.

Application:

Factory production lines, small and medium-sized enterprises, batch production.

Price Range: $70 - $400

Pneumatic rivet nut guns are powered by compressed air and use a pneumatic piston to apply force. They allow for fast and efficient rivet nut installation, making them ideal for medium to high-volume production tasks.

Key Features:

- Pros:

- Fast installation speed, suitable for continuous operation.

- Requires less effort compared to manual tools, improving productivity.

- Moderate price, making them ideal for small and medium manufacturing or repair industries.

- Cons:

- Requires an additional air compressor, increasing overall costs.

- Limited portability due to reliance on an air supply.

Price Reference:

| Brand | Supported Nut Sizes | Price (USD $) | Application |

| GESIPA | M3-M10 | $350-$400 | Industrial production, high-precision needs |

| RIVKLE | M4-M12 | $280-$375 | Automotive manufacturing, metal processing |

| Local Brands | M3-M8 | $70-$170 | Small factories, general maintenance |

Application:

Home repairs, small-scale tasks, light-duty applications.

Price Range: $7 - $70

Manual rivet nut guns are the most budget-friendly option, ideal for small-scale installations. They are manually operated and rely on hand-applied force, making them suitable for DIY projects, repair work, and occasional use.

Key Features:

- Pros:

- Lowest price, ideal for budget-conscious users.

- Lightweight and portable, not dependent on power or air supply.

- Suitable for soft materials (such as aluminum and plastic) and small-sized rivet nuts.

- Cons:

- Labor-intensive, not suitable for high-volume installation.

- Requires significant hand force, leading to fatigue over prolonged use.

- Difficult to install high-strength materials like stainless steel rivet nuts.

Price Reference:

| Brand | Supported Nut Sizes | Price (USD $) | Application |

| Stanley | M3-M6 | $20-$40 | Household repairs, DIY projects |

| HIFESON | M3-M10 | $30-$70 | Mechanical repairs, small-scale jobs |

| Local Brands | M3-M8 | $7-$20 | Basic assembly, small hardware projects |

Application:

Factory assembly lines, mass production, industrial applications.

Price Range: $100 - $700

Electric rivet nut guns use a motor-driven mechanism and are powered by either batteries or direct electricity. They provide fast and efficient rivet nut installation, making them a popular choice for industrial applications.

Key Features:

- Pros:

- Effortless operation and high efficiency, suitable for extended use.

- Some advanced models feature adjustable torque settings for precision control.

- Suitable for installing rivet nuts in high-strength materials like stainless steel and steel.

- Cons:

- Higher price with a significant initial investment.

- Some models can be heavy, causing fatigue with prolonged use.

- Requires charging or a power connection, limiting mobility.

Price Reference:

| Brand | Supported Nut Sizes | Price (USD $) | Application |

| Milwaukee | M3-M12 | $570-$700 | Industrial assembly lines, heavy-duty applications |

| Makita | M4-M10 | $350-$500 | Machinery manufacturing, automotive industry |

| Local Brands | M3-M8 | $100-$270 | Small and medium-sized factories, high-volume production |

Choosing the most suitable rivet nut gun depends on your usage requirements, budget, work efficiency, and maintenance costs.

1. Choose Based on Application

Occasional Use / DIY / Small Repairs (Limited Budget)

- Recommendation: Manual Rivet Nut Gun

- Cost-Effectiveness: Low price ($7-$70), no additional equipment required, suitable for small-scale installations.

- Considerations: Manual operation can be strenuous, leading to fatigue with extended use, not suitable for high-strength materials.

Medium Workload / Repair Workshops / Moderate Production

- Recommendation: Pneumatic Rivet Nut Gun

- Cost-Effectiveness: Fast installation speed ($70-$400), suitable for small and medium-sized businesses or repair industries, moderately priced.

- Considerations: Requires an air compressor, adding to overall costs, and limited portability.

High-Volume Production / Industrial Assembly Lines / Heavy-Duty Use

- Recommendation: Electric Rivet Nut Gun

- Cost-Effectiveness: Efficient and effortless ($100-$700), ideal for mass production, increasing productivity.

- Considerations: Higher initial investment, requires charging or a power source.

2. Choose the Right Brand and Quality

Limited Budget: Choose Domestic Brands (e.g., HIFESON, Dongcheng)

- Manual Rivet Nut Guns: $7-$30, suitable for home or light work.

- Pneumatic Rivet Nut Guns: $70-$170, suitable for small factories.

- Electric Rivet Nut Guns: $100-$270, ideal for cost-conscious needs.

High-End Requirements: Choose Imported Brands (e.g., GESIPA, Milwaukee, Makita)

Suitable for high-precision, high-strength tasks, but more expensive ($280-$700).

3. Focus on Key Features

Torque & Clamping Force: Ensure sufficient clamping power for rivet nuts in various materials.

Weight & Portability: Manual tools are lighter, while pneumatic and electric tools are heavier but more efficient.

Supported Nut Sizes: Ensure support for common sizes like M3-M12 to increase versatility.

Additional Features (e.g., torque adjustment, automatic core ejection, brushless motors) can improve efficiency but may increase cost.

4. Calculate Total Cost of Ownership (TCO)

- Short-Term Costs: Manual rivet nut guns are cheap but less efficient.

- Long-Term Costs: Electric rivet nut guns have higher upfront costs but save time and labor, making them more cost-effective in the long run.

- Maintenance Costs: Pneumatic tools require air compressor maintenance, while electric tools need battery replacement or motor repairs.

Summary: Which Rivet Nut Gun is Right for You?

| Requirement | Recommended Tool | Price Range (USD $) | Advantages | Application |

| Low Frequency / DIY | Manual Rivet Nut Gun | $7-$70 | Low price, no additional equipment needed | Home use, small repairs |

| Medium Frequency / Repair Workshop | Pneumatic Rivet Nut Gun | $70-$400 | Effortless operation, fast installation speed | Mechanical repairs, small factories |

| Heavy-Duty / High-Volume Production | Electric Rivet Nut Gun | $100-$700 | High efficiency, effortless, ideal for assembly lines | Industrial manufacturing, long-term use |

Rivet Nut Gun Price - FAQs

1. Are rivet nut guns universal, and can they be used with different sizes of rivet nuts?

Most rivet nut guns support a variety of sizes (e.g., M3-M12), but different models may have specific application ranges. For example:

- Lightweight manual rivet nut guns typically support M3-M6 sizes, suitable for small DIY projects and low-strength assemblies.

- Medium pneumatic rivet nut guns support M4-M10 sizes, ideal for sheet metal work and medium-strength production environments.

- Industrial-grade electric rivet nut guns can handle M3-M12 or even larger sizes, suitable for high-strength assembly lines.

Before purchasing, make sure to check:

- Whether it includes different pull rods or adapters to fit various rivet nut sizes.

- Thread specifications (metric M-series or imperial UNC/UNF) to ensure compatibility with rivet nuts.

- Gun structure, as some high-torque electric rivet nut guns are designed for steel or stainless steel rivet nuts and may not be suitable for aluminum rivet nuts.

2. How can I ensure good rivet nut installation quality?

Correct Hole Size:

A hole that is too large can cause the rivet nut to become loose or rotate, while a hole that is too small may prevent the rivet nut from expanding properly, affecting the thread engagement. Always refer to the manufacturer’s recommended hole diameter for the rivet nut.

Matching the Right Rivet Nut Material:

- Steel rivet nuts are ideal for steel or high-strength connections.

- Aluminum rivet nuts are suitable for lightweight materials such as aluminum sheets or plastic.

- Stainless steel rivet nuts are ideal for corrosive environments, such as marine or chemical industries.

Adjust Pull Force (for pneumatic and electric rivet nut guns):

- Too much pull force can cause the rivet nut to break or the material to deform.

- Too little pull force can result in incomplete installation, causing the rivet nut to loosen.

- Some high-end rivet nut guns are equipped with torque adjustment features to precisely control the installation quality.

Check Installation Quality:

After installation, inspect the rivet nut to ensure it is securely fixed, with no noticeable looseness, and check that the threads are smooth and functional.

3. Which is better, a pneumatic rivet nut gun or an electric rivet nut gun?

Pneumatic Rivet Nut Gun:

- Advantages:

- Relatively low price, suitable for small to medium-sized businesses or factories with mass production.

- Stable operation, will not overheat during continuous use.

- Suitable for M4-M10 sizes, with a wide application range.

- Disadvantages:

- Requires connection to an air compressor, making the overall setup less portable.

- Needs regular maintenance of the air pressure system to prevent air leaks and oil blockages.

Electric Rivet Nut Gun:

- Advantages:

- No need for an external air source, more flexible, ideal for assembly lines or field work.

- Adjustable torque, suitable for high-precision applications.

- Some electric rivet nut guns feature brushless motors, which last longer and require less maintenance.

- Disadvantages:

- Higher initial cost, suitable for mass production or high-end manufacturing.

- Long periods of use may cause motor overheating, requiring intermittent operation.

Recommendation:

- Low-frequency use or limited budget: A manual rivet nut gun or pneumatic rivet nut gun is more economical and practical.

- Mass production or need for portability: An electric rivet nut gun is better for high-intensity tasks, especially in environments without access to air supply.

4. How should a rivet nut gun be maintained and serviced?

- Clean metal shavings after use to avoid clogging the threads and pull rod.

- Regularly check for wear on the pull rod and replace it if necessary.

- Avoid overloading the tool, as it could lead to incomplete installations or damage to the handle.

- Regular Lubrication: Drop an appropriate amount of lubricant before each use to reduce internal friction.

- Check Air Pressure: Ensure the air compressor provides stable pressure (typically 5-7 bar) to avoid installation failure due to low air pressure.

- Clean Air Hose: Prevent oil or moisture from entering the pneumatic system, which could affect the tool’s lifespan.

- Check Battery Condition: For rechargeable rivet nut guns, avoid over-discharging the battery to prolong its lifespan.

- Clean Riveting Area: Regularly clean the gun’s head parts to prevent rivet nut debris from affecting operation.

- Prevent Overheating: For long periods of use, consider taking breaks to avoid overheating the motor.

5. How do I choose the right rivet nut gun for my needs?

- Daily repairs, DIY, or small-scale production: Choose a manual rivet nut gun, which is low-cost and suitable for occasional use.

- Medium-scale production or factory assembly: Choose a pneumatic rivet nut gun, which is efficient and durable, ideal for mass work.

- High-strength assembly line production or fieldwork: Choose an electric rivet nut gun, which is portable and suitable for prolonged heavy-duty use.

- Matching Rivet Nut Materials:

- Aluminum Rivet Nuts: A standard manual or pneumatic rivet nut gun will suffice.

- Steel or Stainless Steel Rivet Nuts: A high-torque electric rivet nut gun or professional pneumatic rivet nut gun is recommended to ensure sufficient pulling force.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix - Leading Rivet Nuts Supplier in China

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of rivet nuts and rivet nut guns designed to meet the unique demands of your projects. With options like countersunk, flat, and hex heads, as well as knurled and round body types, Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service according to your requirements.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.