Home » Flat Head Rivet Nut Inserts

Flat Head Rivet Nut Inserts

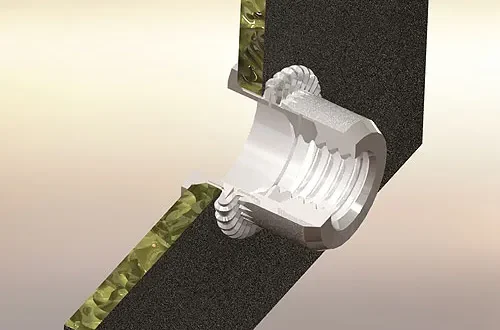

Flat Head Rivet Nut Inserts are an essential fastening solution for applications requiring a flush finish and strong internal threads in thin or soft materials. These inserts provide excellent load-bearing capacity and are ideal for sheet metal, plastic, and composite assemblies. Their flat head design ensures a smooth surface appearance after installation, making them suitable for both functional and aesthetic applications. Easy to install with standard rivet nut tools, they are widely used in automotive, electronics, furniture, and machinery industries. Whether you’re tackling a DIY project or sourcing for industrial production, our high-quality Flat Head Rivet Nut Inserts offer reliable performance and durability.

Browse our selection of Flat Head Rivet Nut Inserts today and find the perfect fit for your fastening needs!

Related Products

Get a Free Quote Now!

custom rivet and rivet nut manufacturer

M3 Flat Head Rivet Nut Inserts

M4 Flat Head Rivet Nut Inserts

M5 Flat Head Rivet Nut Inserts

M6 Flat Head Rivet Nut Inserts

M8 Flat Head Rivet Nut Inserts

M10 Flat Head Rivet Nut Inserts

M12 Flat Head Rivet Nut Inserts

Flat Head Round Rivet Nut Inserts

Flat Head Knurled Rivet Nut Inserts

Flat Head Hex Rivet Nut Inserts

Applications of Flat Head Rivet Nuts

Thin-Walled Material Fastening

Flat head rivet nut inserts are ideal for joining components to thin-walled materials like aluminum sheets or plastic panels, where traditional tapping or welding is not feasible.

Automotive Industry

Commonly used in automotive assembly for securely fastening components such as fenders, brackets, and structural reinforcements, especially when rear access is limited.

Electronics Enclosures

Perfect for mounting hardware inside electrical cabinets or metal enclosures without distorting the panel, providing strong and reusable threads.

Furniture and Appliances

Used in metal and composite furniture, as well as home appliances, to attach hinges, legs, or handles while maintaining a flush, aesthetic surface.

Industrial Equipment and Machinery

Provides strong threaded attachments in control boxes, guards, or covers of machinery, ensuring reliable and vibration-resistant fastening.

Aerospace and Marine Applications

Flat head rivet nut inserts are used in aerospace and marine industries where lightweight, corrosion-resistant, and flush-mounted fastening is required—perfect for panels, bulkheads, and non-load-bearing structures.

Related Articles

What Is the Difference Between Keensert and Threaded Insert?

What Is the Differen

FAQs About Flat Head Rivet Nuts

What is a flat head rivet nut?

A flat head rivet nut is a type of threaded insert with a wide, low-profile head designed to sit flush against the surface of the material once installed. It provides strong, permanent threads in thin or soft materials.

Where are flat head rivet nuts typically used?

These nuts are used in applications where surface flushness is important, such as in automotive body panels, metal enclosures, furniture assembly, and electronic housings.

- Sheet Metal Industry: Frequently used in enclosures, cabinets, and control panels, where the flush head ensures a smooth surface without affecting appearance or structural integrity.

- Automotive Manufacturing: Applied in areas such as inner door panels, dashboards, and vehicle body components where a concealed threaded connection is needed and head protrusion must be avoided.

- Home Appliances and Electronics: Found in products like washing machines, refrigerators, and monitor housings, where the flat head design helps prevent scratching or interference with internal parts.

- Furniture and Architectural Installations: Ideal for wood or metal structures where connectors must be hidden or surfaces kept visually clean and unobtrusive.

- Aerospace and Rail Transit: Suitable for use in lightweight alloy structures requiring strong threads in limited-space installations or critical surface applications.

- Solar Energy and New Energy Equipment: Often used in aluminum frames or housings to provide corrosion-resistant, high-strength threaded connections without compromising sealing surfaces.

What are the advantages of a flat head design?

- Larger contact area: The flat head design offers a wider contact surface, helping to distribute pressure evenly and reduce stress concentration, especially suitable for high-load applications.

- Enhanced fastening performance: The flat head can secure more firmly against the material surface, providing better resistance to pull-out and shear forces, preventing loosening.

- Aesthetic appearance: The flat head has a clean and simple look, making it ideal for applications where appearance matters, offering a neater finish.

- Reduced material damage: The flat head distributes force evenly when in contact with the material, minimizing surface damage and avoiding excessive compression or cutting.

- Suitable for various materials: The flat head works well with both soft and hard materials, especially suitable for thin sheets or applications requiring high fastening strength.

Are flat head rivet nuts reusable?

The nut remains fixed in the material, but the internal threads are reusable for repeated screw insertions, making them ideal for maintenance or assembly.

What thread sizes are available for flat head rivet nuts?

Common sizes include both metric (M3–M12) and imperial (e.g., 6-32, 1/4-20) threads, available to match a wide range of fasteners.

Can flat head rivet nuts be installed into curved or irregular surfaces?

Installing flat head rivet nuts on curved or irregular surfaces is possible, but it is not the most ideal solution.

- Feasibility: Flat head rivet nuts are typically designed for flat mounting surfaces. While they can be installed on mildly curved or uneven surfaces, the head may not sit flush, potentially affecting the appearance and fastening integrity.

- Risk of poor surface contact: Due to their wide, flat head design, flat head rivet nuts may cause local lifting, deformation, or indentation when used on curved surfaces—especially on softer materials like aluminum sheets or plastics.

- Slotted rivet nuts are more recommended: Slotted rivet nuts feature longitudinal slots in the body, allowing greater flexibility during deformation. This design helps them conform better to irregular or curved surfaces, ensuring a more secure and flush installation.

- Tooling and installation precautions: If flat head rivet nuts must be used on a curved surface, it is crucial to use appropriate installation tools and apply controlled force to avoid issues like improper seating or poor retention.

Conclusion: While flat head rivet nuts can be used on curved or irregular surfaces, slotted or half-hex rivet nuts are generally better choices for these applications, offering improved conformity and long-term performance.