What Is the Difference Between Rivet Nut and Insert Nut?

Leading Rivet Nut Manufacturer and Supplier in China

When it comes to creating strong, reliable threaded connections in different base materials, two commonly used fasteners stand out: rivet nuts and insert nuts. While they may seem similar at first glance, they are designed for very different applications. Read the blog “What Is the Difference Between Rivet Nut and Insert Nut?” and understanding the key differences in structure, installation method, and performance is essential for choosing the right fastener for your project—whether you’re working with sheet metal or soft materials like wood and plastic.

Table of Contents

What Are Rivet Nuts and Insert Nuts?

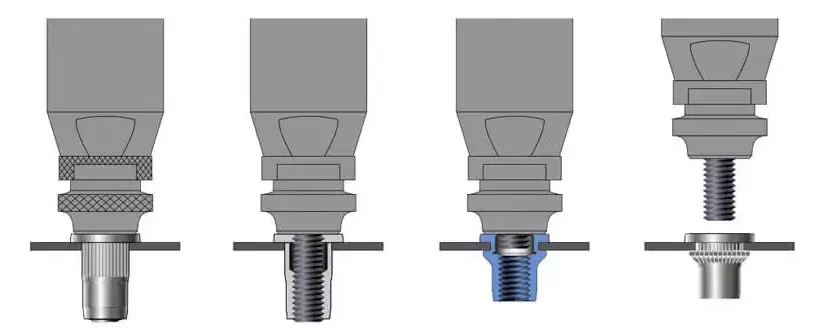

A Rivet Nut is a metal sleeve with internal threads, primarily used to create strong threaded connections in thin sheet materials where access to the backside is not possible. Its key feature is that it can be installed from one side of the workpiece using a specialized pull-rivet tool that applies axial tension to the tail, causing it to deform (“flare”) and tightly clamp the base material.

Main Features:

- One-sided installation: Ideal for applications where only one side is accessible, such as closed profiles, tubes, sheet metal housings, etc.

- Rivet expansion fixing: Using a rivet gun or similar tool, the tail is pulled from the internal thread, causing it to flare and clamp tightly behind the base material.

- Suitable for thin metal sheets (0.5mm–6mm): Widely used in aluminum, stainless steel, carbon steel, and other metal sheets.

- Various types available: Hexagonal, knurled, large flange, countersunk, closed-end, etc., to meet different anti-rotation, waterproofing, and load-bearing needs.

- Common applications: Automotive parts, electrical cabinets, metal enclosures, solar panel brackets, industrial equipment housings, and more.

Insert Nut

An Insert Nut is a threaded fastener designed specifically for soft materials such as wood, plastic, plywood, and composite boards. They are typically installed by press-fitting, hammering, heat-setting, or screwing in, relying on external features such as threads, barbs, or knurls to mechanically grip the base material and provide a reliable internal thread. Insert nuts are commonly used in furniture assembly, pre-threaded plastic parts, 3D printed components, and similar applications.

Main Features:

- Fixed by external structure: Usually have external threads, barbs, knurls, or other features to embed into the base material by press-in, heat-set, or screwing.

- No backside material damage: Installation does not require flange deformation, suitable for applications where the backside surface must remain intact.

- Pull-out and anti-rotation performance depend on material and texture: For example, deep spiral threads are recommended for softwood; heat-set inserts are common for plastics.

- Common types:

- Press-in inserts

- Heat-set inserts

- Barbed inserts

- Threaded inserts (self-tapping)

- Applications include: Furniture joints (e.g., IKEA nuts), threaded inserts for 3D printed parts, plastic housings for appliances, etc.

In summary, although both rivet nuts and insert nuts serve to “create internal threads,” rivet nuts are better suited for thin metal structures, while insert nuts are designed for wood and plastic substrates. Their structures and installation methods differ significantly. Understanding these differences helps avoid mismatches and installation failures during engineering design or selection processes.

What Are the Structural Differences Between Rivet Nuts and Insert Nuts?

Rivet Nut

Rivet Nuts are metal fasteners specifically designed for blind installation (i.e., installation from only one side of the material). Their structural design ensures reliable riveting, anti-rotation, and stable locking, featuring the following characteristics:

a. Body Shape:

- Round Body: The most common type, designed to fit standard round holes. Friction can be enhanced with knurling or ribs.

- Hex Body: Designed for hexagonal punched holes; once riveted, the hex shape mechanically locks to prevent spinning. Especially suitable for high-torque applications.

- Half-Hex Body: Balances anti-rotation performance and manufacturing cost, suitable for medium load conditions.

b. Body Surface Treatment:

- Knurled Body: Raised diamond or cross-hatch pattern pressed onto the surface to increase friction and anti-rotation capability, ideal for smooth holes.

- Ribbed/Slotted Body: Longitudinal ribs or slots increase contact force with the hole wall to prevent rotation.

c. Tail Structure:

- Open End: Allows bolts to pass completely through; suitable for non-sealed conditions.

- Closed End: Seals out moisture, dust, and prevents electrical shorts; commonly used in electronic equipment or sealed environments.

d. Flange Design:

- Standard Flange (Flat Head): Provides a stable bearing surface; the most common type.

- Large Flange: Used for softer base materials (e.g., thin aluminum sheets), offering a larger clamping area to prevent pull-out.

- Reduced Flange (Small Flange): Designed for limited space applications.

- Countersunk: Installed flush with the material surface for improved aesthetics and safety.

e. Material Types:

- Commonly made from aluminum alloy, carbon steel, and stainless steel, often with surface treatments such as zinc plating, Dacromet coating, or anodizing to enhance corrosion resistance and strength.

Insert Nut

Insert Nuts are designed for embedding into soft materials such as wood, plastic, thermoset resins, etc. Their structural focus lies on mechanical interlock and pull-out resistance:

a. Outer Wall Structure:

- Coarse External Thread: Screws into wood or plastic relying on thread locking force.

- Barbed Type: Features serrations or hooked barbs on the surface, typically press-fit once for permanent fixation, preventing reverse rotation or pull-out.

- Knurled Outside: Common in heat-set inserts; external knurling aids fusion with plastic when heated, forming a locked structure.

b. Installation Methods:

- Screw-in Type: Equipped with a cross slot or hex socket, installed by screwing into wood using power tools.

- Heat-Insert Type: Used for thermoplastics; plastic is melted by heat and the insert is embedded.

- Press-in Type: Pressed or hammered in without tools, relying on friction and mechanical interference to hold in place.

c. Head Shape:

- Some inserts have a stop flange or collar to prevent over-insertion or rotation.

- Some feature an internal thread lead-in taper to facilitate fast and accurate bolt engagement.

d. Common Application Environments:

- Used in woodworking furniture for detachable joints (e.g., cabinets, table legs).

- Bolt connections in plastic housings (e.g., electronics devices, battery cases).

- Light-load structural parts where frequent disassembly and reassembly are needed.

What Are the Differences in Materials Used for Rivet Nuts and Insert Nuts?

Rivet Nut

Applicable Materials: Steel sheets, aluminum sheets, stainless steel, composite metal sheets

Therefore, Rivet Nuts are widely used in automotive, machinery, electrical enclosures, and other metal structural applications.

Rivet Nuts achieve fastening through the principle of riveting deformation. When installed into metal sheets, a specialized tool applies axial pressure to the nut’s tail, causing it to expand and clamp firmly against the backside of the sheet, creating a “clamping zone” that ensures secure locking. This structure:

- Relies on material compressive strength and hardness: Metal substrates such as steel and stainless steel possess good resistance to deformation and can withstand the compressive forces during Rivet Nut installation without cracking.

- Provides stable thread load capacity: The expanded Rivet Nut forms a solid mechanical interlock with the metal sheet, capable of bearing relatively high axial tensile and shear forces.

- Suitable for thin-walled materials: Even with thin base materials, as long as hardness is sufficient, Rivet Nuts can be securely fixed to provide strong, stable threaded connections.

Insert Nut

Applicable Materials: Solid wood, particleboard, plastic parts, 3D printed components, and other non-metallic soft materials

Hence, Insert Nuts are commonly applied in furniture assembly, plastic housing installation, 3D printing assemblies, and other soft material.

Insert Nuts are embedded into soft materials through thread cutting or barbed engagement to achieve fastening. These materials (like wood or plastic) cannot directly withstand repeated insertion and removal of metal screws without damaging the internal threads. Insert Nuts enhance connection by:

- Having external threads or barbs: These cut into or grip the soft material upon insertion, providing firm mechanical fixation.

- Avoiding cracking or deforming the soft substrate: Compared to direct screwing, Insert Nuts cause less damage to the base material and distribute stress more evenly.

- Improving repeated assembly capability: Once embedded, they create metal-threaded holes that allow screws to be repeatedly used without wear or stripping.

Summary: Differences in Materials Used for Rivet Nuts and Insert Nuts

Rivet Nuts are primarily designed for connections in metal materials, suitable for installation in steel, aluminum, stainless steel, and composite metal sheets. Because these substrates have high hardness and strength, Rivet Nuts use expansion and clamping to securely fix into the base material, ensuring connection strength and stability. This makes them ideal for automotive manufacturing, machinery, and metal structural parts, where high strength and durability are required.

In contrast, Insert Nuts are mainly used in soft, non-metallic materials such as solid wood, particleboard, plastics, and 3D printed parts. These materials are relatively soft, and traditional threaded connections often damage the substrate or result in weak joints. Insert Nuts are designed with structures suited for soft materials, achieving tight bonding with the substrate via mechanical interlock or adhesive means, providing stable threaded connections. They are widely used in furniture making, plastic product assembly, and rapid prototyping.

How Do the Installation Methods of Rivet Nuts and Insert Nuts Differ?

1. Installation Method Principle Comparison

Rivet Nut: Pull-Riveting Deformation, Clamping Fixation

- Applicable Substrate: Thin-walled metal structures such as steel sheets, stainless steel sheets, aluminum sheets, and composite metal panels.

- Installation Principle:

- Insert the Rivet Nut into a pre-drilled hole.

- The Rivet Nut tool axially pulls the internal threaded mandrel.

- The tail section of the Rivet Nut undergoes localized crushing and radial expansion.

- The Rivet Nut forms an “umbrella-shaped riveted base,” firmly clamping between the upper and lower surfaces of the substrate.

- Advantages:

- Can be installed from one side only (blind installation), suitable for tubular structures.

- Provides a standard metal threaded hole with high strength.

- After deformation, it cannot rotate, ensuring stable and reliable connection.

Insert Nut: Mechanical Interlock or Thread Cutting Fixation

Installation Principle:

- The outer surface of the Insert Nut is designed with threads, barbs, or serrations.

- It is inserted by cutting into, pressing into, or heat-fusing with the substrate.

- Relies on mechanical interlock or friction to lock in place, resisting pullout and rotation.

- Applicable Substrate: Soft, non-metallic materials such as wood, particleboard, plastic, 3D printed parts.

- Advantages:

- Provides high-quality internal threads, enhancing connection strength in soft substrates.

- Allows repeated tightening and removal of screws.

- Simple structure and easy operation.

2. Step-by-Step Installation Process

- Hole Preparation

- Drill a hole in the metal sheet.

- Recommended hole diameter: Ø9.0 mm (tolerance ±0.1 mm).

- Screw the Nut onto the Mandrel

- Fully screw the Rivet Nut onto the threaded mandrel of the Rivet Nut tool.

- Ensure stable engagement.

- Position in the Hole

- Insert the tool head vertically into the hole; the flange of the Rivet Nut should sit flush on the workpiece surface.

- Perform Riveting

- Activate the electric or pneumatic Rivet Nut tool to expand and deform the tail, clamping the sheet.

- Installation time: about 2–4 seconds per nut.

- Remove the Tool

- Release the mandrel and withdraw the tool head, leaving a standard threaded hole.

- The pull-out strength of the M6 Rivet Nut after installation is approximately 5–8 kN.

Note: Hole diameter must precisely match; excessive deviation may cause rotation failure or insufficient clamping force.

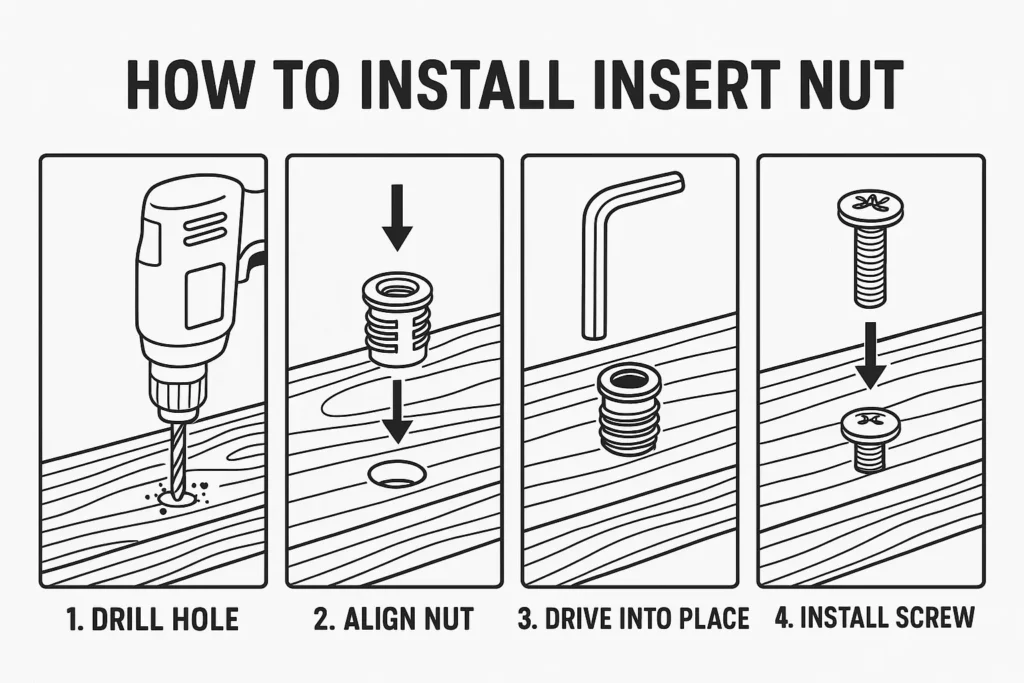

Insert Nut Installation Steps (Example: Wood-threaded Insert Nut)

- Hole Preparation

- Drill a hole in wood, plastic, or 3D printed parts.

- Recommended hole diameter: Ø8.8 mm (slightly smaller than the M6 Insert Nut outer diameter).

- Insert and Align

- Vertically place the Insert Nut into the hole, ensuring accurate positioning.

- Barbs or threads should evenly engage the hole.

3. Perform Installation

- External threaded type: screw in using a hex wrench.

- Barb-press type: gently tap in with a rubber hammer.

- Heat-fused type (for plastics): embed using a soldering iron or ultrasonic tool.

- Typical insertion depth: 10–15 mm.

4. Check Positioning Accuracy

- Ensure the Insert Nut is flush with the surface and threads are vertical without eccentricity.

- Recommended installation accuracy: ±0.2 mm.

5. Screw Assembly

- Use metal screws for assembly to ensure tight bonding.

- High-quality Insert Nuts can withstand more than 10 assembly/disassembly cycles without thread stripping.

Note: Different substrates require different Insert Nut types; for plastics, slotted or heat-fused types are recommended for stronger grip.

3. Perform Installation

- External threaded type: screw in using a hex wrench.

- Barb-press type: gently tap in with a rubber hammer.

- Heat-fused type (for plastics): embed using a soldering iron or ultrasonic tool.

- Typical insertion depth: 10–15 mm.

3. Typical Performance Comparison Data

| Item | Rivet Nut (M6) | Insert Nut (M6) |

| Installation Time | 2–4 seconds per piece (electric) | 5–10 seconds per piece (manual) |

| Pull-out Strength | Carbon steel: ~5–8 kN | Wood: ~1.5–2.5 kN |

| Stainless steel: ~7–10 kN | Plastic: ~0.8–2.0 kN | |

| Anti-rotation Ability | Hexagonal > Knurled > Cylindrical | External thread > Press-fit; barbs have strong anti-rotation |

| Blind Installation | ✅ Yes | ❌ Mostly no, unless special tools |

| Reusability | Medium (may loosen after repeated disassembly) | High (designed for repeated assembly) |

| Hole Tolerance | High (±0.1 mm) | Medium (±0.2–0.5 mm) |

Application Recommendations

- Recommended scenarios for Rivet Nuts:

- Installation where only one side is accessible.

- Metal substrates requiring high strength.

- Connections needing high load capacity.

- Recommended scenarios for Insert Nuts:

- Soft substrates such as wood, plastic, or 3D printed parts.

- Applications requiring multiple screw removal/reassembly without loosening.

- Simple installation tools, suitable for non-industrial environments.

What Are the Differences in Tensile and Torsional Strength Between Rivet Nuts and Insert Nuts?

1. What Are Tensile Strength and Torsional Strength?

Definition: Tensile strength refers to the maximum axial load a fastener can withstand when subjected to a pulling force, usually measured in kilonewtons (kN) or newtons (N). For nut-type fasteners, it indicates the ability to resist being pulled out vertically from the base material after installation. This property directly determines whether the joint can reliably bear “pulling” or vertical loads, especially critical in high-strength structural connections such as automotive chassis or steel frameworks.

Mechanism:

- For Rivet Nuts, the expanded tail forms a “clamping zone” that resists the pulling force, preventing the nut from being pulled out.

- For Insert Nuts, the resistance depends on the engagement of threads, barbs, or serrations embedded in the base material, largely influenced by the material density and insertion depth.

Importance in Typical Applications:

- Used in load-bearing components (e.g., frames, mechanical arms, brackets), the tensile strength should have a safety factor of at least 2 times the expected load.

- Insufficient tensile strength can lead to loosening or, worse, failure, causing structural damage, falling parts, or safety hazards.

Torsional Strength

Definition: Torsional strength is the fastener’s ability to resist rotation under applied torque, measured in newton-meters (Nm) or pound-inch (lb-in). It evaluates whether a nut will slip or spin during tightening or under long-term vibration. This property is crucial in applications requiring repeated assembly or exposure to vibration, such as furniture, plastic housings, and electronic enclosures.

Mechanism:

- Insert Nuts create high friction resistance through external threads and barbs interacting with softer base materials, enhancing anti-rotation.

- Rivet Nuts with a cylindrical shape have lower torsional resistance; however, knurled or hex designs significantly improve anti-rotation performance.

Importance in Typical Applications:

- In repeated assembly scenarios (e.g., cabinet hinges, plugs, 3D printed cases), slipping nuts cause fastening failure and malfunction.

- Under vibration (e.g., fans, vehicles), insufficient torsional strength leads to nut rotation, loosening, or detachment.

2. Importance of These Strengths in Real Applications

- Critical Tensile Strength Applications: Solar panel mounts, electric vehicle battery boxes, aircraft fuselage—these require high load capacity and long service life, making reliable tensile resistance essential.

- Critical Torsional Strength Applications: Cabinet hinge mounts, plug sockets, 3D printed shells—these demand repeated disassembly and must maintain no rotation, no loosening over time.

Consider strengthening these properties if:

- The nut easily pulls out with a light tug → Tensile strength is insufficient.

- The screw loosens automatically after tightening → Torsional strength is insufficient.

- The nut rotates when tightening the screw → Torsional resistance failure, requiring redesign or different fastener choice.

3. How to Assess Tensile and Torsional Strength?

- Theoretical Calculation + Product Data Review

- Check manufacturer’s rated pull and torque values to ensure they exceed expected application loads.

- Example: For a max load of 3 kN, select a rivet nut with ≥ 6 kN tensile strength for safety.

- Destructive Testing

- Tensile test: Pull the nut using a tensile machine and record maximum pull-out load.

- Torsion test: Apply torque with a wrench and measure when slipping or failure occurs.

- Assembly Observation

- If the nut rotates during screw insertion, torsional resistance is inadequate.

- If the nut pulls out prematurely during pull testing, tensile strength is inadequate.

4. Performance Data Comparison: Rivet Nut vs. Insert Nut

Example: M6 size

- Rivet Nut (Carbon Steel) installed in 1.5mm steel plate typically shows tensile strength of 5–8 kN; stainless steel versions reach 7–10 kN, making them ideal for load-bearing metal connections. In torsion, hexagonal shapes can exceed 10 Nm, while smooth cylindrical types with no knurling achieve only 2–4 Nm, prone to slipping.

- Insert Nut (Wood External Thread Type) in hardwood generally provides tensile strength around 1.5–2.5 kN, and in plastic around 0.8–2.0 kN, noticeably lower than rivet nuts. However, torsional strength is excellent—external threads or barbs can reach 6–12 Nm, suitable for repeated screwing and high-friction engagement in soft materials.

Summary Recommendations

- For applications emphasizing structural strength, long-term load capacity, and safety: prioritize Rivet Nuts, especially stainless steel or large flange types.

- For applications requiring repeated assembly and no nut rotation: prioritize Insert Nuts, preferably external thread with slots.

- For plastic base materials, consider heat-set Insert Nuts to improve tensile strength.

- To balance tensile and torsional performance in rivet nuts, select hex, knurled, or closed-end types for best results.

Rivet Nuts or Insert Nuts, Which One Is Better For You?

1. Choose Based on Base Material

- Hard Metal Materials (such as steel plates, aluminum plates, stainless steel, composite metal sheets)

- Prefer Rivet Nuts.

- Reason: Rivet nuts expand or deform to tightly bond with metal sheets, providing high tensile and shear strength, ensuring structural strength and stability.

- Typical applications: automotive bodies, industrial equipment, sheet metal enclosures, etc.

- Soft Materials (such as solid wood, particleboard, plastics, 3D printed parts)

- Prefer Insert Nuts.

- Reason: Insert nuts feature external threads, barbs, or heat-set designs that grip tightly with soft substrates, improving torsional and pull-out resistance and allowing easy repeated assembly/disassembly.

- Typical applications: furniture, home improvement, electronic plastic housings, etc.

2. Choose Based on Installation Method and Accessibility

- Single-side operation only, with no access to the backside

- Choose Rivet Nuts.

- Reason: Rivet nuts can be installed from one side using specialized rivet nut tools without the need for backside access.

- Suitable scenarios: enclosed structures, sheet metal panels with inaccessible backsides.

- Ample installation space with backside access

- You may choose Insert Nuts, especially for applications requiring repeated disassembly.

- For soft substrates, external-thread or heat-set types are recommended.

- Suitable scenarios: furniture assembly, plastic housings, etc.

3. Choose Based on Load and Strength Requirements

- High load-bearing and strict structural safety requirements

- Prioritize Rivet Nuts, especially stainless steel or extended length types.

- Typically offer higher tensile strength than insert nuts, suitable for heavy or vibration-prone machinery.

- Medium to low load with frequent disassembly needed

- Choose Insert Nuts, such as external-thread wood nuts or barbed types, which effectively prevent rotation and loosening.

- Suitable for furniture, electronics, and maintenance-intensive applications.

4. Summary of Selection Guidelines (Comparison Table)

| Selection Criteria | Rivet Nut | Insert Nut |

| Base Material | Steel, aluminum, stainless steel, composite metal sheets | Solid wood, particleboard, plastics, 3D printed parts |

| Installation Method | Single-side installation, backside inaccessible | Single or double side, depending on structure |

| Load Capacity | High tensile and shear strength | High torsional strength; tensile depends on substrate density |

| Frequency of Disassembly | Low to medium, suited for permanent fixtures | High, suited for frequent disassembly |

| Anti-loosening Features | Knurled, hex shapes to prevent rotation | External threads, barbs, heat-set structures enhance grip |

| Typical Applications | Automotive, industrial equipment, sheet metal enclosures, metal furniture | Furniture assembly, wood products, home improvement, plastic housings |

5. Other Considerations

- Corrosion Resistance: For outdoor or humid environments, choose stainless steel rivet nuts or corrosion-resistant insert nuts.

- Hole Size and Material Thickness Matching: Confirm hole diameter and base material thickness before installation to ensure proper expansion or embedment.

- Tool Compatibility: Consider availability and ease of operation of installation tools when selecting fasteners.

Summary

Rivet nuts and insert nuts are two common types of fasteners, each with unique advantages and suitable application scenarios. Choosing the right type requires a comprehensive consideration of factors such as base material, installation environment, load requirements, and frequency of disassembly.

- For metal substrates, especially hard materials like steel and aluminum plates, rivet nuts are the preferred choice due to their excellent tensile strength and structural stability. They are widely used in automotive manufacturing, sheet metal enclosures, industrial equipment, and other fields.

- For wood, plastic, and other soft materials, insert nuts offer good torsional resistance and convenient installation methods, making them particularly suitable for furniture assembly, home improvement projects, and electronic plastic housings.

- Accessibility during installation is also a key factor: rivet nuts are ideal for single-sided installation environments, while insert nuts are often used in more open spaces or where multi-sided access is available.

- Load capacity and usage frequency further influence the choice: rivet nuts are favored for high-strength, long-term fixed applications, whereas insert nuts are better suited for situations requiring frequent disassembly.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix- Leading Fastener Manufacturer

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.