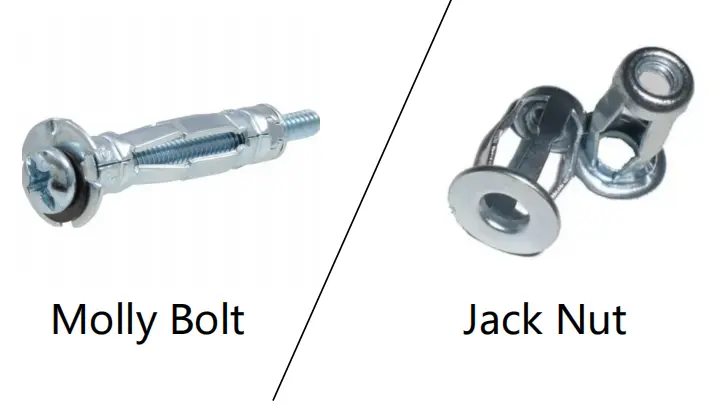

What Is the Difference Between a Jack Nut and a Molly Bolt?

Leading Rivet Nut Manufacturer and Supplier in China

When working with hollow or thin-wall materials, choosing the right fastener is critical for ensuring strength and reliability. Two popular options for such applications are jack nuts and molly bolts, but they serve different purposes and perform differently depending on the base material and load requirements. In this guide, we’ll explore the difference between a jack nut and a molly bolt, examining their structure, installation methods, ideal use cases, and pros and cons—so you can make the best choice for your next project.

Table of Contents

A Jack Nut is a type of expansion nut specifically designed for use in hollow or soft materials such as plastic panels, fiberglass, thin sheet metal, or composite boards. Depending on its design, it may be made entirely of metal or feature a rubber-coated metal body.

Structure and Installation Principle

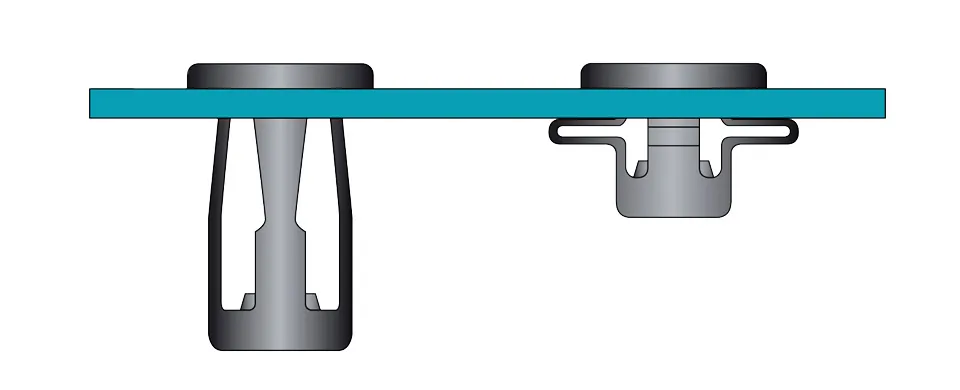

The Jack Nut consists of a slotted metal sleeve with a collapsible tail section, similar to a set of “umbrella ribs.” The installation process involves:

- Inserting the Jack Nut into a pre-drilled hole.

- As the screw is tightened into the Jack Nut, the internal threads pull the tail section inward.

- This causes the slotted end to collapse outward, expanding behind the base material and clamping it securely.

This expansion creates a firm hold without needing access to the backside of the workpiece, making it ideal for single-sided installation in hollow or enclosed applications.

Key Features and Benefits

- Suitable for installation in a variety of non-structural, soft, or hollow materials, such as plastic housings, fiberglass panels, composite materials, and thin sheet metal.

- Easy to install using simple tools like a screwdriver, socket wrench, or basic hand tools—no specialized equipment is required.

- Can be used in tight or enclosed spaces where the backside of the material is not accessible.

- A cost-effective solution for lightweight fastening needs, making it ideal for applications such as trim mounting, non-load-bearing attachments, and plastic component assembly.

What Is a Molly Bolt and How Does It Work?

A Molly Bolt, also known as a hollow-wall expansion anchor, is a type of metal fastener specifically designed for use in hollow or thin wall structures, such as drywall, plasterboard, or thin wall panels. It is widely used in residential and commercial spaces to securely mount objects onto walls. Its key feature is the expanding “wings” that lock into place behind the wall once installed.

Installation Principle

A Molly Bolt typically consists of a metal sleeve with a pre-installed machine screw. The installation process is as follows:

- Drill a hole in the wall and insert the Molly Bolt into it.

- Begin tightening the screw; this pulls the metal sleeve inward.

- As pressure builds, the rear section of the sleeve expands outward, creating metal “wings” that open behind the wall.

- These wings grip the backside of the wall, anchoring the bolt firmly in place.

- Once fully expanded, the screw can be removed and replaced as needed for attaching objects.

Key Features and Benefits

Strong Tensile Strength and Vibration Resistance:

The wide expansion area distributes load evenly, providing solid anchoring for medium-duty applications, such as mirrors, wall lamps, shelves, or framed art.

Reusable Screw Access:

After installation, the screw can be removed and reinserted multiple times without compromising the anchor, making it ideal for adjustable or serviceable mounts.

Ideal for Hollow Wall Materials:

Particularly effective in drywall, hollow panels, and thin sheet materials that cannot support standard screws or bolts.

Easy to Install:

Requires only a drill and screwdriver—no special tools are needed.

How Do Jack Nuts and Molly Bolts Compare?

a. Material

In expansion-type fasteners, the choice of material directly affects the product’s mechanical performance, corrosion resistance, cost efficiency, and applicable scenarios. While Jack Nuts and Molly Bolts have similar structures, their material selections have distinct characteristics.

Materials Used in Jack Nuts:

- Typically made from low carbon steel or zinc alloy, offering good ductility and formability to allow the tail “umbrella ribs” to deform and clamp securely during installation;

- Surfaces are commonly treated with electro-galvanization or nickel plating to enhance rust protection and corrosion resistance;

- Some high-performance variants use stainless steel (e.g., 304 stainless steel) for use in humid, temperature-variable, or mildly corrosive industrial environments;

- Overall lightweight and cost-effective, suitable for mass production and standardized assembly.

Materials Used in Molly Bolts:

- Generally made from cold-rolled carbon steel, providing high strength and reliable expansion deformation performance;

- Most products feature zinc plating or nickel plating on the surface to improve weather resistance and prevent oxidation;

- Premium models are made of 304 or 316 stainless steel to meet the demands of outdoor, humid, acidic, or alkaline environments;

- High rigidity and strength, making them ideal for medium-load structural anchoring applications.

Summary Comparison:

| Aspect | Jack Nut (Metal Type) | Molly Bolt |

| Common Materials | Low carbon steel, zinc alloy, stainless steel | Cold-rolled carbon steel, stainless steel |

| Surface Treatment | Zinc plating, nickel plating | Zinc plating, nickel plating |

| Corrosion Resistance | Moderate (better with stainless steel versions) | Strong (especially stainless steel versions) |

| Cost Level | Lower, suitable for bulk purchase | Slightly higher, suited for medium-load use |

b. Installation Methods

Jack Nut Installation Method

- Prepare the Hole

Drill a hole in the base material that matches the outer diameter of the Jack Nut. The hole size and depth must meet product specifications to ensure smooth insertion. - Insert the Jack Nut

Insert the Jack Nut into the prepared hole, keeping the tail’s multi-segmented “umbrella rib” metal structure in an unexpanded state, closely fitting the hole walls.

3. Screw in the Bolt

Using a screwdriver or manual tool, tighten the bolt through the Jack Nut’s interior. As the bolt is tightened, the “umbrella rib” structure at the tail contracts inward and expands outward.

4. Form Clamping Force

The pulling force generated by tightening the bolt causes the metal tabs at the tail to contract inward and expand outward, firmly gripping and clamping the backside of the base material to achieve a secure locking effect.

5. Complete Installation

After installation, the Jack Nut remains firmly fixed and is typically not recommended for repeated disassembly, making it suitable for one-time assembly in light-load applications.

Molly Bolt Installation Method

- Prepare the Hole

Drill a hole in drywall or thin-walled materials, ensuring the hole size matches the Molly Bolt specifications for smooth insertion. - Insert the Molly Bolt

Insert the Molly Bolt into the hole so that the expansion sleeve is fully inside the hole, in its unexpanded state.

3. Tighten the Screw to Initiate Expansion

Use a screwdriver or power tool to tighten the pre-installed screw. As the screw rotates, the metal “wings” at the tail of the Molly Bolt gradually open and expand behind the wall.

4. Achieve Mechanical Anchoring

Once expanded, the wings form a strong mechanical anchor that locks firmly inside the wall, ensuring even load distribution and good vibration resistance.

5. Disassembly and Maintenance

After installation, the screw can be removed and replaced while the anchor body remains in the wall, allowing for maintenance or replacement of mounted objects.

Summary

- Jack Nuts rely on the inward contraction and expansion of the tail’s “umbrella ribs” to achieve clamping; they are easy to install and suitable for soft or thin-walled materials.

- Molly Bolts achieve anchoring by expanding “wings” at the tail, offering higher load capacity and suitability for medium loads and hollow wall structures.

c. Tools Used

Tools for Jack Nut

Manual Tools

Jack Nuts are designed for simplicity and can be installed using common manual tools such as a standard screwdriver or a handled screwdriver to tighten the screw. This method is ideal for small batches, onsite repairs, or installations in confined spaces.

Specialized Installation Guns

In industrial production or mass assembly, using dedicated Jack Nut installation guns (or pneumatic tools) can significantly improve installation efficiency and quality, ensuring consistent clamping force for each Jack Nut and reducing human error.

Advantages

Flexible and versatile, suitable for both manual operations and automated production lines, adapting to different installation needs.

Tools for Molly Bolt

Screwdrivers

Most Molly Bolt models can be installed using ordinary screwdrivers by tightening the screw to activate the expansion anchoring mechanism at the tail. This approach is simple and convenient, suitable for home renovation and light industrial use.

Power Tools

For larger volume installations or faster construction, power screwdrivers, drills, and other electric tools can greatly reduce installation time and improve work efficiency while ensuring accurate expansion.

Pre-Expansion Screw Activation (Certain Models)

Some Molly Bolts feature a “pre-expansion” screw that must be tightened first to activate the expansion mechanism before continuing installation. This design improves anchoring strength but requires careful installation procedures.

Advantages

A variety of tools can be used, fitting home, commercial, and industrial scenarios, balancing efficiency and safety.

Summary

- Jack Nut installation tools are flexible; they can be manually operated or used with specialized installation guns to boost efficiency, suitable for diverse environments.

- Molly Bolt installation primarily relies on screwdrivers and power tools, with some models requiring a pre-expansion step, accommodating various batch sizes and installation complexities.

d. Load Capacity Detailed Explanation

- Jack Nuts are primarily designed for light-duty applications, suitable for fastening decorative parts, plastic components, and lightweight metal pieces that are non-structural;

- Due to the limited clamping strength of the tail’s “umbrella rib” structure, they are generally not suitable for withstanding high tensile or shear forces;

- Common usage scenarios include automotive interior panel fastening, small electronic device enclosures, and lightweight plastic part connections;

- Although their load capacity is lower than heavy-duty anchors, Jack Nuts offer easy installation and low cost, meeting general light-load requirements.

Load Capacity of Molly Bolt

- Molly Bolts provide strong mechanical anchoring, with the expanded “wings” at the tail creating a large contact area to distribute loads, offering higher tensile and shear strength;

- Suitable for medium-load applications such as wall hooks, lighting fixture mounting, bathroom mirror hanging, and other load-bearing environments requiring safety factors;

- Their stable structure and good vibration resistance make them appropriate for drywall, hollow walls, thin-walled structures, and various substrates;

- Widely used in both industrial and household fields, balancing load capacity with installation convenience.

Summary

- Jack Nuts are suited for light loads, focusing on quick and simple fastening;

- Molly Bolts are suitable for medium loads, emphasizing firmness and safety to meet higher load demands.

e. Removability

Removability of Jack Nut

- Although the screw used during installation can be unscrewed, the tail’s metal “umbrella ribs” have already undergone plastic deformation and expanded to clamp tightly;

- This deformation is irreversible, meaning the expanded structure cannot return to its original state;

- Therefore, once installed and expanded, the Jack Nut’s fastening effectiveness is difficult to guarantee if removed and reused;

- It is generally not recommended to repeatedly disassemble and reuse Jack Nuts, making them suitable for one-time light-load fastening applications.

Removability of Molly Bolt

- Molly Bolts are designed to allow the screw to be removed and replaced multiple times;

- After the screw is removed, the expanded “wing” anchor body remains inside the wall, maintaining a fixed base;

- This feature is ideal for applications requiring periodic maintenance, replacement of mounted items, or adjustment of the fixture’s position;

- It enhances assembly flexibility and maintenance convenience, widely used in both residential and commercial environments.

f. Suitable Base Materials Detailed Explanation

Suitable Base Materials for Jack Nut

- Jack Nuts are primarily used with relatively soft or hollow base materials, especially plastics, fiberglass, thin metal sheets, and soft composite materials;

- Due to their tail “umbrella rib” clamping mechanism, they are suitable for environments where the backside of the hole cannot be directly accessed, effectively achieving a secure grip;

- Common applications include plastic housings for electronic devices, lightweight instrument components, automotive interior panels, and other scenarios with space or material constraints;

- Their lightweight design performs stably in soft base materials, avoiding damage caused by excessive hardness.

Suitable Base Materials for Molly Bolt

- Molly Bolts are mainly used in building structural materials such as drywall, hollow walls, and light steel panels;

- The expansion “wings” at the tail create anchoring force that provides strong fixation in hollow or thin-walled structures, meeting medium load requirements;

- Widely used for wall hangings, lighting fixtures, decorative component fastening, balancing load capacity with installation convenience;

- Their design meets the building industry’s strict safety and stability standards.

Summary

- Jack Nuts suit soft or hollow non-structural materials, emphasizing lightweight design and base material protection;

- Molly Bolts suit hollow walls and construction materials, emphasizing anchoring strength and load capacity.

g. Cost and Availability Detailed Explanation

Cost and Availability of Jack Nut

- Jack Nuts have a relatively simple structure and mature manufacturing processes, resulting in lower production costs and more affordable market prices;

- They are widely available in hardware markets and industrial supply chains worldwide, with a rich variety of specifications for easy procurement;

- Suitable for enterprises and users requiring bulk purchases, meeting the needs of light industry and mass production;

- Their cost advantage makes Jack Nuts highly competitive for budget-sensitive projects.

Cost and Availability of Molly Bolt

- Molly Bolts have a more complex expansion structure and higher performance requirements, leading to more complex manufacturing processes and consequently higher costs;

- In mature markets such as Europe, North America, and Australia, Molly Bolts are standard hardware products commonly stocked in local hardware and building material stores;

- Although priced higher, their excellent performance and reliability make them widely used in construction, renovation, and industrial applications;

- For projects requiring certain load-bearing capacity and safety assurance, Molly Bolts offer a cost-effective solution.

Summary

- Jack Nuts offer low cost and wide availability, suitable for bulk and budget-sensitive applications;

- Molly Bolts excel in performance and reliability, suited for scenarios demanding higher load capacity and safety.

Conclusion - How Do Jack Nuts and Molly Bolts Compare

| Comparison Aspect | Jack Nut | Molly Bolt |

| Material | Metal or rubber-coated metal | Metal |

| Installation Method | Screw in → Tail contracts and clamps | Screw in → Wings expand and anchor |

| Tools Required | Can be installed manually or with a special installation tool | Typically requires a screwdriver or power tool |

| Load Capacity | Moderate, suitable for light-duty applications | Relatively strong, suitable for medium-duty loads |

| Removability | Not recommended for repeated disassembly | Easy to remove; screw can be replaced multiple times |

| Suitable Base Materials | Plastic, thin metal, fiberglass, soft composite materials | Drywall, hollow walls, thin sheet metal and other wall structures |

| Cost & Availability | Low cost, commonly available in the market | Slightly higher cost, commonly stocked in hardware stores in some countries |

Where Are Jack Nuts and Molly Bolts Commonly Used?

Automotive Manufacturing:

Widely used for fastening plastic panels and thin composite components in car interiors, such as dashboards and door trims. Jack Nuts are well-suited for tight spaces and provide stable clamping.

Furniture and Equipment Assembly:

Applied in joining wooden boards, fiberboards, and plastic furniture components—especially in pre-drilled holes where conventional nuts may not hold securely.

Composite and Fiberglass Components:

Used in wind turbine blades, yacht interiors, and HVAC housings. Jack Nuts offer reliable grip in thin or soft composite materials without damaging the base material.

Loose or Oversized Holes in Soft Materials:

Effective in engineering plastic enclosures, oversized round holes, or foam-core panels. The umbrella-shaped expansion structure ensures strong fastening even in uneven or soft substrates.

Common Applications of Molly Bolts (Ideal for medium loads and wall structures)

Home Renovation:

Used for mounting picture frames, mirrors, small wall cabinets, hooks, and light fixtures on drywall. Offers solid anchoring and allows for easy removal and repositioning.

Office Space Modifications:

Suitable for mounting whiteboards, shelving units, acoustic panels, and display systems on partition walls or hollow walls in commercial buildings. Excellent for vibration-resistant mounting.

Indoor Equipment Mounting:

Ideal for securing TV brackets, kitchen accessories, bathroom fixtures, and similar items to hollow walls or light steel framing—ensuring safe and reliable support.

Standard Anchoring in Building Projects:

In European and North American construction standards, Molly Bolts are a go-to fastener for drywall systems. They’re widely available in most hardware stores.

Conclusion - What Is the Difference Between a Jack Nut and a Molly Bolt?

When selecting the appropriate expansion fastener, understanding the structural characteristics and application scenarios of Jack Nuts and Molly Bolts is essential. Below is a breakdown of recommended use based on different conditions:

If your base material is soft

(such as plastic panels, fiberglass, thin metal, or hollow composite boards):

- Jack Nuts are recommended.

- Their “umbrella rib” expansion design allows for secure clamping, even in spaces where the backside is inaccessible. They are especially suitable for low-load applications in limited spaces or on low-strength substrates.

If your base material is wall-type structures

(such as drywall, gypsum board, hollow bricks, or light-gauge steel framing):

- Molly Bolts are the better choice.

- Their expanding “wing” design provides strong anchoring in hollow wall systems, supports repeated screw removal, and is ideal for mounting applications in residential and commercial interiors.

General Recommendation:

- The choice should be based on both load-bearing requirements (light vs. medium duty) and installation environment characteristics (e.g., backside access, need for reusability).

- Proper selection helps improve the stability, safety, and ease of maintenance of the fastening system, while minimizing the risk of loosening or failure over time.

Do You Have Any Questions?

Let Us Solve Your Problem

Buy Jack Nuts & Rivet Nuts & Tools from Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of rivet nuts and rivet nut tools designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service according to your requirements.

Contact us for project advice and the latest rivet nuts and rivet nut tools quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.