What is a Blind Rivet Nut? A Comprehensive Guide

Leading Rivet Nut Manufacturer and Supplier in China

A blind rivet nut, also known as a blind threaded insert, is a fastener used to create strong, reliable threaded connections in materials like metal, plastic, and wood. As a result, they are widely used in industries such as automotive, furniture, and electronics, offering a simple yet effective solution for creating secure, reusable connections. Furthermore, their ability to be installed from one side of the material makes them ideal for situations with limited access.

In this blog, we will explore the concept of “what is a blind rivet nut,” how they work, and why they are a preferred choice for many applications. By the end, you will have a deeper understanding of how blind rivet nuts can benefit your projects and why they are an excellent choice for various industries.

Table of Contents

What is a Blind Rivet Nut?

A blind rivet nut is a specific type that features a sealed, closed bottom. This design provides additional protection by preventing moisture, dust, or other environmental contaminants from entering the connection point, making it ideal for applications where sealing is crucial.

Unlike standard rivet nuts, which have an open bottom, the closed bottom of these rivet nuts offers a more secure and protected fastening solution.

- Closed Bottom: The defining feature is the sealed bottom of the nut, which blocks any foreign particles from entering the fastened joint. This is particularly useful in preventing corrosion or contamination in critical applications.

- Sealing Functionality: Because of the closed bottom, these rivet nuts offer a higher level of protection in environments where moisture, dust, dirt, or chemicals are present. This makes them suitable for outdoor, automotive, marine, and industrial applications where harsh conditions are common.

- Ease of Installation: Just like standard blind rivet nuts, blind rivet nuts can be installed from one side of the material, making them easy to use in situations where access to both sides of the workpiece is not possible.

Types of Blind Rivet Nuts

These rivet nuts feature a countersunk head that allows them to sit flush with the surface of the material once installed. As a result, the countersunk design ensures that the rivet nut does not protrude from the surface, providing a smooth finish. Additionally, this design helps to maintain the integrity of the material and ensures a clean, professional look.

They are ideal for applications where a flush, low-profile installation is needed, such as in aerospace, automotive, and high-end electronics. In particular, they are often used in applications where aesthetic appearance and aerodynamics are important, offering both functional and visual benefits.

These rivet nuts have a flat head design, which offers a larger bearing surface compared to countersunk heads. As a result, the flat head provides a stable, wide surface for load distribution, making it suitable for softer materials. Moreover, this design helps to ensure better stability and reliability under stress.

Specifically, flat head rivet nuts are used in applications where load distribution is essential, such as in the automotive industry, machinery, and structural components. In addition, the flat head helps to prevent the rivet nut from pulling through or damaging the material, ensuring long-term durability and performance.

These rivet nuts have a smaller, more compact head compared to standard flat or countersunk heads. As a result, this design reduces the overall height of the rivet nut, making it suitable for applications where space is limited.

For instance, they are often used in tight spaces or for aesthetic purposes in consumer electronics, automotive interiors, and applications where a reduced profile is necessary. Additionally, their compact size allows for seamless integration into designs that require a sleek, low-profile appearance without compromising strength.

These rivet nuts have a hexagonal body shape, which provides superior grip and anti-rotation properties once installed. As a result, the hex body ensures that the nut won’t rotate in the hole, even under high-stress conditions, making it ideal for high-torque applications.

In particular, they are commonly found in automotive, aerospace, and industrial applications where high mechanical strength, resistance to rotation, and higher torque are required. Moreover, their design offers enhanced stability and durability, making them a preferred choice in demanding environments.

Round body rivet nuts feature a simple, cylindrical shape without any additional contours or features. Therefore, they are the most common and versatile type of rivet nut. In addition, their simplicity makes them easy to install and suitable for a wide variety of applications.

For example, they are ideal for general-purpose use in industries like automotive, construction, electronics, and more. Moreover, the round body is often chosen for applications that don’t require specific load-bearing or anti-rotation features. As a result, they provide a reliable and cost-effective solution in situations where functionality and ease of use are key considerations.

Knurled body rivet nuts have a series of raised ridges or grooves along the body. These ridges provide extra grip during installation, helping to prevent the rivet nut from rotating once it’s inserted into the material, particularly in soft or thin materials.

They are ideal for use in materials that are prone to rotation during installation, such as plastics, composites, or thin metals. Commonly used in applications like electronics enclosures, machinery, and automotive components where additional grip is necessary.

Summary of Different Types of Rivet Nuts

| Type | Head Design | Applications | Material |

| Countersunk Head Blind Rivet Nut | Countersunk (flush) | Aerospace, automotive, high-end electronics | Aluminum, Steel, Stainless Steel |

| Flat Head Blind Rivet Nut | Flat head | Automotive, machinery, structural components | Steel, Stainless Steel, Aluminum |

| Reduced Head Blind Rivet Nut | Reduced (compact) | Tight spaces, consumer electronics, automotive interiors | Aluminum, Steel, Stainless Steel |

| Hex Body Blind Rivet Nut | Hexagonal | Automotive, aerospace, high-torque industrial applications | Steel, Stainless Steel, Aluminum |

| Round Body Blind Rivet Nut | Cylindrical (round) | General-purpose use in automotive, construction, electronics | Steel, Aluminum, Stainless Steel |

| Knurled Body Blind Rivet Nut | Knurled (grooved) | Soft/thin materials, electronics, machinery, automotive | Steel, Stainless Steel, Aluminum, Brass |

If you want to know more about the types of rivet nuts or want to buy blind rivet nuts, please contact us today for the latest advice and complete solutions.

Pros & Cons of Blind Rivet Nuts

Pros of Blind Rivet Nuts

1. Waterproof and Dustproof

Are rivet nuts waterproof? Compared to standard rivet nuts, blind rivet nuts usually have better water resistance due to their design. Closed blind rivet nuts are designed with a sealed end, which helps protect the internal threads from moisture, dust, and contaminants. This makes them ideal for applications in harsh environments, where exposure to water, dust, or debris.

The level of water resistance to be achieved:

The water resistance of closed blind riveted nuts can be measured by the international protection class (IP class). Common waterproof classes include:

- IP65: prevents dust from entering, and can withstand the impact of jet water.

- IP66: Prevent dust from entering, and can withstand the impact of strong water flow.

- IP67: completely dust-proof, able to withstand short periods of immersion.

Closed blind riveted nuts can usually achieve IP65 or higher waterproof rating, suitable for environments requiring water and dust protection, such as outdoor equipment, automotive parts and electronic equipment.

2. One-Sided Installation

Blind rivet nuts can be installed from just one side of the material, making them highly versatile. This one-sided installation process eliminates the need for access to the back or opposite side, making them ideal for thin or inaccessible materials.

It simplifies the installation process, especially when working with pre-assembled structures or panels where access to both sides is not possible. This feature saves time and labor, reducing installation complexity and increasing efficiency. Making closed blind rivet nuts a practical solution for various applications.

3. Enhanced Seal

Blind rivet nuts provide an improved seal compared to standard rivet nuts. This seal improves the durability of the connection, particularly in harsh environments where exposure to moisture or dirt is a concern.

The enhanced seal also reduces the risk of corrosion, which helps extend the lifespan of both the rivet nut and the material it is attached to. This feature is crucial for outdoor applications or in industries where cleanliness and protection from contaminants are critical.

4. Durable

Closed blind rivet nuts are highly durable due to their design and materials. The closed-end structure provides added protection against environmental factors, preventing damage to the fastener.

They are made from strong materials like stainless steel, aluminum, or brass, ensuring they withstand high loads, vibrations, and mechanical stresses. The long-lasting performance of closed blind rivet nuts contributes to a reliable, secure connection over time, reducing the need for frequent replacements.

Cons of Blind Rivet Nuts

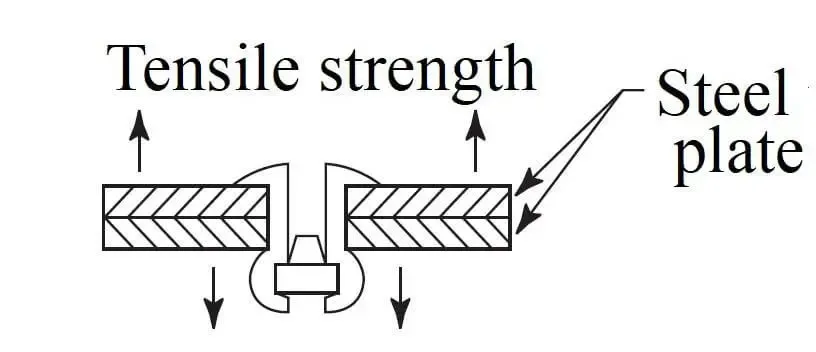

1. Limited Load Capacity

Blind rivet nuts, while offering secure and reliable connections, have a limited load capacity compared to other fastening methods.

| Rivet Nut Type | Tensile Strength | Shear Strength |

| Aluminum Blind Rivet Nuts | 200-500 N | 150-350 N |

| Steel Blind Rivet Nuts | 1,200-2,000 N | 1,000-1,500 N |

| Stainless Steel Blind Rivet Nuts | 1,500-3,000 N | 1,200-2,500 N |

2. Higher Cost

Blind rivet nuts tend to be more expensive than traditional fasteners like screws or bolts. The higher cost is due to several factors, including manufacturing complexity and material selection.

3. May Not Be Reusable

One of the drawbacks of blind rivet nuts is that they may not always be reusable, especially in certain applications.

4. Limited Availability

Blind rivet nuts are less commonly available compared to open rivet nuts. This limited availability can make it more challenging to source the exact type or size needed for a specific application. As a result, users may face difficulties in finding the right fit or may need to consider alternative options.

Do You Have Any Questions?

Let Us Solve Your Problem

What is a Blind Rivet Nut Used for?

A blind rivet nut is a type of fastener used to create a strong, secure threaded connection in materials where access to both sides is limited or impossible. It is typically installed by expanding the body inside the material, creating a secure grip without requiring access to the reverse side.

They offer the advantage of creating reliable, reusable connections without the need for access to both sides of the material.

Automotive Manufacturing:

For attaching body panels, interior components, and other parts where only one side is accessible.

Furniture Assembly:

For connecting wood, metal, or composite materials in applications like tables, chairs, and cabinets.

Electronics:

Used for securing panels or mounting brackets in electronic devices or enclosures.

Construction

For joining structural components, especially when working with metal or composite materials in tight spaces.

How Does a Blind Rivet Nut Work?

A blind rivet nut is installed by expanding its body inside a material to create a strong, threaded connection.

1. Installation Steps

- Pre-drill a Hole: Choose the correct diameter and depth for the rivet nut. Ensure the hole is slightly larger than the outer diameter of the rivet nut.

- Insert the Rivet Nut: Place the rivet nut into the pre-drilled hole with the flanged side facing the surface.

- Position the Rivet Nut Tool: Attach the rivet nut to the installation tool. The tool grips the rivet nut and prepares it for expansion.

- Expand the Rivet Nut: Operate the rivet nut tool, which expands the nut inside the hole. As the tool tightens, the rivet nut expands, creating a strong grip against the material.

- Release the Tool: After the rivet nut has expanded and secured itself, release the tool. The nut is now firmly attached to the material, and the threaded hole is ready for fastening.

2. Key Considerations

- Material Thickness: Ensure the rivet nut’s grip range fits the material thickness. For example, a material thickness of 2mm to 6mm, select a rivet nut with a corresponding grip range of 2mm-6mm.

- Hole Size: The hole diameter should be 0.1mm to 0.2mm larger than the rivet nut’s outer diameter. For a rivet nut with an outer diameter of 8mm, the hole should be between 8.1mm-8.2mm in diameter.

- Tool Selection: The correct installation tool should match the rivet nut size and material. For large rivet nuts (e.g., M10), a hydraulic installation tool is recommended for better torque handling.

- Torque Specifications: For steel rivet nuts, recommended torque values are typically between 5 to 15 Nm, depending on size. For example: M8 stainless steel rivet nuts, the torque specification could be around 10 Nm.

Difference Between a Blind Rivet Nut and Blind Rivet

| Feature | Blind Rivet Nut | Blind Rivet |

| Function | Provides a threaded insert for fastening bolts or screws. | Secures two or more materials together. |

| Installation | Installed by expanding the nut inside the material to form a secure grip. | Installed by expanding the rivet body to secure materials. |

| Usage | Used for creating reusable threaded connections, often in materials like metal, wood, and plastic. | Used for permanent fastening in materials such as sheet metal or plastics. |

| Reusability | Can be reused by removing and replacing the bolt/screw. | Typically permanent and cannot be removed once installed. |

| Applications | Furniture, automotive, electronics, machinery, and more. | Aerospace, automotive, construction, and general manufacturing. |

| Material Options | Aluminum, steel, stainless steel, and brass. | Aluminum, steel, copper, and stainless steel. |

| Strength | Provides high tensile strength and resistance to shear forces. | Primarily designed to hold materials together under shear forces. |

| Installation Tools | Requires special tools like hand rivet nut tools or hydraulic tools. | Can be installed using hand rivet nut tools, pneumatic, or hydraulic rivet guns. |

How to Choose Blind Rivet Nuts for Your Project?

1. Material Selection

- Steel rivet nuts are ideal for heavy-duty applications due to their high tensile and shear strength.

- Aluminum rivet nuts offer a good balance of strength and corrosion resistance for lightweight projects.

- Stainless steel rivet nuts are perfect for outdoor or marine environments, offering superior corrosion resistance.

- Brass or copper rivet nuts are preferred in electronics, providing electrical conductivity and resistance to corrosion.

When choosing blind rivet nuts, consider the following data for proper size compatibility:

- Diameter: Common diameters range from M3 (3mm) to M12 (12mm), matching the required hole size.

- Grip Range: For materials between 0.5mm to 6mm, choose rivet nuts with a grip range of 0.5mm to 6mm. For thicker materials (6mm to 12mm), select rivet nuts with a wider grip range of 6mm to 12mm.

- Hole Size: For an M6 rivet nut, the hole diameter should be around 6.2mm to 6.5mm for optimal fit.

When selecting blind rivet nuts, consider the load requirements for your project. Matching rivet nut materials and sizes to the required load capacity ensures durability and strength in demanding applications.

- Tensile Strength: Rivet nuts typically have tensile strengths ranging from 200 N (for aluminum) to 3,000 N (for stainless steel).

- Shear Strength: Shear strength ranges from 150 N (aluminum) to 2,500 N (stainless steel).

- Load Distribution: For high-load applications, choose rivet nuts with a larger grip range and thicker materials for better load distribution.

Do You Have Any Questions?

Let Us Solve Your Problem

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our factory manufactures 400 million pieces of structural rivets and automobile blind rivets, 1 billion standard blind rivets annually now. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Buy blind rivet nuts now to improve your project efficiency!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.