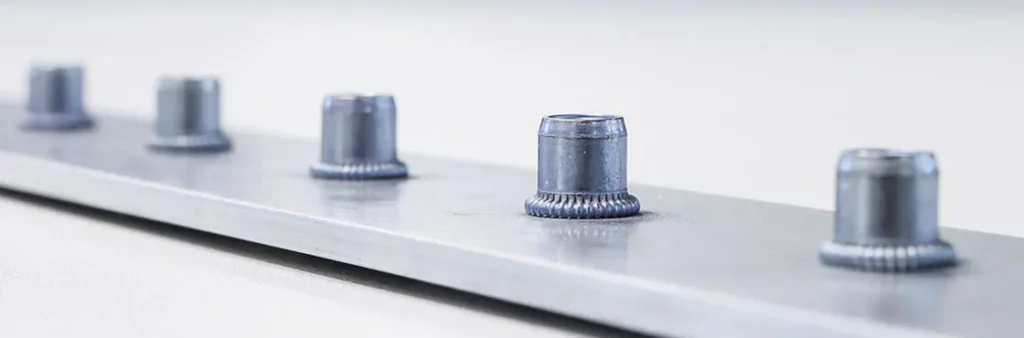

What Drill Bit Size for Rivet Nuts?

Leading Rivet Nut Manufacturer and Supplier in China

Choosing the right drill bit size for rivet nuts is crucial for a secure and reliable installation. Using the wrong size can lead to weak joints or installation failure. This guide provides a clear drill bit size chart for various rivet nut types, helping you achieve precision and durability in your projects. Whether you’re working with aluminum, steel, or stainless steel, knowing the correct drill bit size for rivet nuts ensures optimal performance. Let’s dive into the details!

Table of Contents

Why Drill Bit Size for Rivet Nuts Important?

Before installing a rivet nut, it is essential to drill a hole with the appropriate drill bit size. Incorrect hole sizing can lead to the following issues:

Hole Too Large:

- The expansion part of the rivet nut cannot tightly fit the base material, leading to loosening or rotation.

- Under vibration or torque, the nut may fall off, compromising the connection’s stability.

- It can cause uneven thread stress, accelerating wear or damage.

Hole Too Small:

- The rivet nut may not fit into the hole properly, requiring forceful insertion, potentially damaging or deforming the base material.

- After expansion, the nut may not fully open, weakening the fastening effect and reducing thread strength.

- During installation, uneven forces on the rivet nut may lead to structural deformation or stress concentration, causing material cracking.

The correct hole size ensures the rivet nut inserts smoothly and is securely fixed after installation, thus improving the overall strength and durability of the fastened connection.

When installing rivet nuts, the correct hole size is crucial. The right hole diameter ensures that the rivet nut inserts smoothly, expands properly, and provides a secure threaded connection. If the hole is too large or too small, installation may fail or the fastening effect may be compromised. Therefore, when choosing the drill bit size for rivet nuts, several factors need to be considered to ensure the best installation results and long-term reliability.

①. Specifications and Hole Requirements for Rivet Nuts

Different sizes of rivet nuts correspond to different recommended hole sizes. For example:

- M4 rivet nut: Recommended hole diameter 6.0 – 6.1mm

- M5 rivet nut: Recommended hole diameter 7.0 – 7.2mm

- M6 rivet nut: Recommended hole diameter 9.0 – 9.2mm

- M8 rivet nut: Recommended hole diameter 11.0 – 11.2mm

There may be slight variations depending on the manufacturer, so it’s recommended to refer to the technical data sheet for the rivet nut when selecting the drill bit size.

②. Key Factors Affecting Hole Size

Rivet Nut Type:

Different types of rivet nuts (open-end, closed-end, full hex, half hex, etc.) may require different hole diameters. For example, hex rivet nuts require corresponding hex-shaped holes to prevent the nut from rotating.

Thinner materials require precise hole sizes to prevent rivet nuts from pulling out or deforming during installation. For thicker materials, a slightly larger tolerance range is acceptable.

Base Material Type:

- Metals (steel, stainless steel, aluminum, etc.): The hole diameter must be precise to ensure the rivet nut is securely fixed.

- Plastics and Composites: Holes are usually slightly smaller to prevent loosening or cracking of the material.

- Wood: Due to the soft nature of wood, special nuts may be required, and care should be taken to avoid cracking the wood when drilling.

Installation Process:

If automated equipment is used for installation, stricter hole tolerances are required to ensure the stability of the rivet nut.

Use the Right Drill Bit:

- HSS (High-Speed Steel) drill bit: Suitable for general metals and plastics.

- Cobalt drill bit: Suitable for high-hardness materials like stainless steel.

- Carbide drill bit: Suitable for composite materials or extremely hard materials.

Use Measuring Tools to Confirm Hole Size:

After drilling, use a Vernier Caliper or Thread Gauge to ensure the hole diameter meets the required specifications.

Deburring:

After drilling, check if the hole walls are smooth. If there are burrs, use a deburring tool or sandpaper to clean them, ensuring smooth rivet nut installation.

Do You Have Any Questions?

Let Us Solve Your Problem

What Drill Bit Size for Rivet Nuts?

Standard Drill Bit Sizes for Rivet Nuts

| Rivet Nut Thread Size | Drill Bit Size (Aluminum/Steel) | Drill Bit Size (Stainless Steel) |

| #8-32 | 0.251″ (F) | 0.255″ |

| #10-24 | 0.278″ (I) | 0.281″ |

| #10-32 | 0.278″ (I) | 0.281″ |

| 1/4″-20 | 0.358″ (T) | 0.365″ |

| 5/16″-18 | 0.433″ (7/16″) | 0.438″ |

| 3/8″-16 | 0.500″ (1/2″) | 0.505″ |

| M3 | 5.0 mm | 5.2 mm |

| M4 | 6.0 mm | 6.2 mm |

| M5 | 7.1 mm | 7.3 mm |

| M6 | 9.0 mm | 9.1 mm |

| M8 | 11.0 mm | 11.1 mm |

| M10 | 13.0 mm | 13.1 mm |

Note: Always refer to the manufacturer’s specifications for precise hole size recommendations.

How Different Materials Affect Drill Hole Sizes

The ideal hole size may vary depending on the material in which the rivet nut is installed.

- Metal (Steel, Aluminum, Stainless Steel): Requires highly precise hole sizing. A hole that is too large may cause the rivet nut to spin, while a hole that is too small may prevent proper installation.

- Plastic & Composites: Slightly smaller holes may be needed to compensate for material flexibility, ensuring a tight fit.

- Wood: Depending on wood density, adjustments may be required to prevent splitting. Pre-drilling with a smaller bit before enlarging the hole can improve accuracy.

Using the correct drill bit size ensures the rivet nut grips securely, preventing rotation or loosening over time.

How to Drill Properly to Install Rivet Nuts?

1. Choose the Right Drill Bit

Different materials require different types of drill bits to ensure precise hole sizes, smooth edges, and reduced drill wear.

- HSS High-Speed Steel Drill Bit: Suitable for soft metals (aluminum, copper), plastics, and wood. It is durable, cost-effective, and has good wear resistance.

- Cobalt Drill Bit: Suitable for hard materials like stainless steel, carbon steel, and other tough metals. It has strong heat resistance and resists dulling.

- Carbide Drill Bit: Suitable for high-hardness materials like carbon fiber, fiberglass, and similar. It offers high cutting efficiency but is more brittle, making it ideal for industrial use.

Tip: Choose a drill bit size that matches the recommended rivet nut hole size to prevent the hole from being too large or too small, which could affect the fastening effectiveness.

2. Standard Drilling Steps

Mark the Drilling Position

- Use a center punch to gently tap the drilling point to prevent the drill bit from slipping, improving accuracy.

- You can also use a marking pen or scribing tool to outline the hole position for proper alignment.

Use a Pilot Hole (For larger holes)

- Start by drilling a pilot hole with a smaller diameter drill bit (e.g., 3mm), then gradually enlarge it to the required size. This helps reduce drill bit wobble and improves hole size precision.

Drilling Operation Tips

- Keep the Drill Bit Vertical: Drilling at an angle can lead to an unstable rivet nut installation or deformed hole sizes.

- Control the Drilling Speed:

- Soft Metals (aluminum, copper): 1000-3000 RPM

- Hard Metals (steel, stainless steel): 500-1000 RPM

- Plastics or Wood: 1000-2000 RPM

- Use Cutting Fluid or Lubricant (for metal only) to reduce drill wear and improve hole precision.

Deburring

- Use a deburring tool, file, or sandpaper to smooth the edges of the hole, ensuring the rivet nut fits tightly.

- A smooth hole wall minimizes the risk of the rivet nut rotating and enhances the fastening strength.

3. Drilling Accuracy Tips

Avoid Hole Size Deformation

- Ensure the drill bit is sharp. Dull bits may cause oversized holes or rough hole walls.

- Use step drilling to prevent heat expansion from affecting hole size accuracy.

Check Hole Size Accuracy

- Use calipers to measure the hole size, ensuring it falls within the recommended range.

- You can test by inserting the rivet nut to make sure it fits snugly but doesn’t wobble.

Prevent Material Damage

- Avoid applying excessive pressure while drilling, which may cause metal deformation, plastic melting, or wood cracking.

- For delicate materials (e.g., composite materials), drill at a low speed and gradually increase hole size to avoid cracking or layer separation.

What Drill Bit Size for Rivet Nuts: Common Issues and Solutions

Choosing the correct drill bit size is crucial for rivet nut installation, but in practice, issues such as hole size deviation and installation failure may occur. Below are common problems and their solutions.

Q1. What Issues Arise from Having a Hole That Is Too Large or Too Small?

Hole Too Large

Symptoms:

- Rivet nuts become loose and fail to securely fasten to the base material.

- The rivet nut may rotate under stress, compromising the fastening effectiveness.

- It can lead to a decrease in the overall structural connection strength.

Solutions:

- Use a Larger Rivet Nut: If possible, switch to a larger size rivet nut.

- Use Repair Glue or Structural Adhesive: Apply high-strength epoxy glue or structural adhesive to the hole before installing the rivet nut to enhance the fastening strength.

- Add Washers or Backing Plates: In some applications, adding washers or reinforcement plates on the back can improve the fastening effect.

Hole Too Small

Symptoms:

- Rivet nuts cannot be inserted smoothly.

- Forcing installation may damage the threads or deform the rivet nut.

Solutions:

- Use an Appropriate Drill Bit to Ream the Hole: Slowly enlarge the hole using the correct drill bit, but avoid over-expanding.

- Use Deburring Tools: Sometimes, the hole may be too small due to burrs on the hole wall. Use a deburring tool or file to clean up the hole.

Q2. How to Fix an Oversized Hole or Failed Rivet Nut Installation?

Fixing an Oversized Hole

- Welding Fill Method (for metal): If the base material is metal, weld to fill the oversized hole and then re-drill the correct size.

- Thread Insert Method: Use a thread repair kit or thread insert to restore a stable installation base.

- Use a Larger Rivet Nut: For example, if using an M6 rivet nut, you could switch to an M8 size.

Handling Failed Rivet Nut Installations

- Thread Damage: Use a thread repair tool (such as a tap) to restore the damaged threads or replace the rivet nut.

- Rivet Nut Rotation: If the rivet nut rotates due to an oversized hole, apply strong adhesive to the surface of the rivet nut or use washers to increase friction.

- Removing a Deformed Rivet Nut: If the rivet nut is deformed but not securely fastened, use a specialized removal tool or gently drill out the rivet nut and reinstall it.

Q3. What Are the Considerations When Drilling Into Different Materials?

- Use Cobalt Drill Bits or HSS Drill Bits to ensure wear resistance and heat tolerance.

- Use Lubricating Oil or Cutting Fluid while drilling to reduce drill wear and improve hole precision.

- Avoid High-Speed Drilling to prevent metal overheating, which could affect hole accuracy.

- Drill at Low Speeds to Avoid Material Melting: Plastics are prone to deformation at high temperatures, so use lower speeds (1000-2000 RPM).

- Start with a Small Drill Bit for Pilot Holes, Then Gradually Increase the Hole Size to reduce the risk of cracking.

- Use Step Drill Bits or Tapered Drill Bits to avoid burrs and ensure smooth hole walls.

- Use Wood-Specific Drill Bits like spiral or Forstner bits to ensure clean and smooth holes.

- Apply Tape on the Drilling Spot to reduce the likelihood of wood cracking.

- Drill at Low Speed and Apply Gradual Pressure to ensure precision and prevent the wood from splitting.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix - Leading Rivet Nuts Supplier in China

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of rivet nuts and drill bits designed to meet the unique demands of your projects. With options like countersunk, flat, and hex heads, as well as knurled and round body types, Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service according to your requirements.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.