The Ultimate Guide to Rivet Nut Load Capacity

Leading Rivet Nut Manufacturer and Supplier in China

In mechanical connections, the rivet nut load capacity is a key indicator for assessing its performance and reliability. It encompasses multiple dimensions such as pull-out strength, shear strength, and torque-out strength. These parameters collectively determine whether the rivet nut can withstand external loads and maintain a secure and stable fastening in practical applications, and remain undisturbed and unaltered under the influence of vibration, tensile force, or lateral stress. Understanding these performance metrics is crucial for selection, structural safety design, and subsequent maintenance.

This article will comprehensively analyze the core elements and testing standards of the load capacity of rivet nuts, helping you scientifically evaluate and select the most suitable rivet nut solution.

Table of Contents

Types of Load in Rivet Nut Applications

In practical applications, rivet nuts typically bear various mechanical loads, mainly including tensile load, shear load and torque load. Understanding these three types of loads is crucial for evaluating the performance of rivet nuts, choosing the appropriate installation method and material.

- Tensile Load: The tensile force acting along the bolt’s axis, commonly found in vertical connections or hanging structures. If the pull-out strength of the rivet nut is insufficient, it may lead to the entire nut being pulled out, resulting in connection failure.

- Shear Load: The force acting perpendicular to the bolt’s axis, typically seen in horizontal connections or scenarios subject to lateral impact. The wall thickness, material, and contact surface of the rivet nut directly affect its shear resistance.

- Torque Load: The torque generated when rotating the bolt. If the rotational pull-out force of the rivet nut is inadequate, it may spin idly during tightening or removal, preventing effective fastening or maintenance.

In different industrial scenarios, these load types may occur individually or simultaneously. Designers should select the appropriate type, size and material of rivet nuts based on the actual force conditions to ensure the safety and long-term stability of the structure.

Key Factors Affecting Rivet Nut Load Capacity

1. Material of the rivet nut

The strength of the rivet nut is directly influenced by its material:

| Material | Tensile Strength (MPa) | Description |

|---|---|---|

| Carbon Steel | 400–600 | Low cost, high strength, widely used |

| Stainless Steel (e.g., 304) | 500–700 | Strong corrosion resistance, suitable for harsh environments |

| Aluminum Alloy | 200–300 | Lightweight but lower load capacity |

| 300–500 | Good corrosion resistance, commonly used in decorative/electrical applications |

Theoretical basis: In the calculation of bearing capacity, the ultimate tensile strength (UTS) and shear strength are the key parameters.

2. Base Material and Thickness

The rivet nut is “locked” in the substrate through deformation. The strength and thickness of the substrate play a decisive role in resisting tensile force and torsional force.

- Base material is too thin: It may not provide sufficient grip, and the rivet nut may rotate or come loose;

- Base material is too soft: Such as plastic or thin aluminum sheet, it may cause local cracking after installation;

- Recommended thickness matching: It should be within the clamping range of the rivet nut and leave sufficient deformation space.

Practical experience: When installing M6 carbon steel rivets on a 1.0mm thick low-carbon steel plate, the maximum pulling force is approximately 6-8 kN; under the same conditions, for an aluminum alloy substrate, the pulling force is only 4-6 kN.

3. Matching Degree of Installation Method and Clamping Range

The rivet nut is designed with a fixed gripping range (Grip Range). Exceeding this range will result in:

- Insufficient Clamping: The rivet nut is not fully formed, resulting in a high risk of loosening;

- Excessive Clamping: The substrate undergoes deformation or even damage.

Furthermore, the settings for installing the equipment also have an impact on the forming quality:

- Manual riveting: Susceptible to the influence of the operator;

- Pneumatic/electrical equipment: It is recommended to set torque or stroke control to enhance consistency.

4. Design of Bolt Nut Shape

The geometric shape of the rivet nut directly affects its anti-rotation ability and assembly stability:

| Shape | Features |

|---|---|

| Round | Easy to install but poor anti-rotation ability |

| Hexagonal | Matches stamped hexagonal holes in base material, strong anti-rotation |

| Semi-Hex/Custom | Suitable for some positioning requirements, balances ease of machining |

| Open Type | Low cost, suitable for general environments |

| Closed Type/Blind | Waterproof and dustproof, suitable for sealed applications |

Recommended Choice: For the key stressed areas, it is recommended to use hexagonal closed-type stainless steel rivet nuts, which can balance both structural strength and corrosion resistance.

Standard Testing Methods for Rivet Nut Load Capacity

①. Applicable Standards (International / National Standards)

The following is the commonly used rivet nut standard system in the industry, covering performance verification, structural requirements and testing methods:

| Standard No. | Name (Brief) | Scope |

|---|---|---|

| ISO 14589 | Mechanical Testing Methods for Threaded Rivet Nuts | Includes tensile and torque tests |

| ASTM F2282 | Standard Test Methods for Rivet Nut Mechanical Performance | Covers load testing and installation requirements |

| DIN 73378 | Performance Requirements for Self-Clinching Nuts (e.g., Rivet Nuts) | Commonly used German standard |

| GB/T 26763 | Mechanical Performance and Test Methods for Rivet Nuts (Chinese National Standard) | Widely adopted by Chinese manufacturers |

Recommendation: When exporting to the European and American markets, priority should be given to referring to ISO/ASTM standards to meet the requirements of customer factory inspections and quality certifications; for domestic projects or state-owned clients, it is recommended to refer to GB/T standards.

②. Typical Test Items and Processes

Objective: To verify the axial tensile strength of the rivet nut, that is, whether it can be pulled out of the substrate. The process is as follows:

- Install the rivet nut correctly onto a test sample with the appropriate standard thickness;

- Connect the internal thread of the rivet nut using a tensile testing machine (such as a universal material testing machine);

- Stretch it upwards at a specified rate (usually 10 mm/min);

- Record the maximum tensile force (in N or kN), and whether there is nut pull-out / thread pull-off / sample failure.

Example value: The pull-off force of M6 carbon steel rivet nuts in 1.5mm thick Q235 steel plate can reach 6 – 9 kN.

Torque-Out Test

Objective: To evaluate the torsional resistance of the riveted nuts in the rotational direction, in order to prevent the nuts from rotating or disengaging during the later assembly process. The process is as follows:

- Install the rivet nut into the standard test plate.

- Use a torque wrench or torque tester to apply rotational force through the internal thread to it.

- Continuously increase the torque until the rivet nut starts to rotate or gets damaged.

- Record the maximum torsional resistance (Nm), as well as the failure mode (rotation, shear, or thread loosening, etc.).

Reference value: The anti-torque resistance of M5 stainless steel hexagonal rivet nuts can reach 15 – 20 Nm; for the circular open type, it is lower than 10 Nm. >

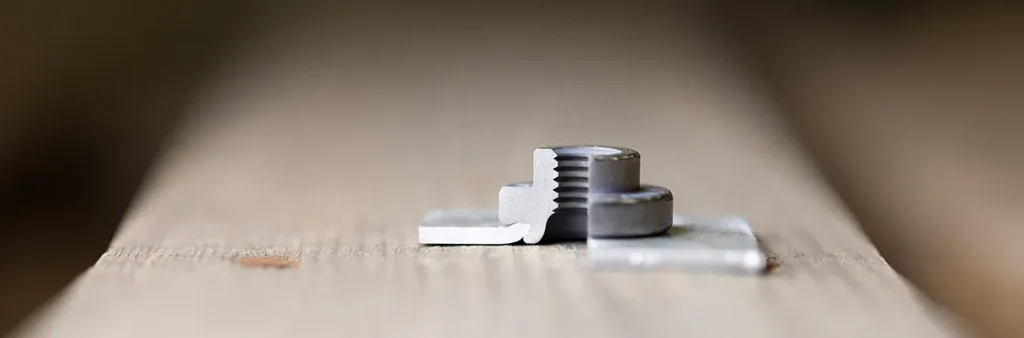

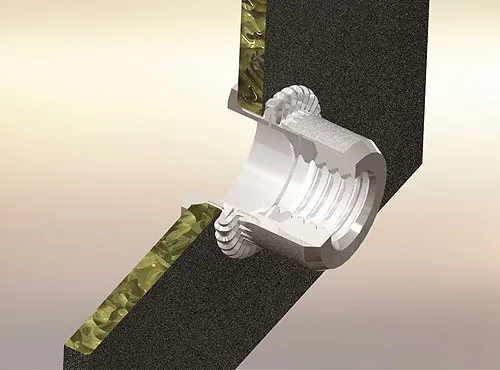

Objective: To confirm the installation and forming quality of the rivet nuts within the recommended clamping thickness range.

Key Points:

- Check whether the deformed area has fully expanded;

- Determine if there are any cases of insufficient deformation, cracking or excessive crushing;

- Some manufacturers will use X-ray imaging or sectional analysis to verify the clamping effect.

③. Test Suggestions and Precautions

- All tests should be conducted in a constant temperature and humidity environment, typically at 23 ± 2°C;

- It is recommended to have a sample quantity of no less than 5 to 10 per model to enhance the statistical reliability;

- Installation quality control is of utmost importance. It is advisable to simulate the actual production assembly equipment and settings;

- For customers with batch shipments, a regular inspection mechanism can be established to maintain consistency.

Rivet Nut Load Capacity Data Chart

(Unit: kN, installed on 1.5mm Q235 steel plate, the clamping range is correct, standard open circular or hexagonal rivet nuts)

| Thread Size | Aluminum Rivet Nut (kN) | Carbon Steel Rivet Nut (kN) | Stainless Steel Rivet Nut (kN) |

|---|---|---|---|

| M3 | 0.8 – 1.2 | 1.5 – 2.0 | 1.8 – 2.2 |

| M4 | 1.2 – 2.0 | 2.5 – 3.5 | 3.0 – 4.0 |

| M5 | 1.8 – 3.0 | 4.5 – 6.0 | 5.0 – 7.0 |

| M6 | 2.5 – 4.0 | 6.5 – 9.0 | 7.5 – 10.0 |

| M8 | 3.5 – 5.5 | 9.0 – 12.0 | 10.5 – 14.0 |

| M10 | 5.0 – 7.5 | 13.0 – 18.0 | 15.0 – 21.0 |

| M12 | 6.5 – 9.0 | 17.0 – 23.0 | 19.0 – 26.0 |

Usage Suggestions Explanation:

- The actual load-bearing capacity is influenced by multiple factors: such as substrate thickness, installation method, bolt-nut structure (hexagonal/round), closed type, etc.;

- The recommended safety factor should be ≥ 1.5 to 2.0 times: when selecting, consider the fatigue under the ultimate load and the long-term loosening risk;

- Key structural components are recommended to be verified through actual measurement: such as frame connections, battery trays, suspension brackets, etc. in high-strength conditions. It is recommended to conduct destructive pull-out tests to confirm;

- There are slight differences in different national standards: for example, in ASTM F2282 and GB/T 26763, the test boundaries for the same specification are slightly different. It is recommended to refer to the market where the project belongs.

How to Select the Right Rivet Nut Based on Load Requirements?

1. Clearly define the load type

- Typical applications: lifting components, load-bearing frames, etc.

- Recommended nuts:

- Full hexagonal rivet nut (Hex Body Rivet Nut) – Strong anti-rotation ability, higher tensile strength.

- Open cylindrical reinforced version – Thickened inner wall or threaded bottom stop design.

b. Shear Load

- Typical applications: structural alignment, lateral support, etc.

- Recommended nuts:

- Semi- hexagonal rivet nuts or cylindrical reinforced type – Provide a larger contact surface, enhancing shear strength.

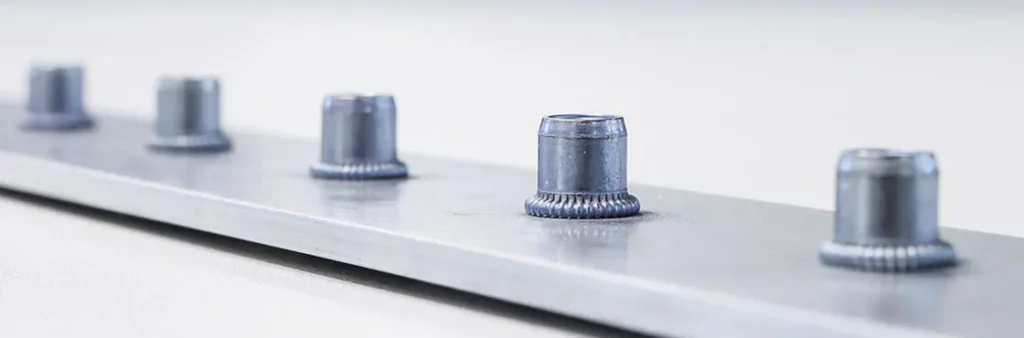

c. Dynamic/Fatigue Load

- Typical application: Mechanical vibration scenarios (such as automotive chassis, rail transportation, etc.).

- Recommended nuts:

- Knurled Body Rivet Nut – Enhances the clamping force through the knurled structure to prevent loosening.

- It is recommended to combine with anti-loosening solutions (such as locking glue, nut encapsulation, etc.).

2. Select materials based on the usage environment

| Usage Environment | Recommended Material | Description |

|---|---|---|

| Indoor / Low Corrosion | Zinc-plated Carbon Steel | Cost-effective and practical for most low-humidity areas |

| High Humidity / Outdoor | Stainless Steel (304/316) | Strong corrosion resistance, suitable for long-term outdoor or humid conditions |

| Lightweight Requirement | Aluminum Alloy | Low density but lower strength than carbon steel, suitable for low-load applications |

| High Temperature / Special Chemical Environment | Special Stainless Steel or Copper Alloy | Customized for chemical corrosion and high-temperature zones |

3. Structural Requirements and Process Matching

| Condition | Recommended Type | Additional Notes |

|---|---|---|

| Thin sheet thickness (<1.0mm) | Open thin-wall rivet nut | Suitable for light loads, easy to install |

| Thick sheet thickness (>3.0mm) | Closed reinforced or hex reinforced | Provides higher pull-out strength and anti-rotation ability |

| Limited space (no access behind) | All rivet nuts (blind installation) | Can be installed from one side only, improving efficiency |

| High appearance requirement | Smooth cylindrical or embedded rivet nut | Can be flush-mounted, does not affect product appearance |

4. Riveting Equipment and Efficiency Considerations

- Pneumatic Riveting Gun/Electric Riveting Gun: Compatible with all standard rivet nuts, with high efficiency.

- Servo Riveting Equipment: Suitable for production lines with high precision requirements (automated scenarios).

- Manual Riveting Tools: Suitable for maintenance/sampling stages, for structures with smaller loads.

Suggestion:

The selection process requires comprehensive consideration:

- Actual load + Operating environment + Plate thickness structure + Cost requirements

- If the key application requires, a destructive load test should be conducted to ensure the design strength has sufficient safety margin

Common Mistakes That Weaken Load Capacity

Inappropriate selection of clamping range

The grip range is a parameter that is most easily overlooked but is of crucial importance when selecting rivet nuts.

If the actual thickness of the base material exceeds the clamping range of the selected rivet nut, the riveting process will not be able to achieve sufficient plastic deformation, resulting in loose locking or assembly failure. On the contrary, if the base material is too thin, problems such as empty riveting, pull-through failure or rotational failure are prone to occur during the riveting process.

It is recommended that you must ensure that the clamping range of the selected rivet nuts covers the actual plate thickness. The middle section of the clamping should be chosen as the best option to ensure good mechanical strength and stability after riveting.

Insufficient thickness or strength of the base material

The installation effect of the rivet nut largely depends on the structural strength and thickness of the base material.

When the substrate is too thin (such as less than 0.5mm) or has low strength (such as certain soft aluminum alloys, plastics, etc.), conventional rivet nuts cannot form an effective bite during the expansion locking process. This may lead to rotation or pull-out phenomena. In such cases, it is recommended to prioritize the use of large flange reinforced type, ribbed type or hexagonal anti-loosening type rivet nuts. For extreme structures, pre-installed screw sleeves or welded nuts can also be used as alternative solutions.

Installation process within the blind zone is uncontrollable

One of the typical advantages of rivet nuts is that they can be installed within the “blind area” of single-sided operation. However, this also poses a risk that the operator cannot visually confirm the riveting status. If the complete riveting is not formed, the structure may appear normal on the surface but actually have severely insufficient internal strength. To ensure the reliability of installation in the blind area, it is recommended to use dedicated equipment with tension feedback or riveting completion indication functions, or to verify the installation quality through torque sampling, pull-out tests, etc. after assembly.

Incorrect or Worn-Out Tool Settings

When using pneumatic or electric riveting tools, common mistakes include: incorrect setting of the pulling force (either too high or too low), or mismatch between the gun head model and the nut. These can easily cause damage to the threads, incomplete formation of the riveted nut, and even lead to the cracking of the nut.

Furthermore, the long-term use of un-maintained tools can lead to unstable output, slipping of the grippers, and other issues. This directly affects the quality of the riveting.

Failure to Fully Consider Working Conditions and Load Characteristics

In some high-intensity or dynamic load environments, if the selection is made solely based on static tension, while ignoring factors such as shear force, impact load, temperature changes, or long-term fatigue stress, it will seriously underestimate the actual usage risks, leading to early loosening or failure of the connection parts.

FAQs

Q1: How are the tensile strength and shear strength of riveted nuts evaluated?

Answer: The strength of the riveted nut mainly includes two aspects: axial pull-out load and shear strength. The axial pull-out load reflects its ultimate capacity in the vertical direction. While the shear strength measures its performance in resisting lateral shear forces.

The evaluation method usually follows standards such as ISO 14589, IFI-145 or GB/T 17880.1, and static load pull-off or shear tests are conducted after the sample is riveted. The test data should be combined with the actual plate thickness, material, and installation process to determine whether they meet the usage requirements.

Q2: How to select the appropriate size of rivet nuts based on the product structure?

Answer: When selecting the type, factors such as the thickness of the sheet material, the base material’s properties, the direction of the load (pulling/trimming/dynamic load), the installation space, and the fastening method should all be taken into consideration. Key parameters include the thread specification, the clamping range, the material of the rivet body, and the type of flange.

If the plate thickness is thin or the base material is soft, a reinforced structure (such as hexagonal or ribbed) should be given priority. If space is limited, a small flange or concealed structure should be chosen. It is recommended to conduct trial installation with actual samples to ensure stable installation and strength meeting the expected requirements.

Q3: Are riveted nuts prone to loosening under dynamic load conditions? How can this be prevented?

Answer: In situations involving vibration, impact, or frequent opening and closing, if no anti-loosening design is adopted, the rivet nuts may become loose due to slight displacement, especially for cylindrical products without anti-rotation features. To enhance stability, a anti-rotation structure (such as knurled or hexagonal) can be selected, and combined with a thread anti-loosening solution (such as gluing, lock nuts, spring washers, etc.) for use. In high-frequency dynamic load conditions, it is recommended to conduct durability fatigue tests to verify its long-term performance.

Q4: Is the rivet nut certified internationally? Is it applicable to industries such as automobiles and rail transportation?

Answer: If the mainstream rivet nuts meet standards such as ISO 15977, DIN 73378, SAE J1231, they usually can meet the requirements for industrial-level applications. In industries such as automobiles, rail transportation, and aviation, some high-strength or special-structured rivet nuts need to pass audits through certification systems such as IATF 16949, ISO 9001, PPAP, IMDS, RoHS.

Q5: How can one determine if the riveting is reliable? Is inspection necessary?

Answer: Reliable riveting should have the following characteristics: The rivet nut should be centered in the base material, the flange should be tightly attached, the back expansion should be uniform, and there should be no cracks or loose teeth. To ensure quality, it is recommended to establish a “pull-out force standard value and inspection frequency” before mass production, and use a torque tester or pull-out testing machine for batch verification. Some factories also adopt automated technologies such as image recognition and force position curve monitoring to enhance process controllability.

Q6: How to choose rivet nuts and welding nuts? What are the differences?

Answer: The rivet nuts do not require back operation. They are suitable for closed structures or thin plates, and the installation speed is fast. They have no impact on the heat affected zone.

Welding nuts are suitable for thick plates and high-strength connections, offering higher strength, but they require welding conditions.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

In terms of structural connection, the selection of rivet nuts not only determines the degree of assembly firmness, but also directly affects the durability, safety and maintenance cost of the entire machine. Inappropriate selection or installation often becomes the root cause of load failure, structural loosening, and process rework.

Therefore, in any application involving structural support, critical connections, or special conditions, it is recommended that users conduct a systematic assessment from the following several aspects:

Load direction, base material strength, plate thickness structure, environmental conditions, installation tools and space limitations. When selecting, priority should be given to test data and standard specifications. Do not simply apply based on experience.

For projects that require professional support, it is recommended to give priority to suppliers with product engineering capabilities, process collaboration capabilities and a well-established certification system. Companies like Rivetfix, which have extensive industry application experience in the field of riveting solutions, not only offer a full range of rivet nuts, but also assist customers in completing selection verification, clamping optimization, tool matching, and riveting reliability testing, ensuring the stability of the entire process from design to assembly.

If you are involved in the fields of automobiles, rail transit, energy equipment or high-end manufacturing, it is recommended to introduce supplier collaboration in the early stage of development for selection and process planning. This will help identify risks in advance and improve the first-time assembly pass rate and structural reliability.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.