T-Nut vs. Threaded Insert: What’s the Difference?

Leading Threaded Inserts Manufacturer and Supplier in China

In woodworking, furniture assembly, 3D printing, and industrial manufacturing, strong and reusable threaded connections are essential. Among the most common internal thread solutions are T-Nut vs Threaded Insert, which are widely used to provide secure threaded connections in materials such as wood, plastic, and even metal.

So, what’s the difference between a T-Nut and a Threaded Insert? This is a frequent question raised by design engineers, manufacturers, and DIY enthusiasts alike. In this article, we’ll provide a systematic comparison of t nut vs threaded insert, covering their structural principles, installation methods, suitable materials, and real-world applications to help you choose the right fastener for your needs.

By the end of this guide, you’ll gain a clear understanding of their key differences, pros and cons, and selection tips—empowering you to make informed decisions for your specific projects.

Table of Contents

What Is a T-Nut?

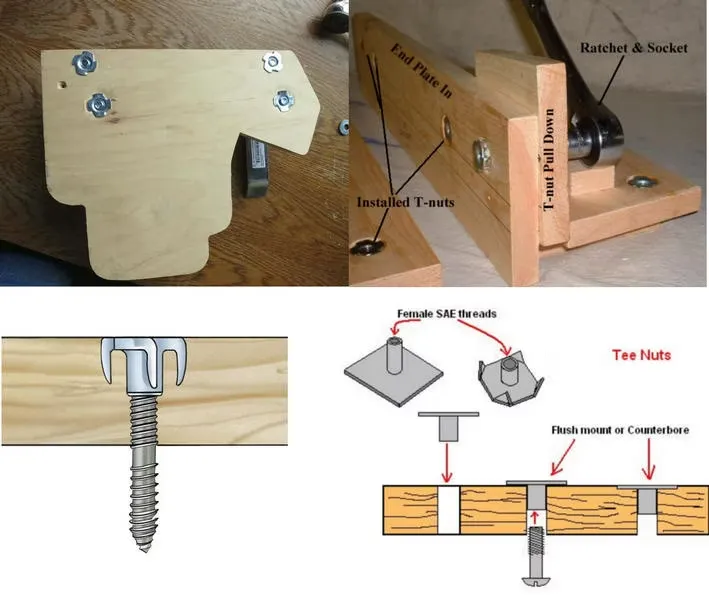

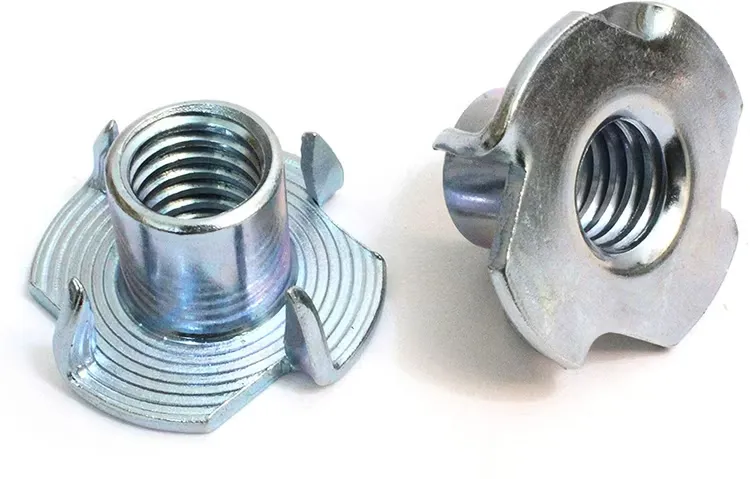

A T-Nut is a metal fastener designed specifically for soft materials such as wood. Its unique “T” shape consists of a flange and a threaded barrel. T-Nuts are typically installed on the back of the material, with the flange featuring teeth or claws that bite into the wood during installation to prevent rotation or loosening.

When in use, screws are screwed into the threaded holes of the T-Nut from the front of the material, achieving a strong and secure connection. Compared to direct threading or using ordinary nuts, T-Nuts provide more durable threaded fastening and are easier to disassemble and replace later.

Suitable Materials and Typical Applications:

- Suitable Materials: Various types of solid wood, plywood, particleboard, medium-density fiberboard (MDF), and other soft materials

- Common Applications: Furniture assembly (e.g., table and chair connections), speaker enclosures, climbing walls, DIY projects, and other structures requiring screws to be installed from the front while hiding fasteners on the back

Due to its ease of installation and structural stability, the T-Nut is one of the most widely adopted internal thread solutions in the woodworking industry, particularly suited for applications requiring high tensile strength and aesthetically pleasing hidden structures.

A threaded insert is a fastener used to create strong, reusable internal threads in materials such as wood, plastic, and metal. Its function is to form standardized threads in the base material, enhancing connection strength and extending structural life. It is widely used in furniture manufacturing, injection-molded parts, electronic enclosures, mold assembly, and industrial structures.

Depending on the installation method and application environment, common types of threaded inserts include:

- Heat-Set Inserts: Primarily used in thermoplastic materials, these inserts are heated to melt into the plastic, creating a secure bond;

- Threaded Inserts for Wood: Featuring coarse external threads, these inserts can be directly screwed into wood or soft materials and are commonly used in furniture;

- Wire Thread Inserts: Used in metal substrates, they can repair damaged threads or reinforce existing threads, suitable for high-strength applications;

- Press-Fit or Self-Tapping Inserts: Suitable for plastics, aluminum alloys, etc., they are installed via press-fitting or screwing.

Applicable Materials and Installation Methods:

- Suitable Materials: Thermoplastic plastics, thermosetting plastics, wood, aluminum alloys, thin metal sheets, etc.

- Installation Methods: Includes hot pressing, ultrasonic welding, screw-in, mechanical pressing, or injection molding insertion, etc.

The primary advantages of threaded inserts lie in their high strength, wear resistance, and excellent tensile and torsional capabilities, making them particularly suitable for structures requiring frequent disassembly/reassembly or long-term load-bearing applications.

Table:Key Differences Between T-Nuts and Threaded Inserts

| Comparison Dimensions | T-Nut | Threaded Insert |

|---|---|---|

| Installation Method | Inserted from the back of the material and secured by hammering or screw tension to bite into the material | Depending on the type, can be hot pressed, screwed in, pressed in, or embedded in plastic/metal |

| Suitable Materials | Primarily used for wood, such as solid wood, plywood, and MDF | Suitable for various materials including wood, plastic, and metal |

| Load-Bearing Capacity | Strong tensile strength but average torsional resistance, relying on claws to prevent rotation | Stronger tensile and torsional resistance, suitable for repeated disassembly/assembly or load-bearing structures |

| Visibility (hidden or exposed) | After installation, the nut is located on the back of the material, with no exposed metal on the front, resulting in a clean appearance | Most inserts are hidden within the material, though some exposed styles are available depending on the application |

| Cost and availability | Low cost, simple structure, widely available in hardware stores | Wide variety of types, some specifications are higher in cost but more professional and reliable |

Are T-Nuts the Right Choice for Your Project?

T-Nuts (T-shaped nuts) are widely used in woodworking and lightweight structures due to their simple structure and easy installation. Below, we provide a professional summary of their advantages and disadvantages to help you determine whether they are suitable for your specific application needs:

Advantages:

- Quick and easy installation: Installation can be completed by hammering or riveting, making it suitable for bulk production.

- Hidden back design: No metal is exposed on the front after installation, enhancing the overall aesthetic appeal.

- Suitable for various types of panels: Especially suitable for soft materials such as solid wood, plywood, and MDF.

- Cost-effective: Simple structure and affordable price, making it a high-cost-effective internal thread solution.

- Provides some tensile strength: Especially suitable for connections where the load direction is perpendicular to the panel surface.

Disadvantages:

- Weak torsional performance: Primarily relies on claws biting into wood, making it prone to loosening under high torque or repeated assembly/disassembly.

- Not suitable for hard materials: Materials like plastic or metal cannot form effective engagement.

- Requires installation precision: If the hole diameter is too large or the panel is too soft, the claws may fail to secure firmly.

- Requires space on the back side: The structure requires sufficient installation space and is not suitable for extremely thin structures.

In summary, T-Nuts are highly suitable for woodworking projects with moderate structural strength requirements, prioritizing installation efficiency and cost control. However, they should be used with caution in high-load or high-frequency disassembly scenarios.

Pros and Cons of Threaded Inserts

Threaded inserts, with their diverse types and superior mechanical properties, are widely used in high-strength connections involving various materials such as wood, plastic, and metal. The following professional summary highlights their advantages and disadvantages to help you fully understand their applicability:

Advantages:

- High load-bearing capacity: Compared to traditional fasteners, threaded inserts offer superior tensile and torsional strength, making them suitable for applications requiring high load-bearing capacity.

- Wide range of applicable materials: Not only suitable for wood, but also effectively applicable to plastics, aluminum alloys, and steel plates, among other materials.

- Excellent performance for repeated installation and removal: With a robust structure, they can withstand repeated installation and removal, making them ideal for maintenance and modular designs.

- Diverse installation methods: Includes various installation processes such as hot melt, screw-in, and press-in, flexibly adapting to different production requirements.

- Enhanced connection quality and durability: Effectively prevents thread wear and damage, extending equipment lifespan.

Disadvantages:

- Relatively high cost: Compared to simple T-Nuts, threaded inserts have higher manufacturing and installation costs.

- Higher installation process requirements: Some types require specialized tools or equipment, increasing installation complexity.

- Some inserts have strict requirements for the base material: For example, hot-melt inserts must be suitable for thermoplastic plastics, and steel wire threaded inserts require pre-machined threaded holes.

- Improper installation may lead to connection failure: For example, over-tightening or under-tightening the insert can affect connection strength.

In summary, threaded inserts, with their excellent mechanical properties and diverse application scenarios, are particularly suitable for industrial and manufacturing fields with high requirements for connection strength and durability, making them a worthwhile investment in high-performance connection solutions.

When to Use T-Nuts vs. Threaded Inserts?

1. Woodworking Projects

In woodworking applications, T-Nuts and Threaded Inserts are both common threaded connection solutions, but they each have their own advantages and disadvantages in terms of structure, installation methods, and performance. Selecting the appropriate type based on factors such as wood type, connection strength requirements, and whether repeated disassembly is needed is critical.

T-Nuts: Ideal for Quick Connections in Woodworking

T-Nuts (T-shaped nuts) are widely used in wooden furniture, speaker cabinets, wooden bases, climbing walls, and other projects due to their simple structure and quick installation. Their four-claw or three-claw structure is hammered into the wood from the back, effectively preventing nut rotation and providing excellent tensile strength.

- Suitable wood types: Solid wood, plywood, MDF, and other soft materials

- Installation advantages: No threading required; installation completed with drilling and hammering

- Frequency of disassembly: Suitable for medium to low-frequency disassembly; avoid high-torque repeated use

Threaded Inserts: Suitable for high-strength or repeatable disassembly

Threaded Inserts, especially the spiral-type designs for woodworking, offer superior torque resistance and reusability. Installed by screwing in, the external threads grip the wood to form a secure bond. Suitable for wood structures with higher structural requirements or those requiring repeated screw installation, such as disassemblable furniture, sliding track structures, or heavy-load platforms.

- Installation method: Screw-in installation, recommended to use a hex wrench or installation tool

- Strength performance: More suitable for scenarios requiring high torque and frequent disassembly

- Aesthetics: Typically installed hidden, with no exposed nuts on the front

Performance Comparison Table: T-Nut vs. Threaded Insert (Woodworking Environment)

| Project Dimension | T-Nut | Threaded Insert for Wood |

|---|---|---|

| Installation Method | Back hammer-in installation | Front screw-in |

| Tensile Strength (Solid Wood) | Medium (approx. 600–1000 N) | High (approx. 900–1500 N) |

| Torsional Strength | Average, prone to loosening | High, screw-in structure provides greater stability |

| Repeated Installation/Removal Performance | Average, prone to wear | Excellent, suitable for repeated screwing |

| Suitable for Wood | Solid wood, plywood, MDF | Solid wood, plywood, not recommended for particleboard |

| Cost and availability | Low cost, high versatility | Slightly higher cost, requires proper selection |

| Aesthetic requirements | Visible claw feet on the back, no exposed nuts on the front | Fully concealed installation, high aesthetic appeal |

Note: The values in the above table are based on test data for standard M6-sized components in solid wood. Actual performance may vary depending on material density and installation quality.

2. Selection Recommendations for Plastic and Metal Materials

Threaded connections are equally critical in plastic and metal structures. However, due to the significant differences in mechanical properties between these two material types, the selected internal threaded inserts should also differ. The following provides a professional analysis from both plastic and metal perspectives, supported by typical data.

①. Selection Recommendations for Plastic Materials

For thermoplastic materials such as ABS, PC, PA, and PP, due to the tendency of their threads to wear out and peel off, it is recommended to use heat-set thread inserts. These inserts are typically made of brass or stainless steel, with a knurled or rolled pattern on the outer wall. They are heated using a soldering iron, ultrasonic welding, or a hot press machine and embedded into the plastic, forming a stable interlocking structure after cooling.

Advantages of heat-set inserts include:

- Tight interlocking after insertion, making them extremely difficult to loosen, capable of withstanding high tensile and torsional forces;

- Suitable for various plastic thicknesses and shapes, applicable to thin-walled plastic shells and reinforced structures;

- Suitable for mass-production thermal processing workflows, such as secondary thermal assembly after injection molding;

- Applicable to multiple industries: such as electronic housings, 3D-printed parts, plastic fixtures, etc.

Performance comparison table for plastic applications:

| Insert type | Installation method | Tensile strength (typical) | Torsional strength (typical) | Disassembly performance | Recommended material |

|---|---|---|---|---|---|

| Heat-Set Inserts | Hot pressing, ultrasonic | 300–600 N | 0.8–1.5 N·m | Excellent | Thermoplastic plastics (ABS/PA) |

| Self-tapping insert | Screw-in | 200–400 N | 0.6–1.0 N·m | Average | Soft plastics, wood-plastic composites |

Note: Values are based on testing of standard M4–M5 sizes in ABS material; actual values may vary depending on material and process.

②. Selection Recommendations for Metal Materials

In metal sheets, aluminum profiles, or machined structures, if the raw material cannot be tapped directly or the thread strength is insufficient, the following two types of inserts are commonly used:

(1) Wire Thread Inserts (Wire Thread Insert / Helicoil)

Wire thread inserts are made from high-strength stainless steel wire wound into a coil and installed within metal threaded holes to form an independent precision threaded structure.

Their advantages include enhancing the thread strength of the base material, preventing thread wear or stripping, and are particularly suitable for low-strength metals such as aluminum alloys.

(2) Press-Fit or Self-Clinching Inserts

These inserts are secured in metal sheets via press-fitting or riveting, suitable for thin plates, enclosures, panels, and other structural components. They provide stable internal threads without requiring threading and are widely used in electronic and electrical equipment.

Performance Comparison Table for Metal Applications:

| Insert Type | Application Scenarios | Installation Method | Recommended Plate Thickness | Features |

|---|---|---|---|---|

| Wire Insert | Aluminum Alloy, Low-Strength Metals | Threading + Screwing In | ≥1.0 mm | Repairable Threads, Enhanced Strength |

| Self-clinching insert | Stainless steel sheets, electronic enclosures | Press-fit | 0.8–2.5 mm | No threading required, compact structure |

| Rivet nut | Thin-walled structures, tubing | Riveting equipment installation | ≥0.5 mm | Can be installed blindly, suitable for mass production |

③. Conclusion and Recommendations:

- For thermoplastic structures (such as injection molded parts or 3D printed parts), it is recommended to prioritize the use of hot melt thread inserts to balance strength and disassembly capability;

- For thin metal sheets or aluminum alloy structures, we recommend using steel wire thread inserts or self-locking inserts to enhance thread performance and extend product lifespan;

- For metal thin-walled components that cannot be tapped (such as tubing or closed-end parts), rivet nuts (Rivet Nut) can be selected to achieve quick installation and bulk processing.

3. High Strength Requirements vs. Easy Installation Requirements: How to Balance Selection?

In engineering structural design, the selection of fasteners often requires a balance between “strength performance” and “installation efficiency and cost.” T-Nuts and Threaded Inserts each have their advantages and are suitable for different application scenarios and budget requirements.

① Scenarios Prioritizing High Strength and Durability

In fields such as industrial machinery, electronic equipment housings, transportation equipment, aerospace, and automotive manufacturing, connection points often need to withstand significant tensile forces, shear forces, or repeated disassembly and reassembly. In such cases, high-performance Threaded Inserts should be prioritized.

Advantage Analysis:

- Provides higher tensile strength (up to 800–1500 N, depending on specifications and base material)

- Higher torsional resistance to prevent the insert from rotating and falling out

- Available in various structures such as wire inserts, hot-melt inserts, and press-fit inserts to accommodate different materials

- Suitable for environments with frequent maintenance, disassembly/assembly, vibration, or heavy loads

Actual Application Examples:

- Engine Mounting Holes: Use wire inserts to enhance the thread life of aluminum alloy structures

- Electric Tool Housing: Use hot-melt inserts to ensure long-term screw tightening in plastic housings

- Precision instrument mounting plate: Use threaded press-fit inserts to ensure flatness and repeatable locking performance

② Scenarios prioritizing easy installation and cost control

If the project does not have high structural strength requirements and focuses more on installation efficiency, labor costs, and material costs, then T-Nut (T-shaped nut) is a more economical and efficient choice.

Advantage Analysis:

- Simple and quick installation, requiring only drilling + hammering or tightening with screws

- No need for threading or special equipment, suitable for manual assembly or small-batch operations

- Low cost, suitable for large-scale applications such as furniture manufacturing and DIY kits

- Clean front structure and hidden rear design, offering aesthetic appeal

Typical Application Scenarios:

- Wooden furniture assembly (e.g., bed frames, table legs, wardrobes)

- Rock climbing wall brackets, wooden speaker back panels

- Various DIY projects (e.g., workbenches, shelves)

Performance and Cost Comparison: T-Nut vs. Threaded Insert

| Comparison Criteria | T-Nut | Threaded Insert |

|---|---|---|

| Tensile Strength (M6) | 600–1000 N | 900–1500 N |

| Torsional Resistance | Medium | High (suitable for frequent reuse) |

| Installation Complexity | Low (hammer-in or pull-in) | Medium to High (heat-press, screw-in) |

| Tool/Equipment Requirement | No special tools needed | May require heat press or insert tool |

| Material Compatibility | Limited to wood | Compatible with wood, plastic, metal |

| Unit Cost | Low (~$0.01–$0.05) | Medium to High (~$0.05–$0.30) |

| Mass Production Suitability | Very suitable | Suitable for standardized assembly |

Note: The above data is based on standard M6 parts tested in solid wood and engineering plastics. For reference only.

Summary Recommendation:

If your project demands maximum fastening strength, reusability, and long-term durability, choose Threaded Inserts.

If your priorities are cost-efficiency, fast installation, and working with wood, T-Nuts are the better choice.

FAQs:T-Nuts vs. Threaded Inserts

1. Which is more suitable for plywood?

- Recommended choice: T-Nuts or special-structure woodworking-specific threaded inserts (deep external threads, coarse threads)*

- Plywood structures are relatively loose, and ordinary metal inserts are prone to falling out. T-Nuts are pressed into the back of the wood panel using “claw nails,” effectively preventing rotation or loosening, and are suitable for structures where screws are screwed in from the front.

- If a high aesthetic standard is required and the insert needs to be hidden from the front, choose threaded inserts with coarse, deep external threads that match the wood density, such as hexagonal or vertically knurled styles.

2. Which is easier to install?

- T-Nuts are easier to install, especially for bulk woodworking applications.

- T-Nuts: Can be hammered in from the back or assembled with a press, no special tools required; suitable for furniture, cabinets, and other one-time assembly applications.

- Threaded Inserts: Offer diverse installation methods (self-tapping, hot-melt, press-in), some requiring threaded installation tools or hot-melt equipment; suitable for projects with high requirements for thread precision and strength.

If you are a DIY user or non-professional installer, T-Nuts are the quickest option to get started with.

3. Can they be repeatedly disassembled and reassembled? Which is more durable?

Threaded Inserts are more suitable for repeated disassembly and reassembly and have a longer service life.

- Threaded Inserts typically feature standard metal thread profiles, such as M4 or M6, which are wear-resistant and capable of withstanding pulling forces. They are suitable for structures requiring frequent maintenance, such as electronic device housings or mechanical equipment.

- While T-Nuts are inexpensive and easy to install, their claw-based fixation has limited strength. Repeated disassembly may cause damage to wooden panels or loosening of nuts.

| Feature | Threaded Insert | T-Nut |

|---|---|---|

| Suitable for Repeated Assembly | ✅ Excellent | ❌ Average |

| Structural Stability After Installation | ✅ Stable | ⚠ Depends on Material |

| Service Life | ✅ Longer | ⚠ May Be Affected by Wood Conditions |

4. How to Choose the Right Size?

Select based on bolt size, material thickness, and load requirements.

Internal Thread Size (e.g., M3/M4/M6): Ensure compatibility with the bolts you plan to use.

Embedment Depth / Outer Diameter: Determines grip and load-bearing capacity—the deeper the insert, the stronger the hold. But ensure the base material is thick enough to accommodate it.

Installation Method: If using heat-set, press-fit, or screw-in methods, the size must match your installation tools.

It’s recommended to consult the manufacturer’s product chart. For example, Rivetfix’s threaded insert series provides clearly marked specifications such as “hole diameter,” “minimum panel thickness,” and “recommended torque,” making accurate selection easier.

Conclusion: Choosing the Right Insert for Your Project

In practical applications, choosing between a T-Nut and a Threaded Insert depends on your project requirements, material type, and structural strength needs. A T-Nut is ideal for woodworking or furniture projects where budget, simple installation, and moderate strength are priorities. In contrast, a Threaded Insert is better suited for professional applications that require higher durability, reusability, or compatibility with materials like plastic and metal.

Through this comprehensive comparison of t nut vs threaded insert, you should now have a clear understanding of their differences. If you still have questions regarding product selection, custom requirements, or installation methods, feel free to contact our engineering team for one-on-one technical support and tailored product recommendations.

Do You Have Any Questions?

Let Us Solve Your Problem

Choose Rivetfix – Your Trusted Threaded Insert Supplier

Whether you are a woodworking enthusiast or an industrial manufacturer, Rivetfix can provide you with a comprehensive range of reliable threaded insert solutions. We support customization, offer multiple material options, ensure fast delivery, and strictly control every quality process.

Contact us now to get the Threaded Inserts that best suit your project!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.