Poly Nut vs Rivet Nut: Key Differences & Best Uses

Leading Rivet Nut Manufacturer and Supplier in China

When choosing between Poly Nut vs Rivet Nut, understanding their key differences is essential for selecting the right fastening solution. Whether you’re working with soft materials or need a high-strength connection, this guide will help you determine which option best suits your needs.

Table of Contents

What is a Poly Nut?

A Poly Nut is a type of nut characterized by its lightweight, corrosion resistance, and non-conductive properties. It is commonly used for securing soft materials such as plastic panels, drywall, or wood, making it ideal for applications where metal fasteners may pose conductivity or corrosion issues.

Performance Features

1. Lightweight

Poly Nut has a significantly lower density compared to metal nuts, reducing overall weight. In weight-sensitive applications—such as aerospace, automotive manufacturing, and electronics—Poly Nuts help lower structural load, improve portability, and enhance energy efficiency. For example, in drone manufacturing or lightweight household appliances, replacing metal nuts with Poly Nuts can effectively reduce weight while maintaining sufficient fastening strength.

2. High Corrosion Resistance

Unlike metal nuts, which are prone to oxidation or rusting due to exposure to air, moisture, or chemicals, Poly Nuts are made from corrosion-resistant polymers that remain unaffected by water, humidity, acidic or alkaline solutions, and salts. This makes them ideal for use in harsh environments, such as marine equipment, swimming pool installations, laboratory apparatus, and chemical processing plants. These environments demand long-term performance stability, where metal fasteners might deteriorate over time due to corrosion.

3. Electrical Insulation

Since Poly Nuts are made of non-conductive materials, they completely lack the electrical conductivity of metal fasteners. This makes them highly suitable for electrical and electronic applications, where preventing short circuits, static interference, or electromagnetic disturbances is critical. Poly Nuts are commonly used for securing circuit boards, terminal blocks, and electrical enclosures. In high-voltage cable supports, power distribution systems, and precision instruments, Poly Nuts help prevent electrical hazards associated with conductive fasteners while ensuring system reliability.

4. Ideal for Soft Materials

Traditional metal nuts, due to their hardness and torque requirements, may cause damage when tightened onto soft materials such as plastic, drywall, or wood. In contrast, Poly Nuts offer a more flexible grip, reducing the risk of material deformation or damage. For instance, in interior decoration projects, using Poly Nuts helps prevent drywall cracking, while in plastic component assembly, they minimize breakage caused by excessive force.

5. Suitable for Low-Load Applications

Since Poly Nuts are made of plastic, their tensile and shear strength are lower than those of metal nuts, making them more appropriate for light-duty fastening requirements. For example, in household applications, they are commonly used for securing lightweight wall fixtures or decorative panels but are not recommended for heavy-duty equipment or high-tensile-load applications. In industries requiring high mechanical fastening strength, such as automotive engine components or structural steel assemblies, metal nuts remain the preferred choice.

Common Applications

- Home Renovation – Used for securing lightweight decorative panels, drywall, or plastic components, making them ideal for DIY projects and home repairs.

- Electronic Equipment – Applied in circuit boards, terminal blocks, and assemblies where metal conductivity must be avoided.

- Light-Duty Machinery – Found in equipment where weight is a critical factor but high fastening strength is not required, such as small automation devices and lightweight plastic assemblies.

- Medical and Laboratory Equipment – Due to their chemical resistance and non-conductive properties, Poly Nuts are widely used in medical devices and laboratory instruments where metal corrosion or conductivity could pose a risk.

- Material Characteristics: Typically made from aluminum, stainless steel, or carbon steel.

- Performance Features:

- Common Applications: Automotive manufacturing, aerospace, industrial equipment, furniture assembly, etc.

Material Characteristics

Rivet Nuts are typically made from aluminum, stainless steel, or carbon steel to meet different strength, corrosion resistance, and application requirements.

- Aluminum Rivet Nuts: Lightweight, corrosion-resistant, and suitable for weight-sensitive applications such as aerospace and automotive manufacturing. While their strength is lower, they provide sufficient clamping force without adding extra weight.

- Stainless Steel Rivet Nuts: Highly corrosion-resistant and strong, making them ideal for humid, acidic, or high-temperature environments, such as marine equipment, chemical industries, or outdoor construction projects.

- Carbon Steel Rivet Nuts: Compared to aluminum and stainless steel, carbon steel rivet nuts offer higher tensile strength and load-bearing capacity, making them suitable for heavy-duty and high-strength applications such as industrial equipment and machinery. However, carbon steel requires surface galvanizing or other anti-corrosion treatments to improve its resistance to corrosion.

Performance Features

1. Suitable for Thin Plates and Tubular Structures

The unique design of the Rivet Nut makes it particularly suitable for thin materials such as metal sheets, plastic panels, or composite materials. These materials are too thin to be directly threaded, but a Rivet Nut can create a stable threaded connection, providing a firm fastening point. For example, in automotive body manufacturing, Rivet Nuts can be used to secure metal panels, ensuring reliable connections that are also easy to maintain.

Compared to Poly Nuts, Rivet Nuts, being made of metal, offer higher tensile strength and torsional strength, allowing them to withstand greater external forces. They do not fail due to thread stripping or material deformation under high loads, making them ideal for industrial applications where long-term vibration, impact, or high torque is involved. For example, in mechanical assembly, Rivet Nuts ensure that components remain securely fastened even after extended use.

3. Suitable for Various Materials

Rivet Nuts are compatible with metals, plastics, composite materials, wood, and other materials, making them versatile for different applications. For instance, in furniture manufacturing, Rivet Nuts are used to secure wooden frames, while in the automotive industry, they are employed to reinforce metal connections. Additionally, specially designed Rivet Nuts (such as slotted Rivet Nuts) can create stronger connections in soft materials, enhancing their applicability.

4. Provides Permanent Threads, Easy Disassembly and Maintenance

Unlike one-time-use rivets, Rivet Nuts offer reusable internal threads, enabling bolt removal and reassembly. This feature makes Rivet Nuts particularly suitable for applications that require future maintenance, repairs, or component replacement. For example, in industrial equipment or aerospace assembly, engineers can easily disassemble parts secured with Rivet Nuts using bolts, without damaging the original materials, thus reducing maintenance costs and improving assembly flexibility.

5. Closed-End Design for Improved Waterproofing and Dust Protection

Some Rivet Nuts feature a closed-end design, forming a sealed structure after installation. This is crucial for preventing water, dust, or other contaminants from entering the connection point. For example, in marine engineering or outdoor equipment, closed-end Rivet Nuts can effectively prevent moisture ingress, avoiding thread corrosion or deterioration of mechanical properties.

1. Automotive Manufacturing

- Used to connect structural components such as doors, hoods, and chassis.

- Solves the issue of threading thin metal sheets, improving assembly efficiency and ease of maintenance.

2. Aerospace

- Suitable for securing threads on lightweight materials (such as aluminum alloys and carbon fiber composites), enhancing structural strength while reducing weight.

- Widely used in aircraft interior structures and seat installations, where reliable fasteners are required.

3. Industrial Equipment

- Applied in sheet metal cabinets, machinery, and piping installations, improving connection reliability.

- The disassembly feature is particularly important during equipment maintenance.

4. Furniture Assembly

- Used to connect lightweight materials like wood and composite panels, increasing the durability of furniture.

- For example, metal-framed furniture and kitchen cabinets often use Rivet Nuts for securing threaded connections.

5. Construction and Rail Transit

- Suitable for connecting structural components like curtain walls and stainless steel railings, providing high-strength fastening solutions.

- Rivet Nuts are also used for securing sheet metal components in rail transit equipment, such as train carriages and subway station installations.

Do You Have Any Questions?

Let Us Solve Your Problem

Poly Nut vs Rivet Nut: Key Differences

1. Features

- Poly Nut: lightweight, non-conductive, corrosion-resistant, and suitable for lightweight connections. When installed, it forms stable threads in soft materials (such as plastic, wood, drywall), but has a lower load-bearing capacity.

- Rivet Nut: Made from metals (aluminum, carbon steel, stainless steel), offering high strength and high torsional resistance. It is suitable for various materials (thin metal sheets, plastics, composites, etc.) and can bear heavier loads.

2. Operating Principle

- Poly Nut: During installation, the Poly Nut expands or compresses, forming a stable fixing point with the material surface. Typically, after tightening the screw, the plastic nut expands and engages with the material, forming a firm connection.

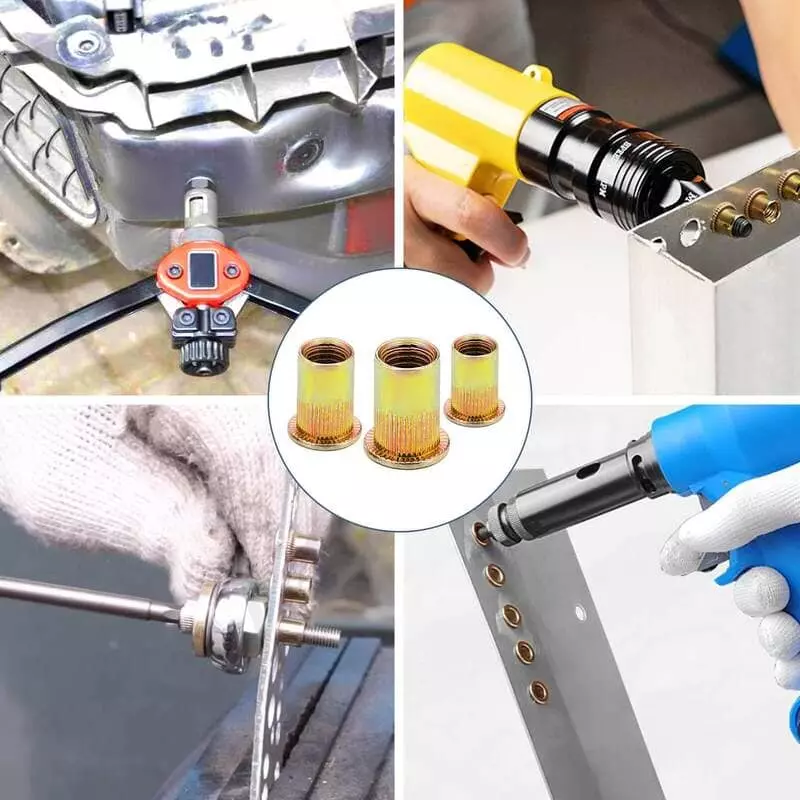

- Rivet Nut: Rivet Nuts are installed by a rivet nut gun, which pulls on the nut, causing its tail to expand and tightly press against the material’s back, thus securing it. Internal threads are then formed for a bolt to be screwed in, providing a strong threaded connection in thin sheets or closed structures.

3. Materials

- Poly Nut: Primarily made from lightweight material, with some high-strength variants incorporating fiberglass reinforcement to improve mechanical properties.

- Rivet Nut: Typically made from aluminum, stainless steel, or carbon steel. Aluminum Rivet Nuts are suitable for lightweight applications, stainless steel for corrosion-resistant environments, and carbon steel for high-strength requirements.

4. Strength

- Poly Nut: Due to its plastic composition, it has lower tensile and torsional strength, making it suitable for light-duty applications and not recommended for high-strength uses.

- Rivet Nut: Made from metal materials, Rivet Nuts have much higher tensile and torsional strength, making them ideal for heavy-duty applications. For example, in automotive, aerospace, and industrial equipment, Rivet Nuts provide a more secure connection than Poly Nuts.

5. Corrosion Resistance

- Poly Nut: Due to its material properties, Poly Nuts are highly resistant to corrosion and unaffected by moisture, chemicals, or salt mist. They are particularly suitable for humid or chemically aggressive environments, such as outdoor equipment or electronic components.

- Rivet Nut: Aluminum and stainless steel Rivet Nuts offer good corrosion resistance and are suitable for humid or chemical environments. However, carbon steel Rivet Nuts require additional rust-proof coatings (such as galvanization or nickel plating) to improve their corrosion resistance.

6. Installation

- Poly Nut:

- Easy installation, can be directly inserted into a hole in the material, and then the screw is tightened to complete the fix. No special tools are needed.

- Suitable for DIY and small lightweight assembly projects.

- Rivet Nut:

- Requires a rivet nut gun for installation, which applies force to expand the tail of the nut and secure it against the material’s back, forming a firm threaded connection.

- Ideal for mass production or industrial applications, providing a more secure installation, but at a higher cost.

7. Suitable For

- Poly Nut:

- Suitable for soft materials (such as plastic, drywall, wood) and low-load applications, such as home renovations, electronic devices, light machinery, etc.

- Due to its non-conductive properties, it is particularly useful for electrical or electronic product installations.

- Rivet Nut:

- Suitable for metals, plastics, composite materials, especially for thin sheets and enclosed structures, such as in automotive manufacturing, aerospace, industrial equipment, and furniture assembly.

- Ideal for applications that require long-term vibration resistance or high load-bearing capacity, such as in machinery assembly, rail transportation, and shipbuilding.

Poly Nut vs Rivet Nut

Poly Nuts are ideal for light-duty assemblies, particularly in soft materials, low-load applications, such as electronics or home renovations. On the other hand, Rivet Nuts are better suited for industrial manufacturing that requires high strength and durability, such as in automotive, aerospace, and machinery assembly. The choice between these two types of nuts depends on the application needs, material type, and installation conditions.

Poly Nut vs Rivet Nut:Which One Should You Choose?

When deciding between Poly Nut and Rivet Nut , it’s important to consider the material properties, application scenarios, load requirements, and installation methods. Here’s a detailed guide to help you choose:

When to Choose Poly Nut

Poly Nut may be the better choice if your application meets the following criteria:

1. Soft Materials (e.g., plastic, wood, drywall)

- Poly Nut is ideal for fragile or soft materials like plastic boards, wood, or drywall.

- Its expansion fixation feature ensures stable threads without damaging the material structure.

2. Lightweight Design Required

- Made from plastic, Poly Nut is much lighter than metal rivet nuts, making it suitable for lightweight structures or applications where weight is sensitive, such as electronic devices, automotive interior decor, or home decoration.

3. High Corrosion Resistance Needed

- Poly Nut is made from nylon or other engineering plastics, so it won’t rust and is unaffected by moisture, chemicals, or salt mist.

- This makes it ideal for outdoor equipment, marine applications, or installations in chemical containers.

4. Electrical/Electronic Industry Applications (Non-Conductive)

- Poly Nuts are insulated and do not conduct electricity, making them perfect for electrical installations, electronic devices, or any application that requires electrical insulation, like circuit board fixation or communication equipment installations.

5. Easy Installation, Suitable for DIY or Light Assembly

- Poly Nuts can be inserted directly into holes and tightened with a screw, requiring no special tools.

- This makes them perfect for home renovations, DIY projects, or simple assembly tasks.

When to Choose Rivet Nut

Rivet Nut may be the better choice if your application meets the following criteria:

1. High Strength Fastening Needed

- Made from aluminum, stainless steel, or carbon steel, Rivet Nuts have much higher load-bearing capacity compared to Poly Nuts, able to withstand greater tensile and torsional forces.

- They are suitable for high-strength fastening in structures like vehicle chassis, industrial machinery, rail transportation, or building fixtures.

2. Materials Include Metals or Composites

- Rivet Nuts provide stable and lasting thread connections when used on thin metal sheets, hard plastics, or composite materials, especially in applications where access is only available from one side, like automobile bodies, aerospace structures, etc.

3. Long-Term Use and Adaptation to Harsh Environments

- Rivet Nuts are resistant to wear and fatigue, making them ideal for applications that involve vibration, impacts, or long-term loads, such as industrial-grade or professional-level projects.

- They ensure reliable fastening over time in mechanical manufacturing, vehicle assembly, and similar industries.

4. Vibration-Resistant Fastening Required

- Rivet Nuts are designed to clamp tightly onto materials, making them less likely to loosen.

- This feature is particularly useful in applications exposed to frequent vibrations or impacts, such as engine components, mechanical equipment, or elevator structures.

5. Efficient, Bulk Installation Needed

- Rivet Nuts require a rivet nut gun for installation, which increases installation speed and is ideal for mass production.

- For example, automobile manufacturers often use pneumatic or electric rivet nut guns to improve production efficiency on assembly lines.

By considering these factors, you can make an informed decision on whether a Poly Nut or Rivet Nut is more suitable for your specific needs, ensuring that you choose the right fastener for the right application.

Conclusion

- Choose Poly Nut: If you need a lightweight, corrosion-resistant, non-conductive nut and are working with softer materials like plastic or wood, Poly Nut is an economical and easy-to-install choice.

- Choose Rivet Nut: If you require stronger fastening power for metal or high-load connections and need long-term stability, Rivet Nut is the more reliable choice.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix - Leading Rivet Nuts Supplier in China

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of rivet nuts and rivet nut tools designed to meet the unique demands of your projects. With options like countersunk, flat, and hex heads, as well as knurled and round body types, Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service according to your requirements.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.