How to Tighten Rivet Nuts

Leading Rivet Nut Manufacturer and Supplier in China

In mechanical assembly and sheet metal structures, rivet nuts are suitable for achieving high-strength internal thread connections in thin plates or hollow components that cannot be operated from the back. Many engineers and technicians often encounter such problems during project execution: how to tighten rivet nuts? This article will provide a professional interpretation around this theme to help you fully grasp the installation essentials.

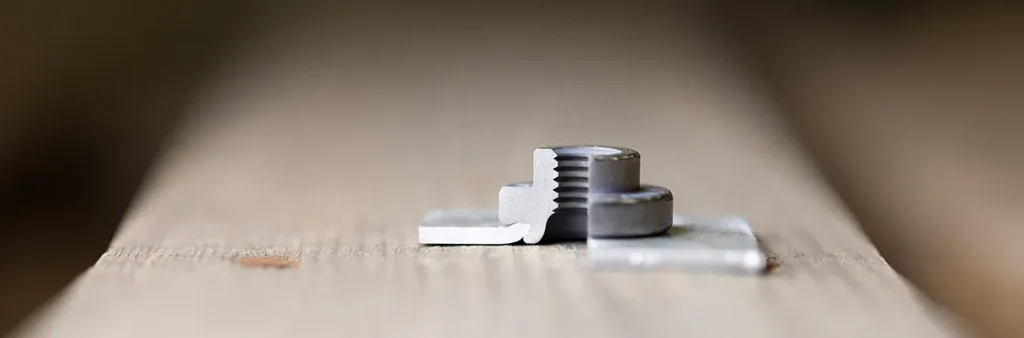

Rivet nut is a type of internal thread fastener that achieves fixation through plastic deformation. Its working principle is to use a special tool to cause the tail of the rivet nut to expand and clamp the substrate. Thus, a strong threaded connection point is formed on thin plates or closed profiles. Examples include metal sheets, aluminum profiles, automotive components, and pipes. It has the advantages of single-sided installation, high efficiency, reliability, and no damage to the substrate.

Next, we will explain step by step how to properly tighten the rivet nuts to ensure that the connection strength and assembly quality meet the industrial standards.

Table of Contents

Why Is Proper Tightening of Rivet Nuts Important?

In various structural connections, the correct tightening of rivet nuts is not merely a procedural action; it is also a crucial step in ensuring the structural strength and product reliability. Improper installation methods are often difficult to detect initially. However, during the service period, they may cause a series of serious problems, especially under conditions of load-bearing, vibration, or repeated temperature variations.

Structural strength: The rivet nut essentially achieves its connection with the base material through “clamping + expansion deformation”. If the tension is set incorrectly or the clamping range does not match, it may lead to insufficient riveting and incorrect connection points. Once the subsequent screw is subjected to force, the nut itself will be unable to effectively transmit the force. This thereby affects the load capacity of the overall structure.

Service life and safety: If the rivet nuts are not firmly tightened, they will undergo slight displacement under long-term load or vibration. Gradually, there will be loosening, abnormal sounds, and even complete detachment. In severe cases, it may cause the components to become loose or detach, posing a threat to the safety of use.

In addition, the common failure types include nut rotation failure (failure to form anti-rotation engagement), pull-off failure (the base material is too thin or the clamping is insufficient), and thread damage (excessive pull-bolting force or improper tool selection). These problems often result from the neglect or improper operation in the fastening process.

Tools You Need to Tighten Rivet Nuts

The manual riveting screw gun is suitable for sample production, small batch manufacturing or maintenance tasks. Its advantages lie in its simple operation, low cost and portability.

However, due to its reliance on manual force application, it is prone to unstable tension and low efficiency issues. Especially when performing repetitive operations multiple times, it requires a significant amount of physical effort from the operator.

Pneumatic or electric riveting guns are suitable for medium to large-scale standardized assembly scenarios, providing stable and controllable riveting force to ensure consistent riveting quality. They are widely used in industries such as automobiles, elevators, and chassis cabinets, where servo control or air-electric hybrid equipment is commonly employed for automated riveting operations. The drawback is that the equipment costs are relatively high, and stable air supply or power supply conditions are required.

Table: Common Tools and Comparison of Their Pros and Cons

| Tool Type | Advantages | Disadvantages | Suitable Scenarios |

|---|---|---|---|

| Manual Rivet Nut Tool | Low cost, flexible operation | Inconsistent pulling force, low efficiency | Samples, small batches, repairs |

| Pneumatic Rivet Nut Tool | Consistent force, fast operation | Requires air supply, needs maintenance | Medium batches, fixed workstations |

| Electric Rivet Nut Tool | Easy to operate, supports various specifications | Limited battery life, higher initial cost | Assembly lines, small-scale production lines |

| Servo-Controlled Riveting System | Precise control, force/stroke monitoring | Expensive, requires automation setup | Automated lines, high-precision applications |

Selection Considerations for Gripping Claws/Retaining Pins

The core components of the rivet nut gun are the mandrel and the clamping爪 assembly. The size and tooth pattern of these components must precisely match the specifications of the nuts being used (such as M6, M8, UNC, etc.). Using a mismatched mandrel may result in:

- Thread damage or slippage

- Uneven pulling force, deformation or rotation of the rivet nut

- Failure to properly engage the tool or inability to firmly hold the nut

It is recommended that before mass production, corresponding pull pins should be set for each type of nut specification, and the wear condition of the grippers should be checked regularly to avoid assembly deviations caused by wear. At the same time, some high-end electric/servo riveting equipment also supports a “quick replacement pull pin system”, which improves the efficiency of model changes.

How to Tighten Rivet Nuts: Step-by-Step Instructions

Step 1: Select the appropriate rivet nut

Ensure that the clamping range of the selected rivet nuts covers the thickness of the base material, avoiding either insufficient clamping (risk of pull-off) or excessive clamping (failure to expand and form properly). At the same time, select the appropriate material and anti-rotation structure based on the working environment (such as whether it is highly humid or highly vibrating). Common materials include carbon steel, stainless steel, and aluminum alloy, with structures such as hexagonal and ribbed types.

Step 2: Prepare the aperture and confirm the substrate conditions

The diameter of the drilling or punching holes must comply with the installation specifications for the rivet nuts. If it is too large, it will cause slippage; if it is too small, it may not be able to be inserted or may damage the nuts. It is generally recommended to use a dedicated drilling jig or CNC punching, and remove the burrs to ensure that the hole walls are clean and vertical. At the same time, confirm whether the thickness of the base material is stable within the target clamping range.

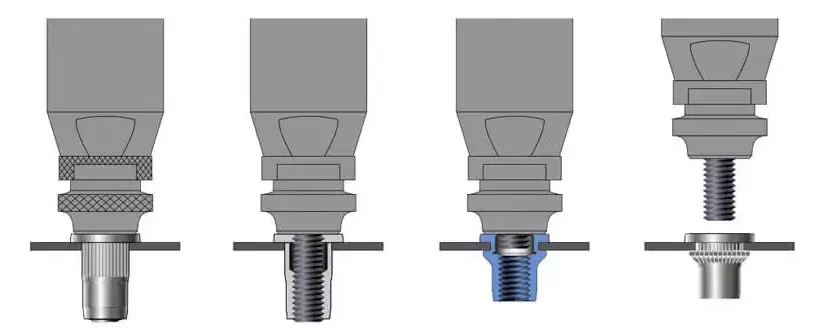

Step 3: Install the rivet nut onto the tool

Insert the rivet nut onto the corresponding specification of the mandrel’s threaded section, ensuring it is screwed in to fit but not compressing the flange area. At this point, check if the tool’s jaws are properly engaged to prevent slippage or failure during the riveting process.

Step 4: Apply pressure and perform riveting

Place the tool and the rivet nut vertically at the hole opening, ensuring that the flange of the rivet nut is tightly against the surface of the base material. While maintaining a vertical angle, start the riveting gun. The tail of the rivet nut will expand and grip between the plates, forming a secure internal thread connection. Avoid operating under loose or skewed conditions to prevent eccentric deformation.

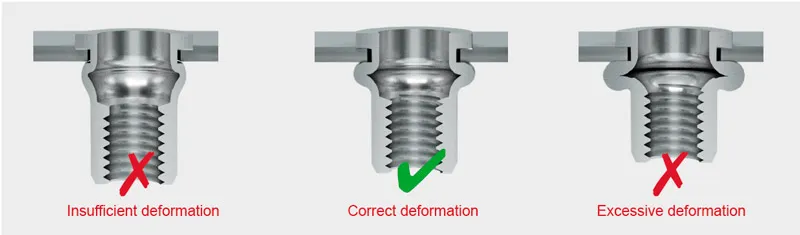

Step 5: Check the riveting status

After the riveting is completed, the following points should be carefully checked:

- Is the flange fully in contact with the base material surface?

- Is the back expansion uniform, without cracks or warping?

- Has the rivet nut rotated or slipped?

- Is the entire assembly centered and aligned with the hole?

If necessary, pull testers or torque wrenches can be used to verify some of the samples.

Step 6: Recommendations for Subsequent Screw Installation

After the rivet nut is tightened, the installation of the matching screws can be carried out. In high-load or vibration conditions, it is recommended to use glued screws, locking washers or structural adhesives to enhance the anti-loosening effect. The tightening torque should be controlled within the recommended load-bearing range of the nut to avoid secondary damage.

Tips for High-Strength and Vibration-Prone Applications

Firstly, anti-torsion rivet nuts should be preferred, such as the embossed type or the hexagonal type. The embossed design enhances the friction between the outer wall and the hole wall of the base material, thereby improving the anti-rotation capability. It is suitable for medium-strength plates. While the hexagonal type achieves almost complete elimination of the risk of torsional failure through geometric anti-torsion interlocking, and is particularly suitable for high-vibration environments.

Secondly, in terms of anti-loosening, it is recommended to use anti-loosening structures or adhesives in combination. For example, during the installation of matching screws, introduce thread locking agents (such as those from Loctite), or use spring washers, locking washers and other structural components to effectively absorb vibration energy and delay the generation of micro-displacements.

In terms of materials, high-stress areas should avoid using low-strength rivet nuts (such as those made of aluminum), and it is recommended to use stainless steel (such as 304, 316) or high-strength carbon steel rivet nuts. Ensure that the surface anti-corrosion treatment meets the requirements of the application environment (such as galvanization, Dacromet coating, adhesive coating, etc.).

Furthermore, for scenarios where product reliability is of high importance, it is recommended to conduct regular pull-out tests during the first trial assembly or batch replacement production. The following frequency suggestions can be referred to:

- Initial Verification: For each specification and each batch of materials, at least 2 samples need to be tested for tensile load.

- Process Sampling: Every 500 pieces or every hour, at least 1 piece should be tested.

- Reference Standards: Refer to ISO 14589, GB/T 17880.1 or the enterprise’s internal control standards to set the minimum breaking force value.

Recommended Rivet Nut Tools and Brands

In high-quality riveting operations, the selection of tools and brands directly determines the assembly efficiency and connection consistency. Whether you are a novice technician dealing with rivet nuts or a process engineer managing a batch assembly line, choosing reliable tool and brand resources is the foundation for achieving stable fastening results.

Recommended Brands of Professional Riveting Equipment

In the industrial riveting field, the following brands, with their accumulated technological expertise and market validation, possess high reliability:

- Rivetfix: Specializes in riveting solutions, offering a complete range of products from manual tools to servo-automated equipment, supporting personalized customization, suitable for various industrial applications in the automotive, elevator, and sheet metal industries.

- GESIPA (Germany): A high-end riveting tool manufacturer, known for its durability and ergonomic design, widely used in aviation and high-end manufacturing industries.

- AVDEL (now part of Stanley Engineered Fastening): An industrial riveting pioneer, offering products such as riveting guns, nut guns, and their consumables, particularly excelling in automated solutions.

- POP, HUCK: Widely recognized in the European and American markets, suitable for riveting applications in high-strength structures and safety components.

Recommendations for Bolt Nut Models and Selection Resources

The commonly used types of rivet nuts include:

- Flat-head round column type (General type, suitable for standard loads)

- Engraved or hexagonal anti-loosening type (Suitable for high-torque working conditions)

- Small flange/counterbore type (Suitable for limited space or occasions with appearance requirements)

- Closed type (Used in waterproof and dustproof scenarios)

It is recommended to refer to the technical manuals or clamping range comparison tables provided by the brand when making the selection. For example, Rivetfix offers the “Rivet Nut Grip Range Chart“, and GESIPA has an application case library. These resources facilitate the rapid selection of models based on material, thickness, and load conditions.

FAQs: How to Tighten Rivet Nuts

Question 1: What should be done if the rivet nut slips during installation?

Answer: The slippage of the rivet nut is usually caused by the failure of the anti-rotation structure or the excessive diameter of the hole. The following methods can be used for troubleshooting and repair:

- Check whether the aperture is too large or the base material is too soft, and if necessary, replace it with a knurled or hexagonal anti-loosening structure.

- Confirm that the pull pin specification matches the nut, incorrect pull pins may cause eccentric loading.

- Check if the riveting tool jaws are worn or loose, and if necessary, replace the accessories.

- If the riveting failure is severe, remove it and replace with a new rivet nut to avoid reusing the original part.

Question 2: Can the already installed rivet nuts be reused?

Answer: It is not recommended to reuse the already riveted rivet nuts, especially in structural components or load-bearing connections. The reasons are as follows:

- During the riveting process, the tail end of the nut has undergone irreversible plastic deformation.

- Repeated riveting will not be able to form an effective clamping force.

- Repeated disassembly and assembly is likely to cause wear or thread slippage of the internal thread, reducing the tightening strength.

- If replacement is needed later, it is recommended to design it as a nut column (weld nut) or use a nut base structural component.

Question 3: How can one determine if the riveting is done correctly?

Answer: A qualified riveting state should possess the following characteristics:

- The rivet nut flange is firmly attached to the base material surface, without any warping or skewing.

- The back expansion is sufficient and symmetrical, without any cracks or imbalance in deformation.

- After the screws are inserted, the threads move smoothly without any looseness.

- Pull-out tests or torque verification can be conducted through random sampling to ensure that the connection strength meets the standard requirements.

It is suggested that a quality inspection system be established during the mass production process, such as first-piece verification and batch sampling inspection, to ensure the consistency of assembly.

Conclusion

In any industrial application involving structural connections, the correct tightening of rivet nuts is not merely an operational action; it is a crucial guarantee for ensuring product performance, extending service life, and preventing structural failure. Ignoring the selection of components, tool settings, or process control often leads to quality issues such as insufficient strength, loosening, and thread damage during later use. This can result in rework, equipment downtime, and even safety accidents.

Therefore, it is recommended that enterprises establish a complete tightening operation standard during the product design and on-site assembly stages, clearly defining the basis for selecting rivet nuts, setting installation parameters, standardizing operation procedures, and specifying quality inspection requirements. At the same time, incorporate tool selection, process verification, and on-site operations into a unified quality control system to form a traceable riveting process loop.

If you have requirements for high-strength loads, batch installation, special-shaped structures or the use of special materials in your specific project, it is recommended to contact a professional service provider (such as Rivetfix) to obtain one-on-one selection support, on-site process assessment or automation transformation suggestions.

Do You Have Any Questions?

Let Us Solve Your Problem

Upgrade Your Assembly with Rivetfix Rivet Nuts

Choose rivet nuts, and you are not just selecting fasteners; you are choosing an entire set of structural connection solutions. Rivetfix specializes in industrial-grade riveting systems, and we offer a variety of high-strength, vibration-resistant, and anti-transformation rivet nuts. These are widely used in the automotive, sheet metal, electrical enclosures, and new energy industries, and are suitable for all working conditions of manual, pneumatic, electric, and automated assembly.

Each nut has undergone strict testing and is of stable and reliable performance. Whether you are in the sample development stage or conducting mass production, Rivetfix can provide you with selection support, clamping optimization suggestions, and recommendations for matching riveting tools, helping you solve the fastening problems from the very beginning.

Now visit our official website rivetfix.com, and immediately explore our complete range of products. Work together with your engineering team to enhance assembly efficiency and connection strength! If you need technical assistance, please contact our engineering expert team to obtain a customized solution.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.