Hex Body Rivet Nuts: When and Why to Use Them

Leading Rivet Nut Manufacturer and Supplier in China

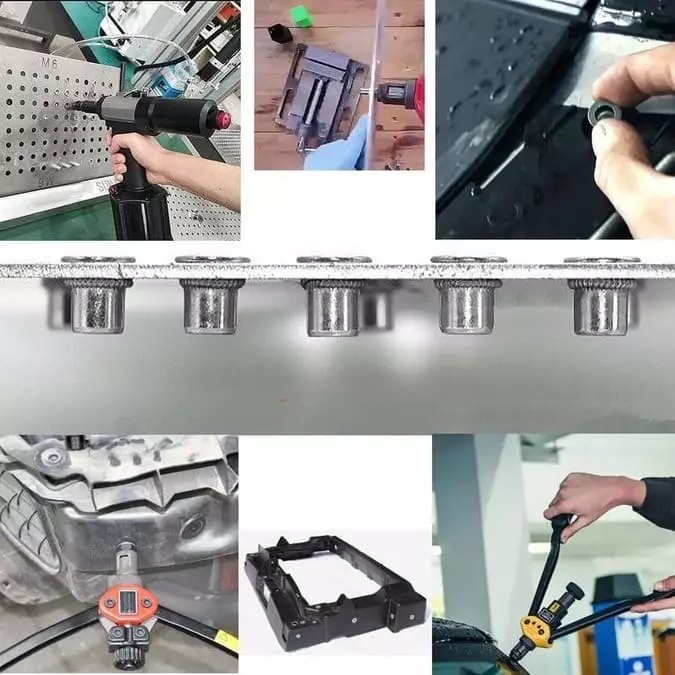

When it comes to creating strong, secure, and vibration-resistant threaded connections—hex body rivet nuts offer a superior solution. Unlike standard round body rivet nuts, their hexagonal shape ensures exceptional resistance to rotation, making them ideal for high-torque applications and environments where stability is critical. In this blog, we’ll explore when and why you should choose hex body rivet nuts, how they outperform other types, and where they’re commonly used across industries like automotive, electronics, and heavy machinery.

Table of Contents

What Are Hex Body Rivet Nuts?

Hex body rivet nuts are fasteners with pre-formed internal threads, featuring a hexagonal or partially hexagonal shaped body. They are widely used in applications such as thin metal sheets and tubes, where direct threading is not possible. During installation, the rivet nut is pulled into place using a specialized rivet tool, creating a secure internal thread connection. Known for their strong anti-rotation capability, ease of installation, and reusability, hex body rivet nuts have become an essential component in metal structure fastening.

Structure Composition:

- Body Shape: These include full hex bodies (Hex Body), half hex bodies (Half-Hex Body), and knurled round bodies (Knurled Round Body). The hex body design tightly engages with a pre-punched hexagonal hole, effectively preventing the nut from rotating or loosening after installation.

- Head Design: Available with flat heads (Flat Head), countersunk heads (Countersunk Head), and large flange heads (Large Flange Head) to meet various surface flushness or load-bearing requirements.

Common Materials:

- Carbon Steel: Offers high strength, suitable for most mechanical structural components; typically galvanized to prevent corrosion.

- Stainless Steel: Provides excellent corrosion resistance, making it ideal for outdoor, humid, or high-temperature environments.

- Aluminum: Lightweight and suitable for applications where weight is a concern, such as in aerospace and electronic devices.

Common Thread Specifications:

- Metric standards include: M4, M5, M6, M8, M10, M12, etc.

- UNC/UNF threads are also common in the North American market, such as #10-24, 1/4-20, 5/16-18, etc.

Why Choose Hex Body Rivet Nuts Over Other Types?

a. Excellent Anti-Rotation Performance

One of the key advantages of the hex body design is its superior anti-rotation capability. During installation, the hexagonal body fits tightly into the pre-punched hexagonal hole, forming a mechanical interlock with the hole wall. This structure effectively resists the torque generated during bolt tightening, preventing the rivet nut from “slipping” or spinning in the base material. It is particularly suitable for high-vibration and repeated assembly/disassembly scenarios.

b. Ideal for High Torque or Frequent Assembly/Disassembly Applications

Due to its anti-rotation design and strong grip, hex body rivet nuts are well-suited for high-torque connections, such as in mechanical equipment, automotive body structures, industrial enclosures, and more. Compared to round body or knurled body products, the hexagonal body can withstand higher assembly forces and repeated torque during use, extending its service life.

c. Solving Threading Challenges in Thin Materials

For thin sheets, tubes, or non-metallic materials (such as aluminum, stainless steel, and engineering plastics) that are not thick enough to thread directly, hex body rivet nuts provide a secure and reliable internal thread connection without the need for complex welding or pre-tapping operations.

d. Ideal Solution for Blind Hole Installations

Hex body rivet nuts can be installed via blind holes, meaning the installation process can be completed from only one side of the workpiece. This makes them perfect for structures like tubes, sealed cavities, or U-shaped components where access to the backside is not possible, simplifying the process and improving efficiency.

e. Achieving High Strength Connections and Better Stress Distribution

In high-load environments, hex body rivet nuts offer a larger contact area and more uniform stress distribution compared to cylindrical rivet nuts. This enhances their performance in terms of pull-out resistance and torsional strength, ensuring a secure and stable connection that won’t loosen over time.

When Should You Use Hex Body Rivet Nuts?

a. When the Base Material Is Soft or Prone to Slipping

In materials such as plastic, aluminum sheets, composite materials, or other low-hardness base materials, standard round rivet nuts are prone to rotating or loosening under force. However, the hex body structure firmly “bites” into the base material’s inner wall, preventing rotation and ensuring stable connections. This makes hex body rivet nuts an ideal fastening solution for soft materials.

b. When the Structure Requires Frequent Assembly/Disassembly of Screws

In applications such as electrical control cabinets, maintenance panels, mold positioning, and other scenarios where screws need to be frequently assembled and disassembled, rivet nuts that loosen or rotate after repeated use can significantly affect the user experience or even cause parts to fall off. The anti-rotation design of hex body rivet nuts ensures they remain firmly in place, allowing for smooth and reliable disassembly every time.

c. For Structural Connections That Handle High Torque Loads

In high-load applications such as automotive chassis, elevator tracks, or mechanical equipment brackets, screws often experience significant torque during installation and operation. Standard nuts may not withstand long-term high-torque tightening, whereas hex body rivet nuts, with their anti-rotation design and embedded structure, effectively absorb and distribute torque, preventing loosening.

d. When the Pre-Punched Hole Is Hexagonal or Can Be Machined into a Hexagonal Shape

Hexagonal holes provide a tight fit with the hex body, maximizing the anti-rotation advantage. If your project can accommodate laser cutting, CNC punching, or other hole processing techniques, upgrading round holes to hexagonal ones will greatly enhance installation reliability and connection performance.

e. When Replacing Welded Nuts in Certain Applications

Weld nuts are commonly used for structural connections but come with challenges such as complex processing, thermal impact on base materials, and potential damage to coatings or corrosion layers. Hex body rivet nuts can be installed cold, without the need for heating, sparking, or affecting surface treatments, making them ideal for structures with strict surface coating requirements (such as automotive and appliance enclosures).

Summary - When Should You Use Hex Body Rivet Nuts

Hex body rivet nuts are the most reliable and efficient fastening solution when facing challenges such as rotation risks, high torque loads, frequent assembly/disassembly, or difficulty with welding. They offer unmatched performance and durability in these scenarios.

How Are Hex Body Rivet Nuts Installed?

a. Recommended Tools

- Manual Rivet Nut Gun: Suitable for small batches or repair scenarios, it is cost-effective and portable but relatively low in efficiency. It requires a considerable amount of hand force during operation.

- Electric Rivet Nut Gun: Ideal for medium-batch installations, it offers ease of operation and high efficiency. It is recommended for use in small to medium-sized factories or assembly lines.

- Hydraulic or Pneumatic Rivet Nut Guns: Used for large-scale production, these guns have high-pressure output capabilities and can handle larger sizes such as M10 or M12 rivet nuts, ensuring even and consistent installation.

Recommendation: For M8 or larger sizes or harder base materials, it is recommended to use electric or hydraulic tools to ensure installation quality and efficiency.

b. Installation Steps Overview

1. Drill the Hole

- A hole is drilled into the base material at the designated location. For hex body rivet nuts, the hole must be hexagonal to ensure anti-rotation functionality.

- The width across flats of the hole must match the rivet nut’s body perfectly. For example, the typical width for an M8 hex body is about 11.1mm, with a tolerance of ±0.1mm.

2. Insert the Rivet Nut

- Insert the rivet nut into the hole, ensuring that it fits snugly against the hole wall and remains vertical without tilting or loosening.

- The body of the rivet nut must be fully embedded in the base material, with no part exposed, to ensure uniform installation.

3. Activate the Rivet Nut Tool

- Connect the rivet nut to the tool’s internal thread, and trigger the pulling mechanism.

- The tool will cause the tail of the rivet nut to expand into a “bulb” shape, securely clamping the rivet nut to the base material.

4. Complete the Installation and Remove the Tool

- Once the rivet nut is installed, the tool will either automatically or manually disengage, and the rivet nut will be securely installed, ready for immediate screw assembly.

c. Hole Size and Shape Must Be Precise

- Round Hole Version (Less Common): This is suitable for half-hex body or partially knurled round body rivet nuts. The hole diameter must be consistent with the recommended value for the rivet nut, such as M10, which typically requires a hole diameter of 14.2mm ±0.1mm.

- Hexagonal Hole Version (Standard): The hole must meet the across flats dimensions requirement and also have good edge clarity and perpendicularity. It is recommended to use laser cutting or CNC punching equipment to achieve high precision for better fit.

Important: If the hole is too large, the anti-rotation performance will be compromised, while a hole that is too small will make it difficult to insert the rivet nut, severely affecting the installation quality.

Do You Have Any Questions?

Let Us Solve Your Problem

Where Are Hex Body Rivet Nuts Commonly Used?

a. Automotive Manufacturing (Chassis, Interior Structures, etc.)

In automotive manufacturing, hex body rivet nuts are used for mounting body accessories, chassis components, and interior brackets. Particularly in aluminum or thin steel plate structures, traditional welded nuts face issues such as heat-affected zones and limitations on surface treatments. Rivet nuts can achieve a cold connection, preserving the base material’s integrity.

- Bumper fasteners

- Seat rail connections

- Dashboard bracket installation

b. Elevators and Rail Structure Components

Elevator and rail transport structures require fasteners with high resistance to vibration and pull-out strength. Hex body rivet nuts can maintain stable connections even in high-vibration environments, and are commonly used in aluminum profiles or steel plate threaded connections.

- Elevator guide rail supports

- Door frames and interior panel connections

- Rail signal box assemblies

c. Air Conditioning/Household Appliance Metal Casings

Modern household appliances such as air conditioners and washing machines use thin sheet metal casings that are unsuitable for welding. Hex body rivet nuts allow for quick, efficient, and heat-free threaded installation, making them ideal for high-volume production assembly lines.

- Wall-mounted air conditioner fasteners

- Refrigerator internal components

- Washing machine support connections

d. Telecommunication Equipment Enclosures

Telecommunication equipment’s sheet metal enclosures require multiple high-strength screw connection points. Hex body rivet nuts provide stable, anti-loosening internal threads, making them suitable for equipment structures that require frequent maintenance and disassembly.

- Base station power boxes

- Network switch enclosures

- Server rack installation points

c. Industrial Equipment Assembly

Hex body rivet nuts are widely used in industrial automation equipment, electrical control cabinets, and equipment supports, enabling the formation of high-strength, durable threaded connections in various materials such as stainless steel, coated steel, and plastic composite panels.

- Industrial robot enclosures

- Automation support modules

- Control cabinet door panel installations

How to Choose the Right Hex Body Rivet Nut?

a. Choose Based on Thread Size

The rivet nut sizes should match the bolt or screw used. Common metric thread sizes include:

| Internal Thread Size | Typical Application |

| M4 | Small electronic enclosures, household appliances |

| M6 | General fastening, mechanical parts |

| M8 | Medium-strength mechanical connections |

| M10–M12 | Heavy-duty equipment, high-torque assemblies |

b. Choose the Appropriate Head Style

- Flat Head Rivet Nuts: Commonly used in applications where the surface is relatively flat and appearance is not a concern. The nut slightly protrudes after installation.

- Countersunk Head Rivet Nuts: Suitable for installations requiring a flush surface, as the nut head can be fully embedded in the base material.

c. Consider the Nut Material

| Material | Characteristics & Recommended Applications |

| Carbon Steel | Cost-effective, suitable for indoor, general environments |

| Stainless Steel (304/316) | High corrosion resistance, suitable for humid, outdoor, or chemical environments |

| Aluminum Alloy | Lightweight, corrosion-resistant, ideal for light structures or electronic products |

d. Choose the Appropriate Surface Finish

Surface treatment enhances corrosion resistance and affects appearance and friction performance:

- Zinc Plated: Basic corrosion protection, suitable for indoor applications.

- Nickel Plated: Improves wear resistance and electrical conductivity.

- Stainless Steel: No additional coating required, can be used directly.

e. Recommended Hole Size for Compatibility

Hex body rivet nuts need to fit hexagonal or laser-cut holes to ensure proper anti-rotation locking. The following table provides recommended rivet nut hole sizes for common specifications:

| Nut Size | Recommended Hex Hole Across Flats | Recommended Hole Depth |

| M6 | 9.00–9.10 mm | ≥12 mm |

| M8 | 11.90–12.00 mm | ≥14 mm |

| M10 | 14.90–15.00 mm | ≥16 mm |

Do You Have Any Questions?

Let Us Solve Your Problem

Using Hex Body Rivet Nuts Today

Hex Body Rivet Nuts, with their unique design and reliable performance, are widely used across various industries. Their greatest advantage lies in their powerful anti-rotation capability, particularly in thin plates and materials that are difficult to connect through welding. They effectively prevent the nut from loosening or rotating during use, ensuring a stable connection.

Buy Hex Body Rivet Nuts from Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

If you’re looking for a high-strength, reliable, and anti-rotation fastening solution, choose our premium Hex Body Rivet Nuts today. They will help make your projects more efficient and durable! By selecting the right Hex Body Rivet Nut, you can optimize your production process, enhance connection quality, and ensure long-term stability of your products. Contact us now for more information and customization options on Hex Body Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.