Can You Reuse Rivet Nuts?

Leading Rivet Nut Manufacturer and Supplier in China

Can You Reuse Rivet Nuts? This is a common question among engineers, technicians, and DIY enthusiasts who work with rivet nut fasteners. While rivet nuts offer strong and reliable threaded connections, their reusability depends on several critical factors such as installation method, material condition, and application environment. In this article, we’ll explore whether rivet nuts can be reused, what risks are involved, and when it’s safer to replace them instead.

Table of Contents

Rivet nuts—also known as rivnuts, blind rivet nuts, nutserts, or threaded inserts—are blind fasteners designed to provide strong internal threads in thin-walled or hollow structures. Combining the functions of both a nut and a rivet, they allow for installation from one side only (the “blind side”), making them ideal for situations where access to the backside is restricted.

Structure and Components

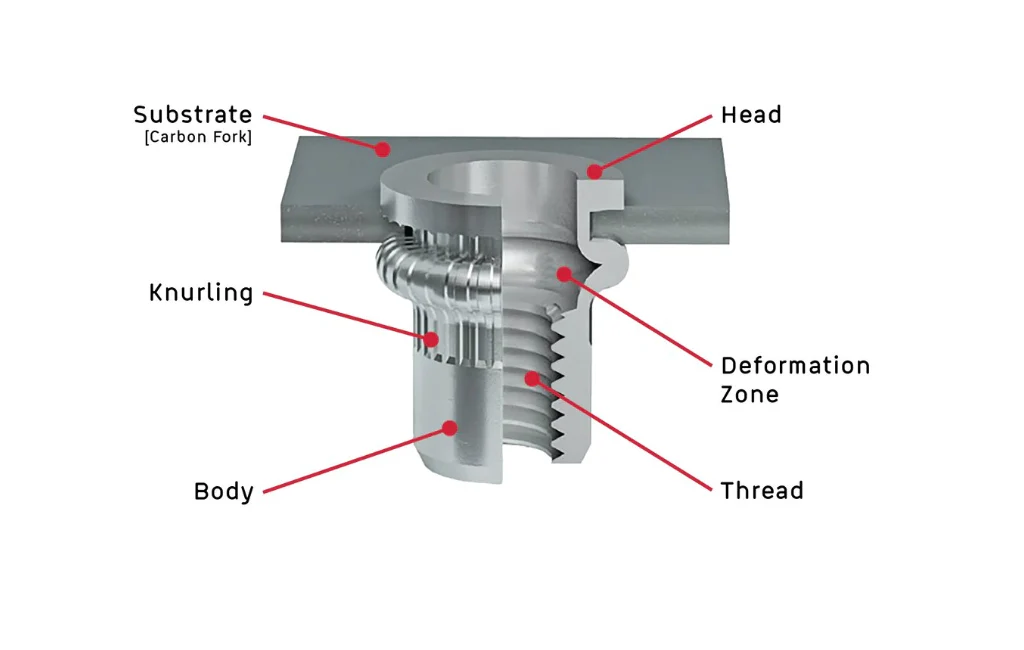

A typical rivet nut consists of the following parts:

Threaded Inner Hole: Provides standard internal threads for screw or bolt fastening;

Deformation Section: Designed to plastically deform during installation, allowing for a tight grip with the base material;

Flange or Head: Helps distribute load and improve pull-out resistance. Common head types include round, flat, and countersunk;

Body Shape: Available in round, hexagonal, or knurled forms to suit different anti-rotation and holding force requirements.

During installation, a mandrel is pulled through the rivet nut using a dedicated tool, causing the body to compress axially and expand radially on the blind side. This deformation creates a “bulge” that clamps securely onto the base material. Since the entire process is performed from one side, rivet nuts are perfect for blind-hole applications.

Sheet Metal Assembly: Commonly used in automotive panels, enclosures, air conditioners, and elevators;

Tubing and Hollow Sections: Ideal for inserting threads inside aluminum profiles or steel pipes;

Composite and Plastic Components: Provides durable threads in non-metal materials;

Restricted-Access Environments: Suitable for installations in areas such as engine bays, wall-mounted systems, or sealed enclosures where rear access is not possible.

Can Rivet Nuts Be Removed?

Rivet nuts are blind fasteners designed to be permanently installed by deforming and anchoring themselves into the base material. Their primary function is to provide a secure, one-sided installation, meaning they are not intended for removal or reuse under normal circumstances. However, if removal is necessary—such as for maintenance, rework, or product end-of-life—there are methods available to extract them. These methods are generally destructive, and the rivet nut cannot be restored to its original condition.

1. Drilling Out

Method: Use a drill bit slightly larger than the internal thread diameter to drill through the center of the rivet nut. This destroys the threads and weakens its grip on the base material.

Best For: Most metal rivet nuts, including aluminum, steel, and stainless steel.

Pros: Controlled process, allows gradual removal; ideal for small-scale tasks.

Cons: Produces metal shavings, may damage the hole wall, often requires hole rework.

2. Punching or Cutting

Method: Use a hydraulic punch or manual cutting tool to shear off or press out the rivet nut from the back or side.

Best For: Softer materials like aluminum rivet nuts or those installed in thin or plastic base materials.

Pros: Fast and efficient; suitable for repetitive operations in industrial settings.

Cons: May deform or damage the base material; not suitable for thick plates or hard metals.

3. Forcible Removal

Method: Pry or hammer the rivet nut out using chisels, pry bars, or hammers, typically from the outer flange or side.

Best For: Emergency repairs or when the rivet nut has already loosened.

Pros: Requires no power tools; can be done manually.

Cons: Most destructive method; high risk of damaging hole or surface coatings.

Post-Removal Considerations

1. Rivet Nut Cannot Be Reused

The deformation area responsible for anchoring the rivet nut will be permanently damaged during removal. Even if the exterior appears intact, its structural integrity and threading are compromised and it should not be reinstalled.

2. Base Hole May Need Repair or Enlargement

The removal process may distort or enlarge the original hole, requiring either a larger rivet nut, hole patching, or thread tapping;

In critical applications (e.g., automotive chassis, electronic housings), hole damage could affect structural reliability.

3. Design With Maintenance in Mind

- For applications requiring future access or multiple disassemblies, consider alternatives such as lock nuts, weld nuts, or PEM nuts;

- For reusable threads, consider high-strength threaded inserts like Helicoils or Keyserts.

Conclusion - Can Rivet Nuts Be Removed

Although rivet nuts can technically be removed by drilling, punching, or prying, all these methods are destructive and may damage both the rivet nut and the base material. Therefore, during product design and assembly, it’s essential to balance permanence vs. maintainability, and choose fasteners that meet long-term service and access needs while minimizing future removal costs and risks.

Can Rivet Nuts Be Reused After Removal?

1. Structural Deformation Principle: Irreversible Riveting Process

The core installation mechanism of a rivet nut relies on plastic deformation of its tail section, which is irreversible once formed. This is the fundamental reason why rivet nuts cannot be reused. Here’s a detailed explanation:

a. Riveting Mechanism Explained

- A rivet nut consists of an internally threaded core, an outer cylindrical wall, and a deformable tail section;

- During installation, a special tool pulls on the internal threads, forcing the tail to expand outward and fold back against the rear side of the base material;

- This process creates plastic deformation in the tail, clamping the rivet nut firmly in place and forming a mechanical lock;

- The locking is not achieved via thread engagement with the base material but rather through press-fit pressure and friction from the deformed tail and outer wall.

b. Deformation Is Irreversible

- The installation process pushes the material beyond its yield limit, causing permanent shape change;

- Once removed, the rivet nut cannot regain its original geometry, even if it appears intact;

- During reinstallation, the already-deformed tail section cannot deform properly again, leading to poor holding performance.

c. Original Performance Cannot Be Restored

- In a new rivet nut, deformation is symmetrical and uniform, ensuring structural integrity;

- After removal, the tail is often cracked, distorted, or flattened, and cannot provide the same structural clamping effect;

- Any reuse may lead to loss of locking capability, resulting in pull-out or rotation failures under load.

2. Risk Analysis of Reusing Rivet Nuts

While some users may attempt to reuse rivet nuts for cost or time-saving reasons, this practice involves serious structural and safety risks. Here are the primary concerns:

a. Loss of Clamping Force

- Clamping strength comes from the flange formed during tail deformation pressing against the backside of the material;

- After removal, the deformed tail cannot form an effective flange again;

- The clamping force during reuse is significantly lower, increasing the risk of pull-out or loosening in service.

- Anti-rotation functions depend on:

- Knurled cylindrical rivet nuts generating friction with the hole wall;

- Hexagonal rivet nuts locking into hex holes;

- After removal, outer surfaces may be worn or deformed, weakening the fit;

- Upon reuse, this often leads to rotation and slippage, compromising torque transfer and thread locking.

c. Structural Integrity Compromised

- Removed rivet nuts often show signs of cracks, fatigue, or edge damage;

- These flaws may propagate during reinstallation, resulting in sudden failure under vibration, shear, or impact loads.

d. Base Material Damage Amplifies the Risk

- The removal process can damage the base hole: enlarged diameter, burrs, out-of-round shapes;

- Reusing an old rivet nut in a damaged hole leads to a loose fit and reduced clamping and anti-rotation strength;

- In worst cases, the base hole may become unusable, leading to part scrappage.

3. Material Impact on Reusability

| Material | Strength Characteristics | Deformation Recovery | Structural Retention After Removal | Reuse Risk Level | Notes |

| Steel | Medium strength, common | Low | Poor | ★★★★☆ | Flange likely cracks or permanently deforms after removal. |

| Stainless Steel | High strength, tough | Very low | Very poor | ★★★★★ | Difficult to deform; irreversible once installed. Not reusable. |

| Aluminum | Low strength, ductile | Relatively high | Fair | ★★★☆☆ | Easier to remove, but prone to fatigue and deformation. |

| Copper | Soft, highly ductile | High | Fair | ★★☆☆☆ | Can deform and recover, but only suitable for light-duty reuse. |

| Plastic | Weakest, corrosion resistant | High | Fair to poor | ★★☆☆☆ | Some engineering plastics may support reuse, but have low load capacity. |

Recommendations

- Steel and stainless steel rivet nuts are not recommended for reuse, especially in high-load or vibration-sensitive applications;

- Aluminum and copper are softer and easier to manipulate, but still carry risk and should be reused only in non-critical or temporary repairs;

- If reusability is essential, consider switching to detachable nut inserts or threaded studs designed for repeated assembly.

4. Recommended Reusable Alternatives

Since rivet nuts are mostly non-reusable once installed, the following alternatives are suitable for applications that require future disassembly or replacement:

a. Captive Nut Clips / Cage Nuts

- How it works: A nut is housed inside a spring steel cage that snaps into a pre-cut hole. The structure allows tool-free insertion and removal;

- Advantages:

- Easily removable and reusable;

- Suitable for thin sheet metal and enclosures;

- Widely used in server racks, control boxes, and electronics;

- Limitations:

- Lower strength than rivet nuts;

- Requires hole shapes that match the clip design.

- How it works:

Inserted into base material via threads, knurling, barbs, or bonding. Common types include press-in, heat-set, and self-tapping;

- Advantages:

- Most types can be reused;

- Ideal for soft materials such as plastics and wood;

- Variety of options for different strength and tooling requirements;

- Limitations:

- Must match the material and installation method;

- Requires special tools such as soldering irons or tapping tools.

c. Weld Nuts

- How it works: Permanently welded to the surface of a metal part using resistance or arc welding;

- Advantages:

- High strength and durability;

- Perfect for structural parts, vehicle chassis, machinery frames;

- Limitations:

- Requires welding equipment;

- Not suitable for non-metallic or heat-sensitive materials;

- Weld nut itself is not reusable (but the bolt is).

- How it works: Press-fit into a sheet metal hole with high force, causing the knurled or grooved body to mechanically interlock with the sheet;

- Advantages:

- Secure and compact installation;

- Threaded hole can be used repeatedly;

- Widely used in enclosures, appliances, telecom housings;

- Limitations:

- Requires access to both sides for installation;

- Needs pressing equipment.

Summary Table: Alternative Options

| Alternative | Reusable | Non-Destructive to Base | Required Tools | Suitable Materials | Ideal Use Cases |

| Nut Clips | ✅ | ✅ | Hand tools | Sheet metal | Cabinets, electrical enclosures, racks |

| Threaded Inserts | ✅ | ✅ | Heat gun, hand tools | Plastic, wood | Furniture, molded parts, electronics |

| Weld Nuts | ❌ (but durable) | ❌ (requires welding) | Welding machine | Metal | Chassis, heavy machinery, structural use |

| Clinch Nuts | ✅ | ✅ | Press machine | Sheet metal | Consumer electronics, appliance housings |

Conclusion: Can Rivet Nuts Be Reused After Removal?

While it is technically possible to remove rivet nuts, they are generally not designed for reuse. Their installation relies on permanent deformation to grip the base material, and once removed, this structure is no longer intact.

- Rivnut reuse poses risks such as reduced holding strength, thread damage, or failure under load.

- Material matters — stainless steel offers slightly better reusability than aluminum, but still not ideal.

- For applications requiring removability and repeat fastening, consider alternatives like cage nuts, threaded inserts, weld nuts, or clinch nuts, which are designed for multiple-use scenarios.

Best practice: Treat rivet nuts as single-use components and use purpose-built alternatives for assemblies that demand maintenance or disassembly.

When Should You Replace Instead of Reuse?

①. Rivet Nut Body Damage or Stripped Threads

During removal, rivet nuts are highly susceptible to fatigue, cracks, or deformation of the metal body;

If the internal threads are stripped, burred, or worn eccentrically, they will no longer provide reliable clamping torque even after reinstallation;

Such issues often lead to fastener loosening or load failure, which is a common cause of reuse-related failures.

②. Deformation or Damage to the Mounting Hole

The holding strength of a rivet nut heavily relies on precise fit with the mounting hole;

If the base material’s hole becomes enlarged, cracked, or loses wall integrity during removal, even a new rivet nut may not ensure proper installation;

In this case, the hole should be repaired first (e.g., welding, reinforcement sleeve) before installing a new rivet nut.

③. Structural Joints with High Load Requirements

If the rivet nut is used in connections subject to high tensile or shear forces (e.g., frame assemblies, chassis mounts, support structures), any reduction in strength due to reuse can seriously compromise structural safety;

Under such conditions, only brand-new, tested rivet nuts should be used to ensure the joint meets design requirements.

④. Applications Involving Critical Safety Components

In industries like aerospace, automotive, railway, elevators, or robotic machinery, rivet nut failure may lead to severe consequences;

These safety-critical applications typically have strict regulations against the reuse of fasteners;

Once removed or found defective, rivet nuts must be replaced with new OEM parts and installed and inspected according to specified standards.

Summary Recommendation

If any of the above conditions are present, do not attempt to reuse an old rivet nut. For long-term safety and performance, timely replacement with new fasteners is essential.

How Can You Extend the Life of Rivet Nuts?

1. Use Proper Installation Tools and Torque Settings

- Use dedicated rivet nut tools: Always select manual or pneumatic tools specifically designed for rivet nut installation to ensure precise and uniform pulling force during installation.

- Avoid over-installation: Excessive torque or stroke may cause the rivet nut to crack or the base material to deform, reducing joint strength and accelerating wear.

- Set torque parameters according to material and size: Different materials and rivet nut sizes require tailored torque settings, especially in automated assembly environments.

2. Perform Regular Fastening Inspections

Rivet nuts under long-term load or in vibrating environments can loosen or experience thread wear;

It is recommended to inspect key fastening points every 3 to 6 months, especially in high-temperature, heavy-load, or vibration-prone settings;

If thread stripping or poor clamping is detected, replace the rivet nut promptly and check for any damage to the mounting hole.

3. Select the Right Material and Structural Type

Choose materials based on environmental conditions:

Steel rivet nuts: Suitable for general structural applications;

Stainless steel rivet nuts: Ideal for humid or corrosive environments;

Aluminum rivet nuts: Best for lightweight materials with limited load requirements.

Choose designs that improve anti-rotation performance:

Hex-shaped rivet nuts prevent spinning in the hole;

Knurled or anti-rotation designs increase stability and load capacity.

4. Use Alternatives for High-Strength Applications

For demanding conditions requiring higher strength or vibration resistance, consider alternative solutions such as:

Weld nuts: Permanently welded to the base material, offering superior tensile and shear performance;

Locking flange nuts: Used with high-strength bolts for enhanced anti-loosening and load-bearing capacity;

For applications requiring frequent disassembly, consider threaded inserts with flanges or retainers, which are designed for reuse.

Do You Have Any Questions?

Let Us Solve Your Problem

Your Trusted Rivet Nut Supplier — Choose Rivetfix Today

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.