Aluminum vs Steel Rivet Nuts: Which is Best for your Project?

Leading Rivet Nut Manufacturer and Supplier in China

When choosing the right fastener for your project, understanding the differences between aluminum vs steel rivet nuts is essential. Each material offers distinct advantages in terms of strength, weight, corrosion resistance, and cost. Selecting the optimal rivet nut can impact the performance and longevity of your structure. In this article, we’ll compare aluminum and steel rivet nuts in detail to help you make the best decision for your specific application.

Table of Contents

What Are Aluminum Rivet Nuts?

Aluminum rivet nuts are threaded fasteners made from aluminum. Specifically, they are designed to be inserted into pre-drilled holes in various materials, thus creating a strong, durable threaded connection.

Furthermore, they are used in applications where a secure fastening is needed without the need for tapping or threading the base material. Once installed, aluminum rivet nuts provide a reliable anchor point for bolts or screws, making them an ideal choice for a wide range of fastening needs.

What Are the Key Characteristics of Aluminum Rivet Nuts?

1. Lightweight Design

One of the key advantages of aluminum rivet nuts in industrial design is their lightweight nature, making them especially suitable for applications with strict overall weight control requirements.

a. Density Comparison Data:

- Aluminum (Al) density: 2.7 g/cm³, approximately 1/3 the weight of steel

- Carbon Steel density: 7.85 g/cm³, baseline 100%

- Stainless Steel (304) density: 7.93 g/cm³, about 101%

For example, an M6 aluminum rivet nut weighs about 2.5 grams, while the same size in carbon steel weighs approximately 7.5 grams.

b. Impact on Equipment:

- Using 100 pieces of M6 rivet nuts in an electrical control device:

- Total weight for aluminum: ~250 grams (0.25 kg)

- Total weight for steel: ~750 grams (0.75 kg)

- Weight saved: 0.5 kg

- In automotive manufacturing, lightweighting many fasteners can significantly reduce vehicle weight:

- Reducing 10 kg vehicle weight improves fuel efficiency by about 0.3 to 0.5 L/100km

- For electric vehicles, weight reduction also helps extend driving range

2. Excellent Corrosion Resistance

Aluminum rivet nuts possess outstanding natural corrosion resistance, thanks to a dense aluminum oxide (Al₂O₃) protective film that quickly forms on the surface when exposed to air. This film effectively isolates moisture, oxygen, and corrosive agents, preventing further corrosion.

a. Oxide Film Protection Mechanism:

- Aluminum surfaces develop a dense oxide layer approximately 2 to 5 microns thick upon air exposure

- This oxide layer is highly stable and self-healing; even if scratched lightly, it reforms rapidly in air

- Therefore, aluminum rivet nuts maintain good condition even in humid or mildly corrosive environments

b. Suitable Environments:

- Indoor electronics, communication devices, light industry products: Can be used without extra corrosion protection

- Outdoor environments: Anodized aluminum rivet nuts are recommended to further enhance corrosion resistance

- Neutral salt spray test standards: Anodized aluminum rivet nuts can withstand 240 to 500 hours of neutral salt spray (NSS) without corrosion

3. Easy Installation and Good Formability

a. Lower Installation Force Required

Aluminum has moderate hardness (Mohs hardness ~2.5–3), softer than steel but still sturdy. Installation force required is significantly lower than for steel rivet nuts. For example, an M6 aluminum rivet nut typically requires around 3000 N installation force, while the steel counterpart may require over 5000 N.

b. Lower Equipment Requirements

Due to the lower installation force, aluminum rivet nuts can be installed with hand tools or small pneumatic rivet nut guns, facilitating fieldwork and small-batch production.

c. Suitable for Thin Materials and Low-Strength Substrates

- Aluminum rivet nuts form stable, firm clamps on thinner substrates, with typical grip ranges from 0.5 mm to 4.0 mm, ideal for aluminum plates, plastic parts, and lightweight metal sheets.

- The lower installation force reduces stress concentration, minimizing substrate deformation or damage and protecting structural integrity.

- Aluminum’s good plasticity ensures uniform expansion of the rivet nut tail, distributing clamping force evenly and enhancing connection stability and durability.

4. Moderate Strength, Suitable for Light to Medium Loads

- Rivet nut Strength (Tensile and shear strength) are lower than steel or stainless steel rivet nuts

- Suitable for applications with lower load demands, such as housings, electronic enclosures, and light brackets

- Not recommended for heavy-duty structures, high vibration, or high-stress environments

5. Excellent Electrical and Thermal Conductivity

a. Good Electrical and Thermal Conductivity

- Aluminum has excellent electrical conductivity, with a standard conductivity of about 3.5×10^7 S/m, approximately 60% that of copper. This makes aluminum rivet nuts ideal for applications requiring electrical grounding or current conduction.

- Aluminum’s thermal conductivity (~205 W/(m·K)) is much higher than typical carbon steel (~50 W/(m·K)), enabling more effective heat transfer and preventing local overheating.

b. Applications Requiring Electrical or Thermal Performance

- Used in electronics, heat sinks, LED lighting, and other fields demanding effective heat management

- Aluminum rivet nuts not only provide mechanical fastening but also aid in rapid heat dissipation, improving system stability and lifespan

- For example, in LED lighting heat sink assemblies, aluminum rivet nuts help transfer heat from the light body to the heat sink, keeping the lamp cool and preventing performance degradation or lifespan reduction due to overheating

6. Moderate Cost and High Cost-Performance Ratio

- Material cost is lower than stainless steel but higher than common carbon steel

- When strength demands are not high, aluminum rivet nuts offer an excellent cost-performance solution

What Are the Main Applications of Aluminum Rivet Nuts?

Aluminum rivet nuts are versatile, offering a cost-effective, lightweight, and corrosion-resistant solution across various industries. From aerospace and automotive to marine and electronics, their ability to create strong, secure threaded connections in thin or lightweight materials makes them ideal for a wide range of applications.

a. Aerospace

Help reduce weight without sacrificing strength. They are used in the assembly of aircraft parts, especially in non-structural components like interior panels, trim, and other lightweight parts. Aluminum’s light weight is critical in reducing overall aircraft weight, leading to fuel savings and improved performance.

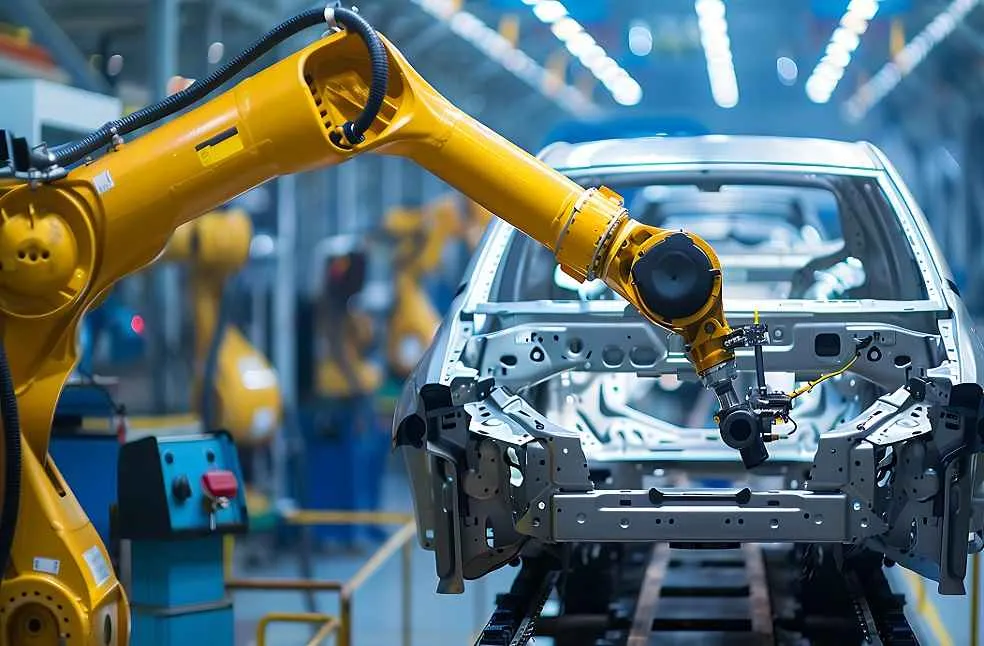

b. Automotive

Secure parts such as body panels, trim pieces, and interior fittings. Their corrosion resistance is ideal for automotive applications exposed to the elements. They help reduce the overall weight of vehicles, which contributes to better fuel efficiency and performance.

c. Electronics

In the assembly of electronics such as computers, smartphones, and audio equipment. Their ability to create secure threaded connections in lightweight plastic or metal enclosures makes them essential for these applications. They are also used to mount components like circuit boards or external attachments to electronic housings.

d. Marine

Their resistance to corrosion from saltwater is critical. Boat hulls, decks, and marine equipment often use them given aluminum’s natural resistance to corrosion.

e. Furniture and Appliances

They are found in products like refrigerators, washing machines, and ovens, where they are used to fasten internal components and secure housing panels. They allow for easy assembly and disassembly, which is crucial for items that need to be transported or adjusted.

f. Sports Equipment

For bicycles, sports equipment, and outdoor gear where lightweight and corrosion resistance are crucial. They help fasten parts such as frames, seats, and handlebars securely. Aluminum rivet nuts also ideal for sporting goods that need to withstand outdoor conditions, such as camping equipment, tents, and hiking gear.

Do You Have Any Questions?

Let Us Solve Your Problem

Steel rivet nuts are threaded fasteners create a strong, durable threaded connection, allowing bolts or screws to be securely fastened into materials that may not have their own threads.

Applications that require higher strength and durability typically use steel rivet nuts instead of aluminum or plastic fasteners.

Why Are Steel Rivet Nuts So Popular?

1. Lightweight Design

Steel rivet nuts offer exceptional mechanical strength, with tensile strength reaching 22,000–30,000 N (approximately 2200–3000 kgf) and shear strength ranging from 16,000–22,000 N. This is significantly higher than aluminum rivet nuts (typically 6000–12000 N), allowing them to withstand large axial and lateral loads—ideal for high-strength structural applications.

Commonly used in automotive chassis and suspension systems;

Structural fastening in construction machinery and rail equipment;

Heavy-duty industrial equipment, support frames, and steel structures.

In these applications, aluminum or plastic rivet nuts often fall short in terms of strength, while steel rivet nuts provide the necessary load-bearing capacity and durability.

2. Broad Applicability

Steel rivet nuts can be installed in:

Base materials from 0.5–6.0 mm thick, including steel, stainless steel, and aluminum sheets;

Closed profiles and tubular structures, where access is only available from one side;

High-load, high-temperature, and high-humidity environments (operational range from -40°C to 150°C).

Typical application areas:

Thin metal sheets (steel, stainless steel, aluminum, etc.);

Blind hole installations in tubing, profiles, or enclosed components;

Indoor equipment as well as large-scale outdoor installations—even in humid or corrosive environments (when surface-treated).

Compared to some materials (like aluminum), which may not suit hard base materials, steel rivet nuts are compatible with nearly all industrial scenarios.

3. Diverse Structural Designs

Steel rivet nuts are available in a wide range of structural designs, tailored for various complex use cases:

Hex body rivet nuts: Designed for hexagonal holes, offering outstanding anti-rotation strength. M8 models can reach torque resistance of 35–60 Nm, ideal for high-vibration environments.

Knurled body rivet nuts: Surface knurling increases friction by over 30%, effectively preventing rotation.

Closed-end rivet nuts: Provide water-tight sealing, suitable for electrical and outdoor applications.

Countersunk head rivet nuts: Sit flush with panel surfaces, improving both safety and appearance.

Extended grip range types: Designed for thick panels (grip range can exceed 10 mm).

4. Corrosion Resistance via Versatile Surface Treatments

Though carbon steel is inherently prone to rust, steel rivet nuts often undergo various surface treatments to enhance corrosion resistance. These treatments can be selected based on the application environment to ensure stability in humid, salty, or corrosive conditions.

Zinc Plating

Dacromet Coating

Nickel Plating, Phosphating, Black Oxide, etc.

| Surface Treatment Type | NSS (Neutral Salt Spray) Corrosion Resistance |

| Zinc Plating | 72–120 hours |

| Dacromet Coating | ≥ 500 hours |

| Nickel Plating | ≥ 96 hours |

5. Reasonable Cost

- Compared to stainless steel rivet nuts, steel rivet nuts are more cost-effective, while offering similar performance.

- Though heavier than aluminum rivet nuts, they outperform them in load capacity and impact resistance.

- This balance of cost and performance makes steel rivet nuts the default choice for most industrial users.

6. Mature Installation Methods

Steel rivet nuts are compatible with a wide variety of tools:

- Manual rivet nut tools: Affordable (approx. 300–500 CNY), ideal for maintenance work;

Pneumatic or electric rivet nut guns: Common on assembly lines for efficient, large-scale installation;

For larger sizes (M10/M12), hydraulic tools can be used, with pull force up to 8000–12000 N, ensuring proper installation.

What Are the Main Applications of Steel Rivet Nuts?

Steel rivet nuts are versatile fasteners commonly used in applications requiring moderate to high strength and durability.

In particular, their excellent tensile and shear strength, combined with their resistance to deformation, make them ideal for various industries and applications. Moreover, with proper material coatings or treatments, such as zinc plating, steel rivet nuts can also resist corrosion, further expanding their application potential.

a. Automotive

Automotive sector for assembling body panels, chassis components, and interior structures. Their high strength ensures reliable performance under heavy loads and continuous vibrations.

b. Industrial Equipment

Construction of heavy machinery, conveyor systems, and manufacturing equipment. They create secure anchor points in sheet metal, allowing for the attachment of parts that endure heavy loads or vibrations.

c. Construction Industry

Assemble facades, panels, and modular structures in the construction industry. Their strength and resistance to wear make them ideal for both indoor and outdoor applications.

d. Electronics and Appliances

Home appliances, electronic enclosures, and casings to securely attach components. Their strength and durability ensure the longevity of assemblies in high-use environments.

e. Railway and Transportation

Fasten components in trains, buses, and transport systems. Ensuring secure and vibration-resistant connections in dynamic environments. Their strength ensures that the components remain securely fastened during high-speed travel and under the stresses of continuous operation.

f. Agricultural and Heavy-Duty Equipment

Assembling agricultural machinery and heavy-duty equipment that operate under high stress, vibrations, and harsh environmental conditions. The high strength ensures that parts stay secure under the heavy load and vibration typical of agricultural operations.

Do You Have Any Questions?

Let Us Solve Your Problem

What's the Difference - Aluminum vs Steel Rivet Nuts

| Feature | Aluminum Rivet Nuts | Steel Rivet Nuts |

| Material Strength | Moderate strength, suitable for light to medium load applications | High strength, ideal for heavy-duty and high-stress applications |

| Weight | Lightweight, reduces overall assembly weight | Heavier, increases the weight of the assembly |

| Corrosion Resistance | Naturally corrosion-resistant, suitable for mild environments | Excellent if stainless; carbon steel needs coatings for corrosion protection |

| Durability | Less durable, prone to wear under heavy load | Very durable and long-lasting, suitable for harsh environments |

| Cost | Generally more affordable | Typically more expensive, especially stainless steel versions |

| Vibration Resistance | Adequate for light-duty applications | Excellent vibration resistance, ideal for high-vibration scenarios |

| Temperature Resistance | Limited temperature resistance | Better resistance to high temperatures, especially with alloy steels |

①. Weight Comparison

Aluminum rivet nuts: are lightweight, making them suitable for applications where reducing weight is a key factor.

Steel rivet nuts: are heavier compared to aluminum. While the increased weight can be a disadvantage in applications where reducing mass is a priority, the additional weight often correlates with higher strength and durability, which makes them ideal for high-stress and heavy-duty applications.

②. Vibration Comparison

Aluminum rivet nuts: can handle some level of vibration. However, they are not as durable as steel rivet nuts when subjected to continuous or high-intensity vibrations. In cases where vibration is not a primary concern or in lighter-duty applications, aluminum rivet nuts can perform adequately.

Steel rivet nuts: offer excellent vibration resistance, making them more suitable for high-vibration environments, such as in automotive, aerospace, and industrial machinery.

③. Temperature Comparison

- Aluminum rivet nuts: are suitable for moderate temperatures (up to 150-200°C). Beyond this range, aluminum may lose strength, and the material could become more prone to deformation or failure.

- Steel rivet nuts: offer superior high-temperature resistance (up to 500°C), depending on the steel type and any protective coatings. They are ideal for demanding, heat-intensive environments.

Aluminum vs Steel Rivet Nuts – Conclusion

- Aluminum rivet nuts are ideal for lightweight applications, cost-effective solutions, and moderate strength requirements.

- Steel rivet nuts are best for high-strength, heavy-duty applications where durability, corrosion resistance, and vibration resistance are critical.

Aluminum vs Steel Rivet Nuts: How to Decide for Your Specific Project Needs

a. Choose Steel Rivet Nuts

If your project requires high strength, vibration resistance, or high-temperature tolerance, steel rivet nuts are the better choice. They also offer excellent corrosion resistance. Steel rivet nuts are ideal for heavy-duty or industrial applications where durability is critical.

b. Choose Aluminum Rivet Nuts

For lightweight applications and cost-effective solutions, aluminum rivet nuts are ideal. They meet moderate strength requirements and offer good corrosion resistance. They are also a good choice when aesthetic appearance is important, but extreme durability is not needed.

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.