How Do You Get Rid of Loose Rivnuts?

Leading Rivet Nut Manufacturer and Supplier in China

Loose rivnuts can compromise structural integrity, create safety concerns, and lead to costly repairs if not handled properly. If you’ve encountered a rivet nut that spins, falls out, or no longer holds securely, you’re not alone. In this guide, we’ll answer the critical question: how do you get rid of loose rivnuts safely and effectively? From identifying early signs of failure to removal techniques and long-term reinforcement methods, we’ll walk you through practical solutions for restoring a secure and reliable connection.

Table of Contents

What Are Loose Rivnuts and How Do They Behave?

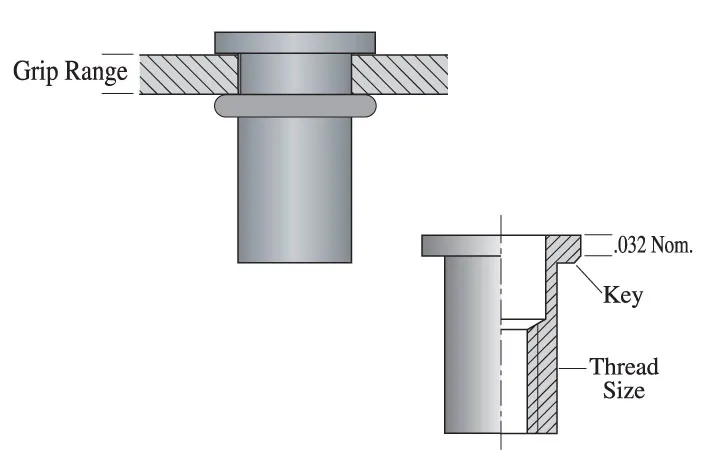

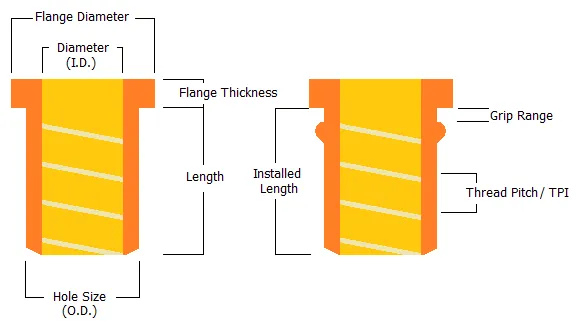

Rivnuts are fasteners designed to be securely anchored into base materials through plastic deformation of their rear section. During installation, a specialized tool applies a pulling force to the tail of the rivnut, causing it to expand and form a tight mechanical lock with the base material. This process creates a strong, reliable threaded connection.

Loose rivnuts refer to situations where this fastening integrity is compromised. They typically exhibit the following symptoms:

- Stripped or rotating threads: The internal threads of the rivnut may become damaged due to uneven force or material fatigue, resulting in slippage that prevents proper bolt retention.

- The entire rivnut spins or slips in the base material: If the rivnut is not firmly embedded in the mounting hole, it may rotate or shift under torque, losing its fastening function.

- Loss of clamping force after installation: In cases of insufficient deformation, oversized holes, or material fatigue, the rivnut loses its grip on the base material. This weakens the connection and can cause the attached component to loosen or fall off.

Such looseness not only compromises the structural integrity of assemblies but can also lead to increased maintenance difficulty and cost. Therefore, recognizing the signs and root causes of loose rivnuts is essential for effective prevention and repair.

What Causes Rivnuts to Become Loose?

①. Oversized or Out-of-Tolerance Holes

The hole size is critical for ensuring a secure rivnut connection. If the hole exceeds the allowed tolerance, it creates excessive clearance between the rivnut and the base material, reducing mechanical interlock and increasing the risk of loosening or detachment.

For example, a standard M6 rivnut typically requires a hole diameter of 6.00 mm, with a tolerance of +0.05 mm / -0.00 mm (i.e., 6.00–6.05 mm). A hole over 6.10 mm may prevent proper expansion and contact, weakening the joint.

Test data shows that a 0.1 mm oversize in hole diameter can reduce the rivnut’s resistance to torque by more than 20%, significantly compromising clamping strength. This results in slippage or spinning under load, leading to joint failure.

Additionally, out-of-spec holes can complicate installation and increase labor costs due to rework or rejection. Maintaining tight control of hole diameter during manufacturing and assembly is essential for a secure rivnut joint.

②. Insufficient Rivnut Expansion

Inadequate deformation of the rivnut’s tail section results in insufficient clamping force. Ideally, the pulling force during installation should reach 80%–100% of the rated value. If the force is below 50%, clamping strength may drop by 40%–60%, making the connection unreliable. Common causes include manual tools or incorrectly set pneumatic guns.

③. Improper Installation Angle

If the rivnut is installed at an angle exceeding 2° from vertical, the deformation becomes uneven, causing stress concentration and reducing joint strength by over 30%. This can lead to cracking or loosening. Vertical alignment during installation is crucial for uniform expansion and a strong hold.

④. Prolonged Vibration or Repeated Disassembly

Although rivnuts offer solid holding strength, long-term vibration or frequent assembly/disassembly can lead to loosening or failure.

a. Vibration Effects

In automotive, rail, and industrial machinery applications, rivnuts are often exposed to continuous vibration. This can cause:

- Reduced friction between the rivnut and the base material;

- Micromovements that gradually degrade the seating stability;

- Loss of clamping force and eventual spinning or loosening.

Example: In a fatigue test simulating 1 million vibration cycles, standard round-body rivnuts without anti-rotation features lost over 30% of their clamping force by 500,000 cycles. In contrast, rivnuts with locking features retained over 90%.

b. Repeated Disassembly

Products like electronics and appliances often require maintenance involving repeated removal of screws. This can result in:

- Thread wear and slippage;

- Micro-deformation of the rivnut over time;

- Loosening of the contact between the rivnut and base material.

Tests show that standard rivnuts typically withstand 3–5 reassemblies before showing signs of degradation. For higher durability, use 316 stainless steel or rivnuts with anti-fatigue designs.

⑤. Base Material Too Soft or Too Thin

Rivnuts work by plastically deforming to clamp the base material. If the base material is too soft or too thin, the joint’s strength and reliability are compromised.

1. Soft Base Materials (e.g., plastic, wood, thin aluminum)

These materials may deform or compress under load, resulting in:

- Weak clamping, leading to loosening;

- Distortion under axial or torque loads, causing spin-out or detachment;

- Cracking or bulging during installation, weakening structural integrity.

Example: When an aluminum rivnut is installed into a 3 mm ABS plastic sheet, it starts spinning after only 3 screw cycles at 5 N·m torque.

Solutions:

- Use large flange, knurled, or hex-body rivnuts;

- Embed a metal backing plate or washer to strengthen the support;

- Consider threaded inserts (e.g., heat-set or expansion inserts) for plastic or wood.

2. Thin Base Materials (<0.8 mm metal)

If the base material is thinner than the rivnut’s deformation zone, it cannot form a secure clamp:

- The rivnut may sink or fail to grip;

- Clamping force is inadequate;

- The panel may crack or warp under load.

Example: Installing a rivnut rated for 0.5–3.0 mm in a 0.3 mm stainless steel panel often results in failure due to incomplete expansion. Read the blog “how thick of steel can you use a rivet nut“.

Solutions:

- Match the rivnut’s grip range with material thickness;

- Add reinforcement plates;

- For ultra-thin materials, consider weld nuts or self-piercing rivets.

Summary Table:

| Problem | Risk | Suggested Solution |

| Material too soft | Poor bite, spin-out | Use hex/knurled rivnuts, metal reinforcement |

| Material too thin | Inadequate grip, tearing | Select correct grip range, add thickness or switch method |

Always evaluate both hardness and thickness of the base material to ensure compatibility with the rivnut design.

⑥. Lack of Anti-Rotation Features (e.g., Hex or Knurled Bodies)

Anti-rotation resistance is critical in rivnut applications. If the rivnut rotates when the bolt is torqued or removed, it compromises the entire joint.

Smooth cylindrical rivnuts rely solely on friction for fixation. When used in smooth metal or soft materials:

- They lack mechanical locking;

- Slight loss in clamping can lead to spinning;

- They’re especially prone to failure in high-torque or repeat-use environments.

b. Anti-Rotation Design Options

To improve rotational resistance, use rivnuts with:

- Hex Bodies: Installed into hexagonal holes for mechanical interlock. Can withstand torques of 10 N·m or more;

- Knurled Bodies: Feature ridges or grooves that bite into the base material, improving friction. Boost anti-rotation by 50%–100%;

- Splined/Toothed Bodies: Serrated profiles embed into the surface for added grip;

- Threadlockers or adhesives: Used with standard designs to improve long-term hold.

c. Comparison of Anti-Rotation Performance

| Rivnut Type | Hole Shape | Torque Resistance (N·m) | Recommended Use |

| Smooth round | Round | 3–5 | Low-load conditions |

| Knurled | Round | 5–8 | Medium-load or soft materials |

| Hex | Hexagonal | 10–20+ | High-load or anti-rotation critical |

Final Recommendations:

- Avoid using rivnuts without anti-rotation features in vibration-prone or high-torque environments;

- Prioritize hex or knurled types for secure, long-lasting joints;

- Match rivnut design with application demands—Hex > Knurled > Smooth in terms of performance.

How Do You Get Rid of Loose Rivnuts?

1. Destructive Removal with a Drill

This is the most common method, suitable for most failed or loosened rivet nuts that can no longer provide effective clamping:

Procedure:

Choose a drill bit slightly larger than the internal thread diameter of the rivet nut (e.g., use a 6.5–7 mm drill bit for an M6 rivet nut);

Drill vertically through the center of the rivet nut, destroying the internal threads and deformed back section to compromise its structure;

The rivet nut will loosen as the structure collapses, or you can tap it out gently with a small hammer.

Applicable For:

Carbon steel and aluminum rivet nuts;

Stainless steel rivet nuts can also be removed this way, but due to higher strength, the process is slower and more prone to bit slipping.

Precautions:

- Always wear safety glasses and gloves during the operation;

- Control the drilling depth and angle carefully to avoid penetrating the base material;

- For thin or soft materials, place a steel backing plate behind to prevent distortion.

2. Use of Cutting Tools (e.g., Mini Grinder or Saw Blade)

When the rivet nut protrudes from the surface or drilling is not feasible, cutting tools can be used to detach it:

Procedure:

Use a mini angle grinder, saw blade, or electric saw to make a flush cut along the surface of the rivet nut;

After removing the protruding section, use a screwdriver to pry out or push out the remaining part from behind.

Applicable For:

Rivet nuts with clearly exposed flanges;

Ideal for confined spaces or base materials not suitable for drilling.

Precautions:

- Cutting generates high heat and sparks—keep away from flammable materials;

- Apply protective tape around the base material to avoid surface scratches;

- Not recommended for plastic or composite substrates due to risk of melting or burning.

3. Use of Specialized Removal Tools

Some fastening systems or tool brands offer dedicated reverse-pulling tools for non-destructive rivnut removal:

Procedure:

Insert a reverse-torque tool into the rivet nut;

Using reverse threading and support sleeves, gradually extract the rivet nut;

The hole remains undamaged and can be reused for a new rivet nut.

Applicable For:

Rivet nuts that are loose but not spinning or that haven’t damaged the hole;

Ideal for high-end equipment or sheet metal products where the base material must be preserved.

Precautions:

Higher cost—not suitable for quick fixes or one-off repairs;

Tool size must match the rivet nut specification to avoid slippage or failure;

Suitable for professional maintenance, OEM after-sales service, or high-volume repair scenarios.

Summary: How Do You Get Rid of Loose Rivnuts?

For severely loose or damaged rivet nuts, drilling is the most efficient removal method;

For rivet nuts with exposed flanges, cutting tools are a practical choice;

If you want to preserve the hole and maintain a clean appearance, opt for specialized removal tools;

Always follow proper safety measures to avoid damaging the base material during removal.

How to Repair and Reinforce Rivnut Holes?

a. When the Hole Is Damaged or Enlarged

If the original hole has become oversized due to repeated removal, improper installation, or rivnut loosening—making standard rivet nuts no longer secure—you can repair it using the following methods:

Metal Sleeves (Inserts): Insert a stainless steel or brass sleeve of appropriate size into the damaged hole to restore it to standard diameter. The inner bore should match the original rivnut tolerance, allowing standard rivet nuts to be installed again.

Weld and Redrill: For steel structures, you can fill the damaged hole via spot welding, then redrill to the correct size. This method requires welding experience to avoid damaging the surrounding area through heat distortion.

- Epoxy Filling and Redrilling: In aluminum or non-metal substrates, use a high-strength metal repair adhesive (e.g., AB epoxy) to fill the damaged hole. Once fully cured, drill a new hole at the correct location. This is suitable for low-load or temporary repair scenarios.

Regardless of the repair method, ensure that the repaired hole wall is strong enough to prevent loosening or pull-out during the next installation.

b. When the Hole Is Only Slightly Deformed

If the hole has only slightly enlarged and the structure is otherwise intact, you can strengthen the grip by replacing the rivnut with a type that offers a larger contact area or outer diameter:

Large Flange Rivet Nuts: These have a wider flange that covers a larger hole area, distributes stress more evenly, and improves installation stability.

Oversized Body Versions: Some manufacturers offer rivet nuts with an enlarged body (e.g., M6 rivet nut suitable for a 10.5 mm hole), which fit loosely expanded or slightly off-tolerance holes better, enhancing friction and grip strength.

This method is simple and effective, especially for quick field repairs or replacements.

c. For Soft Materials

In substrates like plastic sheets, aluminum panels, or plywood, standard rivet nuts may loosen or spin due to soft material properties or load-induced forces. Use reinforced designs to improve performance:

Hexagonal Hole + Hex Rivet Nut: Hex holes provide a mechanical locking mechanism that prevents spinning, offering much better anti-rotation performance than round holes.

Add Reinforcement Washers: Place a large washer (preferably stainless steel) between the rivet nut flange and the base material to distribute load, prevent surface damage, and improve structural support.

Use Serrated or Lock Washers: These improve anti-rotation and anti-loosening performance, especially useful in applications with vibration.

It’s recommended to assess the base material’s hardness at the design stage and choose a more robust fastening solution accordingly.

Conclusion – How to Remove and Prevent Loose Rivnuts

Loose rivet nuts are a common issue, but they often indicate deeper problems related to installation precision, product selection, and material compatibility. To ensure long-term structural reliability, users should address the issue from multiple angles:

a. Identify Early Signs of Loosening

Thread slippage or bolts that no longer tighten properly;

The rivnut spins along with the bolt or can be easily pulled out of the base material;

Looseness, rattling, or other abnormal movement between connected parts.

These are early warnings of insufficient clamping force, hole mismatch, or structural fatigue. Early intervention is strongly recommended.

b. Remove Loose Rivnuts with the Right Method

Use drilling, cutting, or specialized tools for destructive removal;

Avoid further damaging the base material during removal—use protective measures;

For delicate or thin substrates, non-destructive removal methods should be prioritized.

c. Repair Damaged Holes and Reinforce with Suitable Solutions

For minor damage, large flange or oversized rivet nuts may restore secure clamping;

For severely damaged holes, consider metal sleeves, welding, or epoxy repair to restore hole integrity;

In soft materials or high-vibration environments, hex body rivet nuts with anti-rotation features plus washers or locking devices can significantly improve performance.

d. Installation Quality Determines Lifespan

In practice, over 90% of rivnut failures are caused by improper installation, such as:

Incorrect hole size or excessive tolerance;

Inadequate or inconsistent installation force;

Misaligned installation angle.

To avoid these issues, always use the correct tools, ensure precise control over hole dimensions and pull force, and select anti-loosening designs for critical structural applications.

e. Post-Installation Maintenance Matters

For assemblies subject to frequent use, high vibration, or heavy load, it is recommended to:

Inspect joints periodically for signs of loosening;

Use reusable or replaceable fastening solutions in high-frequency disassembly areas;

Treat rivet nuts as maintainable components and replace worn-out ones as part of regular maintenance.

Do You Have Any Questions?

Let Us Solve Your Problem

Why Choose Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.