Are Jack Nuts Strong?

Leading Rivet Nut Manufacturer and Supplier in China

Wondering are Jack nuts strong enough for your projects? These versatile fasteners are ideal for thin sheets and soft materials, but their strength can vary depending on the material and installation method. In this blog, we’ll explore how strong Jack Nuts really are and when they’re the best solution for your fastening needs.

Table of Contents

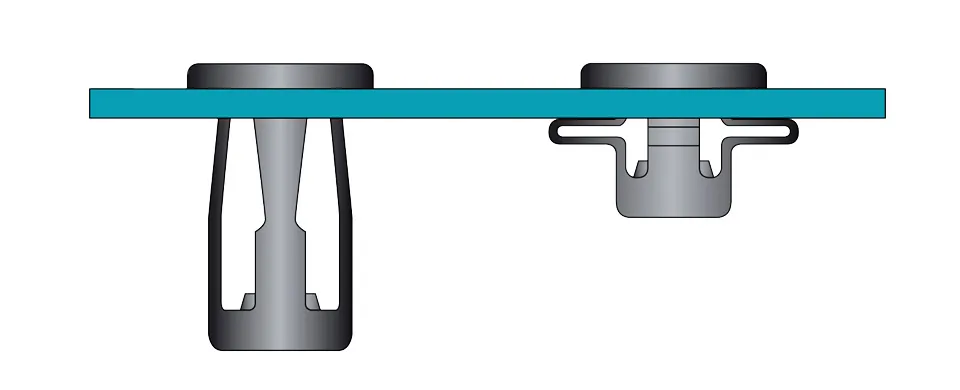

Jack Nuts are special fasteners designed for soft or thin materials. Their structure is similar to that of rivet nuts but with a different installation method. A Jack Nut consists of a metal sleeve with an internal thread and four expandable wings. During installation, the wings expand on the backside of the material, creating a stable clamping force that secures the threaded connection firmly.

The key feature of Jack Nuts is that they work well with soft or thin materials, such as thin metal sheets, plastics, composites, and drywall. They are particularly effective when there is no direct support available on the backside. Common applicable materials include:

- Metal Sheets (Aluminum, Steel, Stainless Steel, etc.): Used in automotive, machinery, and sheet metal applications, Jack Nuts provide stable threaded fastening.

- Plastic Materials (ABS, Polycarbonate, PVC, etc.): Commonly used in electronic device housings and home appliance casings.

- Composite Materials (Fiberglass, Carbon Fiber, etc.): Ideal for aerospace, sports equipment, and other lightweight yet strong connection applications.

- Drywall and Wood Panels: Used in interior decor and furniture assembly, especially when traditional wood screws are not feasible.

Advantages and Disadvantages of Jack Nuts

Advantages:

- Suitable for Soft and Thin Materials: Jack Nuts provide a secure threaded connection in materials such as plastic, wood, composites, and thin metals.

- Easy Installation: No need for tapping or complex pre-treatment; they can be installed using simple hand or pneumatic tools.

- No Backside Support Required: Unlike standard nuts, which require access to the backside of the material, Jack Nuts secure themselves by expanding.

- Ideal for Tight Spaces: Useful in applications where access to the backside is limited or where traditional nuts cannot be used.

Disadvantages:

- Limited Strength: Compared to rivet nuts, Jack Nuts have lower pull-out resistance and are not suitable for high-load or high-vibration environments.

- Not Suitable for Thick Materials: If the material is too thick, the Jack Nut’s expansion wings may not fully deploy, reducing its holding power.

- Tool Requirements: While manual installation is possible, achieving optimal fastening often requires specialized tools or pneumatic equipment.

Are Jack Nuts Strong?

1. Strength Characteristics of Jack Nuts

A Jack Nut consists of a metal sleeve with internal threads and four expandable wings. During installation, the wings expand on the backside of the material, creating a clamping force to secure the threads. However, this clamping force largely depends on the material’s own strength, which is why Jack Nuts perform well on soft materials but may not be ideal for high-strength applications.

Pull-out and Torque Resistance of Jack Nuts

- Pull-out Strength: The expansion wings of the Jack Nut are limited by the material’s strength. Under high pull-out force (axial load), the Jack Nut may loosen or fail.

- Torque Resistance: Since the Jack Nut primarily relies on the expansion wings to hold the material, its torque resistance is relatively low. Over-tightening the screws could cause the nut to loosen or fail.

- Vibration Resistance: Jack Nuts do not perform well in vibration-prone environments. Prolonged exposure to vibration may cause loosening, making them unsuitable for high-vibration applications (such as engine compartments and machinery structures).

| Fastener Type | Suitable Materials | Installation Method | Pull-out Strength | Torque Resistance | Vibration Resistance |

| Jack Nut | Thin metals, plastics, composites | Requires specialized tools for expansion | Low (depends on material strength) | Low (affected by expansion wings) | Moderate (prone to loosening) |

| Rivet Nut | Thin metals, plastics | Requires riveting tools | High (tightly bonded with material) | High (stable threads) | Good (suitable for vibration environments) |

| Weld Nut | Steel, stainless steel | Requires welding | Very High (directly welded for maximum strength) | Very High (cannot loosen) | Very High (suitable for high-vibration environments) |

| Self-clinching Nut | Metal sheets (thicker materials) | Stamping installation | High (tight integration with material) | High (stable threads) | Excellent (widely used in metal structures) |

3. Which Fastener Is Best for Your Needs?

- Suitable for soft materials (plastics, composites, drywall, etc.) where traditional nuts cannot be used.

- No backside support required, ideal for tight spaces.

- Light loads, mainly for decorative applications, light machinery, and electronic device housings.

If higher strength is required, consider:

- Rivet Nuts: Ideal for stronger thin metal sheets, providing higher pull-out strength and torque resistance.

- Weld Nuts: Best for high-strength structures, such as automotive chassis and building steel structures.

- Self-clinching Nuts: Suitable for electronic devices and enclosures, offering stable threaded connections.

How Strong Are Jack Nuts?

Jack nuts are specialized fasteners used for thin metals, plastics, and composite materials, particularly in situations where thread tapping is not possible. But how strong are they? Can they withstand high loads? This article will explore the strength performance of Jack Nuts in terms of load-bearing capacity, applicable environments, and material influences, using experimental data and industry standards.

1. Load-Bearing Capacity

Jack Nuts primarily rely on expansion wings that spread behind the material to provide clamping force, so their strength depends on:

- Material thickness

- Jack Nut material (steel, stainless steel, aluminum, etc.)

- Correct installation

Pull-out Strength

Pull-out strength refers to the maximum resistance Jack Nuts can provide when subjected to axial pull force. The following are experimental data for Jack Nuts of different materials on 1.0mm thick steel plates (in Newtons, N):

| Material | M4 | M5 | M6 | M8 | M10 |

| Carbon Steel | 1200N | 1600N | 2000N | 2800N | 3500N |

| Stainless Steel | 1400N | 1800N | 2300N | 3100N | 4000N |

| Aluminum | 800N | 1100N | 1500N | 2100N | 2700N |

Stainless steel Jack Nuts have the highest pull-out strength, making them suitable for applications that require higher strength. Aluminum Jack Nuts, on the other hand, have lower strength and are more suited for light-load applications like electronic device housings or furniture.

Shear Strength

Shear strength refers to the limit of a Jack Nut’s resistance to lateral forces (such as side impact or pressure). The following are experimental data for different Jack Nut materials on 1.0mm thick steel plates (in Newtons, N):

| Material | M4 | M5 | M6 | M8 | M10 |

| Carbon Steel | 1000N | 1400N | 1900N | 2600N | 3200N |

| Stainless Steel | 1200N | 1600N | 2100N | 2900N | 3700N |

| Aluminum | 700N | 1000N | 1300N | 1900N | 2500N |

Shear strength trends align with pull-out strength, with stainless steel Jack Nuts performing the best, while aluminum may deform or fracture under high loads.

2. Applicable Environments

The strength of Jack Nuts depends not only on the material but also on the environment in which they are used. How do they perform in high humidity, high vibration, and outdoor environments?

High Humidity Environments (e.g., Marine, Food Processing)

- Carbon Steel Jack Nuts: Prone to rusting, and their strength decreases with prolonged use in moist environments.

- Stainless Steel Jack Nuts: Highly corrosion-resistant and suitable for humid environments or food processing equipment.

- Aluminum Jack Nuts: Moderate corrosion resistance, but may oxidize if exposed to moisture for extended periods.

Stainless steel Jack Nuts are better suited for humid or corrosive environments.

High Vibration Environments (e.g., Automotive, Machinery)

- Expansion wings of Jack Nuts may loosen under prolonged vibration, causing the connection to fail.

- Solution:

- Add locking devices (e.g., locknuts or thread adhesives)

- Switch to rivet nuts, as they form a more secure connection with the material

Jack Nuts are not suitable for high vibration environments, and rivet nuts or weld nuts are recommended instead.

Outdoor Environments (e.g., Construction, Outdoor Equipment)

- Carbon Steel Jack Nuts: Not corrosion-resistant and have a short lifespan in outdoor use.

- Aluminum Jack Nuts: Better corrosion resistance, but relatively lower strength.

- Stainless Steel Jack Nuts: The best option for withstanding wind, rain, and corrosion, maintaining stable mechanical properties over time.

Stainless steel Jack Nuts are ideal for outdoor environments, while carbon steel Jack Nuts are not recommended for long-term outdoor use.

3. Material Influence

Common materials for Jack Nuts include carbon steel, stainless steel, and aluminum, each with varying strength, corrosion resistance, and suitability for different applications.

| Material | Pull-out Strength | Shear Strength | Corrosion Resistance | Applicable Environments |

| Carbon Steel | High | High | Low | Dry environments, machinery |

| Stainless Steel | Highest | Highest | Highest | High humidity, outdoor, food industry |

| Aluminum | Low | Low | Moderate | Light-load applications, electronics, furniture |

For higher strength, stainless steel Jack Nuts are recommended; carbon steel Jack Nuts are cost-effective for general applications, while aluminum Jack Nuts are suitable for light-load and corrosion-resistant needs.

4. Conclusion: How Strong Are Jack Nuts?

Jack Nuts perform well in light-duty assembly and soft material fastening but are less strong than rivet nuts or weld nuts in high-load and high-vibration environments.

Applicable Scenarios:

- Suitable for light metal plates, plastics, composites, and other soft materials.

- Ideal for electronic devices, automotive interiors, furniture, and other low-load applications.

- Not recommended for high-load, high-vibration, or thick metal plate applications.

Strength Influencing Factors:

- Stainless steel Jack Nuts provide the best strength and corrosion resistance, suitable for high-demand environments.

- Carbon steel Jack Nuts offer higher strength but poor corrosion resistance, ideal for dry environments.

- Aluminum Jack Nuts have the lowest strength, suitable for light-load and corrosion-resistant applications.

If your application requires higher strength (e.g., machinery, automotive chassis), consider switching to rivet nuts, weld nuts, or self-clinching nuts for more stable fastening results.

Do You Have Any Questions?

Let Us Solve Your Problem

What Applications Are Jack Nuts Suitable For?

Jack nuts, due to their easy installation and suitability for thin sheets and soft materials, are widely used in various industries. Below are common applications for Jack Nuts and their advantages:

1. Automotive Industry

Application Areas:

- Door Linings: Used to secure interior panels and door assemblies

- Dashboard Brackets: Provide firm threaded connections on thin metal plates

- Body Accessories: Such as vent pipes, sensor brackets, bumper attachment points, etc.

Why Use Jack Nuts?

- Suitable for thin metal sheets, providing stable threaded connections without welding

- Can be used in hard-to-reach areas, allowing installation in enclosed cavities

- Reduces vehicle weight, being lighter compared to traditional welding or bolt connections

2. Electronic Devices

Application Areas:

- Plastic Enclosure Fixing: Such as laptop cases, server racks, power supply enclosures, etc.

- Lightweight Metal Frame Connections: Such as LED displays, industrial control panels, etc.

Why Use Jack Nuts?

- Suitable for plastic and lightweight metals, preventing material damage

- No need for tapping, providing internal threaded connections directly

- Ideal for small space installations, easy to use in precision electronic devices

3. Furniture Assembly

Application Areas:

- Wood and Composite Board Fixing: Such as cabinets, tables, chairs, bookshelves, etc.

- Soft Material Connections: Such as plastic furniture or laminated board structures

Why Use Jack Nuts?

- Prevents wood from cracking, more stable than traditional self-tapping screws. In some Hydraulic Pump systems, the jack nut appears as a safety lock or mechanical limiting structure, which is an additional mechanical protection component.

- Removable, making it easier to maintain and replace parts of furniture

- Easy to install, no special tools required for fixation

4. Construction

Application Areas:

- Lightweight Bracket Installation: Such as air conditioning brackets, lighting brackets, etc.

- Pipe Fixing: Installing pipe clamps on walls or metal frameworks

- Soundproof and Decorative Panel Installation: Used for fixing wall panels, ceiling structures

Why Use Jack Nuts?

- Suitable for thin-wall materials, such as metal sheets, gypsum boards, plastic wall panels

- Forms a strong threaded point after installation, supporting repeated disassembly and reassembly

- Saves construction time, faster compared to traditional expansion bolts

How to Improve the Installation Strength of Jack Nuts?

Jack nuts are primarily used for threaded connections in thin sheets and soft materials, but improper installation methods or material selection can lead to loosening of the nut or insufficient load-bearing capacity. To improve the installation strength of Jack Nuts, the following optimizations can be made:

1. Correctly Choose the Jack Nut Specifications

Before installing the Jack Nut, ensure the specifications match the application scenario to avoid poor fastening or premature failure due to inappropriate selection.

- M4, M5, M6: Suitable for light structures, such as electronic devices and plastic housing fixation

- M8, M10: Suitable for furniture, light mechanical brackets, and applications with slightly higher strength requirements

- M12 and above: Suitable for larger load-bearing applications, such as building bracket fixation

(2) Choose the Right Material

The material of the Jack Nut directly affects its strength. Select according to the application requirements:

| Material | Features | Applicable Scenarios |

| Carbon Steel Jack Nuts | Higher strength but may rust | Suitable for general industrial use, such as machinery, automotive fields |

| Stainless Steel Jack Nuts | Strong corrosion resistance, moderate strength | Suitable for humid or outdoor environments, such as construction, ship equipment |

| Aluminum Alloy Jack Nuts | Lightweight, relatively lower strength | Suitable for weight-sensitive applications, such as electronic devices |

Recommendation: For high-strength or high-vibration environments, prioritize stainless steel Jack Nuts. Avoid using aluminum Jack Nuts to prevent deformation or loosening.

2. Optimize the Installation Method

The installation method of Jack Nuts affects its stability and load-bearing capacity, and the choice of installation tools also influences the result.

Manual Tools vs. Pneumatic Tools vs. Hydraulic Tools

| Installation Method | Features | Applicable Scenarios |

| Hand Tools (wrenches, rivet guns) | Suitable for small batch installations, low cost, but uneven force may lead to unstable installation | DIY, maintenance, furniture assembly |

| Pneumatic Tools (pneumatic rivet guns) | Fast speed, even installation, but requires an air source | Workshop production, mass assembly |

| Hydraulic Tools (hydraulic rivet guns) | Provides higher pulling force, suitable for high-strength applications | Industrial manufacturing, construction |

Recommendations:

- For mass installations, use pneumatic or hydraulic tools to ensure uniform and stable installation of the Jack Nut.

- Ensure the installation hole size is appropriate. Too large a hole will prevent the Jack Nut from clamping effectively, while too small may cause deformation or damage to the installation material.

3. Alternative Solutions: When Jack Nuts Are Not Suitable

Although Jack Nuts are suitable for many scenarios, their strength may be insufficient in high-load, high-vibration, or thick material applications. In these cases, consider the following alternative solutions:

- Suitable for metal sheets and thicker materials

- Provides higher pull-out and shear strength

- Forms a strong threaded connection after installation, ideal for high-vibration environments (such as mechanical equipment)

(2) Threaded Inserts

- Suitable for soft materials like wood and plastic

- Provides a more secure threaded connection, preventing Jack Nuts from loosening in soft materials

- Commonly used in furniture assembly and plastic product installation

(3) Weld Nuts

- Suitable for high-strength connections, such as heavy machinery and steel structures

- Requires welding processes but offers extremely high stability

Do You Have Any Questions?

Let Us Solve Your Problem

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of rivet nuts and jack nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service according to your requirements.

Contact us for project advice and the latest rivet nuts and rivet nut tools quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.