Where to Buy Rivet Nuts?

Leading Rivet Nut Manufacturer and Supplier in China

We have already discussed the ultimate guide to buying rivet nuts. When it comes to sourcing rivet nuts, knowing where to buy rivet nuts is key to ensuring quality and cost-effectiveness. Rivet nuts are essential fasteners used across a wide range of industries, and finding the right supplier can make a significant difference in the overall success of your projects.

Table of Contents

Why Buy Rivet Nuts?

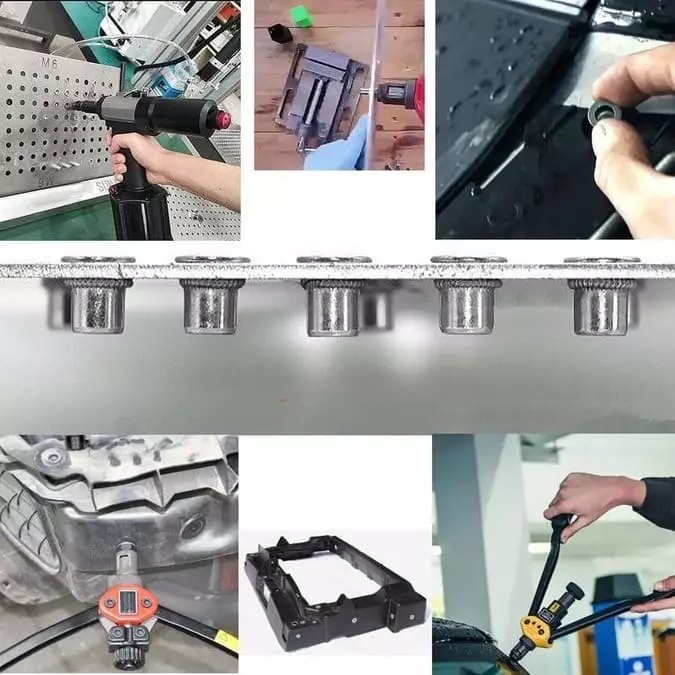

Rivet nuts are a fastener with internal threads used to create a strong threaded connection on thin-walled material. Rivet nuts are the best choice for joining and securing two or more materials in situations where they cannot be operated by conventional means, such as bolts or screws. Buying riveted nuts can bring you many benefits.

1. Materials not suitable for drilling and tapping

Rivet nuts are widely used in thin-walled metal, plastic and composite materials. For materials that are not suitable for conventional threading operations, tapping may cause the material to deform or break. The use of rivet nuts can avoid this and at the same time provide a strong threaded connection point.

2. Save space and weight

Rivet nuts are generally more compact and lighter in weight than other connection methods. Rivet nuts are therefore ideal for applications where space and weight requirements are stringent. In industries such as aerospace, automotive and electronic equipment, where lightweight and space optimization are very important, rivet nuts provide a good solution for these industries.

3. Easy to automate and improve production efficiency

When combined with automation, the installation of rivet nuts is very simple and fast. Automated rivet nut mounting systems can significantly improve production efficiency. Such as reducing labor costs, and improving the efficiency of the overall production line.

4. Provide a strong connection

Rivet nuts are renowned for their ability to provide exceptional shear and tensile strength, making them highly effective in applications that require the ability to withstand significant loads. The design of rivet nuts allows them to distribute stress evenly, providing a secure and reliable fastening point. This feature is especially valuable in industries and applications where high strength and durability are paramount.

Common materials rivet nuts general shear and tensile strength range:

The following are the general shear and tensile strength ranges for rivet nuts of common materials (steel, stainless steel, aluminum, copper).

These values may vary depending on the specific design, size, mounting method, and surface treatment. The following are typical material rivet nut strength data.

| Tye of Rivet Nuts | Tensile Strength | Shear Strength | Applications |

| Steel Rivet Nuts | 400 MPa – 600 MPa | 250 MPa – 350 MPa | High load applications like automotive, construction, and machinery |

| Stainless Steel Rivet Nuts | 500 MPa – 750 MPa | 300 MPa – 450 MPa | Harsh environments like marine and chemical industries |

| Aluminum Rivet Nuts | 250 MPa – 400 MPa | 150 MPa – 250 MPa | Aviation, automotive, lightweight structures with strict weight requirements |

| Copper Rivet Nuts | 200 MPa – 300 MPa | 150 MPa – 250 MPa | Electrical equipment and electronics with high conductivity requirements |

5. well-adapted

Rivet nuts are incredibly versatile fasteners that can be riveted to a wide variety of surfaces and materials, making them an ideal choice for a broad spectrum of industrial applications. While they are commonly used in metals, their adaptability extends well beyond this. Rivet nuts can also be used in plastics, composite materials, and other non-metal substrates.

This flexibility allows rivet nuts to be widely used across various industries, including automotive, aerospace, electronics, and construction. Their adaptability makes them ideal for a diverse range of applications, from lightweight components to heavy-duty structural assemblies.

Where to Buy Rivet Nuts?

1. Offline Fastener Stores

Offline fastener stores typically sell a variety of standard rivet nuts, including materials such as steel, aluminum, and stainless steel. The sales staff usually have technical knowledge and can offer advice. Customers can directly inspect the rivet nuts’ appearance, size, and material to ensure they meet their requirements.

Suitable Scenarios:

- Urgent Needs: If a quick solution is needed, offline stores are the fastest option. They are ideal for immediate projects or when there is no time to wait for shipping.

- Small Quantity Purchases: Offline stores are well-suited for customers who need only a few rivet nuts without having to wait for delivery.

Advantages:

- Instant Purchase: Customers can buy products immediately without waiting for shipping.

- Face-to-Face Communication: Direct interaction with store staff to ask for product details, usage methods, and suitability.

- No Waiting: Instant acquisition of products, solving urgent issues quickly.

Disadvantages:

- Stock Limitations: The store may not have a wide range of rivet nuts available due to space and supplier constraints.

- Higher Prices: Offline retail prices tend to be higher, particularly without bulk purchasing discounts.

- Limited Variety: Specialty rivet nuts or non-standard sizes/materials may not be available in-store.

2. Online Retail Marketplaces

Suitable Scenarios:

- Small to Medium-Scale Purchases: Online retail marketplaces are ideal for single or small batch purchases, especially for standard rivet nut types.

- Standard Rivet Nuts: These platforms are excellent for common specifications and materials.

Advantages:

- Wide Variety: Online stores offer an extensive range of rivet nuts in different sizes, materials, and types to meet diverse needs.

- Price Transparency: Customers can compare prices from different sellers and find the most cost-effective option.

- Customer Reviews: Reading reviews from other customers helps understand product quality and performance before purchasing.

- Convenient Delivery: Products are delivered to your doorstep, saving time and effort in purchasing.

Disadvantages:

- Waiting for Delivery: Shipping time varies depending on location, and customers may have to wait for their orders.

- Return/Exchange Issues: Returning or exchanging products may be cumbersome, especially in international purchases.

- No Face-to-Face Support: Unlike offline stores, customers cannot directly interact with sales staff for immediate technical assistance.

3. Specialized Rivet Nut Suppliers

Specialized rivet nut suppliers are manufacturers or large-scale wholesalers who provide bulk purchases, customization services, and technical consulting. These suppliers typically offer a wide selection of rivet nuts in various materials (steel, stainless steel, aluminum, copper, etc.) and specifications to cater to specific industry needs. Many also offer custom-made options, such as different lengths, surface treatments, or strength specifications.

Suitable Scenarios:

- Bulk Purchases: If a large quantity of rivet nuts is needed, specialized suppliers can offer bulk discounts.

- Special Specifications or Customization: For unique material, size, or performance requirements, these suppliers can offer tailored solutions.

- Long-Term Partnerships: Ideal for companies or projects with ongoing needs for rivet nuts, allowing for stable supplier relationships.

Advantages:

- Customization Services: Specialized suppliers can customize rivet nuts according to specific customer needs.

- Quality Assurance: Products from specialized suppliers undergo stringent quality control, ensuring high manufacturing standards and performance.

- Technical Support: Most suppliers offer technical assistance to help customers select the right rivet nuts and provide installation guidance.

- Bulk Discounts: For large orders, specialized suppliers typically offer lower prices, reducing the overall cost per unit.

Disadvantages:

- Longer Lead Times: Due to bulk production or customization, delivery may take longer, and customers need to plan ahead.

- More Complex Procurement Process: The purchasing process for customized products may involve more communication and longer lead times.

- Best for Large Orders: For smaller quantities, purchasing from specialized suppliers may be less cost-effective and more complicated.

Conclusion: Which purchase route is more suitable for you

- Small-Scale or Urgent Needs: Offline fastener stores are best for quick solutions, although they may have limited selection and higher prices.

- Standard Purchases: Online retail marketplaces are ideal for buying common rivet nut types, offering convenience and price transparency.

- Bulk Purchases or Custom Needs: Specialized rivet nut suppliers are most suitable for large orders or custom specifications, offering competitive prices and extensive support.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Reilable Rivet Nut Manufacturers?

- Quality certification and standards:

Select manufacturers that meet rivet nut standards (such as ISO, DIN, etc.) to ensure that the rivets and nuts produced meet the relevant performance and safety requirements. - Production capacity and technical support:

Ensure that they can deliver the product within the specified time. If you have special needs, choose manufacturers that can provide customized services. In addition, pay attention to whether the manufacturer provides technical support. Especially in product selection, installation, maintenance and other aspects of help. - Price and cost-effectiveness:

Reasonable price is very important. Compare the prices of different manufacturers to ensure that the most cost-effective products are obtained under the premise of meeting the quality requirements. - Customer evaluation and word of mouth:

View the manufacturer’s customer evaluation and market reputation. You can understand the manufacturer’s word of mouth through online reviews, industry recommendations and other ways.

Choose to buy from a rivet nut manufacturer for large orders

1. Cost-Effectiveness

- Discounted Pricing: Manufacturers typically offer discounts for bulk orders, reducing the unit cost per rivet nut. Buying in bulk can significantly lower procurement costs.

- Eliminating Intermediary Costs: Purchasing directly from the manufacturer avoids the additional costs imposed by distributors or resellers, making the process more cost-efficient.

2. Higher Production Flexibility

- Customization Options: Manufacturers can provide tailored services, such as custom sizes, materials, surface treatments, and finishes. For large orders, this flexibility ensures the products meet your specific requirements.

- Quick Response: Manufacturers can quickly adjust production lines to meet order demands, ensuring timely delivery, especially for bulk orders.

3. Stable Quality Control

- Strict Quality Assurance: Manufacturers generally have robust quality control processes to ensure each batch meets standards. This guarantees consistency and high quality across large-volume orders.

- Reduced Quality Fluctuations: Direct collaboration with the manufacturer allows you to monitor and control the production process, minimizing the risk of quality inconsistencies.

4. Shorter Lead Times

- Direct Production: Working with manufacturers reduces delays typically caused by intermediaries. Large orders are better scheduled, ensuring timely delivery.

- Flexible Production Scheduling: Manufacturers with high production capacity can adapt schedules to meet bulk demand, ensuring fast turnaround times.

5. Stronger Technical Support

- Expert Assistance: Manufacturers often offer more specialized technical support and after-sales services, helping with design customization, installation, and troubleshooting.

- Tailored Solutions: For large, customized orders, manufacturers can provide end-to-end support, ensuring you receive the best product solution.

6. Supply Chain Stability

- Long-Term Partnerships: Establishing a long-term relationship with a manufacturer ensures a more stable supply chain, which is especially critical for ongoing large-volume needs.

- Reliable Supply Capacity: Experienced manufacturers typically have established procurement networks and strong production capabilities, ensuring consistent, on-time delivery of large orders.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs

1. What is the MOQ for Rivet Nuts?

When purchasing rivet nuts directly from manufacturers, the minimum order quantity (MOQ) is typically 50,000 units.

Purchasing large quantities significantly reduces the per-unit cost, making it a cost-effective option for high-volume projects. Manufacturers can provide a limited number of samples for testing, allowing buyers to assess the quality and suitability of the rivet nuts before committing to the full order.

2. How to ensure rivet nuts meet industry standards?

To ensure rivet nuts meet industry standards, verify that they are made from high-quality materials like steel, stainless steel, or aluminum, and confirm they meet relevant rivet nut standard such as ISO or ASTM.

Check the threading specifications to ensure compatibility with screws and bolts. Ensure proper finish and coating to resist corrosion, particularly for materials used in harsh environments. Additionally, perform load-bearing tests to verify tensile and shear strength, and check for dimensional accuracy to ensure the rivet nuts fit the required specifications.

It is important to work with reputable manufacturers and suppliers. They have strict products quality control and provide thoroughly tested product samples.

3. Are rivet nuts customizable?

Yes, excellent manufacturers offer custom rivet nut services to meet specific application needs.. They can tailor key features like material (steel, stainless steel, aluminum, brass), size (diameter, length, thread size), and thread type (metric or imperial) to ensure a perfect fit. These options allow rivet nuts to be designed for optimal strength, corrosion resistance, and functionality.

Additionally, customizable coatings, such as zinc plating or anodizing, can be applied to improve durability and aesthetics. The head design can also be adapted (e.g., countersunk or flat), offering flexibility in meeting both technical and visual requirements.

4. Does it provide after-sales service?

Yes, many rivet nut manufacturers provide after-sales service to ensure customer satisfaction. This includes technical support for installation and troubleshooting, as well as guidance on optimizing the use of rivet nuts for specific applications.

In addition, if a defect is found, the return or replacement of the product is supported to ensure that the customer receives a functional and reliable product.

Why Buy Rivet Nuts from China?

China has a well-established manufacturing industry, which enables cost-effective production due to economies of scale and competitive labor costs. This results in lower prices for high-quality rivet nuts, making them an attractive option for bulk purchases.

Additionally, China also provides robust export infrastructure, ensuring efficient global shipping. These factors make China a reliable source for affordable, high-quality rivet nuts.

If you want to know more about China’s outstanding rivet nut manufacturers, you can refer to the top 10 rivet nut manufacturers in China to help you make the right choice.

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our factory manufactures 400 million pieces of structural rivets and automobile blind rivets, 1 billion standard blind rivets annually now. Choose Rivetfix for your next project and experience the difference that superior rivet nut solutions can make.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.