Buy Self-Waterproof Nuts

Self-waterproof nuts are also called self-clinching blind nuts, are fasteners designed to provide a secure, watertight seal in environments exposed to moisture, humidity, or harsh weather conditions. These nuts feature built-in sealing mechanisms that prevent water, dirt, and contaminants from entering threaded connections, ensuring long-term reliability.

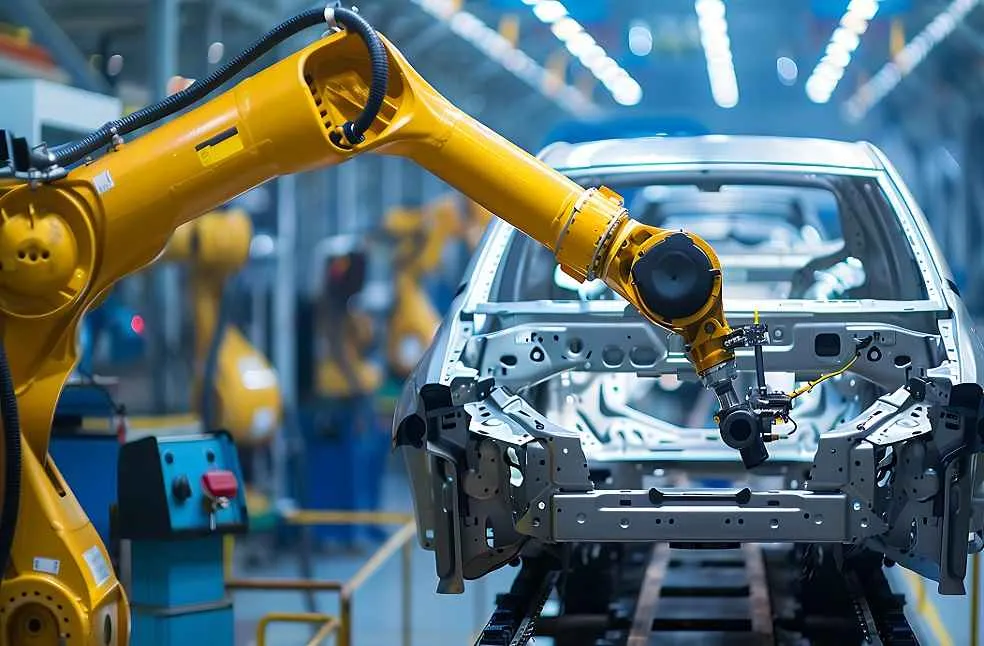

Used in industries like automotive, aerospace, and electronics, self-waterproof nuts enhance component durability and prevent corrosion. They protect assemblies from rust and degradation, improving system performance. With excellent sealing capabilities, these nuts are essential for equipment exposed to wet or outdoor environments.

Home » Self-Waterproof Nuts

Key Features of Self-Waterproof Nuts

- Integrated Waterproof Seal: Built-in elastomeric sealing element (rubber or silicone) to prevent water ingress.

- Corrosion Resistance: Made from materials like stainless steel for durability in harsh, wet environments.

- Easy Installation: Can be installed using standard tools, no need for additional gaskets or adhesives.

- Durable Construction: Resistant to extreme temperatures, vibration, and mechanical stresses.

- Leak-Proof Performance: Ensures a secure, waterproof connection without the need for extra sealing steps.

- Wide Application Range: Suitable for automotive, marine, outdoor equipment, and electrical devices.

Customize Your Self-Waterproof Nuts

At Rivetfix, we offer customizable self-waterproof nuts tailored to meet the specific needs of your project. Whether you require different materials, sizes, or thread specifications, our customization options allow you to design the perfect solution for your application.

- Thread Sizes: Customize the thread type and size to fit your assembly needs.

- Materials: Select from corrosion-resistant materials. Stainless steel is recommended as the material of choice

- Coatings & Finishes: Choose from a variety of coatings to enhance durability and resist corrosion or wear.

Versatile Applications of Self-Waterproof Nuts

Automotive Industry

Engine and Exhaust Components: Used to seal engine parts and exhaust systems, protecting them from moisture and corrosion.

Electrical Housings: Sealing electrical enclosures to safeguard sensitive components from water ingress, ensuring reliable performance in all weather conditions.

Marine Applications

Boat and Ship Construction: Essential in marine environments to prevent water damage in critical parts, such as hulls, motors, and electrical systems.

Offshore Equipment: Used in offshore drilling rigs and platforms where constant exposure to water and salt is a concern.

Outdoor Equipment

Construction Machinery: Protects heavy-duty machinery, like bulldozers and cranes, from water damage in harsh, wet environments.

Generators and HVAC Systems: Ensures outdoor generators and HVAC units operate without moisture-related issues.

Solar Panels

Helps seal electrical connections and prevent moisture ingress in solar power systems exposed to the elements.

Agriculture

Irrigation Systems: Prevents water from leaking into threaded connections in irrigation pumps and piping systems.

Farm Equipment: Protects critical farm machinery and systems exposed to frequent contact with water.

Custom Self-Waterproof Nuts For Your Project

No matter what scenario you want to use the self-waterproof nuts in, please consult us for professional advice and technical support.

How to Install Self-Waterproof Nuts

Similar to the installation steps for self-clinching nuts, here are the installation steps and precautions for Self-Waterproof Nuts. Knowing the following will help you achieve the best results when pressing the nut.

Installation Steps

- Place the self-waterproof nut into a lower die fixture that fits the nut precisely. Ensure the depth of the fixture hole matches the outer height of the nut.

- Align the hole in the thin sheet with the self-waterproof nut and position the nut on top of the sheet.

- Use a press to press the self-waterproof nut into the sheet, ensuring it forms a tight, secure seal and attachment

Note: During installation, pressure should be applied to the sheet metal, not the nut.

Why You Should Buy Self-Waterproof Nuts?

Self-waterproof nuts offer a unique combination of convenience, reliability, and performance, making them an excellent choice for a variety of applications where moisture and environmental protection are critical. Here’s why they should be considered for your next project:

1. Reliable Waterproof Sealing

- Integrated Seal: Self-waterproof nuts come with an integrated sealing element (typically made from high-quality elastomers like rubber or silicone). This feature eliminates the need for additional gaskets or sealing tapes, ensuring a secure, leak-proof connection that prevents water, dust, and contaminants from entering threaded assemblies.

- Durability: These nuts are specifically designed to maintain a tight seal even in wet or humid conditions, ensuring the integrity of the entire assembly over time.

2. Enhanced Protection Against Corrosion

- Corrosion-Resistant Materials: Typically manufactured from stainless steel or other corrosion-resistant materials, self-waterproof nuts are ideal for use in environments prone to moisture, salt, or chemicals—such as marine, outdoor, and automotive applications.

- Extended Service Life: By preventing water ingress, these nuts help protect sensitive components from corrosion and rust, thereby increasing the lifespan of your equipment or structure.

3. Maintenance-Free or Low Maintenance

- Minimal Upkeep: Once installed, self-waterproof nuts typically require little to no maintenance, as their integrated sealing technology prevents water and dirt from affecting the threads. This makes them ideal for applications in remote or hard-to-access locations.

- Long-Term Solution: With their durability and resistance to water, these nuts provide long-term performance with fewer issues related to loosening, corrosion, or degradation of the fastener.

4. Space and Weight Efficiency

- Compact Design: Because they integrate the sealing function into the nut itself, these fasteners save valuable space and reduce the need for bulky external sealing mechanisms, making them ideal for tight or confined spaces.

- Lightweight Option: Often made from materials like stainless steel or nylon, they provide a lightweight solution while still delivering a high level of protection and durability.

5. Cost-Effective Solution

- Reduced Assembly Costs: The self-sealing nature of the nuts eliminates the need for additional parts, such as separate seals or adhesives, reducing overall material costs and simplifying the installation process.

- Lower Maintenance Costs: By preventing water damage, corrosion, and other forms of wear and tear, these nuts help reduce the frequency of repairs or replacements, ultimately lowering maintenance costs.

In addition, using self-waterproof nuts instead of welding can better protect the environment.

Have more questions?

Contact us for technical support, advice and quotes.

Buy Self-Waterproof Nuts in Bulk from Rivetfix

- High-Quality Materials: We offer self-waterproof nuts made from durable, corrosion-resistant materials like stainless steel and brass, ensuring long-lasting performance even in harsh conditions.

- Cost-Effective Bulk Pricing: Buying in bulk from Rivetfix helps you save on costs while ensuring you have the fasteners needed for large-scale projects.

- Customizable Options: Our self-waterproof nuts come in various thread sizes, materials, and sealing types, allowing for a tailored solution based on your specific application.

- Fast Delivery: We understand the importance of deadlines. When you order in bulk, we guarantee quick and efficient delivery to keep your projects on track.

Ordering Process:

- Select Your Specifications: Choose from various sizes, materials, and sealing types to match your project requirements.

- Request a Bulk Quote: Contact our team to get the best pricing on bulk orders. We offer competitive rates tailored to your needs. MOQ:50000

- Fast Delivery: Once your order is confirmed, we will ship it promptly to your location (within 1 month).

Rivetfix, as part of Rivmate, can also supply high quality rivets and riveted parts. If you have a requirement, please contact us!