Home » Rivet Nut Applications

Rivet Nut Applications

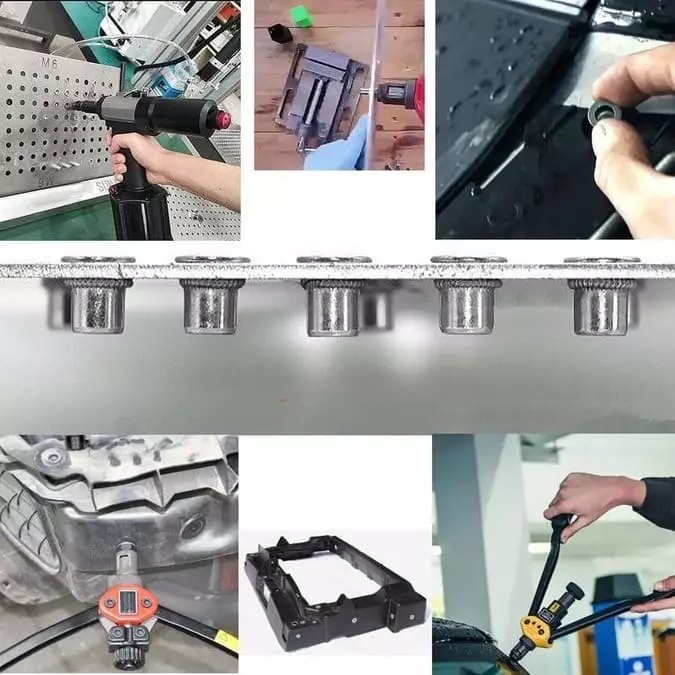

The advent of Rivet Nuts has opened up more possibilities for thin sheet connections.Rivet nuts can provide a stable threaded connection point while fastening thin sheets. Rivet nuts can provide a stable threaded connection for sheet metal, plastics, composites, etc. by simple one-sided operation in situations where direct tapping is not possible or where a high strength connection is required. As a result, Rivet Nut applications are numerous. These include automotive manufacturing, aerospace, electronic equipment, furniture and industrial assembly where it is suitable for fixing brackets, mounting components and other structures that need to be dismantled repeatedly.

In the automotive manufacturing process, rivet nuts are often used to provide strong threaded connections to automotive sheet and tube structures. Below are specific scenarios where rivet nut applications are used in automobiles:

- Door systems

- Roof and luggage racks

- Chassis and suspension systems

- Dashboards and center pivot systems

- Seat and seat belt systems

- Front and rear bumpers

- Engine and Hood

- Vehicle Lighting Systems

- Interior trim

Rivet nuts are widely used in aerospace manufacturing to provide threaded fastening points for thin-walled materials and tubular components in the lightweight construction of aircraft. Their unilateral mounting characteristics, high-strength connections and lightweighting advantages have led to their use in several critical areas of aircraft assembly. The following are specific application scenarios of rivet nuts in aircraft:

- Connection of aircraft skin to skeleton

- Tail assembly

- Installation and fixation of cockpit internal parts

- Fixing of heat insulation panels

- Fixing of engine accessories and other small parts

- Assembly of cargo doors, interior panels and fixtures

- Installation of air-conditioning piping brackets and fixtures

The housings of electronic devices are basically thin panels, so rivet nuts are widely used in housing construction. The following are specific application scenarios of rivet nuts in electronic devices:

- Fixing panels, brackets and decorative parts of electronic equipment housings

- Fixing heat sinks or heat sinks

- Mounting of displays, touch panels and support frames

- Fixing printed circuit boards (PCBs) to brackets or housings

Of course, rivet nuts are also used in a wide range of industrial applications. rivet nuts provide high-strength, portable threaded joints for equipment components. Below are some of the specific applications of rivet nut applications in industrial equipment:

- Securing machine tool frames, panels and accessories

- Securing equipment housings and mounting motion control components

- Mounting brackets, guards and components for conveyor systems

- Providing fastening points for thin-walled brackets and housings

- Fixing shelves, automated storage systems

- Threaded attachment points for lightweight robotic components

Rivet Nuts are widely used in furniture assembly to secure frames, brackets, and connectors, especially in scenarios that require strong threaded connections or frequent disassembly. Below are specific scenarios where Rivet Nuts are used in furniture assembly:

- Connecting components of metal frames to provide threaded points for tubular structures.

- Ideal for furniture that needs to be disassembled and reassembled several times, such as desks, display racks or storage units.

- Attaching metal fittings to wooden structures.

- For portable furniture such as folding tables and chairs.

- Provides threaded points for internal and external components of lockers and closets.

Rivet Nuts are used in a wide range of applications in construction, mainly in thin-walled materials, tubular structures, or in difficult-to-tap scenarios to provide high-strength threaded joints for building components.

- Fixing of curtain wall panels and brackets.

- Installation of stair handrails, balustrades and supports.

- Fixing door and window frames and related hardware.

- Installation of interior partitions, suspended ceilings and decorative panels.

- Fixed pipe supports and cable routing assemblies.

Rivet Nuts are widely used in the manufacture and installation of solar equipment. They provide a strong, durable and easy-to-disassemble threaded connection point for solar modules, and are suitable for photovoltaic power generation, solar water heating and solar tracking systems.

- Provide fastening points for solar panel mounts.

- Connects solar PV panels to the support structure.

- For mounting and fixing of dynamic components in tracking systems.

- Fixes the inverter housing and mounting brackets.

- Provide grounding connection points for metal components of PV systems.

Applicable to Wider Range of Materials

It is possible to apply rivet nuts to metals, plastics and composites.

More Stable Threaded Connections

Compared to other connections, rivet nuts are more stable.

Provides Versatile Connectivity

Supports a wide range of functional requirements beyond threaded connections.

Faster Installation

One side completes the installation. Reduces installation time and process.