What Is the Life Expectancy of a Heli-Coil?

Leading Threaded Insert Manufacturer and Supplier in China

In the field of engineering, Heli-Coil (also known as Wire Thread Insert) is a precise fastening solution used to enhance and repair internal threads. It is made of high-strength stainless steel wire and is installed in pre-processed threaded holes to provide a more wear-resistant and stronger internal thread meshing surface. When we discuss the life expectancy of a heli-coil (the lifespan of Heli-Coil), it is important to note that the threaded sleeve does not have a uniform or fixed lifespan. Its lifespan depends on various factors.

When installed correctly and used under appropriate conditions, Heli-Coil can significantly extend the service life of the internal threads in the base material. It is particularly effective in preventing thread stripping or failure in low-strength materials such as aluminum and magnesium, and can support multiple assembly and disassembly while maintaining reliable performance.

Table of Contents

How a Heli-Coil Works and Why It Lasts?

Wire Thread Insert Structure & Load Distribution

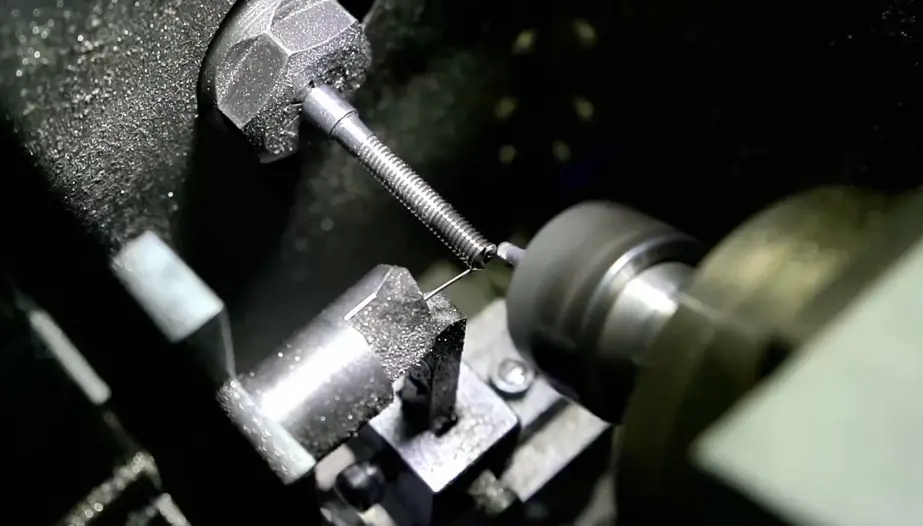

The core structure of Heli-Coil (thread sleeve) is a section of elastic thread coil with a rhombic cross-section made of stainless steel wire (commonly 304, 316 or Inconel materials) wound precisely to a specific pitch. When it is installed in a threaded hole processed by an STI (Screw Thread Insert) tap, the outer thread of the sleeve engages with the base material, while the inner thread forms a standard fit with the bolt.

This diamond-shaped cross-sectional design enables the sheath to generate radial elastic tension after installation, allowing the load to be evenly distributed along the entire meshing length. Compared to directly screwing the bolts into the base material (especially low-strength materials such as aluminum and magnesium), Heli-Coil can disperse the stress over more thread teeth. Reducing the load on a single tooth, thereby significantly reducing the risk of thread spalling or pulling caused by local overload.

Engineering test data show that properly installed threaded sleeves can increase the pulling strength of the internal threads in the base material by 1.5 to 2.5 times. Under the same load conditions, the deformation and wear of the threaded holes with the sleeves are significantly lower than those without the sleeves.

Stress Reduction and Wear Resistance

Due to a more even distribution of the load, Heli-Coil can effectively reduce the peak shear stress of the base material. This is crucial for extending the lifespan of the threads. A reduction in shear stress means that under high loads or vibration conditions, the thread tooth profile is less likely to undergo plastic deformation or fatigue cracks, thereby delaying the failure time.

Furthermore, the stainless steel wire material has high hardness and excellent wear resistance (with a hardness typically above HV 430). During repeated assembly and disassembly processes, the internal threads of the sheath are not prone to wear or deformation, ensuring that the bolts maintain stable mating accuracy after multiple cycles. This wear-resistant characteristic is also an important basis for the brand’s statement that “Heli-Coil can be repeatedly assembled and disassembled while maintaining reliability”.

In terms of corrosion resistance, 304/316 stainless steel can be used for a long time in most industrial environments without significant rusting.

Key Factors That Influence Service Life

a. Load Type and Magnitude

The lifespan of Heli-Coil is closely related to the type and magnitude of the load it is subjected to (tension, shear, combined stress). High tensile loads directly affect the pressure-bearing capacity of the mating surface between the sheath and the parent material’s threads, while alternating shear loads or impact loads may accelerate fatigue damage.

When designing, it is recommended that the working load should not exceed 60% – 70% of the shear strength of the base material’s thread, and a safety factor should be reserved. For impact conditions, an additional 1.5 – 2 times the impact coefficient can be added during the testing stage for verification.

Testing Method: The designed load-bearing capacity is verified through the pull-out test and the fatigue test.

b. Installation Quality and Precision

Installation accuracy forms the basis of the lifespan of Heli-Coil. The machining accuracy of the holes, the cutting quality of the STI taps, the qualification of gauge inspections, and the coaxiality of the holes all directly affect the load distribution.

Practical indicators:

- Use the dedicated STI taps to ensure that the tooth profile and dimensions comply with ASME B18.29.1 or DIN 8140-1.

- The coaxiality of the holes is recommended to be ≤ 0.05mm to prevent load imbalance.

- After installation, use the Go/No-Go gauge for inspection to ensure that the internal threads are properly engaged.

- Testing method: Use a three-coordinate measuring machine to measure the position of the holes and coaxiality, and record the quality inspection data as the basis for life tracking.

c. Parent Material Selection (Aluminum, Magnesium, Plastics)

The shear strength and hardness of the base material directly determine the load-bearing platform of the sheath. Aluminum, magnesium alloys, and engineering plastics belong to low shear materials. Directly machining threads is prone to peeling under high loads. Installing Heli-Coil can significantly increase the lifespan.

- Practical indicators:

- For aluminum alloys, it is recommended to use a 1.5D – 2D mesh length of the protective sleeve;

- For plastic substrates, it is recommended to increase the mesh length or select a dedicated plastic threaded sleeve (with external thread self-tapping design).

- Testing method: Conduct tensile strength tests and cyclic assembly/disassembly tests on the base material sample block to verify the failure mode of the protective sleeve on different substrates.

d. Fit Class and Engagement Length

The mating grade (such as metric 5H/4H 5H, or American 2B/3B) and the engagement length determine the tightness and load-bearing capacity of the thread. A higher mating grade can enhance the connection rigidity, but it will increase the assembly resistance; an excessively short engagement length will reduce the shear area, thereby shortening the service life.

- Practical indicators:

- For normal operating conditions, a recommended meshing length of 1.5D is recommended; for high-load conditions, it can be increased to 2D – 3D.

- For self-locking sheaths, it is recommended to select a tighter fit grade (such as 3B or 4H5H) to maintain the long-term locking torque.

- Testing method: Use a thread ring gauge to test the fit grade and ensure that the installation resistance is consistent with the standard.

e. Torque Application and Vibration

The correct torque and preload are crucial for extending the lifespan of Heli-Coil. Excessive torque can cause the base material threads to shear or the sheath to deform, while too low a torque may cause loosening during vibration. Connections that are exposed to high-frequency vibration for a long time should be designed with anti-loosening features (such as self-locking sheaths, gluing).

- Practical indicators:

- Refer to the torque values recommended by ISO 898-1 or SAE J429 for the bolt specifications, and reduce by 5% – 10% based on the material properties of the base metal.

- For high-vibration environments, it is recommended to check the locking torque once every 500 – 1000 hours.

- Testing method: Use a torque wrench for installation and regular re-inspection. Record the torque retention rate as the basis for life monitoring.

Materials & Coatings – Impact on Longevity

When discussing the lifespan of Heli-Coil (thread protection sleeve), the material and surface coating are crucial factors determining its durability. Different alloy materials exhibit significant differences in strength, corrosion resistance, temperature resistance, and friction characteristics. Moreover, appropriate surface treatment can further extend its service life.

Stainless Steel (304/316)

304 and 316 stainless steel are the most commonly used materials for Heli-Coil, featuring high strength, excellent corrosion resistance and low manufacturing costs.

- 304 Stainless Steel: Performs exceptionally well in most industrial environments, with a tensile strength of approximately ≈ 1700 MPa, and a hardness of about HV 430. It is suitable for general machinery, electronics, and automotive industries.

- 316 Stainless Steel: Due to the presence of molybdenum (Mo), it has stronger resistance to pitting in chloride environments (such as in the ocean and chemical plants).

Temperature Range: The brand’s data indicates that the 304/316 materials maintain stable mechanical properties within the temperature range of —320°F to +800°F (—196°C to 427°C).

Application Scenarios: General industry, outdoor machinery, marine equipment, lightweight aluminum alloy structures.

Inconel X-750 for High-Temperature Use

Inconel X-750 is a nickel-based superalloy with excellent creep resistance, oxidation resistance and stress corrosion cracking resistance. Its lifespan under high-temperature conditions is much longer than that of stainless steel.

- Mechanical Properties: It can maintain high strength and structural stability even at 650°C.

- Temperature Resistance Range: It can operate stably at +1300°F (≈704°C) in practical applications, and can withstand higher temperatures for short periods.

- Application Scenarios: Aerospace engine compartments, gas turbines, nuclear power equipment, high-temperature exhaust systems.

- Life Advantage: In high-temperature and high-load cycles, the cyclic fatigue life of Inconel X-750 can be 2-3 times longer than that of stainless steel.

Phosphor Bronze for Anti-Galling

Phosphor bronze Heli-Coil is mainly used in situations where high electrical conductivity is required or where thread seizing (Galling) needs to be prevented.

- Characteristics: Excellent electrical conductivity (electrical conductivity approximately 15% IACS), low friction coefficient. When used in conjunction with stainless steel or coated bolts, it significantly reduces the risks of cold welding and jamming.

- Corrosion Resistance: Good tolerance to seawater and some acidic media.

- Application Scenarios: Electrical grounding connections, marine vessels, instruments and meters, and precise mechanisms that are frequently disassembled.

Coatings – Dry Film Lubricant, Silver Plating

In high-temperature, self-locking sheaths or in special environments, the surface coating plays a crucial role in enhancing the lifespan.

- Dry Film Lubricant (AS5272 Standard): Forms a uniform solid lubricating layer on the outer sheath, reducing assembly torque and friction wear, while enhancing corrosion resistance. Suitable for high-cycle, self-locking Heli-Coil, especially in the aerospace industry.

- Silver Coating (Silver Plating): Maintains excellent lubrication performance even at high temperatures (>400°C), preventing high-temperature thread locking. Commonly used in combinations of Inconel or stainless steel sheaths with high-temperature alloy bolts.

- Life Enhancement Effect: Tests show that self-locking sheaths with dry film lubrication can maintain over 85% of the original locking torque after 500 assembly and disassembly cycles, while the torque retention rate of sheaths without coating may drop to below 60% under the same conditions.

Free-Running vs. Screw-Locking Inserts

Structural Differences

Free-Running Helicoil

- Structure: The internal and external threads are perfectly symmetrical. After installation, there is no additional friction resistance when the internal thread mates with the bolt.

- Features: Easy to assemble, smooth to screw in. Suitable for high-frequency rapid assembly or connections requiring precise torque control.

- Advantages: Low friction, low wear. Suitable for applications where high precision in bolt preload is required.

Self-locking (Screw-Locking) Heli-Coil

- Structure: Add “straight segments” to one or more turns of the internal thread. When the bolt is screwed in, this segment will exert continuous radial pressure on the bolt’s tooth profile.

- Feature: Provide additional anti-loosening resistance, maintaining the bolt’s tightened state even under vibration, high temperature or impact load conditions.

- Standard basis: NASM21209 has clear requirements for the initial locking torque and the retention rate of cyclic torque for self-locking type.

Torque Retention Over Multiple Cycles

Performance Differences:

- The free-spin type maintains almost no change in torque during multiple assembly and disassembly processes, but it does not provide additional anti-loosening function.

- The self-locking type provides a high resistance torque during the initial installation and tests show that after 500 assembly and disassembly cycles, it can still maintain more than 85% of the initial locking torque (in compliance with NASM21209 requirements), while the non-locking type of protective sleeve relies solely on the pre-tightening force of the bolts.

Life Advantage:

In environments with strong vibrations, the self-locking type of protective sleeve can reduce the probability of bolt loosening by more than 50%, especially suitable for connection points that cannot be frequently maintained.

Best Application Scenarios for Each

Free Rotational Type

It is suitable for scenarios requiring rapid assembly and low installation resistance, such as aviation electronic equipment, precision instruments, and components with high frequency of maintenance and replacement.

It is applicable in cases where the pre-tightening force of the bolts can be precisely controlled by torque, avoiding additional friction that may interfere with the torque reading.

Self-locking type

Suitable for structures subjected to high vibration, high impact or harsh environments, such as aerospace components, engine compartments, rail transportation equipment, and military equipment.

Suitable for working conditions that require long-term tightness and have long maintenance intervals, such as satellite components, ship deck connectors, and key parts of wind turbines.

Installation Quality – The 50% Rule in Life Expectancy

In the life management of Heli-Coil, the installation quality determines at least 50% of the service life. Even if the best material, the optimal meshing length and the appropriate sheath suitable for the working conditions are selected, if the installation is improper, the service life may still be significantly shortened.

Firstly, special STI taps must be used to machine the threaded holes, and the thread accuracy should be confirmed through a Go/No-Go gauge before installation. The depth of the hole bottom and the head size should be strictly followed the standards to ensure that the cover fully meshes after installation, avoiding partial suspension which may lead to stress concentration. For covers with broken tails, after installation, a special tail-breaking tool should be used to cleanly break the tail to avoid the generation of FOD (Foreign Object Debris); if there is a concern about the FOD risk, a Tangless design without a tail can be selected.

During the installation process, the coaxiality between the threaded holes and the installation tools should be maintained to prevent the sheath from being inserted obliquely, which could cause uneven meshing surfaces. The torque applied when assembling the bolts should be strictly carried out in accordance with the specifications to avoid the failure of the parent material’s threads due to excessive pre-tightening or the deformation of the sheath.

Environmental and Corrosion Considerations

When evaluating the service life of Heli-Coil (threaded sleeve), environmental factors are often underestimated, but in fact, they have a significant impact on the long-term performance. Factors such as medium composition, temperature variations, humidity, heat, salt fog, and electrochemical corrosion between metals all affect the durability of the sleeve and the base material. By choosing the right materials, performing proper surface treatment, and using the correct installation techniques, the adverse effects of the environment on the lifespan can be significantly reduced.

Temperature Ranges and Thermal Cycling

The temperature resistance performance of Heli-Coil mainly depends on its material:

- 304/316 Stainless Steel: Can maintain stable mechanical properties within the range of —320°F to +800°F (—196°C to 427°C).

- Inconel X-750: Exhibits stronger high-temperature stability and can withstand +1300°F (≈704°C) for a long time, while maintaining high creep resistance during high-temperature cycles.

Repeated changes in high and low temperatures will cause thermal expansion and contraction differences between the threaded hole and the sheath. If the difference in expansion coefficients of the materials is too large, it may lead to loosening or stress concentration.

Suggestion:

- Under conditions of high-temperature shock or frequent thermal cycling, it is recommended to use Inconel X-750 or stainless steel with a silver coating as the insulation jacket.

- For environments below -100°C, it is essential to ensure that the insulation material does not have cracks during the low-temperature brittleness test.

Salt Spray, Humidity, and Chemical Exposure

Salt fog, humidity and chemical corrosion are common environmental factors that contribute to the shortened lifespan of Heli-Coil:

- Salt Spray Test: According to the ASTM B117 standard, 304 stainless steel can withstand more than 1000 hours of neutral salt spray without significant rusting, while 316 stainless steel has better corrosion resistance.

- Humid Heat Environment: High humidity accelerates metal oxidation, especially in areas with poor ventilation or frequent condensation.

- Chemical Media: Acids, bases, and some solvents may corrode the surface of the protective cover or accelerate the deterioration of the base material.

Suggestion:

- In marine or chemical environments, use 316 stainless steel or self-locking sheaths with dry film lubrication.

- For threaded connections that will be exposed for a long time, apply anti-corrosion lubricant (such as MoS₂ dry film) before assembly to prevent moisture and salt from penetrating.

Preventing Galvanic Corrosion in Dissimilar Metals

When stainless steel Heli-Coil is installed on the base material of reactive metals such as aluminum or magnesium, in a humid or electrolyte-containing environment, galvanic corrosion may occur: the aluminum/magnesium will act as the anode and be accelerated in corrosion, and the risk of thread hole failure increases.

Engineering Safety Measures

- Isolation Method: Apply anti-corrosion isolation coating (epoxy, dry film lubricant) between the outer thread of the sheath and the parent material thread.

- Material Selection Method:

- For marine and salt spray environments: Preferentially use 316 stainless steel or Inconel X-750, which have higher corrosion resistance.

- For high-temperature conditions: Choose a silver-coated sheath, which can both lubricate and reduce potential differences.

- Lubrication and Protection: During assembly, use aviation-grade anti-corrosion grease (such as MIL-PRF-83483), which can prevent seizing while delaying electrochemical reactions.

FAQ

How Long Can a Heli-Coil Last?

The service life of Heli-Coil is not fixed. It depends on the number of assembly and disassembly cycles, the load size, environmental conditions and installation quality. Under normal operating conditions, its service life can match the design life of the equipment, and it can even be used permanently in low-frequency assembly and disassembly environments. The cycle test of NASM21209 shows that the high-quality sheath can maintain its locking performance after more than 500 assembly and disassembly cycles.

Can It Wear Out or Loosen Over Time?

Yes, especially in cases of high-frequency vibration or long-term overloading. Common failures include internal thread wear, a decrease in torque retention rate, or the sheath coming off when removing the bolts. To prevent loosening, a self-locking type (Screw-Locking) sheath can be selected, and combined with torque cycle monitoring to track performance changes.

Is It Suitable for High-Temperature Applications?

Yes, but the appropriate material needs to be selected. 304/316 stainless steel can withstand temperatures ranging from 196°C to 427°C, while Inconel X-750 can operate for a long time at 704°C. For high-temperature anti-adhesion, you can choose a sheath with a silver coating or a dry film lubrication coating to comply with aviation-grade anti-adhesion standards such as AS5272.

Can It Be Removed and Reinstalled?

Sure. The Heli-Coil can be completely removed using a dedicated disassembly tool. If necessary, the same-sized protective sleeve can be reinstalled in the same hole. However, it is important to pay attention to the condition of the parent material’s threaded hole. If the outer thread is severely damaged, the hole should be repaired or reprocessed with a larger-sized STI thread.

When Should It Be Replaced?

When the sheath has any of the following conditions, it should be replaced:

- The torque retention rate decreased by more than 20% compared to the initial value (refer to NASM21209).

- There was significant obstruction or slippage during the assembly and disassembly process.

- The sheath came off or cracks appeared on the parent material’s threads.

- In critical applications, it reached the preset number of cycles or working hours (such as 500-1000 cycles or during regular overhauls).

Summary & Engineering Checklist

The service life of Heli-Coil (thread protection sleeve) is not solely determined by the material, but is influenced by factors such as design selection, installation process, usage environment, and maintenance strategy. The correct meshing length and matching grade can ensure the bearing capacity, while the appropriate material and surface treatment can cope with different temperature and corrosive environments. And precise installation and regular inspection can significantly delay wear and loosening.

For industries with high reliability (such as aviation, military, and energy), life management should be incorporated into the selection criteria at the initial design stage. This can avoid the costs and downtime risks caused by frequent maintenance in the later stages.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix Heli-Coil — Engineered for Strength, Built to Last

In the world of critical connections, every thread is crucial for safety and reliability. Choosing the right Heli-Coil is not only an engineering decision to extend equipment lifespan, but also a wise choice to reduce maintenance costs and avoid unexpected downtime. Rivetfix is dedicated to providing high-quality thread protectors and solutions that meet international standards (ASME, NASM, DIN) to global customers. No matter whether you are dealing with high temperatures, high vibrations, or extreme corrosive environments, we can customize the most suitable selection and protection plan for you.

Contact Rivetfix right now and ensure that every fastening you perform is stronger, longer-lasting and safer! We not only offer products, but also bring you long-term stable engineering value and peace of mind.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.