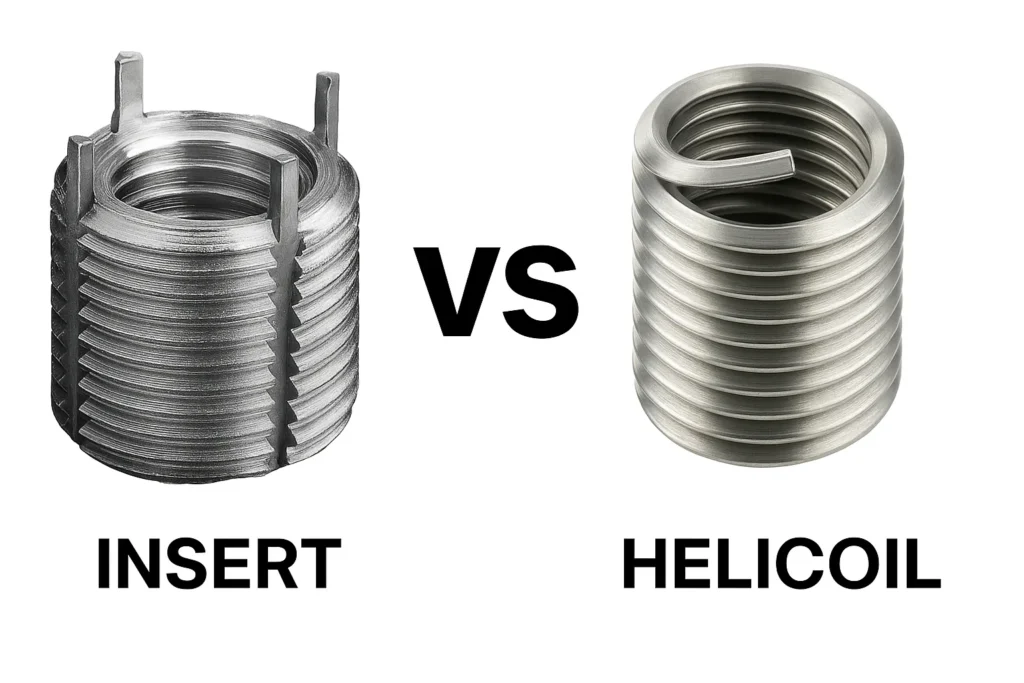

What Is The Difference Between Helicoils And Inserts?

Leading Thread Insert Manufacturer and Supplier in China

In the fields of mechanical processing, maintenance, and manufacturing, it is common to encounter situations where threaded holes are worn, stripped, or lack sufficient strength. At such times, Helicoils and Inserts are two common and effective solutions. Although their core functions are both to repair and reinforce threaded holes, there are significant differences between them. These differences not only affect the repair outcome but also directly relate to the lifespan and reliability of the parts. This blog post helps you understand the difference between helicoils and inserts. When facing different processing requirements, choose the more suitable and cost-effective solution.

Table of Contents

What is a Helicoil?

Helicoil is a threaded sleeve made of high-strength stainless steel wire, with an overall structure resembling a spring. Its design concept is to insert a coil of metal wire into a damaged or slipped-threaded hole, thereby creating a new set of threads within the original hole. Due to the use of a rhombic cross-section metal wire, Helicoil can achieve a larger contact area and locking force within a limited space, resulting in a repaired thread strength often exceeding the original base material.

Structure and Principles

- Material: Usually made of 304 or 316 stainless steel, it possesses excellent corrosion resistance and wear resistance.

- Shape: Spiral spring-like, the rhombic cross-section design ensures uniform load distribution.

- Installation Method: It is screwed into the pre-drilled threaded holes using a dedicated installation tool (generally, the threads are tapped with an enlarged specification compared to the standard size). After installation, the outer ring of Helicoil closely adheres to the base material, and the inner ring forms a new precise thread.

Common Uses

- Thread Repair: Suitable for high-precision components such as engine cylinder blocks of automobiles, aircraft engine casings, and molds.

- Material Reinforcement: Especially on soft metals like aluminum and magnesium, Helicoil significantly enhances the load-bearing capacity of the threads (with an increase of up to 200% or more).

- Wear Resistance and Longevity Extension: At connection points subjected to frequent disassembly and assembly, Helicoil can extend the lifespan of the threads and reduce replacement costs.

What is an Insert?

An Insert (embedded component) is a broad concept of engineering components, referring to the elements that are embedded into the base material (usually metal, plastic or composite materials) to improve, repair or modify the performance of the original holes or structures. Unlike Helicoil, the types of Inserts are very diverse, including not only threaded types (Threaded Inserts), but also non-threaded types (such as positioning sleeves, reinforcement rings, etc.).

Type and Structure

Threaded Inserts

- Material: Commonly available in stainless steel, brass, carbon steel, aluminum alloy, etc.

- Structure: Usually an integral solid sleeve shape. The outer side may have knurled patterns, spikes, or threads to ensure a secure fit into the base material; the inner side has precision-machined threads for attaching bolts or screws.

- Installation Method: Can be accomplished by press fitting, screwing in, hot melting, or in-mold embedding.

Non-threaded Inserts

- Mainly used for positioning, anti-abrasion, and bearing shear loads. They are commonly found in molds, fixtures, or load-bearing holes.

Functions and Benefits

- Enhanced connection strength: In soft materials such as aluminum and plastic, using steel threaded inserts can significantly improve the tensile and torsional strength of the threads (experimental data shows that the improvement can reach 2 to 4 times that of the original material).

- Wear resistance and longevity extension: In high-frequency assembly and disassembly environments, it can reduce the wear of the threaded holes and extend the service life of the parts.

- Compatibility with multiple materials: It can provide stable connections between materials with different thermal expansion coefficients, avoiding thread loosening or damage caused by thermal expansion and contraction.

- Design flexibility: The Insert can be customized in shape and size according to structural requirements, adapting to different product designs.

Key Difference Between Helicoils And Inserts

| Comparison Dimension | Helicoils | Inserts |

|---|---|---|

| Structure Form | Spring-like metal wire (usually diamond-shaped cross-section), hollow | Solid sleeve shape, with knurling, external threads, or barbs on the outside |

| Installation Method | Requires tapping a larger threaded hole → installed with special tool → forms new internal thread | Can be pressed in, screwed in, heat-set, or molded in; some types require pre-machined external thread holes |

| Strength Performance | Internal thread strength usually higher than base material, suitable for tensile loads | Overall load capacity is strong, with more stable torque and tensile resistance, suitable for high-load environments |

| Durability | Excellent wear resistance, suitable for frequent disassembly | Good wear resistance and more stable under high impact or vibration environments |

| Suitable Base Materials | Especially suitable for soft metals like aluminum and magnesium, also steel | Wider application range including metals, plastics, and composites |

| Maintenance & Replacement | Replacement requires removal of old Helicoil and reinstallation | Some inserts can be replaced directly, making maintenance easier |

| Cost | Low unit cost, suitable for large-scale repairs | Higher unit cost, but more cost-effective in high-strength applications |

- In industries that are sensitive to weight (such as aerospace), the lightweight structure of Helicoil is preferred.

- In environments with high impact or continuous high load (such as large machinery or mold production lines), Inserts usually offer more stable performance.

- Data comparison shows that under the same base material conditions, the tensile strength of steel solid Inserts can be approximately 15% to 25% higher than that of Helicoil, but the weight and cost will also increase.

Helicoils VS. Inserts:Material and Strength Comparison

Table: Common Materials and Performance Characteristics

| Material | Commonly Used for Helicoils | Commonly Used for Inserts | Performance Characteristics |

|---|---|---|---|

| Stainless Steel (304/316) | ✅ High strength, corrosion resistant | ✅ High strength, corrosion resistant | Suitable for humid, chemically corrosive, or high-temperature environments; 316 stainless steel performs better in marine and chemical conditions |

| Carbon Steel | ❌ Rarely used | ✅ High strength, low cost | High tensile strength but poor corrosion resistance; requires zinc or nickel plating |

| Brass | ❌ Rarely used | ✅ Good conductivity, corrosion resistant | Common in electronics and communication devices; moderate wear resistance |

| Aluminum Alloy | ❌ Uncommon | ✅ Lightweight, corrosion resistant | Suitable for weight-sensitive structures but has lower load capacity than steel |

| Special Alloys (Inconel, Titanium, etc.) | ✅ High-end applications | ✅ High-end applications | Maintains stable performance under extreme temperatures or corrosive environments; high cost |

Stainless steel (Stainless steel) - Commonly found in Helicoils and high-strength inserts

- Advantages: High tensile/shear strength, corrosion resistance (especially 316 is superior in marine/chemical environments), wear resistance, suitable for long-term bearing and high-frequency disassembly scenarios.

- Engineering practice: Helicoil is mostly made of stainless steel wires (such as 304/316), as its spring shape can distribute the load and provide good compatibility with bolts. Solid steel inserts (alloy steel/hardened steel) perform more stably under high shear or impact loads.

- Notes: Direct contact between stainless steel and aluminum may cause electrochemical corrosion (galvanic corrosion), so isolation coatings or compatible materials/dip coatings should be used.

Brass - commonly used in plastic/light alloy or electronic applications

- Advantages: Good processability, excellent conductivity, sufficient corrosion resistance for general atmospheric conditions, and heat-setting is very mature in plastics.

- Limitations: The strength and shear resistance are lower than those of steel, and it is not suitable for high structural loads or high fatigue cycles.

- Application suggestion: If the base material is a thermoplastic or if there is a need for conductivity/ corrosion resistance and the load is low, brass Insert is the preferred choice.

Carbon steel / Alloy steel (Carbon/Alloy steel) - The preferred choice for high-strength applications

- Advantages: It can significantly enhance tensile/shear strength and fatigue resistance through heat treatment, making it suitable for heavy-load, impact and vibration environments.

- Limitations: It requires anti-corrosion treatment (such as galvanizing, nickel plating, phosphating, etc.), and there are electrochemical compatibility issues with lightweight base materials (metals or composite materials).

- Practical application: Large machinery, molds and structural connections often use alloy steel inserts or surface hardening inserts.

High-temperature alloys and titanium alloys (Inconel, titanium) - Applications in extreme environments

- Application: Suitable for aerospace, aviation and high-temperature engine applications, where it is required to maintain thread strength and oxidation resistance at high temperatures.

- Cost: The material and processing costs are high. They are only adopted when necessary (extreme temperatures or special chemical environments).

Aluminum and Light Alloy Insert —— Lightweight but with Limited Load-bearing Capacity

- Scenario: Structures with weight sensitivity and low load (consumer electronics, internal non-structural components of aerospace).

- Note: Aluminum inserts are prone to creep or deformation under high temperature or high stress cycles and are not suitable for high-load connections.

Application Scenarios

Engine/Transmission/Chassis

- Typical locations: cylinder head bolt holes, transmission housing, suspension connection parts, intake and exhaust flanges, etc.

- Advantages of Helicoil: Used to repair loose or damaged threads on aluminum castings or machined parts, low installation cost, can be repaired on-site and restore or exceed the original internal thread bearing capacity.

- Advantages of Inserts: For high-torque or structural loads (such as engine brackets, suspension parts), solid alloy Insert (or Insert with locking structure) provides higher pull-out and fatigue stability.

- Engineering suggestion: For critical load-bearing connections, prefer to use alloy steel Insert; for maintenance and light-load positions, use Helicoil; acceptance should include torque-preloading test and pull-out test.

Airframe & Engines

- Typical areas: fuselage fasteners, cabin covers, engine accessories, control surface hinges, etc.

- Helicoil advantages: For non-structural or secondary parts, certified stainless steel/nickel-based Helicoil can effectively repair them; it is lightweight and easy to replace.

- Inserts advantages: For structural connections and high-temperature/fatigue environments, solid Inserts made of high-strength or high-temperature-resistant alloys (titanium, nickel-based alloys) are preferred, and traceable material certificates and batch records are required.

- Engineering advice: Aviation parts have strict requirements for materials, processes and tests; any selection should be based on manufacturer test data (fatigue life, torque-tightening curve) and quality certification documents (material certificates, inspection reports).

Molds and Tool Maintenance

- Typical parts: mold inserts, fixed bolt holes, pin bases, etc.

- Advantages of Helicoil: Used for quickly repairing worn or slipped installation holes in molds, reducing downtime.

- Advantages of Inserts: The working surfaces and load-bearing holes of molds often endure impacts and high temperatures. Solid quenched alloy Inserts (or replaceable bushings) can provide higher wear resistance and impact resistance.

- Engineering suggestion: For production molds, it is recommended to adopt replaceable Inserts in the initial design for maintenance; conduct pull-out and cyclic load tests on the repair parts.

Electronics & Plastics

- Typical locations: screw mounting holes of the plastic housing, PCB bracket, interface seat fixation.

- Advantages of Helicoil: Not often used for direct installation in plastic (installation is complex), mainly used for the repair of metal components.

- Advantages of Inserts: Heat-set brass Insert, ultrasonic/press-in type plastic Insert, etc. are preferred, which can significantly improve the pull-out and cyclic disassembly lifespan in plastic (usually several times higher than direct thread cutting).

- Engineering suggestion: For plastic parts, prefer thermal insert or in-mold embedded Insert. Verify the thermal insert temperature, pull-out force and long-term creep performance.

Consumer Electronics & Lightweight Alloys

- Typical parts: Notebook hinge, chassis fixation, fiberglass/magnesium-aluminum components.

- Helicoil advantages: Repairing loose teeth and enhancing local strength in lightweight alloys such as magnesium/aluminum, suitable for lightweight repair scenarios.

- Inserts advantages: In small-sized connections that require frequent disassembly or have high reliability, brass or stainless steel miniature Inserts are more stable.

- Engineering suggestion: Due to weight sensitivity, considering both strength and quality, prioritize using miniature solid Inserts for high-cycle positions, and Helicoil for maintenance or low-frequency disassembly positions.

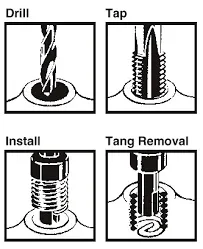

Installation Process Differences Between Helicoils And Inserts

① Drilling

- Use the corresponding drill bit according to the specification of the screw sleeve to drill the hole (generally slightly larger than the original thread diameter), maintaining verticality.

- For example, an M6×1.0 screw sleeve requires a 6.3 mm hole (refer to the manufacturer’s specification table).

② Tapping

- Use the special screw sleeve tap, whose thread size is different from the ordinary tapping.

- Strictly control the tapping depth to ensure the screw sleeve is fully inserted.

③ Installation (Insertion)

- Use the screw sleeve installation tool to insert the screw sleeve into the thread hole.

- During the installation process, the drive handle (tang) at the tail of the screw sleeve is used for guidance and insertion.

④ Breaking off the Drive Handle (Tang Break-off)

- Use a special impact rod to gently tap or use a breaking tool to break off the drive handle to avoid affecting the bolt passage.

⑤ Inspection (Acceptance)

- Check the thread integrity and depth to ensure there are no burrs or deformations.

Common Tools: Electric drill or bench drill, special drill bit, STI tap, screw set installation tool, drive handle breakage tool, compressed air or cleaning brush.

① Drilling

- Drill holes according to the outer diameter of the bushing (usually larger than the screw hole), maintaining verticality and ensuring accuracy of positioning.

② Tapping

- Use the corresponding standard taps (usually standard metric or imperial threads), no special STI taps are required.

③ Installation

- Insert the bushing into the hole, using a torque wrench or installation tool to ensure the specified torque is reached.

- Some solid bushings have external threads coated with glue, which can prevent loosening and provide sealing.

④ Locking

- For bushings with locking key type (Keensert), use a punch to insert the locking key into the base metal to achieve mechanical locking.

⑤ Inspection

- Check that the bushing is flush with the hole opening, the locking key is fully inserted, and the internal threads are undamaged.

Common Tools: Electric drill or bench drill, standard taps, installation wrench or tools, punch, hammer, cleaning equipment.

c. Summary of Key Differences

- Hole size and tap type: Helicoil requires a special STI tap, while Insert can use a standard tap.

- Installation method: Helicoil is fixed by spring tension and friction, while Insert is mostly mechanically locked through an external thread and a lock pin, providing stronger anti-pull-out capability.

- Disassembly and maintenance: Helicoil is relatively easy to remove; Insert with a lock pin needs to have the lock pin removed before it can be unscrewed.

- Tool complexity: The Helicoil tool is lightweight and has a low cost; the Insert tool is slightly more complex, but the structure after installation is more stable.

Advantages and Limitations of Helicoils And Inserts

1. Cost (Materials & Lifecycle Cost)

Helicoil

- Initial material cost is low: Each spring-type sleeve requires less material and has a simpler manufacturing process, resulting in a unit price typically lower than that of the same specification solid bushing.

- Tool and consumable cost is low: Installation kits (drills, STI taps, installers, folding tools) for batch maintenance/assembly have a relatively small investment.

- Lifecycle cost: There is a significant overall cost advantage in light-load or maintenance scenarios; however, if frequent replacements are required due to vibration/high loads, the cumulative cost will increase.

Insert (Solid Sleeve / Locking Key Sleeve)

- Initial cost is higher: Solid bushings (especially those with locking pins or external threads) require large material usage and complex processing, resulting in a significantly higher unit price compared to Helicoil.

- Installation labor and equipment costs are high: Installation involves locking pin impact, precise torque or hydraulic tensioning, which incurs higher labor and time costs.

- Long-term cost advantage: More durable in high-load/high-vibration/critical structural components, reducing maintenance frequency, and the long-term total cost may be lower than the low-cost solution of frequent replacements.

When making a choice, it should be evaluated based on “the entire machine’s life cycle (LCC)”: For small batches or maintenance purposes, Helicoil should be preferred; for critical structures or parts that are difficult to disassemble, Insert should be selected as the first option.

2. Ease of Installation

Helicoil

- The process is relatively simple: drilling → using a special tap (STI tap) → installing the screw sleeve → breaking off the driving handle.

- The skill requirements for personnel are moderate: skilled workers can complete it quickly, suitable for rapid maintenance in workshops or for use in assembly lines.

- High batch efficiency: it can be easily achieved with high production capacity on automated or semi-automatic assembly lines.

Insert (Solid Sleeve / Locking Key Sleeve)

- More steps and high precision requirements: Drilling → Standard/Special Thread Cutting → Insertion or Press-fitting → Installation of Locking Key (if any) → Verification.

- Higher requirements for tools and skills: Locking key insertion, torque control or tension control require skilled workers and more specialized tools.

- Site environment limitations: For sites where it is inconvenient to use impact or tension equipment, the complexity of installation significantly increases.

If the goal is to quickly repair or achieve high production capacity of the production line, Helicoil is more preferable; if it can be completed in a controllable workshop environment and can withstand longer installation time, then Insert is worth investing in.

3. Repeatability & Serviceability (Reusability)

Helicoil

- Maintenance-friendly: Spring-type screw sleeves can usually be disassembled and replaced, making them suitable for applications requiring multiple repairs due to damaged threads.

- Low damage to the base material: The installation/removal process causes minimal secondary damage to the base material (depending on the operation), facilitating on-site cyclic maintenance.

- Limited lifespan for multiple disassemblies: Frequent disassembly in soft materials will gradually wear down the contact surface between the base material and the screw sleeve, affecting the lifespan.

Insert (Solid Sleeve / Locking Key Sleeve)

- Strong ability to disassemble and reassemble: The solid bushing itself has good rigidity, and the internal thread can withstand more loading and unloading cycles; however, this is only possible if the bushing is correctly installed and the base material is not damaged.

- High complexity in disassembly: Bushings with locking pins or external threads often require special tools or even damage to the bushing for disassembly, resulting in high maintenance costs.

- Better protection of the base material (long-term): In high-frequency disassembly and reassembly scenarios, the solid bushing can provide a more stable reassembly interface compared to directly repairing the base material threads.

If multiple disassembly and assembly (for maintenance or modular replacement) is anticipated, consider using solid bushings for “long-lasting interfaces”; if quick on-site replacement and low-cost spare parts are prioritized, Helicoils are more suitable for short-term cycles.

How To Choose the Right Solution?

1)First, clarify the "application profile"

Before making a choice, collect and document the following points in writing:

- Load type: Static load, shear, cyclic fatigue, impact or combined load.

- Vibration level: None, low amplitude, periodic high amplitude, frequent impact.

- Base material type and thickness: Aluminum alloy (such as 6061), magnesium, mild steel, stainless steel, plastic, etc.; thin-walled or solid parts.

- Maintainability and disassembly frequency: Frequent disassembly/repair or one-time assembly.

- Space limitation and hole depth: Radial space and axial depth.

- Environmental conditions: Corrosion (salt spray, chemicals), temperature, marine/underground, etc.

- Cost constraints: Unit cost vs. Life Cycle Cost (LCC).

2)Make independent judgments based on key project objectives

Judged step by step in order of importance, until the feasible options are selected:

- Safety/Critical Structures > Vibration/Fatigue > Maintainability > Cost > Space.

- If it is a safety-critical or high-cycle fatigue (aircraft structures, main load-bearing joints, wind turbine towers, etc.) → The preferred option is solid bushing/keensert bushing (Insert, Keensert, etc.), as they offer superior mechanical locking, stress dispersion, and fatigue life compared to spring-type.

- If it is light load, frequent maintenance or on-site rapid repair (aftermarket automobiles, instrument casings, furniture) → The preferred option can be Helicoil (spring-type screw sleeve), as it has low cost, lightweight installation tools, and quick replacement.

3)Judgment of Material Compatibility between Base Material and Substrate

- Soft base materials (aluminum alloy, magnesium, plastic): Preferentially consider solid bushings/ bushings with large surface contact, which can distribute the load over a larger volume of the base material, reducing thread crushing and fatigue cracking. Helicoil can be used to restore the original thread, but caution is needed in high-cycle environments.

- Highly corrosive environments (marine, chemical): Select compatible materials (such as 316/316L stainless steel, nickel-based alloys or titanium), and consider electrochemical corrosion (separation or similar materials should be added when contacting different metals).

- High-temperature conditions: Confirm the thermal expansion and strength reduction of the material with temperature and the compatibility with the thread (some spring steels have decreased elasticity and clamping force at high temperatures).

4)Cost Evaluation: Unit Price vs. Life Cycle Cost (LCC)

- Helicoil: The cost per piece and per tool is low, and the maintenance and replacement are quick. It is suitable for short-term or low-load working conditions.

- Insert (Solid/Key): The unit price is high, and the installation cost (time/tool) is also high. However, in high-load/high-vibration/areas that are difficult to access, it can significantly reduce the downtime and maintenance costs.

Engineering practice suggestion: Incorporate “unit item price difference × expected lifespan (years) + maintenance cost” into the LCC model for decision-making (simply quantify it by using the estimated failure rate × estimated annual maintenance hours for the maintenance cost).

5) Installation and On-site Feasibility

- Helicoil: Requires special STI taps, installation tools, and folding handles; has a low training requirement and is convenient for on-site repairs.

- Insert: Usually requires more precise torque control, locking impact, or hydraulic tensioning equipment; installation is difficult when the on-site conditions are limited.

Conclusion – Helicoil vs Insert

In the thread repair and reinforcement solutions, Helicoil (spring-type sleeve) and Insert (solid bushing/locking sleeve) have their respective applicable scenarios. The correct selection not only affects the installation efficiency and cost, but also directly relates to the structural safety, service life and maintenance cycle.

- Helicoil is renowned for its low cost, light weight, small footprint, and ease of installation. It is suitable for applications with light loads, thin walls, frequent maintenance, or limited space. Its drawback is that it has relatively limited long-term reliability under high vibration, high cyclic fatigue, or extreme loads.

- Insert demonstrates greater stability in mechanical locking, load distribution, and excellent fatigue life. It is suitable for high loads, high vibration, and critical structural connections. However, the cost is higher for individual pieces and installation, and on-site replacement is more complex.

Professional Advice

- In scenarios with safety-critical or high-reliability requirements, Insert should be given priority and the installation and inspection specifications should be strictly followed.

- In maintenance situations where cost and efficiency are prioritized or in non-critical areas, Helicoil offers a cost-effective solution.

- Regardless of the chosen solution, it is necessary to evaluate it based on the base material characteristics, usage environment, and life cycle cost (LCC), and to verify its feasibility through trial installation, drawing tests/fatigue tests.

Do You Have Any Questions?

Let Us Solve Your Problem

Secure Your Projects with Rivetfix Helicoils and Inserts

Whether you need to enhance the thread strength in a lightweight structure or ensure the long-term stability of the connection in a high-load environment, Rivetfix’s Helicoils and Inserts can provide you with precise and reliable solutions. We select high-quality materials such as stainless steel and special alloys to ensure that the products meet the industry-leading standards in terms of wear resistance, corrosion resistance and load-bearing capacity.

Choosing Rivetfix is not just about selecting a fastener; it’s about adding a lasting and secure safety guarantee to your equipment – Act now and bring professional-level connection experience to your project!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.