What is Rivet Nut Tensile Strength?

Leading Rivet Nut Manufacturer and Supplier in China

As a reliable fastening solution, rivet nuts are widely used to connect and secure parts of different materials. Especially in the case of large tension and pressure, the tensile strength of the riveted nut is very important. Tensile strength determines the performance of the rivet nut under high loads, which affects the stability and long-term durability of the connection. In this article, we will delve into the rivet nut tensile strength and how to select the most suitable rivet nuts according to different application requirements.

Table of Contents

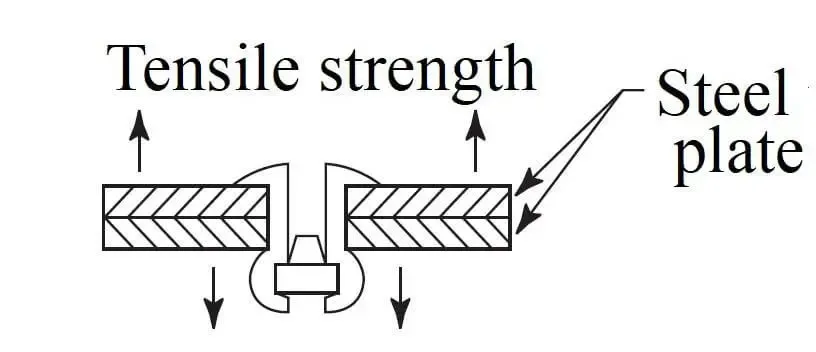

What is the rivet nut tensile strength?

Tensile strength refers to the maximum tension or stress that a material can withstand during the tensile process until the material breaks or deforms. For a rivet nut, tensile strength is its ability to not deform or fall off under the action of tension. In short, it determines the strength and durability of the rivet nut when it is loaded after installation.

Selecting the rivet nut with appropriate tensile strength can effectively improve the performance and safety of the connection system. In addition, it ensures stable operation under high loads and harsh conditions.

1. Maintain connection stability: The tensile strength of the rivet nut determines whether it can maintain a firm connection with the substrate. Especially in high-load or dynamic working environments. The rivet nut with high tensile strength can better prevent loosening and falling off, ensuring a stable connection.

2. Suitable for high load applications: In applications that bear large tensile forces, such as mechanical equipment, auto parts, etc.. The tensile strength of the rivet nut is crucial. Ensure that more weight can be carried to avoid damage or failure of the rivet nut due to excessive tension.

3. Impact on safety: Rivet nuts with high tensile strength can provide reliable fixation under harsh conditions. Ensure the safety of equipment or structures, especially in high vibration or frequent load environments.

4. Durability and long life: The tensile strength of the rivet nut directly affects its durability in long-term use. The higher the tensile strength, the longer the service life of the rivet nut. This reduces the frequency of maintenance and replacement.

The Importance of Tensile Strength in Practical Applications

The tensile strength of rivet nuts is one of the key performance indexes. It determines its stability and safety when subjected to external forces. Understanding its application significance in different fields can help us better choose the right rivet nut.

In automotive, aviation, electronic products and other industries

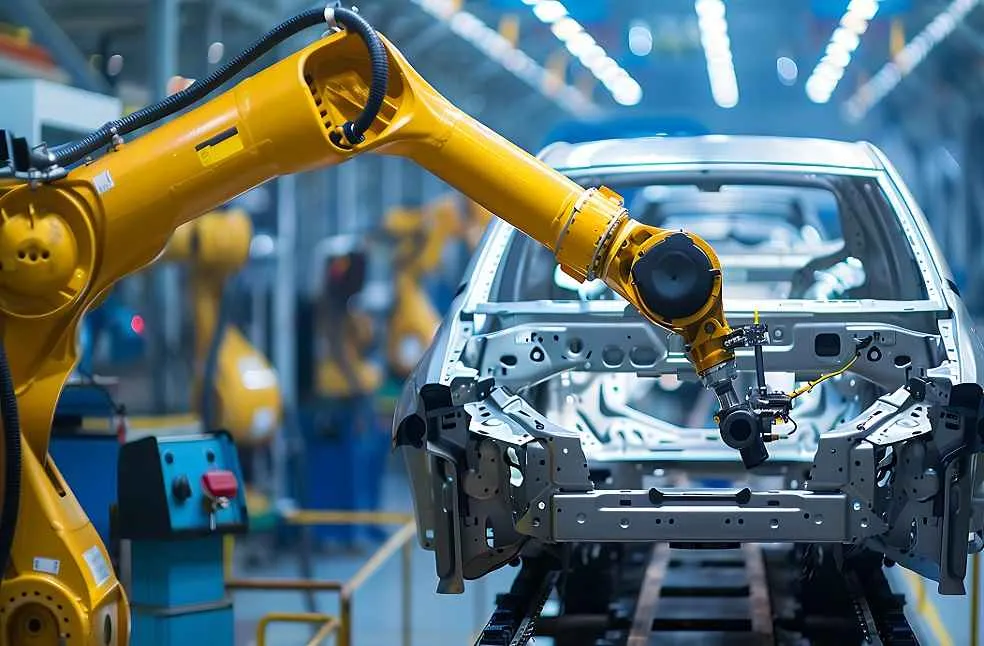

In the automotive industry, the tensile strength of riveted nuts ensures a solid connection between body, engine and chassis components. It can withstand the vibration and impact during driving to ensure safety.

In aviation, riveted nuts are used for the connection of aircraft structures and engine components. The high tensile strength ensures that the aircraft can carry various dynamic loads stably during flight. And avoid the failure caused by loose connections.

In electronics, rivet nuts provide a firm hold on the housing and internal components. High tensile strength prevents loosening and damage caused by external impact to ensure long-term stable operation of the equipment.

In heavy machinery, building structures

In heavy machinery applications, the tensile strength of riveted nuts enables them to withstand large loads stably. And avoid failure due to excessive tension, so as to ensure the safe and efficient operation of mechanical equipment.

In the construction industry, the tensile strength of riveted nuts directly affects the stability and durability of buildings, especially in high loads and harsh environments. Ensure that the building holds the pressure for a long time without loosening or structural failure.

Do You Have Any Questions?

Let Us Solve Your Problem

Key Factors Influencing the Rivet Nut Tensile Strength

1. Material Type

The tensile strength of rivet nuts of different materials is significantly different. Materials with higher hardness (such as stainless steel) usually have greater tensile strength and can withstand greater loads and stresses. Softer materials, such as aluminum, are suitable for lighter loads.

Stainless steel:

Stainless steel rivet nuts have excellent corrosion and high temperature resistance and are widely used in harsh environments. Due to their higher strength and hardness, stainless steel riveted nuts usually have higher tensile strength. They are suitable for applications with heavy loads and high strength requirements, such as the automotive, aerospace and chemical industries.

Carbon steel:

Carbon steel rivet nuts usually have good mechanical properties, especially in terms of withstanding tension and pressure. Carbon steel material is relatively strong, moderate tensile strength, suitable for most industrial applications. Its low cost is suitable for applications with moderate strength requirements.

Aluminum:

Aluminum rivet nuts are light weight and corrosion resistant. However, its tensile strength is low, and it is suitable for bearing small loads. They are commonly used in electronics and lightweight equipment to reduce weight and ensure connection stability.

2. Size and design of rivet nuts

The outside diameter, inside diameter, length and structural design of the rivet nut directly affect its tensile strength.

In general, larger outer diameters and longer nuts provide stronger holding forces and higher tensile strength. Reasonable design of the structure helps to enhance its bearing capacity.

3. Material thickness

The thickness of the connection material has significant influence on the tensile strength of the rivet nut.

The thicker material is able to better distribute the tension, which allows the riveted nut to withstand higher tension.

The thinner material may cause the tensile strength of the riveted nut to be insufficient to withstand the larger load.

4. Surface treatment

The surface treatment of the rivet nut, such as galvanizing, anodizing, etc., can improve its tensile strength, especially in terms of corrosion resistance. Through these surface treatments, the riveted nut can maintain high mechanical properties in harsh environments, thus extending the service life.

Tensile strength comparison of different rivet nuts

| Material | Tensile Strength Range | Key Features | Applications |

| Stainless Steel | 600 MPa – 1000 MPa | High strength, excellent corrosion resistance | Aerospace, automotive, chemical industries |

| Carbon Steel | 450 MPa – 700 MPa | Good strength, cost-effective, suitable for heavy loads | Manufacturing, heavy machinery, construction |

| Aluminum Alloy | 250 MPa – 400 MPa | Lightweight, good corrosion resistance, lower strength | Electronics, lightweight machinery, consumer products |

1. Stainless steel rivet nuts

Although stainless steel provides higher tensile strength, it is heavier. For applications that require high strength and corrosion resistance (such as aerospace and automotive manufacturing), stainless steel rivet nuts provide the best strength performance. However, it may affect the overall weight, especially in applications with strict weight requirements.

2. Carbon steel rivet nuts

Carbon steel rivet nuts provide a good balance between strength and weight. Its tensile strength is sufficient for most industrial applications, while weighing less than stainless steel and costing less. Carbon steel rivet nuts are an economical and reliable choice for most mechanical equipment and structural applications.

3. Aluminum rivet nuts

Although aluminum rivet nuts have low tensile strength, due to their lightweight characteristics, they are suitable for applications with strict weight requirements, such as electronics and light machinery. Aluminum rivet nuts are ideal for low weight requirements and low strength requirements. However, it does not have the performance advantages of stainless steel and carbon steel under high load conditions.

Selecting rivet nuts with appropriate tensile strength

When selecting riveted nuts, the tensile strength requirements should be determined according to the specific application scenario and working environment.

Select rivet nuts according to different application scenarios

Automotive manufacturing: In automotive manufacturing, riveted nuts are subjected to high tensile, vibration and impact. Therefore, it is ideal to choose stainless steel or carbon steel riveted nuts with high tensile strength. This ensures a stable connection between the body and engine components in harsh operating environments.

Furniture assembly: Furniture generally does not bear excessive load. The use of aluminum alloy or carbon steel rivet nuts with moderate tensile strength is usually sufficient to provide sufficient stability while reducing weight.

Building construction: Metal structures and frames in buildings require strong tensile strength to ensure long-term stability and durability. Therefore, stainless steel or carbon steel riveted nuts are usually chosen, especially in structures that bear high loads.

Recommendations for rivet nut selection under high load and high vibration environment

High load environments: In construction applications with high load requirements such as heavy machinery, rivet nuts with high tensile strength need to be selected. We usually recommend stainless steel or carbon steel. These materials have high tensile strength and corrosion resistance, which can keep the connection stable under long-term load.

High vibration environment: such as automotive engine, aerospace, railway and other high vibration environment, choose stainless steel or carbon steel rivet nuts. This ensures that the riveted nut will not loosen, deform or fall off. Reinforced nut construction and locking design (such as locking washers) further improve tensile strength and vibration resistance, ensuring the reliability of fasteners under dynamic loads.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Test the Rivet Nut Tensile Strength?

The tensile strength of rivet nuts is tested by tensile test, thread pulling test and cyclic load test. The experimental data show that the tensile strength of rivet nuts of different materials is significantly different. Stainless steel and titanium alloys offer the highest strength, while aluminum are suitable for light load environments.

It is very important to choose the right rivet nut material according to different application requirements. Suitable tensile strength ensures the reliability and durability of the connection.

Rivetfix maintains strict quality control throughout the production process, ensuring high standards in every product. We offer comprehensive quality testing, including tensile strength tests for rivet nuts, to guarantee their performance and reliability.

By conducting these rigorous tests, we ensure that each rivet nut meets the required specifications for durability, load-bearing capacity, and long-term use. Our commitment to quality ensures that our customers receive reliable, high-performance fasteners for their critical applications. The following are some types of riveted nut test videos:

Methods to Improve the Tensile Strength of Rivet Nuts

1. Choose the right materials

High strength materials: Choose stainless steel, carbon steel, titanium alloy and other materials with high tensile strength. These materials have excellent tensile, fatigue and corrosion resistance and can significantly improve the load carrying capacity of rivet nuts.

Material optimization: The use of high-strength materials that have been heat treated or cold worked can further improve their tensile strength. For example, quenching carbon steel can increase its tensile strength.

Balance of weight and strength: Select the appropriate material according to the specific application to avoid excessive material resulting in unnecessary mass increase. For example, although the tensile strength of aluminum alloy riveted nuts is low, it can still provide sufficient strength under the lightweight requirements.

2. Reasonable design of rivet nuts

Increased contact area: Optimized nut outer diameter, inner diameter and thickness design. This increases the contact area with the joining material, which in turn increases the tensile strength.

Reasonable thread design: the depth, shape and Angle of the thread directly affect the tensile strength. The design of deeper threads and larger contact areas helps to increase the friction between the nut and the connecting material, thereby increasing the tensile strength.

3. Surface treatment and coating improvements

Galvanized treatment: The use of galvanized rivet nuts can significantly improve its corrosion resistance and tensile strength. The galvanized layer prevents the riveted nut from being damaged in humid or chemically corrosive environments and ensures its long-term stability.

Anodizing: For riveted aluminum alloy nuts, anodizing treatment can effectively improve their corrosion resistance and surface hardness, and further enhance their tensile strength.

Coating technology: By using coating technology (such as polyurethane coating or powder coating), a protective layer can be formed on the surface of the riveted nut. It can not only improve the tensile strength, but also increase its wear resistance and chemical resistance.

Summary

Tensile strength is a key index to measure the performance of rivet nuts, which determines their reliability under load and stress. Through a series of methods, such as the selection of suitable materials, rational design and effective surface treatment. We can significantly increase the tensile strength of the rivet nut, thus ensuring the stability and safety of the connection.

Understanding and selecting the right rivet nut is crucial to improving the overall performance of the product. Especially in automotive manufacturing, building construction, and heavy machinery. Hope this blog post has provided you with valuable information to help you make smarter choices in practical applications.

Do You Have Any Questions?

Let Us Solve Your Problem

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.