What is Rivet Nut Grip Range? The Comprehensive Guide

Leading Rivet Nut Manufacturer and Supplier in China

What is rivet nut grip range? How to select the right rivet nut for your project through the Grip Range of the rivet nut? Read this blog to help you gain insight into rivet nuts and make recommendations for your choices.

Table of Contents

What is Rivet Nut Grip Range?

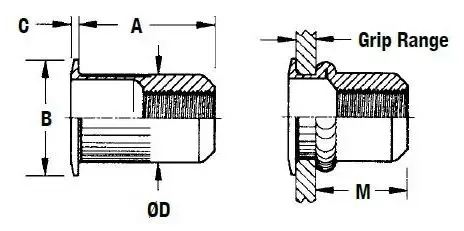

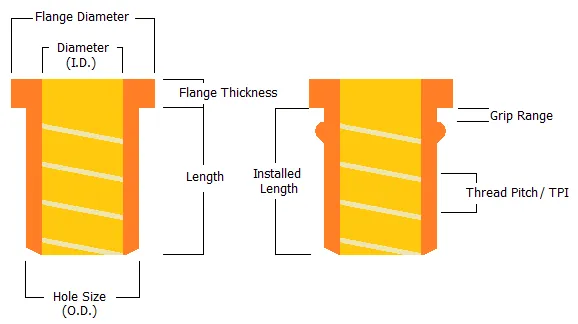

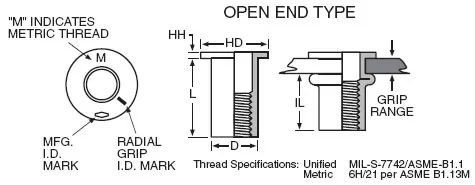

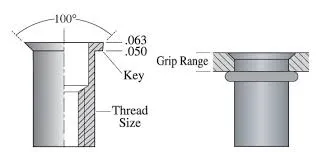

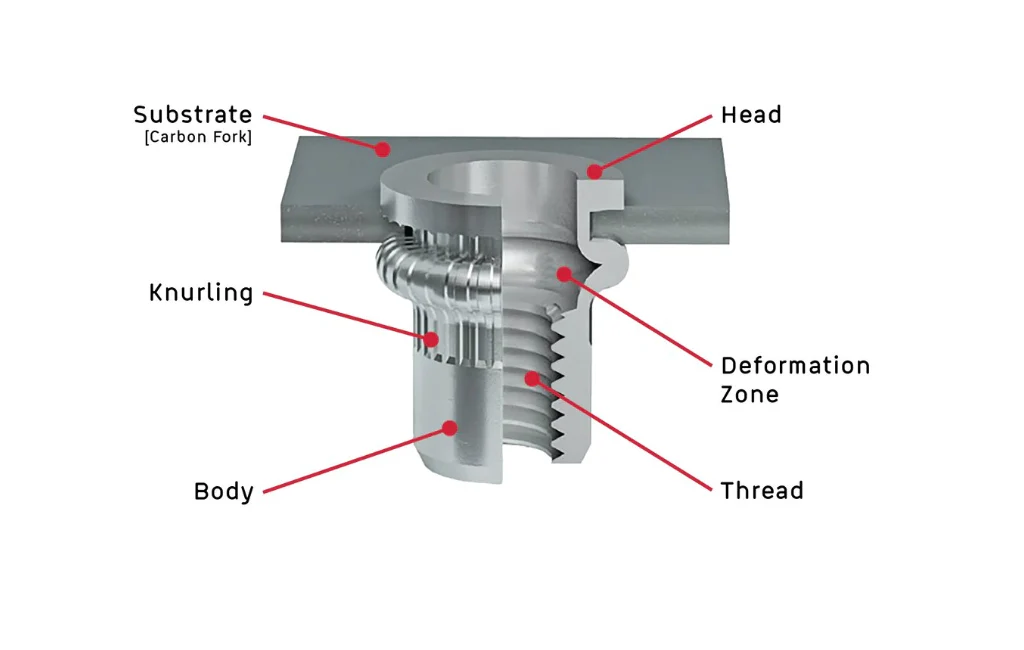

The grip range of a rivet nut refers to the thickness of the material it can fasten. It is the range of material thicknesses in which a rivet nut can be installed. The rivet nut securely holds its threaded connection within this range.

It is determined by the size and design of the rivet nut. This includes its length, thread size, and the tool used for installation.

It is a critical specification because it determines the range of materials that can be effectively joined using a rivet nut. The correct grip range ensures that the rivet nut provides a secure, reliable, and lasting connection without damaging the materials or failing to hold under load.

Importance of Rivet Nuts Grip Range

The grip range of a rivet nut is important for ensuring a secure, strong connection between the fastener and the base material. If the material falls outside the recommended range, the rivet nut may not function properly, leading to weak connections or installation failure.

The connected material is too thick

If the connected material is too thick, the rivet nut may not be able to properly expand and create a strong hold. This could result in:

Insufficient expansion: The rivet nut’s internal sleeve may not expand fully against the material, leading to a loose fit.

Weak connection: The rivet nut may not engage properly with the base material, leading to potential pull-out failures or a lack of torque retention.

Installation issues: The rivet nut may be difficult to install, as the tool may not be able to exert enough force to correctly expand the nut over such a thick material.

Solution:

Select a rivet nut with a wider grip range that can handle thicker materials. Use a thicker, longer rivet nut that is specifically designed for larger ranges.

The connected material is too thin

If the connected material is too thin, the result can be:

Over-expansion: The rivet nut may expand too much, potentially deforming the thin material or causing it to tear.

Loss of torque or shear strength: In thin materials, the rivet nut may not create enough friction or contact area, leading to a loss of clamping force or holding strength.

Cosmetic damage: Excessive expansion can cause surface deformation, which could be problematic for aesthetic finishes or precision assemblies.

Solution:

Choose a rivet nut with a shorter or narrower grip range designed for thinner materials.

Consider using washers or other reinforcements to distribute the load and prevent damage to the thin material.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Measure Grip Range of Rivet Nuts

- Manufacturer Specifications: The most reliable way to determine the grip range is to refer to the rivet nut’s datasheet or technical specifications provided by the rivet nut manufacturers. This will list the exact minimum and maximum material thickness that the rivet nut is designed to handle.

- Installation Testing:

a. Install the Rivet Nut: Choose a material of known thickness and install the rivet nut. Use the manufacturer’s recommended installation tools and process.

b. Assess the Results: Check for proper expansion of the rivet nut, ensuring it does not deform the material and that it forms a secure bond. - Grip Range Formula (General):

If no data is provided, you can estimate the grip range by considering the overall length of the rivet nut and subtracting the necessary minimum distance for proper expansion. It is essentially the distance from the rivet nut’s collar (where it rests on the material) to the end of the bolt or thread.

Example: If a rivet nut has an effective length of 15mm and requires 1mm of expansion space for each material side, the grip range may be 13mm (if the bolt or mandrel doesn’t cover that portion). - Visual Inspection and Testing: After installation, if the rivet nut doesn’t form a complete or tight connection, then the grip range might not be sufficient for the material thickness. This can also be identified if the material starts to deform under load.

Considerations When Choosing Rivet Nut Grip Range

The grip range dictates whether the rivet nut can effectively fasten the materials you’re working with. It ensuring both performance and longevity of the connection. Below are the key considerations when choosing the appropriate rivet nut for your rivet nut.

1. Material Thickness

The primary consideration is the thickness of the materials being fastened. If the grip range is too narrow or too wide, the rivet nut may fail. This can prevent the rivet nut from creating a secure, reliable connection.

Thick Materials: For thicker materials, you will need a rivet nut with a wider grip range to ensure the rivet nut can expand fully and create a strong hold.

Thin Materials: For thinner materials, choose a rivet nut with a narrower grip range to prevent excessive expansion that could deform the material.

| Material Thickness | Recommended Grip Range | Considerations |

| Thick Materials (e.g., >6mm) | Larger grip range (e.g., 6-12mm) | Ensure full expansion for secure attachment, high load-bearing capacity, and strong material. |

| Thin Materials (e.g., <3mm) | Smaller grip range (e.g., 1-3mm) | Avoid over-expansion to prevent deformation, consider reinforcement if necessary. |

2. Material Type and Properties

The material type you are fastening plays a critical role in selecting the right rivet nut. Materials such as aluminum, steel, and plastics have different hardness and ductility, which affect how the rivet nut will expand and engage with the material.

Harder Materials: Materials like steel may require a rivet nut with a larger range to properly engage and create a strong bond.

Softer Materials: Softer materials like aluminum or plastics may require a smaller range to avoid damaging the material during installation.

3. Load Requirements

The load that the rivet nut will be subjected to, both in terms of shear and tension, will affect the grip range you should choose. It is important to pay attention to whether your riveted nuts are strong.

High Load Applications: If the connection will bear significant forces, you will need a rivet nut with a larger grip range and robust material to provide better shear strength and prevent failure.

Low Load Applications: For lighter-duty applications, a narrower grip range may be sufficient, and may even help reduce cost and improve efficiency.

| Application Type | Grip Range Recommendation | Key Considerations | Typical Load Capacity |

| High Load Applications | Larger grip range (e.g., 4mm to 10mm) and robust material (e.g., steel or stainless steel). | Requires higher shear strength (typically 400-600 N) and tensile strength (800-1200 N). | Tensile: 800-1200 N, Shear: 400-600 N |

| Low Load Applications | Narrower grip range (e.g., 1mm to 3mm). | Sufficient for lighter forces; lower shear strength (typically 100-300 N) and tensile strength (200-500 N). | Tensile: 200-500 N, Shear: 100-300 N |

4. Installation Considerations

Tooling and Equipment: Different grip ranges require different installation tools. Rivet nuts with wider grip ranges often require more powerful installation tools. If you are working with a large range of material thicknesses, ensure your tool can accommodate these variations without damaging the rivet nut or materials.

Installation Space: Larger grip range rivet nuts might require additional space for proper installation. This must be considered if space is limited in your assembly process.

5. Vibration and Fatigue Resistance

In many rivet nut application scenarios, special attention should be paid to applications affected by vibration or cyclic load. The grip range of the rivet nut should be carefully selected to ensure that it does not loosen over time.

A rivet nut with too wide a grip range could result in less surface contact, reducing friction and torque retention.

A rivet nut with the correct grip range ensures optimal expansion and torque resistance, minimizing loosening over time.

Do You Have Any Questions?

Let Us Solve Your Problem

Is the Grip Range of Rivet Nut Related to the Thread Size?

The grip range of a rivet nut is influenced by the thread size, but it also depends on other factors like the rivet nut’s overall length, material, and design. Generally, larger thread sizes are designed to work with thicker materials and require a wider grip range, while smaller thread sizes are used for thinner materials with a narrower grip range.

1. Larger Thread Size:

Rivet nuts with larger thread sizes (e.g., M8, M10) typically have a larger grip range.

These rivet nuts can accommodate thicker materials (e.g., 5mm to 10mm) and provide higher strength and load-bearing capacity.

The larger diameter allows for more material engagement, ensuring a stronger connection in thicker materials.

2. Smaller Thread Size

Rivet nuts with smaller thread sizes (e.g., M3, M4) generally have a narrower grip range.

These are suitable for thinner materials (e.g., 1mm to 3mm) and lighter-duty applications.

A smaller thread size means the rivet nut has less surface area for expansion, and as a result, it requires a narrower grip range to maintain a secure connection.

How Thread Size Affects Grip Range

The thread size indirectly influences the grip range because it affects the physical size of the rivet nut.

Larger threads lead to more substantial rivet nuts, which naturally require a wider grip range to accommodate thicker materials. Conversely, smaller threads lead to smaller rivet nuts with a narrower grip range, suitable for thinner materials.

Are There Rivet Nuts to Accommodate a Wider Range of Thicknesses?

Yes, there are rivet nuts designed to accommodate a wider range of material thicknesses. These versatile rivet nuts offer flexibility, durability, and cost savings. They include extended grip range, multi-grip, long body, and oversized rivet nuts. For applications where material thickness varies, these rivet nuts are very ideal choice.

They are especially useful in industries like automotive, construction, and manufacturing, where different materials are used in a single assembly.

- Flexibility: One rivet nut can handle multiple thicknesses, reducing the need for different sizes.

- Cost-Effectiveness: Fewer part types are needed for applications with varying material thicknesses, leading to inventory and cost savings.

- Ease of Installation: Reduces the number of different rivet nuts needed, making the installation process faster and simpler.

You can also consult Rivetfix for rivet nuts that can accommodate a wider thickness range. We provide a variety of sizes and styles of riveted nuts and mass rivet nuts customized service.

Custom Rivet Nuts for Your Porject

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.