What Are the Limitations of Rivnut?

Leading Rivet Nut Manufacturer and Supplier in China

When evaluating fastening solutions for thin-walled materials, rivet nuts (Rivnuts) are often praised for their ease of installation and ability to provide strong threads in blind applications. However, it’s important to understand that they are not suitable for every situation. In this article, we’ll explore what are the limitations of Rivnut, helping engineers and designers make informed decisions when selecting fasteners for structural integrity, safety, and long-term performance.

Table of Contents

What Are the Structural Limitations of Rivnuts?

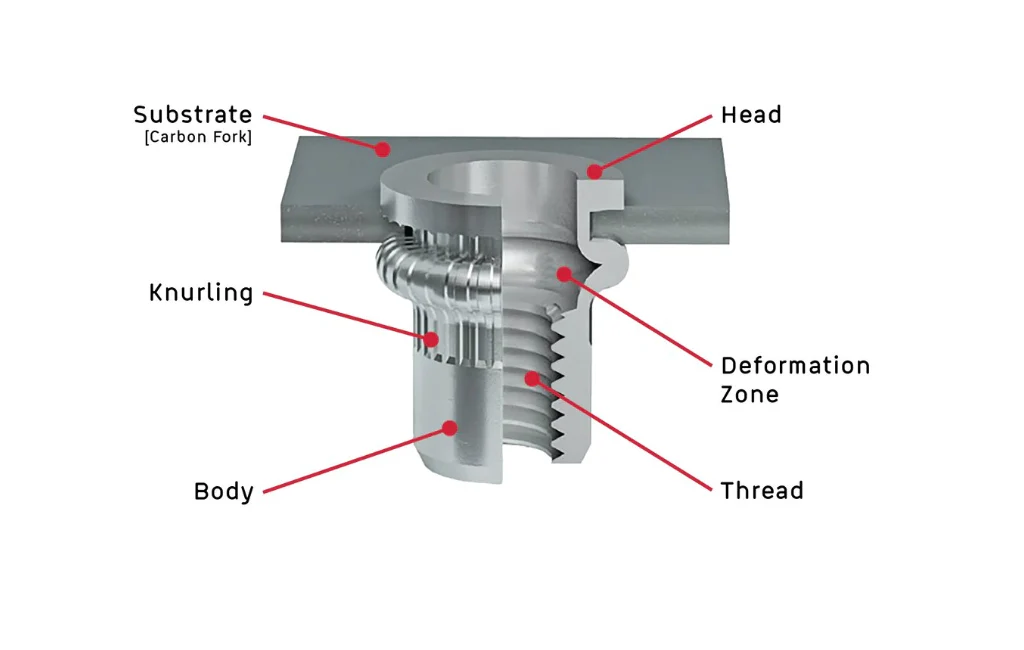

Rivnuts, also known as rivet nuts, are threaded fasteners installed through a “cold forming” or deformation-by-pulling process. Their structural design inherently imposes certain limitations, particularly in terms of reusability, adjustability, and installation precision. Below is a detailed explanation of the three key structural constraints:

1. Irreversible Deformation: Typically Not Reusable After Installation

The installation of a Rivnut relies on the plastic deformation of its tubular rear section. Under the force of a rivet gun, the tail end of the Rivnut expands outward and clamps against the backside of the base material, forming a secure mechanical grip. This process is akin to cold forging and results in permanent geometric change.

Once deformed, the shape of the Rivnut cannot be restored to its original state;

If removed and reinstalled, the deformed tail can no longer form a secure grip, leading to insufficient clamping force;

In addition, the removal process often involves destructive torqueing, further damaging the Rivnut body.

According to tests, over 80% of previously installed Rivnuts fail to maintain sufficient clamping force or rotate freely when reinstalled.

Conclusion: Rivnuts are generally single-use fasteners and should not be reused after removal.

2. No Positional Adjustment After Installation

The locking mechanism of a Rivnut depends on mechanical interlock achieved through permanent deformation. Unlike conventional nuts, once installed, Rivnuts cannot be rotated or repositioned for fine adjustment.

If misaligned during initial installation (e.g., eccentric or off-center placement), the only remedy is to fully remove and reinstall;

A misalignment greater than ±0.3 mm can significantly affect the bolt’s axial alignment, compromising load distribution;

According to DIN 1624 and ISO 15977 standards, the allowable positional tolerance is about 1.5%–2% of the Rivnut body diameter. Exceeding this leads to increased risk of connection failure.

Conclusion: Rivnuts require precise one-time positioning and offer no post-installation adjustability.

3. High Dependence on Hole Precision

The anti-rotation and clamping performance of a Rivnut heavily depends on the fit accuracy between the fastener and the pre-drilled hole. This is especially critical for round-body or knurled Rivnuts, where surface contact and friction are key.

If the hole is too large, the Rivnut may fail to anchor properly, causing spinning or slipping;

Smooth cylindrical Rivnuts rely heavily on friction with the hole wall — poor surface finish or excessive clearance will drastically reduce holding power;

For hexagonal or knurled-body Rivnuts, mismatched hole geometry or poor tolerance also compromises anti-rotation performance.

Therefore, installing Rivnuts requires precisely machined and cleaned holes. Any error in hole size or wall finish can significantly reduce the fastener’s structural integrity.

While Rivnuts are convenient to install and suitable for thin sheet materials and moderate-load applications, their structural characteristics impose significant limitations when it comes to high tensile, shear, or vibration-resistant demands.

1. Relatively Low Tensile and Shear Strength

Rivnuts are typically made of thin-walled tubular metal, and their retention relies on a flanged deformation at the tail end to clamp against the back of the base material. This makes them suitable for providing medium-strength threaded connections but significantly weaker than weld nuts or solid nuts, especially under high axial or shear loads.

- Tensile loads are primarily borne by the deformed flange, which is structurally thin and prone to yielding;

- When installed in thin sheets (1.0–2.5 mm) or soft materials like plastic or composites, the base material itself becomes a limiting factor in load capacity;

- Compared to weld nuts of the same thread size, Rivnuts typically have 30%–50% lower tensile pull-out strength and 20%–40% lower shear strength.

Example Data:

| Thread Size | Rivnut Max Tensile Strength | Weld Nut Max Tensile Strength |

| M6 Carbon Steel | 7.5–9.5 kN | 13–15 kN |

| M8 Stainless Steel | 10–12 kN | 18–21 kN |

Conclusion: Rivnuts should be used with caution in load-critical structural connections such as chassis parts or frame joints where large axial or shear forces are present.

2. Poor Vibration Resistance and Loosening Risk

Rivnuts are held in place through mechanical deformation and frictional grip, lacking the rigid support offered by welds or keyed features. As a result, under high-frequency vibration, impact, or alternating loads, Rivnuts are more prone to slight movement that may cause thread loosening or stripping over time.

- In thin sheet applications, the limited bearing surface on the backside can lead to gradual loosening under vibration;

- Cylindrical Rivnuts in particular have weak anti-rotation capacity unless paired with locking hardware like spring washers or nylon-insert locknuts;

- In environments such as automotive, machinery, or rail applications with significant vibration, Rivnuts without additional locking measures can suffer premature failure.

A comparison of vibration resistance among different fastener types shows:

- Weld nuts and solid nuts perform best, rated 9 and 8 respectively for vibration resistance;

- Hexagonal Rivnuts offer better anti-rotation and vibration resistance than round-body types;

- Cylindrical Rivnuts rank the lowest in vibration performance, scoring around 3, making them suitable only for low-vibration environments.

Practical Recommendations:

- Use locking features such as nylon locknuts, thread-locking compounds, or spring washers in conjunction with Rivnuts;

- Opt for anti-rotation Rivnut designs such as hexagonal or keyed body styles;

- For high-vibration areas, consider alternatives like weld nuts, embedded nut plates, or rivet bolts for greater reliability.

What Are the Installation Challenges of Using Rivnuts?

1. Specialized Installation Tools Required

The installation of Rivnuts requires plastic deformation at the tail end to form a flange through a stretching process. This must be done with a specialized rivet nut tool, such as a manual rivet nut gun, pneumatic riveter, or electric riveting device.

Without these specialized tools, standard wrenches or screwdrivers are ineffective, and attempts to install may result in Rivnut failure or incomplete deformation, compromising connection strength.

Tool Comparison:

| Tool Type | Cost | Application Frequency | Description |

| Manual Rivet Nut Gun | Low | Low-frequency / small batches | Low cost but labor-intensive and slow |

| Pneumatic Rivet Nut Gun | Medium | Medium to high frequency | High efficiency, consistent force, requires compressed air system |

| Electric Rivet Nut Gun | High | Automated / assembly line use | Precision control of force and stroke, suitable for standardized production |

2. Installation Quality Has a Significant Impact on Performance

Key Issue: Proper Rivnut installation requires accurate hole alignment, correct pulling force, and uniform flange formation. Even minor deviations can lead to installation failure.

Common Errors and Their Effects:

- Misaligned holes or oversized holes → Rivnut becomes eccentric, slips, or loses anti-rotation capability;

- Stroke too short/too long → Inadequate flange formation or damage to the base material;

- Not flush with the material surface → Gaps after installation, compromising load transfer.

Example:

For an M6 carbon steel Rivnut, the recommended installation pull force is 13–15 kN. Exceeding 18 kN may cause the body to crack; less than 10 kN results in incomplete flange formation—both considered failed installations.

For beginners or non-professional operators, it is highly recommended to use rivet tools with torque or stroke control features, and to calibrate settings through actual testing.

3. Structural Limitations

Although Rivnuts are known for blind-side installation, they still require clearance behind the hole to allow flange formation. If the application involves a blind hole or enclosed thick-wall structure (e.g., sealed welded tubes or inaccessible cavities), the Rivnut will not properly deform and lock in place.

Examples of Structural Suitability:

- Suitable: Sheet metal, sidewalls of tubing, plastic casings—single-layer thin materials;

- Not Suitable: Filled cavities, materials thicker than Rivnut’s grip range, or areas without backside access for inspection or repair.

Additionally, if the base material thickness exceeds the Rivnut’s standard grip range, the flange cannot properly engage the material even if installed, resulting in loose and unreliable connections.

What Are the Material Compatibility Issues of Using Rivet Nuts?

When selecting and using rivet nuts, material compatibility is a critical factor. Ignoring it can lead to poor installation, connection failures, or long-term corrosion issues. Key considerations are as follows:

①. Incompatibility with Soft Materials

Rivet nuts are primarily designed for use in metal or hard substrates, where their installation relies on plastic deformation to create a secure mechanical grip. However, when used with soft materials like wood, plastic, or composites, standard rivet nuts often fail to provide a reliable hold.

This is because soft materials have lower tensile and compressive strength, which means that under pulling or torque forces, the rivet nut is more likely to loosen or pull out, compromising connection strength and safety.

Recommendation: For soft materials, use alternatives like jack nuts or threaded inserts, which are specifically engineered to match the mechanical properties of softer substrates and provide more secure fastening.

②. Corrosion Risk and Galvanic Corrosion

The material of a rivet nut must be compatible with both the base material and the application environment. If the rivet nut and base material have significantly different electrochemical properties, they are prone to galvanic corrosion in moist or corrosive environments.

This type of corrosion degrades the material over time, leading to pitting at the joint interface, eventual connection failure, and a shortened product lifespan.

a. Galvanic Corrosion Principle

When two dissimilar metals with different electrochemical potentials come into contact in the presence of an electrolyte (such as moisture, water, or salt), they form a tiny galvanic cell.

- The less noble metal (anode) corrodes faster

- The more noble metal (cathode) is protected

Over time, the anode material is gradually “sacrificed,” which weakens the structural connection.

Example:

Installing zinc-plated steel rivet nuts into stainless steel panels in a humid or salty environment may result in the zinc layer corroding first, exposing the steel underneath and compromising the joint.

b. Electrochemical Potential Comparison of Common Materials

| Material | Electrode Potential (vs SHE) | Corrosion Tendency |

| Magnesium | -2.37 V | Extremely Corrosive |

| Aluminum (Pure) | -1.66 V | Highly Corrosive |

| Carbon Steel | -0.50 to -0.70 V | Moderate Risk |

| Zinc-Plated Steel | -0.76 V | High Corrosion Risk |

| Stainless Steel 304/316 | -0.10 to 0.00 V | Highly Corrosion-Resistant |

| Copper / Brass | +0.30 V and above | Low Corrosion Risk |

- Potential Difference > 0.25 V: Noticeable risk of galvanic corrosion

- Potential Difference > 0.50 V: High risk — avoid unless protective measures are in place

c. Effects of Galvanic Corrosion

- Reduced Mechanical Strength: Nut deformation, thread stripping, and weaker joint strength

- Surface Peeling and Rusting: Poor aesthetics, which affects final product quality

- Connection Failure: Especially critical in high-load or safety-sensitive structures (e.g., automobiles, marine equipment, outdoor installations)

- Increased Maintenance Costs: Frequent replacements and repairs due to accelerated degradation

d. Typical High-Corrosion Environments

- Marine Environments: High salt + humidity → ideal conditions for galvanic corrosion

- Industrial Areas: Acidic gases (SO₂, NOₓ) → accelerate metal oxidation

- Damp / Condensation-Prone Areas: Persistent moisture → constant presence of electrolyte

What Are the Limitations of Rivet Nuts in High-Safety Applications?

1. Unsuitable for Critical Safety Components

In industries or applications where extremely high safety margins are required—such as:

- Aerospace structures (e.g., aircraft skin joints, cabin supports)

Automotive chassis, suspension systems, and braking systems, where components are exposed to impact or fatigue loads

Main structural joints of industrial robots or robotic arms

These areas are typically subject to high stress or dynamic loads, demanding fasteners with exceptional strength redundancy, fatigue resistance, and stability.

Rivet nuts function by plastic deformation of the collar during installation, which relies on:

The mechanical strength of the rivet nut body

The localized contact area with the base material

The quality of deformation and interference fit during installation

However, compared to rigid fastening methods such as welded nuts or threaded bolts in solid tapped holes, rivet nuts have inherent limitations in tensile strength, shear strength, and fatigue resistance. They are also less capable of withstanding impact loads.

If subjected to overload, vibration, or long-term stress, rivet nuts are prone to:

Loosening of the deformed joint

Thread stripping or deformation

Connection instability, which can compromise the entire structure

Therefore, for critical load-bearing points or safety-related joints, rivet nuts are not recommended as the primary fastening method.

2. Limited Performance Under High-Frequency Assembly

Although rivet nuts provide threaded connections, their bodies are typically made of aluminum alloy, mild steel, or stainless steel, and the internal threads can degrade under repeated use due to:

Thread wear: Repeated tightening or excessive torque can deform or strip the threads

Fatigue at the deformed zone: Repeated assembly weakens the clamping force of the installation zone

Off-angle tool insertion: Can damage the threads or mar the surface, compromising fit and strength

In applications requiring frequent maintenance or component replacement (e.g., electrical control panels, service hatches), rivet nuts do not offer the same reusability as welded nuts, threaded inserts, or machined metal threads.

Over time, this may lead to loosening or connection failure, especially under continuous servicing conditions.

Conclusion:

While rivet nuts offer advantages like quick installation and single-sided access, they have clear limitations in high-safety applications due to:

Inferior structural performance

Lower long-term reliability

Limited reusability under repeated loading or disassembly

In scenarios that demand safety redundancy, impact resistance, or frequent servicing, it is advisable to use higher-strength and more durable fastening solutions, such as welded nuts, solid studs, or threaded metal inserts, to ensure long-term connection stability and safety.

What Are the Cost and Maintenance Considerations of Using Rivet Nuts?

While rivet nuts are widely used in sheet metal assembly for their convenient installation and broad applicability, they come with hidden costs related to maintenance and installation risks, particularly noticeable in mass production or structural repair scenarios. These cost considerations mainly fall into two categories:

1. High Maintenance Costs

Single-Use Design, Not Reusable After Removal

During installation, the rear portion of a rivet nut undergoes irreversible plastic deformation via specialized tools, forming a clamping zone on the back side of the base material. While this ensures a secure connection, it also brings significant drawbacks:

Once removed, it fails: The original form cannot be restored

Cannot be reused: The old rivet nut must be completely replaced, increasing part consumption

Especially when using expensive materials such as aluminum or stainless steel, replacements can significantly raise maintenance costs

Difficult Removal Reduces Efficiency

Removing a rivet nut typically involves destructive methods, such as:

Drilling out the body

Cutting off the surface flange

Forcing or breaking the deformed back-end structure

These processes are time-consuming and labor-intensive, and often damage the hole walls of the base material—potentially weakening or even ruining the component entirely.

2. High Cost of Installation Errors

Installation Errors Are Irreversible

Rivet nuts require precise control during installation. Several factors must be managed carefully:

Hole diameter compatibility: Too small, and insertion is impossible; too large, and the nut won’t grip

Proper pull force: Too little results in loose installation; too much can tear the base material or break the rivet nut

Correct perpendicularity: Misalignment leads to poor contact and weak load transmission

Common consequences of installation failure include:

Deformed or oversized holes, compromising subsequent assembly

Torn or bulged sheet surfaces, reducing strength and visual appeal

Time-consuming repairs, such as welding, grinding, or re-drilling—all of which increase labor costs and slow down production

Greater Risk for Expensive or Irreplaceable Base Materials

With high-value materials like stainless steel, aerospace-grade aluminum, or custom components, a single failed installation often means the part cannot be reused, leading to:

Material waste

Project delays

Escalated costs

Summary and Recommendations

Although rivet nuts offer a low upfront cost, their non-reusability, irreversible installation, and destructive removal methods introduce significant hidden costs and maintenance challenges in real-world applications.

Particular caution should be exercised in scenarios such as:

High-precision assemblies with low tolerance for error

Structures requiring frequent disassembly or maintenance

Expensive or non-repairable base materials (e.g., titanium, stainless steel, carbon fiber composites)

Conclusion - What Are the Limitations of Rivnut?

Rivet nuts (Rivnuts) are a classic solution for threaded connections in thin-walled materials, widely used in sheet metal, tubing, and profiles, especially where single-sided access is required. Their popularity stems from advantages such as lightweight design, low cost, and simple installation. However, due to their structural characteristics and installation mechanism, rivet nuts are not a universal fastener and are not suitable for all working conditions.

Advantages:

Ideal for blind holes: Can be installed from one side only, perfect for tubular structures or enclosed spaces.

Quick installation: Requires no welding or tapping, saving significant processing time.

Cost-effective: Lower material and labor costs compared to welding or machined threads.

Wide adaptability: Available in various materials (aluminum, steel, stainless steel), thread sizes, and head styles.

Limitations should not be overlooked:

Limited strength: The clamping relies on localized deformation, making rivet nuts weaker in tensile and shear strength—unsuitable for high-load applications.

Non-reusable: The deformable structure is single-use. Once removed, the rivet nut must be replaced, increasing maintenance costs.

High sensitivity to installation quality: Incorrect hole diameter, misalignment, or insufficient pull force can lead to installation failure.

Material compatibility restrictions: In soft materials (e.g., wood, plastic), rivet nuts can loosen easily and may require alternative fasteners.

Unsuitable for critical safety components: Not recommended in applications requiring high safety redundancy, such as aerospace or automotive chassis systems.

Correct Fastener Selection Guide:

| Application Scenario | Recommended Fastening Method |

| Standard sheet metal (one-time assembly) | ✅ Rivet Nut |

| Frequent disassembly or maintenance | ⛔ Avoid Rivet Nut → Use Threaded Insert / Weld Nut |

| High-load or critical structural areas | ⛔ Avoid Rivet Nut → Use Solid Stud / Welded Structures |

| Limited installation access (single side only) | ✅ Rivet Nut or Clinch Nut |

| Soft materials (wood, plastic) | ⛔ Not suitable for Rivet Nut → Use Jack Nut, Threaded Insert, or Heat-Embedded Brass Nut |

Final Recommendation:

Before using rivet nuts, it is essential to evaluate the specific application conditions—including load requirements, base material, maintenance frequency, and safety level. Do not select rivet nuts solely based on speed or convenience.

For product designers and assembly engineers, understanding the strengths, weaknesses, and application boundaries of rivet nuts is critical to ensuring product reliability and minimizing maintenance costs.

Rivet nuts deliver excellent value only when used in the right applications. In unsuitable conditions, they can lead to structural failures, safety risks, and expensive repairs. Therefore, choosing the appropriate fastening method is a wise investment in long-term performance and system safety.

Do You Have Any Questions?

Let Us Solve Your Problem

Buy Rivet Nuts from Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.