What Are Rivet Nuts Used for ?

Leading Rivet Nut Manufacturer and Supplier in China

When working with various materials that require secure, threaded connections, it’s important to understand the functionality of different fasteners. One common question that arises is, “What are rivet nuts used for?” Read this blog to understand the basic knowledge of riveting nuts and solve your doubts.

Table of Contents

Rivet Nuts - Brief Introduction

Rivet nuts, also known as rivnuts, are versatile fasteners used to create a threaded insert in materials that are too thin or soft to support a threaded hole. They are designed to be installed from one side of a workpiece (blind installation), making them highly practical in a wide range of applications.

History of Rivet Nuts

The rivet nut was invented by the B.F. Goodrich Company in the late 1930s. It was developed as a solution for securing de-icing boots to aircraft during World War II, where access to the opposite side of the material was not possible. The innovation quickly expanded into other industries due to its versatility and ease of use.

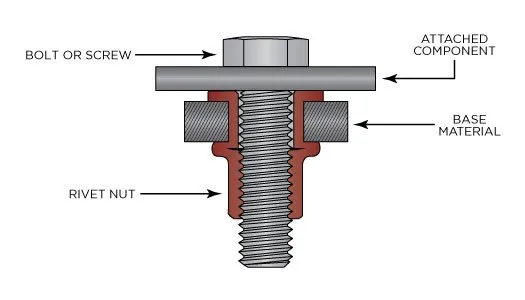

Main Parts of a Rivet Nut

The main parts of a rivet nut are:

Body: The cylindrical part of the rivet nut, which is inserted into the pre-drilled hole. The body is typically made of metal like steel, aluminum, or stainless steel and is designed to provide a durable, strong foundation for threading.

Thread: The internal threads within the body that allow a screw or bolt to be fastened securely.

Flange: The flat, circular rim at the top of the rivet nut. This flange helps to anchor the rivet nut in place and prevents it from being pulled through the hole once installed.

Mandrel (in some types): A rod or shaft used in the installation process, which applies pressure to the rivet nut to expand it and secure it in place within the material.

These features vary depending on the type of rivet nut and its specific application.

Why Use Rivet Nuts?

Rivnut provide several key benefits in various applications.. Here we list a few main benefits of using riveted nuts in your project.

1. Threaded Fastening

Rivet nuts provide a strong, threaded insert in materials that may be too thin or soft to hold threads on their own, such as sheet metal, plastic, or composite materials. This enables the attachment of bolts, screws, or other fasteners for secure connections.

2. Easy Installation

Rivet nuts can be installed quickly and efficiently with tools like hand tools, pneumatic, or hydraulic tools. The installation process is relatively simple compared to traditional welding or tapping.

3. Vibration Resistance

Vibration resistance refers to the ability of a rivet nut (or any fastener) to maintain its integrity and secure connection despite the presence of vibrations or dynamic forces that could otherwise cause loosening or failure of the joint.

It is a critical feature, especially in applications where the assembled components are exposed to frequent or continuous movement. Rivet nuts create a permanent, secure threaded connection that resists loosening due to vibrations, making them ideal for automotive, aerospace, and machinery applications.

4. Blind Installation

One of the key features of rivet nuts is that they can be installed from one side of the material (blind side), which is particularly useful when access is limited to only one side of the workpiece.

- Single-Sided Access: With rivet nuts, the installation can be completed using just one side of the material. This eliminates the need for holes, threads, or fasteners on the opposite side, making it ideal for thin-walled materials or when there’s limited space.

- Efficient and Convenient: The process is typically faster and simpler compared to traditional methods like welding, tapping, or using other types of fasteners that require access to both sides of the workpiece.

5. Versatility

Rivnuts are available in a variety of sizes, materials and thread types, enabling them to meet the needs of different project use scenarios.

For example, if your project environment is harsh, you can choose rivet nuts made of corrosion-resistant materials, such as stainless steel or aluminum, which ensure long-lasting performance even in harsh environments.

Rivnuts offer a convenient and durable solution for creating secure, reusable, and vibration-resistant threaded connections in thin or inaccessible materials.

What Are Rivet Nuts Used for?

Rivet nuts have a wide range of applications in multiple industries, and their ability to create secure, strong threaded connections in thin or soft materials makes them ideal for solving many challenges that are difficult to handle with traditional fastening methods.

Automotive & Bicycles

Manufacturers often use rivet nuts to attach panels, trim, and other parts in cars and trucks. They are especially useful in places where access to both sides of the material is limited.

Bicycle and motorcycle manufacturers also commonly use it to securely attach parts like racks, fenders, or accessories to the frame.

Aerospace & Maritime

In aircraft construction, rivet nuts provide strong, vibration-resistant threaded connections in thin, lightweight materials such as aluminum or composite panels.

Rivnuts provide secure fastenings in the construction of boats and other marine vehicles, where resistance to vibrations and corrosion is crucial.

Electronics

These fasteners are also very helpful to secure components inside electronic devices like computers, printers, and telecommunications equipment, where space is tight and ease of assembly is important.

Construction

Manufacturers use rivet nuts to fasten parts together in machinery, appliances, or structural components. They often use rivet nuts in sheet metal fabrication to attach hardware like brackets, handles, or panels.

Furniture Assembly

In the assembly of metal or composite furniture, rivet nuts play a crucial role by enabling easy attachment of parts like legs, arms, panels, and other structural components. These fasteners offer a reliable way to connect components with bolts or screws, ensuring that the furniture remains sturdy and durable over time.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose the Right Rivet Nuts for Your Project?

Choosing the right rivet nuts for your project requires considering several key factors to ensure optimal performance and durability.

1. Material Type

The material of the rivet nut should match the type of material you’re working with. Common materials include steel, stainless steel, aluminum, and copper.

Consider the conditions the rivet nuts will be exposed to. If the application is subject to high temperatures, moisture, or chemicals, you may need rivet nuts made from specialized materials, such as heat-resistant alloys or those coated for extra protection against corrosion.

For projects exposed to harsh environments, such as outdoor or marine applications, corrosion-resistant materials like stainless steel or coated rivet nuts are ideal.

2. Size and Thread Type

Rivet nuts come in various sizes and thread types. It’s important to choose the appropriate thread size (e.g., M6, M8, M10) based on the bolt or screw you plan to use.

The hole diameter in your workpiece should also match the rivet nut’s size, so ensure you select the correct size for the hole.

3. Grip Range

Grip range refers to the thickness of the material that a rivet nut can securely fasten. It indicates how thick the material can be while still allowing the rivet nut to expand and provide a strong, stable connection. Choosing the correct grip range is crucial to ensure that the rivet nut fits properly and performs effectively.

When selecting a rivet nut, you should match the grip range with the material thickness you’re working with. For example, if you’re working with a metal sheet that’s 5mm thick, you’d select a rivet nut with a grip range that accommodates that thickness to ensure a tight and secure fit.

To determine the right grip range, consider the following:

- Material thickness: Ensure the rivet nut can accommodate the thickness of the material.

- Expansion and compression: The rivet nut must expand enough to lock securely in place but also compress properly when installed.

Different rivet nuts require different installation tools. Consider the available tools for your project and choose rivet nuts that are compatible with your equipment. Installation tools should also offer consistent pressure to ensure proper expansion and secure attachment.

- Hand Tools: Manual tools for light-duty projects, using a lever to expand the rivet nut.

- Pneumatic Tools: Air-powered tools for medium-volume applications, offering speed and efficiency.

- Hydraulic Tools: High-power tools for heavy-duty applications, ideal for thicker materials.

- Electric Tools: Electric-powered tools, balancing portability and efficiency for various tasks.

- Manual Threaded Mandrel Tools: Simple, slower tools for DIY or small-scale projects.

5. Flange Style

Rivet nuts come with different flange styles, such as flat, reduced, or countersunk. The choice of flange depends on the design requirements of your project.

For example, a countersunk flange may be preferred if a flush finish is needed, while a wider flange is ideal for spreading the load and preventing pull-out in softer materials.

6. Load Requirements

Depending on the application, you may need rivet nuts that can withstand higher loads or vibrations.

For heavy-duty applications or environments subject to significant stress, such as machinery or automotive assembly, choosing high-strength rivet nuts is crucial for long-term reliability.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusions

Rivet nuts are versatile fasteners that create secure, threaded connections in thin or soft materials. They offer features like vibration resistance, easy installation from one side, and durability, making them ideal for applications in automotive, aerospace, electronics, and furniture assembly.

To choose the right rivet nuts, consider factors such as material, size, thread type, grip range, and environmental conditions. Selecting the appropriate installation tool is also key for a secure and efficient installation. By understanding these aspects, you can ensure the success and reliability of your project.

Rivetfix has fifteen years of manufacturing experience in the fastener manufacturing industry. With our wide range of solutions, services and corporate vision, we are the first choice for riveted nut manufacturers. Whatever your field and the nature of your project, we can choose the best product for your needs.

Get free sample proofing or request an instant quote to improve the efficiency of your project now.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.