What Are Jack Nuts Used for?

Leading Rivet Nut Manufacturer and Supplier in China

Jack nuts are versatile fasteners widely used to create secure threaded inserts in soft materials like metals, plastics, and composites. When asking “what are jack nuts used for?“, it’s important to understand that they provide a reliable solution for applications where traditional threading isn’t feasible.

Jack nuts provide a quick, efficient, and non-destructive method of creating threaded connections. They are essential for thin or delicate materials.

Table of Contents

Why Use Jack Nuts?

1. Secure Threaded Inserts

Jack nuts provide a reliable way to create a strong, permanent threaded insert in softer materials such as plastics, composites, and thin metals. This allows bolts and screws to be used, which can be removed and replaced multiple times without damaging the base material.

Their ability to create reliable, reusable threaded connections ensures a long-lasting and secure fastening solution. This feature is especially beneficial in industries like automotive, aerospace, and electronics.

2. Prevent Material Damage

Jack nuts are particularly effective in preventing material damage during installation. Since they expand inside the material rather than cutting threads directly, they avoid the risk of damaging or weakening the surrounding area. This is especially important when workers use delicate or thin materials like plastics, composites, or soft metals, which may crack or distort if conventional threading methods are used.

They distribute the load evenly, creating a strong, stable connection. They preserve the integrity of the base material. This makes them reliable for material-sensitive applications.

Jack nuts offer ease of installation, making them a popular choice in various applications. Workers can install them quickly and easily using simple hand tools or pneumatic tools, reducing labor time and effort.

The installation process involves inserting the nut into a pre-drilled hole and then expanding it to create a secure, permanent threaded insert. This eliminates the need for complex threading or welding processes. Jack nuts have a straightforward installation procedure. They are ideal for high-volume manufacturing or repair tasks. This ensures consistency, efficiency, and high-quality connections across various materials.

4. Versatility in Applications

Jack nuts offer versatility in various applications, providing reliable threaded inserts across different materials like metal, plastic, and composites. Their adaptability suits industries ranging from automotive to electronics, and they work well in both light and heavy-duty applications.

Their ability to work with a wide range of materials ensures that jack nuts can create strong, durable connections in diverse environments. Whether in manufacturing, repair, or assembly,they offer a versatile, efficient, and cost-effective solution for securely fastening components without damaging the base material.

The Essential Role of Jack Nuts

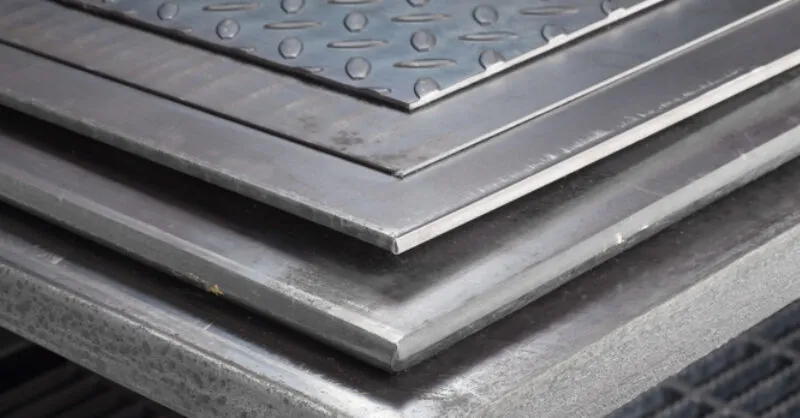

Metal Materials

Jack nuts commonly work with metal materials such as aluminum, steel, and other metals. These materials often require secure threaded inserts to handle high mechanical loads and prevent damage to the base material. Jack nuts provide a reliable solution by creating a strong, permanent anchor point for bolts, screws, and other fasteners.They ensure threads remain intact after repeated use. This reduces the risk of stripping and enhances connection durability.

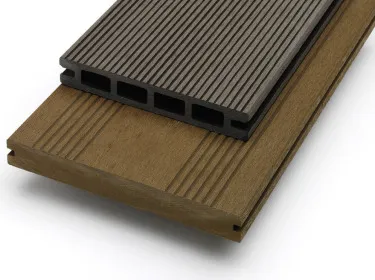

Jack nuts are also ideal for use in plastic and composite materials such as fiberglass, carbon fiber, and reinforced plastics. These materials often crack or strip when direct threading is applied. Jack nuts provide a secure alternative. They create a reliable threaded insert that withstands bolted connection forces without damaging the material.

Industries like electronics, automotive interiors, and lightweight structures commonly use jack nuts. They ensure secure fastening without compromising the base material’s integrity.

What are Jack Nuts Used for?

Jack nuts can create secure, reusable threaded inserts in soft or thin materials that cannot support direct threading. Here are the key applications:

1. Creating Strong Threaded Connections in Soft Materials

Jack nuts are ideal for materials like plastics, composites, and thin metals, where traditional threading would cause damage. They create a reliable, durable threaded connection for bolts, screws, and other fasteners, all while preserving the material’s integrity. Additionally, using jack nuts in soft materials reduces the need for specialized tools or equipment, making them a practical choice across various applications. Moreover, their versatility makes them suitable for industries ranging from electronics to automotive, ensuring strong connections without compromising the base material. As a result, jack nuts offer an efficient and cost-effective solution for creating secure threaded inserts in challenging materials.

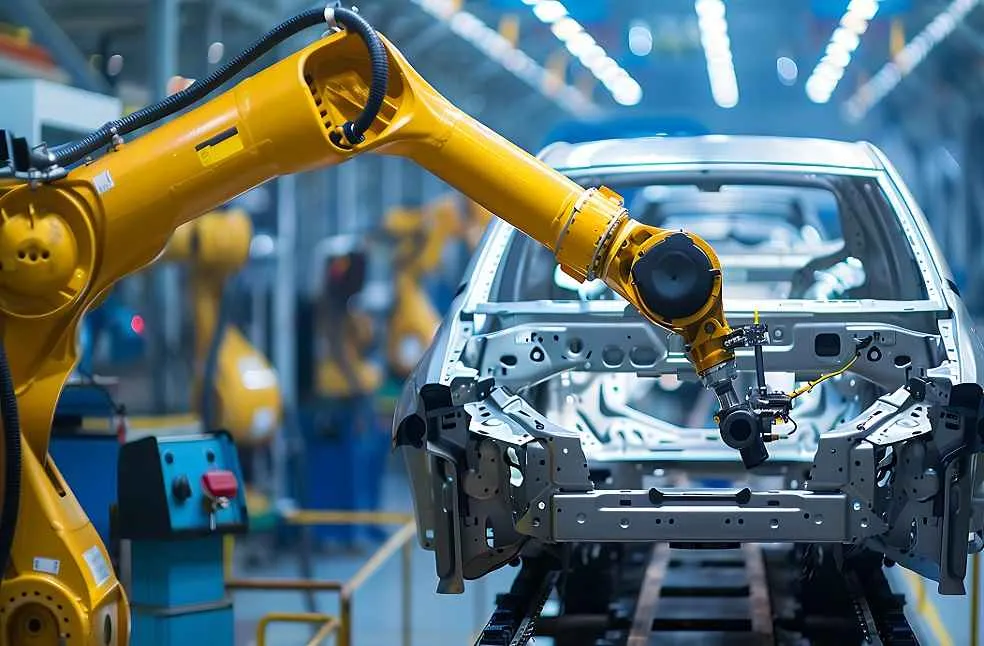

2. Automotive and Aerospace Applications

Jack nuts play a critical role in automotive and aerospace applications, where they are used to create strong, reliable threaded inserts in materials like sheet metal, composite panels, and plastics. These industries often require fasteners that can handle high-stress environments and resist vibrations and impacts. Jack nuts provide a secure, permanent anchor point for bolts, screws, and other fasteners, ensuring that critical components remain firmly in place. Their use is particularly valuable in lightweight structures where traditional fasteners may not provide sufficient strength.

Additionally, in the automotive and aerospace industries, the ability to install jack nuts in thin or soft materials like aluminum and composites is essential for reducing weight without compromising safety or performance.

3. Electronics and Electrical Equipment

In the electronics industry, jack nut can secure components to enclosures, circuit boards, and panels. Jack nut allows for the installation of screws and bolts that hold electronic parts, connectors, or shielding in place, offering both mechanical strength and electrical conductivity when necessary. Their use ensures that components remain securely fastened, preventing damage or loosening due to vibrations or external forces.

In electronics and electrical equipment, jack nut is useful in lightweight, compact designs where space is limited, and high-strength fastening solutions are required. They are often employed in assembling power supplies, telecommunications devices, consumer electronics, and control systems. Their ability to facilitate easy maintenance, repair, or component replacement makes them ideal for the fast-paced and high-demand electronics sector.

4. Furniture and Appliances

In the furniture and appliance industries, manufacturers widely use jack nuts to create secure threaded connections in materials that are too soft or delicate for traditional fasteners. These materials often include softwoods, MDF, particleboard, and thin metals.

By providing a strong, permanent threaded insert, jack nut ensures bolts or screws are securely fastened without damaging the material. This solution is particularly important in the furniture industry, where components need to remain securely attached while avoiding material damage such as cracking or stripping. As a result, jack nut offer a reliable way to maintain the integrity of delicate materials while ensuring long-lasting, secure connections.

Do You Have Any Questions?

Let Us Solve Your Problem

| Feature | Rivet Nut | Jack Nut |

| Installation Method | Using a rivet nut tool or a hydraulic tool to install | Installed by expanding inside the material with a special tool |

| Primary Use | Provides secure, permanent threaded inserts in a variety of materials | Soft materials like plastics and thin metals |

| Material Compatibility | Metals, plastics, and composites | Soft materials like plastics, composites, and thin metals |

| Expansion Mechanism | Expands uniformly to form a strong, durable thread | Expands by deforming at the base, gripping the material securely |

| Load Bearing Capacity | Generally higher strength and durability | Moderate strength, better suited for low to medium load applications |

| Removability | Typically not removable without damage | Permanent once installed, but bolts/screws can be removed |

| Applications | Automotive, aerospace, construction, and heavy-duty applications | Furniture, appliances, electronics, and lightweight structures |

Conclusion

Rivet nuts and jack nuts are both types of threaded inserts, but they differ in key aspects.

Rivet nuts are designed for high-strength applications and work well with materials like metals, plastics, and composites. They expand uniformly and manufacturers commonly use them in industries such as automotive, aerospace, and construction.

On the other hand, manufacturers primarily use jack nuts for softer materials like plastics and thin metals. They offer moderate strength and are easier to install. Jack nuts expand by deforming at the base and are commonly used in industries like furniture, appliances, and electronics. While rivet nuts offer a higher load-bearing capacity, jack nut excel in lighter-duty applications.

Can Jack Nuts be Used in Heavy Duty Applications?

Jack nuts are typically not suitable for heavy-duty applications, as they are primarily designed for use in softer materials like plastics, thin metals, and composites.

Jack nuts are more appropriate for lighter-duty applications where ease of installation and moderate strength are sufficient. While they provide a secure threaded insert for moderate loads, they lack the strength and durability required to withstand the high stress and forces found in heavy-duty environments, such as in heavy machinery or high-torque applications.

For heavy-duty applications, rivet nuts made from stronger materials (such as steel or stainless steel) are a better choice. These provide superior strength, load-bearing capacity, and resistance to wear, making them ideal for use in industries like automotive, aerospace, and construction.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Jack Nut Solutions for Your Business

If you have the need to buy Jack Nuts, learn the ultimate guide to buying Jack Nuts. Rivetfix specializes in providing custom jack nuts solutions tailored to meet the unique requirements of your business. We offer a wide range of jack nuts made from high-quality materials, designed to create strong, secure threaded inserts in soft materials such as plastics, composites, and thin metals. Whether you need jack nut for automotive, furniture, electronics, or industrial applications, we ensure precise customization to fit your specific needs.

Our team of experts works closely with you to understand your requirements, offering personalized advice and high-quality products that enhance your manufacturing processes. With Rivetfix, you gain access to industry-leading jack nuts that ensure efficient, durable, and cost-effective fastening solutions for your business.

Rivetfix - Leading Jack Nut Supplier in China

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our commitment to quality, innovation, and customer satisfaction has established Rivetfix as a trusted partner for businesses seeking reliable fasteners. We prioritize the use of premium materials, cutting-edge technology, and rigorous quality control processes to ensure that our jack nuts meet international standards and exceed customer expectations. As a global supplier, Rivetfix offers competitive pricing and fast delivery, making us the ideal choice for your jack nut needs.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.