TOP 10 Clinch Stud Manufacturers and Suppliers in USA 2025

Leading Self-Clinching Fasteners Manufacturer and Supplier in China

Looking for reliable clinch stud manufacturers and suppliers in USA 2025? Whether you’re sourcing for automotive assemblies, electrical enclosures, or heavy-duty machinery, finding the right partner is crucial for product integrity and long-term performance. In this guide, we’ve compiled the Top 10 Clinch Stud Manufacturers and Suppliers in the USA for 2025, showcasing industry leaders known for their precision, quality materials, and customization capabilities. From high-volume OEMs to specialists in stainless steel fasteners, discover the best sources to meet your clinch fastening needs.

Table of Contents

What Makes Clinch Studs Essential?

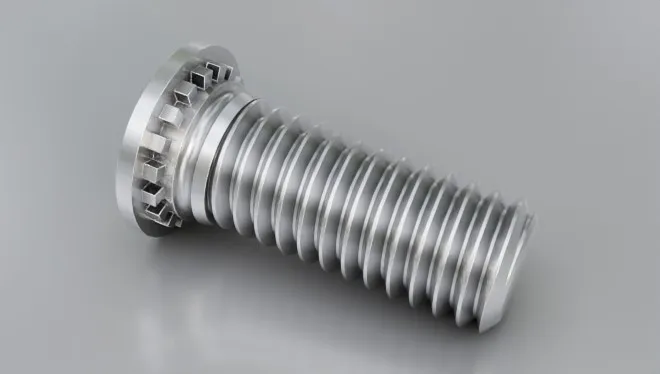

Clinch studs are fasteners installed into sheet metal through a cold-press or riveting process, offering structural advantages such as self-locking, anti-rotation, and pull-out resistance. By creating mechanical interference, the stud becomes an integral part of the base material, delivering a durable and reliable threaded connection—especially useful for thin sheet metal where traditional welding or drilling might weaken the structure or increase costs.

In Which Industries Are Clinch Studs Commonly Used?

Thanks to their efficiency, strength, and ease of installation, clinch studs are widely adopted in the following industries:

- Automotive Manufacturing: Used to secure structural components, electrical brackets, and engine bay accessories.

- Sheet Metal Fabrication: Employed in electrical enclosures, server cabinets, and heat sink frames for high-strength assembly connections.

- Electrical Cabinets & Distribution Boxes: Used to fasten electrical components securely inside metal enclosures.

- Machinery & Industrial Equipment: Provide durable assembly interfaces for housings and support structures, facilitating maintenance and part replacement.

- Rail Transit & Aerospace: Essential in high-vibration, fatigue-resistant environments, offering secure and lasting connections.

How Did We Choose These Top Manufacturers?

To help users find reliable partners among a wide range of brands, we carefully evaluated and selected the top clinch stud manufacturers and suppliers in the USA for 2025 based on the following key criteria:

Product Quality and Reliability

All selected companies offer products with consistent performance that can withstand harsh working conditions over the long term. We focused on factors such as tensile strength, anti-rotation capability, and secure clinching performance to ensure compliance with industrial-grade standards.

Customization Capability and Delivery Time

High-quality suppliers not only offer standard parts but also respond quickly to non-standard customization needs. We prioritized manufacturers with in-house design and tooling capabilities, as well as flexible and controlled delivery timelines.

Industry Certifications (e.g., ISO 9001, IATF 16949)

We gave preference to companies certified under international quality management systems. These certifications indicate standardized production processes and complete traceability systems, making them suitable for high-standard industries such as automotive and rail transit.

Customer Feedback and Service Capability

Leading manufacturers often enjoy a wide customer base and strong market reputation. We reviewed multi-platform customer feedback and focused on their responsiveness to pre-sale inquiries, after-sales support, and overall professionalism in project collaboration.

OEM/ODM Support

For customers with specific application needs, OEM or ODM support is crucial. Therefore, we gave priority to companies capable of offering customized production and design assistance.

TOP 10 Clinch Stud Manufacturers and Suppliers in USA 2025

Rivetfix focuses on the research, development, manufacturing, and distribution of high-performance clinch studs, serving industries such as automotive manufacturing, rail transport, electronics, and sheet metal processing. With advanced automated production lines and a rigorous quality control system, Rivetfix has established a stable supply network in North America and globally, providing high-strength fastening solutions to several Fortune 500 manufacturing companies.

Main Products and Services:

- Stainless steel and carbon steel clinch studs

- Welded, blind hole, and self-locking studs

- Full range of metric and imperial thread specifications

- Supporting installation tools and clinching equipment

Customization and Solutions:

- Custom services for special threads, lengths, and head shapes

- Available surface treatments: galvanizing, nickel plating, Dacromet, etc.

- Corrosion-resistant designs for extreme environmental applications

Quality and Certifications:

- ISO 9001, IATF 16949 certified quality management systems

- Strict batch traceability and performance testing systems

Other Highlights:

- Warehousing and logistics services covering multiple U.S. states

- One-stop OEM/ODM solutions

- Technical support team assisting customers in optimizing fastening structure design

Founded in 1942 and headquartered in Pennsylvania, PennEngineering is one of the world’s leading manufacturers of clinch fasteners, known for its PEM® brand. The company focuses on providing innovative fastening solutions for sheet metal and precision manufacturing fields. With over 80 years of technical expertise, PennEngineering leads industries such as automotive, electronics, telecommunications, and medical devices. The company has advanced manufacturing bases in the U.S. as well as international factories and logistics centers in China, Ireland, and Germany, offering global customers localized rapid response.

Main Products and Services:

- Clinch studs in various materials (stainless steel, carbon steel, aluminum alloys, etc.)

- Welded studs, clinch nuts, screws, and integrated fasteners

- Patented self-locking designs for thin metal sheets

Customization and Solutions:

- Customization of stud length, diameter, and thread specifications on demand

- Surface treatments available: galvanizing, nickel plating, Dacromet, etc.

- Custom component structures for automated assembly systems

Quality and Certifications:

- ISO 9001, IATF 16949 certified quality systems

- Multiple patents and product testing standards

Other Highlights:

- Multiple global technical support centers

- Automated smart factories and environmentally friendly processes

- Online CAD downloads and engineering selection support

Dodge® Fasteners, a brand under Consolidated Aerospace Manufacturing (CAM), is headquartered in Torrance, California, with a history dating back to the 1950s. Dodge specializes in producing embedded fasteners for metal and plastic substrates, with products widely used in aerospace, electronics, medical, industrial equipment, and military industries. The company is known for its high-precision clinch fasteners and inserts and has strong engineering development and on-site technical support capabilities.

Main Products and Services:

- Clinch studs for metal and plastic substrates

- Anti-rotation, anti-pullout studs

- Miniature inserts for electronics and high-performance composite fasteners

Customization and Solutions:

- Custom solutions for ultra-small sizes and high-temperature environments

- Development of insert structures for plastic injection molding and composite materials

- High-strength thread customization and corrosion-resistant coatings

Quality and Certifications:

- AS9100, ISO 9001, ITAR registered

- Complete experimental testing capabilities, meeting military and aerospace standards

Other Highlights:

- Part of PCC Group, with strong resources and global service

- Offers high-reliability aerospace-grade products

- Engineering support for sample design, finite element analysis, and prototype manufacturing

Founded in 1946 and headquartered in Illinois, ATF Inc. is a global provider of engineered fastening and assembly solutions. The company specializes in precision cold-formed parts, clinch studs, welded studs, and custom fasteners, with a strong focus on the automotive, heavy equipment, electrical systems, and household appliance industries. Through vertically integrated production, ATF controls the entire process from mold design and material selection to surface treatment and quality testing, ensuring product performance and delivery efficiency.

Main Products and Services:

- Stainless steel and carbon steel clinch studs

- Precision cold-formed parts, welded studs

- Various anti-loosening and anti-corrosion fastening technologies

Customization and Solutions:

- OEM/ODM customization for dimensions and structures

- Surface coatings, corrosion treatments, and strength optimization designs

- Multi-position forming capabilities for complex non-standard needs

Quality and Certifications:

- ISO 9001, IATF 16949, ISO 14001 certified

- Advanced quality laboratories and testing systems

Other Highlights:

- Manufacturing and distribution centers in North America, Mexico, and China

- Technical innovation lab supporting customers in early-stage R&D

- Commitment to green manufacturing and sustainable practices

Stafast Products Inc., founded in 1958 and headquartered in Germantown, Wisconsin, is known for providing high-performance metal fastening solutions. The company specializes in clinch studs, welded studs, and inserts, serving industries such as furniture, heavy machinery, automotive, and industrial manufacturing. With a flexible delivery system and strong customer collaboration, Stafast has become a long-term partner for many OEM manufacturers.

Main Products and Services:

- Various clinch studs (metric and imperial)

- Metal inserts and special-shaped fasteners

- Welded studs and clamping fastening solutions

Customization and Solutions:

- Custom solutions for complex structural studs and composite material studs

- Surface treatments available: galvanizing, nickel plating, electrophoresis, etc.

Quality and Certifications:

- ISO 9001 certified

- Comprehensive quality inspection processes and procedural control systems

Other Highlights:

- Quick sample production service

- Bulk stocking and local warehousing solutions

- One-stop procurement platform for multiple categories

Avibank, a subsidiary of Precision Castparts Corp. (PCC), is a leading U.S. manufacturer of aerospace and high-precision fastening components, headquartered in Los Angeles, California. Avibank specializes in producing lock-fastening and clinching components for aerospace, defense, and high-performance industrial systems. Its clinch studs are widely used in environments with the most demanding safety and quality standards and are qualified suppliers to companies such as Boeing and Lockheed Martin.

Main Products and Services:

- High-strength aerospace-grade clinch studs

- Military-spec lock fasteners and quick-release devices

- Specialized inserts and spring-locking mechanisms

Customization and Solutions:

- Products tailored to MIL, NAS, and AS standards

- Development support for special materials, high-temperature applications, and complex assemblies

Quality and Certifications:

- Certified to AS9100, NADCAP aerospace standards

- Fully compliant with ITAR, DFARS, and FAA requirements

Other Highlights:

- Focus on mission-critical safety systems

- Offers system-level fastening solutions

- Highly reliable and robust global supply chain

Founded in 1912 and headquartered in Northvale, New Jersey, Industrial Rivet is a family-owned business with over a century of experience in the fastening industry. The company specializes in manufacturing and global distribution of riveted and non-welded fastening products, including clinch studs, solid rivets, and semi-tubular rivets. With its vast inventory and global logistics network, Industrial Rivet is a trusted and responsive supplier.

Main Products and Services:

- Various types of clinch studs and specialty rivets

- Quick-install fasteners

- High-strength industrial-grade rivet products

Customization and Solutions:

- Supports both mass production and small-batch prototyping

- Offers OEM/ODM solutions and inventory management

- Capable of material substitutions and design optimizations per industry requirements

Quality and Certifications:

- ISO 9001 and multiple product compliance certifications

- Rigorous in-house inspection and pre-shipment quality control

Other Highlights:

- Over 100 years of industry experience

- Multiple U.S.-based warehouses for rapid fulfillment

- Online ordering platform and expert technical support team

Founded in 1974 and based in New Jersey, Captive Fastener is a well-known manufacturer of clinch-type fasteners. Its products are widely used in sheet metal, electronics, telecom, and industrial automation sectors. Initially specializing in PEM®-compatible parts, the company has since developed its own brand, offering cost-effective and fast-delivery clinch studs and related fasteners.

Main Products and Services:

- Stainless steel and steel clinch studs

- PEM-compatible studs and nuts

- Slide-in and insert-type quick fasteners

Customization and Solutions:

- Supports custom sizing, material selection, and thread specifications

- Offers corrosion-resistant and high-strength design options

- Accommodates both bulk and project-based custom orders

Quality and Certifications:

- ISO 9001 certified

- Fully equipped with in-house testing facilities

Other Highlights:

- Fast turnaround ideal for urgent projects

- U.S.-based manufacturing with stable stock levels

- Long-term partnerships with numerous OEMs

Sherex, headquartered in Buffalo, New York, is an innovative company focused on stud and rivet nut technologies. With manufacturing facilities in the U.S., Mexico, and China, Sherex offers a wide range of structural clinch studs, heavy-duty nuts, and fasteners for automated assembly. Its products are used in EVs, rail, construction, telecom, and more. The R&D team emphasizes performance and assembly efficiency, holding multiple patents.

Main Products and Services:

- High-strength clinch studs and heavy-duty nuts

- Automated clinching equipment and installation tools

- Cold-formed and structural fastener solutions

Customization and Solutions:

- Supports custom development for large-scale projects

- Offers assembly process analysis and automation integration services

- Available in various special materials and corrosion-resistant finishes

Quality and Certifications:

- ISO 9001, IATF 16949 certified

- Equipped with in-house testing labs and R&D centers

Other Highlights:

- Own brands include RIV-FLOAT, RIV-FORM, and TSS

- Rapid prototyping and automation line integration support

- Dual supply model across the Americas and Asia to shorten lead times

Rivmate is a global fastening solution provider with sales and warehouse operations in the U.S. and manufacturing based in China. As a strategic partner of Rivetfix, Rivmate focuses on delivering high-value clinching fasteners to the North American market. Its clinch studs are available in various materials and configurations, serving industries such as telecom equipment, industrial enclosures, and sheet metal automation.

Main Products and Services:

- Standard and custom clinch studs

- Quick-install, pilot-type, and anti-rotation designs

- Optimized solutions for sheet metal and aluminum applications

Customization and Solutions:

- Highly flexible OEM/ODM order processes

- Drawing-based customization, material alternatives, and anti-corrosion designs

- Supports prototyping, testing, and batch delivery

Quality and Certifications:

- ISO 9001 certified manufacturing facility

- 100% inspection before shipment with routine batch testing

Other Highlights:

- Local inventory and quick shipping in North America

- Bilingual technical support (Chinese/English)

- Joint delivery model with Rivetfix to serve global manufacturers

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose the Right Clinch Stud for Your Application?

1. Select Specifications Based on Material Thickness and Load Requirements

- Material Thickness Compatibility: Different types of clinch studs are designed for different base material thicknesses. If the material is too thin, it may not provide sufficient clamping force or could crack; if it’s too thick, extended or heavy-duty studs should be considered.

- Axial and Shear Load Capacity: For high-load or vibration-prone applications (such as machinery housings or chassis components), high-strength carbon steel or stainless steel studs should be prioritized to ensure adequate pull-out and shear resistance.

- Operational Environment: In applications involving long-term stress, select studs with high fatigue resistance and evaluate product lifespan based on working frequency and impact intensity.

2. Evaluate the Supplier’s Delivery Capacity and Production Stability

- Production Scale and Automation Level: Does the supplier have mass production capability with automated equipment such as CNC machines and cold headers? These factors directly impact lead time consistency.

- Inventory Support and Delivery Mechanism: Does the supplier maintain stock of common sizes? Do they offer JIT or local warehousing and distribution services? These features help reduce project delays.

- Client Base and Case Studies: A track record of cooperation with large enterprises or international clients often indicates strong batch production and quality control capabilities.

3. Surface Treatment Options and Environmental Compatibility

- Zinc Plating: Suitable for general industrial environments. It’s cost-effective but offers moderate corrosion resistance.

- E-coating (Electrophoretic Coating): Provides some corrosion protection and is suitable for mildly humid environments.

- Dacromet or Zinc-Nickel Coating: Offers excellent corrosion resistance, ideal for harsh conditions such as marine, outdoor, or salt spray environments.

- Stainless Steel: For applications involving long-term exposure to corrosive elements, it’s recommended to use clinch studs made of 304 or 316 stainless steel, eliminating the need for additional surface treatments.

Conclusion - Clinch Stud Manufacturers and Suppliers in USA

Clinch studs are an essential fastener choice for ensuring strong, vibration-resistant, and long-lasting connections across various heavy-duty applications—from automotive body panels to industrial enclosures. In this blog, we’ve carefully selected the TOP 10 clinch stud manufacturers and suppliers in the USA for 2025, based on product quality, customization capability, certifications, and supply reliability.

Choosing the right supplier is just as critical as selecting the right fastener. A professional, certified manufacturer not only delivers quality products, but also provides reliable technical support and efficient delivery—ensuring your projects run smoothly from design to production.

Do You Have Any Questions?

Let Us Solve Your Problem

Buy Clinch Studs from Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Rivetfix offers a wide range of self-clinching fasteners designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized clinch studs service according to your requirements.

Contact us for project advice and the latest clinch studs quote!

Get High Quality Rivet Nuts Quote!

Other Highlights:

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.