Top 10 Brass Threaded Inserts Manufacturers in China 2025

Leading Threaded Inserts Manufacturer and Supplier in China

Brass threaded inserts are widely used in wood, plastic, 3D printed components, and industrial molds due to their excellent mechanical properties and corrosion resistance. Brass inserts provide more stable threaded connections and stronger anti-pullout performance in various scenarios. Whether it’s screw fixation in household furniture or repeated disassembly and assembly of precision electronic device casings, brass threaded inserts are indispensable. Looking for a reliable supplier? This “Top 10 Brass Threaded Inserts Manufacturers in China 2025” will provide you with an authoritative guide to help you select a cooperative manufacturer with high cost performance and stable delivery.

China is the core base for global brass insert manufacturing. It has a complete and mature industrial chain, ranging from raw materials (such as high-purity brass rods) to precision processing, surface treatment, and export packaging. Compared with the European and American markets, Chinese manufacturers have obvious advantages in production cost control, batch delivery capacity, and customization response speed. Moreover, most leading enterprises have passed international certifications such as ISO 9001 and ROHS. They possess the technical capabilities and rich experience to provide OEM/ODM services for overseas customers, thus becoming the preferred partners for global buyers.

Table of Contents

What Are Brass Threaded Inserts?

Brass Threaded Inserts are a type of fastening component used to enhance the strength of threaded connections. They are widely used in plastics, wood, soft metals, and 3D printed parts. Through their internal threaded structure, they ensure that the material maintains its screw tightness even after multiple disassemblies and assemblies, avoiding problems such as stripped threads and loosening. Brass itself has excellent thermal conductivity, corrosion resistance, and processing performance, making it one of the most commonly used materials for threaded inserts.

Common types of brass inserts:

- Press-in Inserts: They are mechanically inserted into plastic or soft materials and are often used in injection molded parts. They are easy to install and have a stable structure.

- Self-tapping brass Inserts : With external threads, they can be directly screwed into the plastic to form a firm lock, suitable for quick on-site installation.

- Wire Thread Inserts : They are used in metal base materials to enhance the strength of internal threads and prevent thread slippage. They are suitable for high-frequency disassembly and assembly scenarios or thread repair.

Compared with inserts made of stainless steel or aluminum alloy, brass inserts have the following obvious advantages:

- Better machinability: Allows for more precise internal threads and structural details;

- High thermal conductivity: More suitable for hot-press installation;

- Strong corrosion resistance and moderate cost: More resistant to oxidation than aluminum alloy, easier to process than stainless steel, and more competitively priced.

Therefore, whether used in consumer electronics, industrial structural components, or 3D printed custom assemblies, brass inserts are a reliable and cost-effective solution for enhancing threads.

How to Choose a Reliable Manufacturer in China?

When looking for a Chinese brass threaded insert manufacturer, choosing a reliable supplier is of vital importance. The following are the core criteria for determining whether a factory is worth cooperating with:

- Product Quality: Check whether high-precision processing equipment is used and whether there are quality control processes such as size inspection and salt spray testing. Samples can be requested for comparison tests.

- Production Capacity: Understand whether the monthly production capacity can meet the long-term supply demand and whether it has an automated production line to handle large orders.

- Customization Services: Whether it can provide one-stop services such as non-standard customization, drawing sampling, and coating treatment is an important criterion for measuring technical strength.

- Export Experience: Manufacturers with many years of export experience to Europe, America, Japan, and South Korea are usually more familiar with the quality and delivery requirements of international customers.

- Certification Qualifications: Whether it has passed quality or environmental certifications such as ISO 9001, ROHS, and REACH is related to whether the product can enter the mainstream market.

In addition, the following practical issues need to be noted to avoid uncertainties in subsequent cooperation:

- Minimum Order Quantity (MOQ): Some factories require a relatively high minimum order quantity for customized products. It is recommended to confirm this in advance.

- Delivery Cycle: It is necessary to assess whether the goods can be delivered on time according to the project schedule, especially for large orders or special customization.

- Packaging and Transportation: Whether the export packaging is sturdy, moisture-proof, and shock-proof, and whether it can provide support for various trade terms such as FOB, CIF, and DDP.

Top 10 Brass Threaded Inserts Manufacturers in China (2025)

| Ranking | Company Name & Website | Main Products |

|---|---|---|

| 1 | Rivetfix | Brass threaded inserts, rivet nuts, and custom fasteners |

| 2 | FENGFAN | Brass inserts for plastic, press-in and ultrasonic types |

| 3 | Fastoscrews | Brass heat-set inserts, self-tapping inserts, metal fasteners |

| 4 | Dongguan Yuhuang Electronic Technology Co., Ltd. | Brass inserts, custom metal fasteners, electronic components |

| 5 | HMaking (HM) | Precision CNC brass inserts, threaded fasteners, hardware components |

| 6 | Shenzhen Sandum Precision Parts Co., Ltd. | CNC brass inserts, custom machining parts, turning parts |

| 7 | Elite Aviation Manufacturing Co., Ltd. | Brass threaded inserts, aerospace fasteners, special hardware |

| 8 | TCL/Xingye Alloy Materials Group | Brass rods and raw materials for insert manufacturing |

| 9 | Guangzhou Sunbo Technology Co., Ltd. | Brass inserts, coil inserts, metal hardware solutions |

| 10 | Rivmate | Rivet nuts, brass inserts, blind fasteners for thin materials |

Rivetfix is a leading provider of threaded inserts and riveting solutions in China. Its headquarters is located in Suzhou, Jiangsu Province, and it has modern production workshops and a complete quality inspection system. The company focuses on providing various high-precision threaded fasteners to global customers, especially having accumulated rich experience in the field of brass inserts. Its products are widely used in plastic injection molding, woodworking, 3D printing, and electronic equipment, etc. With a professional engineering team and strong export capabilities, Rivetfix serves multiple countries and regions including Europe, America, Southeast Asia, and the Middle East.

Core Products and Services

- Brass heat-set inserts

- Brass press-in inserts

- Self-tapping inserts for plastics

- Custom threaded inserts and OEM services

- Specialized brass inserts for wood

- Design support and sample production

Core Strengths

- Own factories and precision processing equipment, with flexible delivery schedules

- Rich export experience, familiar with European and American technical standards and packaging requirements

- Capable of supporting small-batch customization and rapid prototyping

- Provide one-stop screw fastening solutions, suitable for various application scenarios

FENGFAN is a professional manufacturer of brass inserts and brass accessories in China, affiliated with Zhejiang Fengfan Technology. It has over 20 years of experience in copper product processing. The company is located in Yuhuan, Zhejiang Province and is equipped with automated CNC processing equipment, high-precision CNC lathes, and a complete surface treatment line. It produces tens of millions of brass inserts annually. FENGFAN has long provided high-quality brass threaded inserts to domestic and foreign plastic product manufacturers, automotive component suppliers, and 3D printing users, and has rich experience in exporting to Europe, America, and the Middle East.

Core Products and Services

- Brass Heat Melt Inserts (Heat Inserts for Plastic)

- Press-fit Brass Inserts

- Ultrasonic Inserted Inserts

- Knurled Brass Inserts with High Torque

- Custom Inserts and OEM/ODM Services

Core Strengths

- All products are made of high-quality H59 brass, which combines strength and heat conductivity.

- Various surface treatment processes (such as nickel plating, tin plating, etc.) are provided to meet different environmental requirements.

- The mold design and automation processing capabilities are strong, making it suitable for large-scale procurement.

- It has ISO 9001 certification and strictly adheres to quality control standards.

Fastoscrews is a Chinese enterprise specializing in the manufacturing of precision fasteners. It was established in 2012 and its headquarters is located in Wenzhou, Zhejiang Province. The company has modern manufacturing workshops and research and development laboratories. It is renowned for its “high precision and high stability”. Its products are widely exported to markets in Europe, the United States, Japan, and Southeast Asia. Fastoscrews focuses on non-standard customization and high-demand application areas, such as electronic equipment, medical devices, consumer electronics, and smart home industries. It is particularly skilled in the development and manufacturing of various brass threaded inserts.

Core Products and Services

- Heat-set brass inserts

- Ultrasonic inserts for plastic

- Self-tapping brass inserts

- Hexagonal inserts and ribbed design components

- Custom OEM services and rapid prototyping

Core Strengths

- Equipped with over 100 CNC lathes, suitable for processing complex and precise structures

- Capable of handling small-batch and multi-variety customization with short delivery periods

- Offers quality assurance services such as material reports, size inspection reports, and salt spray tests

- Complies with ISO 9001 and RoHS certifications, meeting the environmental standards of the European Union

Dongguan Yuhuang Electronic Technology Co., Ltd. was established in 2005 and is located in Dongguan, Guangdong Province. It is a high-tech enterprise specializing in the manufacturing of fasteners and the research and development of precision hardware accessories. The company has a complete brass insert production system, including CNC processing, thread tapping, hot pressing and post-processing lines, and has been providing OEM/ODM services to automotive parts, consumer electronics, and industrial equipment for many years. Yuhuang has accumulated rich experience in exporting to the European, Japanese and Middle Eastern markets, with high product qualification rates and stable customer satisfaction.

Core Products and Services

- Heat-set inserts for plastic (Yellow brass heat-melt inserts)

- Press-fit brass inserts (Self-tapping brass inserts)

- Self-tapping inserts (CNC customized brass inserts with customizable patterns, lengths, and head shapes)

- Customized brass inserts available for CNC processing (with options for patterns, lengths, and head types)

- Supports small batch customization and rapid sample testing

Core Strengths

- Strong technical capabilities, with a professional R&D team and laboratory facilities

- Products can obtain international certifications such as ISO 9001, RoHS, and REACH

- Quick response to customer customization needs, providing one-stop services from drawings to prototyping

- Long-term stable supply of export assembly parts, with a mature packaging and logistics system

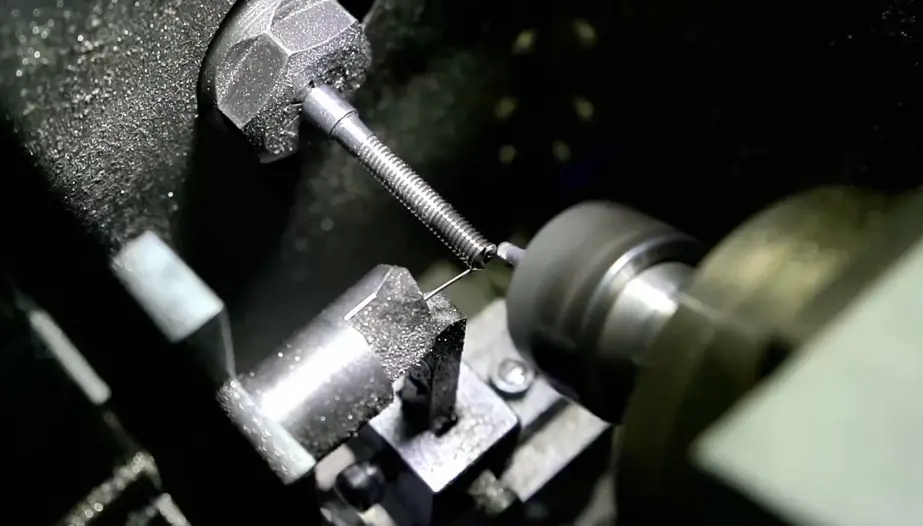

HMaking (short for HM) was established in 2014 and its headquarters is located in Suzhou, Jiangsu Province. The company is dedicated to the research and development as well as manufacturing of precision hardware and brass fasteners. It is equipped with advanced CNC machining centers, automatic lathes, and fully automated thread processing lines, and has established a complete quality testing laboratory. With high-quality products and stable delivery capabilities, HMaking has been providing high-precision fastener solutions for consumer electronics, medical devices, industrial control equipment, and high-end furniture brands for a long time.

Core Products and Services

- Precision CNC Brass Thread Inserts (Press-in & Self-tapping Inserts)

- Custom Thread Inserts (including various head types, lengths, and patterns)

- OEM/ODM services, accepting custom orders as small as a few hundred pieces

- Can provide insert design support, 3D prototyping and batch production integration

Core Strengths

- The processing capability is precise, with dimensional tolerance controlled to ±0.01 mm.

- Specialized in customizing complex structures, suitable for various non-standard connection requirements.

- Quick response to customer needs, with an average sample cycle of less than 5 working days.

- Certified by ISO 9001 and RoHS, and the products have passed standard tests such as NSF and IP.

Shenzhen Suidun Precision Components Co., Ltd. was established in 2010, with its headquarters located in Shenzhen, a major manufacturing hub in China. The company specializes in precision metal processing and CNC technology, and has over ten years of experience in manufacturing brass threaded inserts. Its production equipment includes high-precision lathes, thread cutting equipment, and automated inspection systems. Its products are widely used in furniture, electronic products, lighting assembly and other industries, and are exported to the European and American markets.

Core Products and Services

- Precision CNC brass threaded inserts (including types such as Press-In and Self-Tapping)

- Customizable length, head shape and surface treatment (such as nickel plating, tin plating, phosphating, etc.)

- Provide threaded coil inserts, nuts and complete hardware components for integrated supply

- Support OEM/ODM batch customization and integrated assembly solution for complete assembly.

Core Strengths

- Focus on high-precision processing, with precise dimension control down to ±0.02 mm

- Strong batch production capacity, stable delivery schedule, suitable for medium and large-sized orders

- Rich experience in assembly for the electronics and consumer goods industries, ensuring consistent connection standards

- Certified to ISO9001 quality management system, strictly following QC procedures

Elite Aviation Manufacturing was established in 2008, with its headquarters located in Dongguan City, Guangdong Province. The company specializes in the manufacturing of aerospace-grade fasteners and high-end brass inserts. The technical team of the company has extensive experience in the research and development of military and aerospace components. Its products have been supplied to military, aerospace, defense, and high-precision equipment manufacturers for a long time. Elite Aviation is equipped with clean workshops, precision lathes, and standardized production lines. All products meet the requirements of AS9100 and ISO 9001 certifications.

Core Products and Services

- Aviation-grade brass threaded inserts (such as Key-locking inserts)

- High-precision press-fit/self-locking inserts

- Brass nuts, riveting kits and matching fastening systems

- OEM/ODM services, supporting customization of insert head shapes, patterns, and pitch specifications

- Providing support for thread matching analysis and strength testing

Core Strengths

- The product complies with aviation quality management system standards such as AS9100 and is suitable for high-reliability applications.

- Strong R&D capabilities and precise processing capabilities, capable of meeting the requirements of non-standard and complex structures.

- Long-term cooperation with aerospace and automotive industry customers, familiar with the quality control processes in the industry.

- Strict quality control procedures, with the factory products passing multiple performance verifications such as mechanical tests and corrosion resistance tests.

TCL/Xingye Alloy Materials Group was established in 1993 and its headquarters is located in Zhejiang Province. It is a leading supplier of copper materials and alloy materials in China. Although it does not directly produce threaded inserts, the high-quality brass rods, strips and wires it provides offer crucial raw material support to numerous threaded insert manufacturers, and it holds a core position in China’s brass insert industry chain.

Core Products and Services

- High-purity H59 and H62 brass rods and strips

- Specialized threaded copper wires and copper wire materials

- Offer customized specifications of copper alloy materials and processing services

- Support customers’ non-standard alloy requirements and specific mechanical performance requirements

Core Strengths

- The raw materials are of high quality, with stable chemical composition and mechanical properties, and are compatible with multiple precision fastener brands.

- It has a national-level metal material testing laboratory and certification qualifications, and provides factory material reports.

- It has long-term cooperation with many domestic and foreign thread inserts manufacturers, forming a close supply ecosystem.

- It has strong capacity for large-scale supply, ensuring the stability of the production line, and is an important resource source for many OEM manufacturers.

Guangzhou Sunbo Technology Co., Ltd. was established in 2012, specializing in the research and development and production of threaded inserts, threaded coils and precision hardware accessories. The company is located in the core manufacturing area of Guangzhou, equipped with advanced CNC lathes and automated thread insertion and inspection equipment. Its products are sold to multiple industries in Europe, the United States and Chinese mainland. It has particularly rich practical experience in furniture assembly and small-batch customization.

Core Products and Services

- Brass threaded inserts (including press-fit and self-drilling types)

- Wire thread inserts

- Brass coil inserts

- Custom fasteners (with special thread specifications, patterns and surface treatments)

- Provide one-on-one selection advice, sample testing services and OEM support

Core Strengths

- Focus on handling small and medium-sized batch orders, meeting the requirements for rapid response and flexible production

- High precision control, with dimensional tolerance reaching ±0.015 mm, ensuring assembly quality

- Provide a wide range of customer cases and construction suggestions, emphasizing the customer’s usage experience

- Support various surface treatment methods (such as nickel plating, tin plating, anti-rust coating), meeting the standards of multiple industries

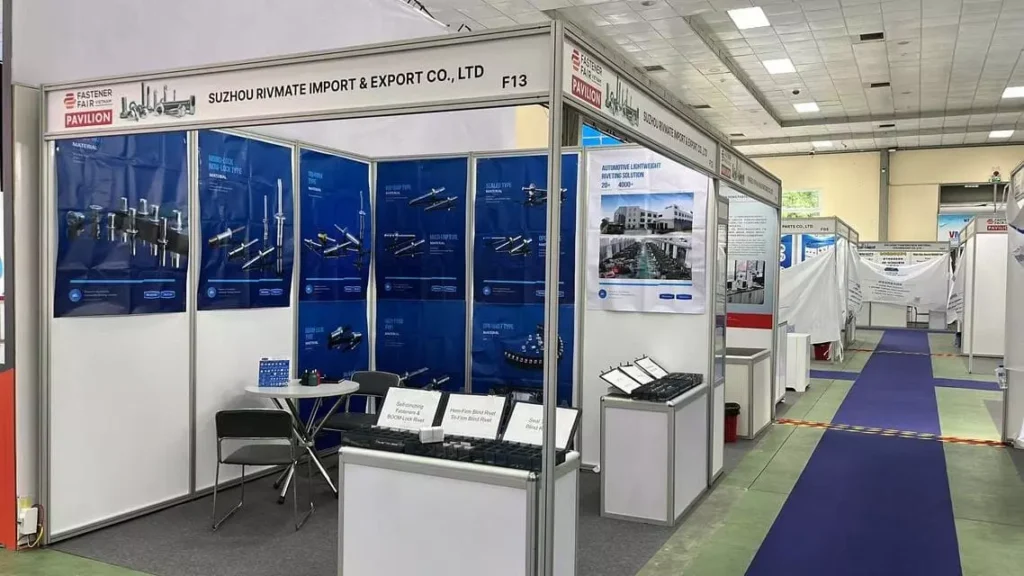

Rivmate was established in 2014 and its headquarters is located in Jiangsu, China. It focuses on the research and manufacturing of various riveted nuts and brass inserts. Although its brand mainly focuses on riveted components, in recent years it has expanded its product line to include threaded inserts, including pressed type and hot-melt type brass threaded inserts. Rivmate has accumulated a stable customer base in the fields of thin plate fixation, furniture assembly, and fastener applications, and provides OEM services.

Core Products and Services

- Rivet Nuts and Blind Hole Nuts

- Brass Press-in and Heat-melt Threaded Inserts

- Riveting Equipment and Installation Tools

- OEM Customization and Small Batch Processing Services

Core Strengths

- The product design mainly adopts thin plate connection, suitable for furniture, lamps, hardware accessories and box panel structures.

- The rivet nuts and inserts can be used together to achieve a durable and quick connection solution.

- It has strong flexibility in accepting orders, supporting low MOQ orders and fast delivery.

- It has passed ISO 9001 and RoHS certifications, and possesses the qualification for international trade exports.

Comparison Table: Top 10 Suppliers at a Glance

| Company Name | Main Products | Certifications | Main Export Regions | Customization Services |

|---|---|---|---|---|

| Rivetfix | Brass threaded inserts, rivet nuts, installation tools | ISO9001, RoHS | Global | Supports customization |

| FENGFAN | Brass inserts, self-tapping nuts | ISO9001 | Europe, Americas, Asia | Provides customization |

| Fastoscrews | Brass inserts, fasteners | ISO9001 | Europe, North America | OEM customization |

| Dongguan Yuhuang Electronic Technology | Precision threaded inserts, special fasteners | ISO9001 | Global | Supports customization |

| HMaking | Brass press-in, self-tapping nuts | ISO9001 | Asia, Europe | Customized production |

| Shenzhen Sandum | Precision threaded inserts | ISO9001, IATF16949 | Global | OEM customization |

| Elite Aviation | Aviation-grade brass inserts, hardware parts | AS9100 | North America, Europe | High-end customization |

| TCL/Xingye Alloy Materials Group | Brass materials and inserts | ISO9001 | Global | Large-scale customization |

| Guangzhou Sunbo Technology | Brass inserts, hardware components | ISO9001 | Europe, North America | Customization services |

| Rivmate | Brass threaded inserts, rivet nuts | ISO9001, RoHS | Global | Supports OEM and customization |

Do You Have Any Questions?

Let Us Solve Your Problem

Why Rivetfix Is a Recommended Global Supplier?

Rivetfix, as a globally recommended supplier, has gained the trust of numerous customers due to its outstanding product stability and a comprehensive global supply chain system. The company can provide customers with comprehensive OEM and ODM solutions to meet the individualized needs of different markets and industries. At the same time, Rivetfix supports sample testing to ensure that the product performance meets the customer’s requirements and has the ability to deliver quickly, helping customers achieve efficient production and market response. Whether it is quality control or service support, Rivetfix demonstrates strong professional strength and global supply guarantee, becoming the preferred partner for brass threaded inserts for many customers.

FAQs: About Brass Threaded Inserts from China

Are brass inserts durable for plastic?

Bronze threaded inserts are highly suitable for use in plastic materials due to their excellent corrosion resistance and mechanical strength. They can effectively enhance the connection strength of plastics, prevent thread slippage or damage, and are particularly suitable for high-precision plastic products such as 3D printed parts and injection molded parts. The service life of bronze inserts in plastics is usually several thousand times of disassembly and assembly, far exceeding that of ordinary plastic threads.

How to verify a supplier’s credibility?

Verifying the credibility of suppliers mainly involves checking their qualification certifications (such as ISO9001, RoHS certification), production scale and history, customer evaluations and case demonstrations. At the same time, high-quality suppliers usually have a complete quality control system and after-sales service guarantee.

It is recommended to request samples for performance testing, or to have them tested by a third-party quality inspection agency, in order to ensure that the product quality meets the requirements.

What's the typical MOQ for custom brass inserts?

The minimum order quantity (MOQ) for custom-made brass inserts usually varies depending on the supplier and the complexity of the product, typically ranging from 5,000 to 10,000 pieces.

Some suppliers offer small-batch trial orders to assist customers in verifying product designs and market feedback. Large-scale orders, on the other hand, can lead to more competitive prices and more stable delivery schedules.

Can I request custom dimensions or knurling patterns?

Most professional manufacturers support customizing the size, shape and patterns (such as embossing, hook design) of brass threaded inserts according to customer requirements. The customization service helps enhance the grip force and installation effect of the inserts in specific applications, meeting the functional requirements of different products. Customers can provide detailed drawings or samples. The suppliers will provide technical evaluations and professional advice.

Conclusion: Work With the Right Manufacturer to Maximize Performance

Selecting a high-quality supplier of Chinese brass threaded inserts can not only ensure the stability and accuracy of the products, but also meet the special requirements of your different projects through comprehensive technical support and customized services. An excellent supplier possesses mature production processes, strict quality management systems, and global supply chain capabilities. They can provide you with cost-effective and timely solutions.

We recommend that you contact professional manufacturers directly to obtain accurate quotations and sample tests. Make sure the selected inserts truly fit your application scenario, thereby maximizing the reliability and durability of the connection structure.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.