The Ultimate Guide to Rivet Nut Pull Out Strength

Leading Rivet Nut Manufacturer and Supplier in China

When evaluating the performance of rivet nuts, the “pull-out strength” of the rivet nut is a key indicator. The term “pull-out strength” refers to the maximum force at which a rivet nut is pulled out from the substrate when subjected to axial tensile force. It is usually expressed in Newtons (N) or pounds-force (lbf). It directly affects the stability of the connection component in the force-bearing environment. Especially in situations such as vibration, tension, or load suspension, how it performs is of great significance.

The test of pull-off strength is usually conducted using a universal material testing machine. The rivet nut is stretched on the sample at a specified speed, and the maximum force value before it detaches is recorded. It is particularly important to note that pull-off strength ≠ tensile strength. The former focuses on the “overall connection force” between the rivet nut and the base material, while the latter is the breaking strength of the rivet nut’s own material. “Clamping force” is the compressive force generated by the rivet nut after installation, and this value has a greater impact on the fastening performance and anti-loosening performance.

This article will provide you with a comprehensive analysis of the definition, testing methods, influencing factors, improvement strategies, and selection suggestions for rivet nut pull-out strength.

Table of Contents

Why Pull Out Strength Matters in Rivet Nut Applications?

In the practical application of riveted nuts, the level of pull-off strength directly affects the structural safety and reliability of the connection area. If the riveted nut fails to maintain its pull-off strength during use and is pulled out from the base material, it may cause the components to loosen, fall off, and even lead to overall machine failure.

- Take the automotive industry as an example. Parts such as body panels, bumper brackets, and seat slides often use rivet nuts for installation. If the rivet nuts come loose due to intense vibration or sudden load changes at the connection points, it may endanger the safety of passengers.

- In the home appliance sector, for instance, in washing machines, power tools, or air conditioner shells, rivet nuts are commonly used to firmly connect metal sheets. If the tensile strength is insufficient, they are prone to loosen during long-term use or transportation.

- In industrial machinery and equipment manufacturing, such as operation consoles, frame structures, and electrical control cabinets. In case of a detachment failure, it not only affects the stability of operation but also may cause safety hazards and high maintenance costs.

The pull-out strength of rivet nuts is not merely a technical indicator; rather, it is a crucial foundation for ensuring the structural integrity, usability safety, and long-term reliability of the product. Accurately assessing and optimizing this strength is of utmost importance.

Key Factors Affecting Rivet Nut Pull Out Strength

①. Base material type

The mechanical properties of the substrate (base material) determine the upper limit of the locking capacity of the rivet nut. The influence of common materials on the tensile strength is as follows:

| Material | Tensile Strength (MPa) | Pull-Out Risk Level |

|---|---|---|

| Stainless Steel (e.g., SUS304) | ≥520 | Low |

| Mild Carbon Steel (e.g., Q235) | ~375 | Medium |

| Aluminum Sheet (e.g., 5052) | ~260 | High |

| Engineering Plastic (e.g., PA66+GF) | ~100–150 | Very High |

Soft or low-strength substrates are more prone to local deformation or material tearing, which can lead to the detachment of the rivet nuts.

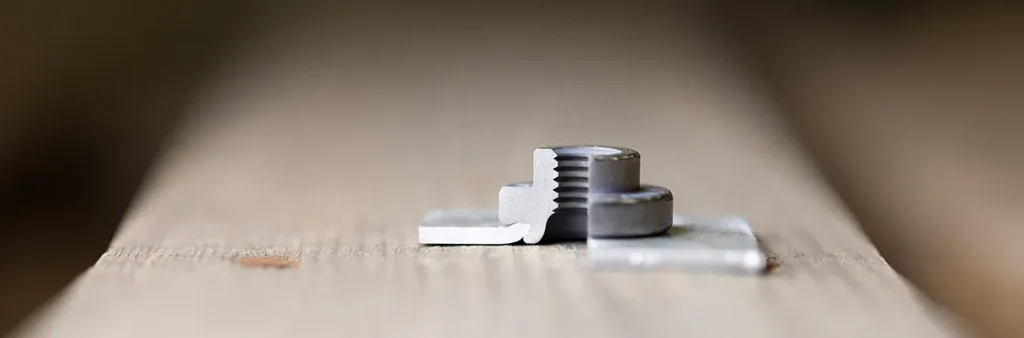

②. Plate Thickness and Hole Diameter Accuracy

- Insufficient Thickness: When the plate thickness is lower than the recommended minimum clamping thickness for the rivet nut, it will reduce the mechanical grip force of the “reversed” part after forming, seriously affecting the tensile strength.

- Excessive Hole Diameter: If the hole diameter exceeds the upper limit of the tolerance, it will cause the nut to be “floatingly” installed, unable to achieve a tight fit, significantly reducing the tensile strength.

For example: The recommended hole diameter for M6 stainless steel rivet nuts is 9.00 ± 0.10 mm. If the hole diameter reaches 9.3 mm, the pull-out strength may decrease by 10 – 25%.

③. Material of the Bolts

Different types of rivet nuts have varying levels of bite strength, thread retention force, and corrosion resistance after being formed. It is recommended to choose hard nuts when the base material is soft, such as steel or stainless steel, to ensure sufficient reaction force during the forming process.

| Material | Strength Performance | Corrosion Resistance | Suitable Applications |

|---|---|---|---|

| Stainless Steel (SUS304) | High | Excellent | Outdoor / Structural Load-Bearing |

| Aluminum | Medium | Moderate | Lightweight Requirements |

| Brass | Low–Medium | Good | Electrical Conductivity / Decorative Use |

④. Surface Treatment and Corrosion Resistance Properties

Although the surface treatment has a limited effect on the “initial peel strength”, it significantly affects the long-term service performance:

- Galvanization (electroplating or hot-dip plating): Offers good cost-effectiveness and has an average lifespan in terms of corrosion resistance.

- Dacromet/Zinc-Nickel Alloy: Exhibits excellent salt spray resistance and is suitable for automotive or marine industries.

- Unprocessed (bare material): Prone to corrosion, reducing the bonding strength between the nut and the base material.

The salt spray test results show that the untreated steel rivet nuts experienced significant corrosion at the joint surface after 96 hours, and their tensile strength decreased by more than 20%.

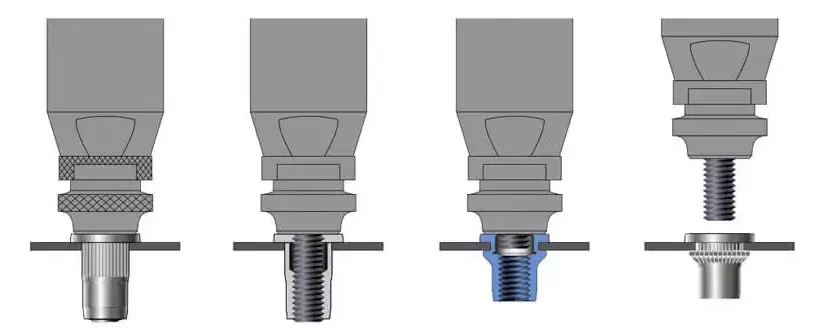

⑤. Installation Process

- Insufficient riveting force: The forming process is insufficient, resulting in incomplete reverse threading.

- Excessive riveting: It may damage the base material or cause deformation of the internal thread of the rivet nut.

- Differences in tool types: The force of manual tools is unstable. It is recommended to use pneumatic and hydraulic automated equipment for critical application scenarios.

Experimental data show that the pull-off strength of the same type of rivet nuts differs by up to 15-30% when installed with manual tools versus pneumatic-hydraulic tools.

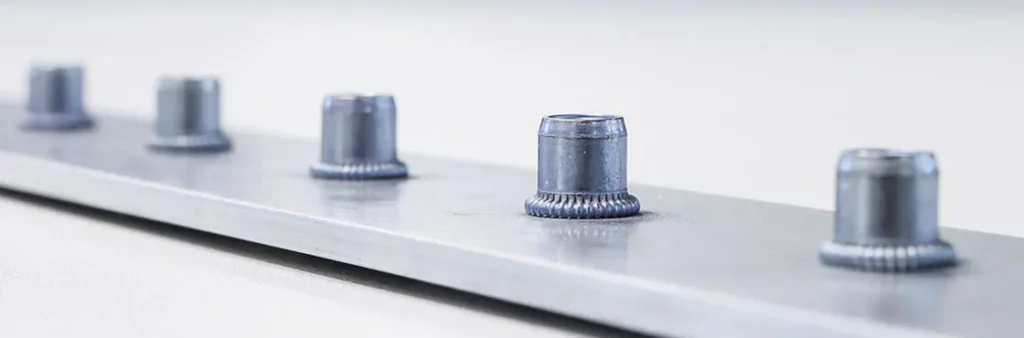

Rivet Nut Design Types and Their Strength Performance

| Type | Appearance Features | Pull-Out Strength | Spin-Out Resistance | Typical Applications |

|---|---|---|---|---|

| Hexagonal | Hexagonal outer wall, full shape engagement | ★★★★☆ | ★★★★★ | High torque / Structural components |

| Half-Hexagonal | Half-hex outer wall, semi-circular shape | ★★★☆☆ | ★★★★☆ | Cost control, light-duty use |

| Slotted | Cylindrical with longitudinal slots | ★★☆☆☆ | ★★☆☆☆ | Plastics / Soft base materials |

| Closed-End | Sealed bottom, dust and fluid resistant | ★★★★☆ | ★★★☆☆ | Dustproof / Fluid-resistant scenarios |

- Structural Advantage: Through the hexagonal wall surface and the locking with the substrate holes, it effectively prevents rotation.

- Pull-off Performance: The contact area of the hexagonal surface is large, and the compression-bolt deformation is sufficient, resulting in the highest pull-off strength.

- Typical Data (M6 stainless steel in 1.5mm steel plate):

- Tensile pull-off strength: approximately 7.8 – 9.5 kN

- Anti-rotation torque: ≥ 18 Nm

2. Half Hexagon Head Rivet Nut

- Structural Feature: Only some hexagonal surfaces, suitable for some irregularly shaped holes or those with lower precision.

- Performance Trade-off: The anti-rotation ability is better than that of the cylindrical type, while the pull-off strength is slightly lower than that of the full hexagonal type.

- Advantages: Balances cost and performance, suitable for large-scale medium-load applications.

- Design Principle: Achieves “petal-like” expansion through longitudinal slot deformation. Suitable for soft materials (plastics, composite boards, etc.).

- Advantages and Disadvantages:

- Advantages: Low installation force, low pressure on the substrate.

- Disadvantages: Poor tensile strength and rotational mechanical properties.

- Application Limitations: Not suitable for high-strength connection scenarios.

4. Closed-End Type Rivet Nut

- Design purpose: To seal the bottom to prevent liquids, dust or gases from entering the threaded cavity.

- Structural manifestation:

- The tensile strength is slightly higher than that of the open type (due to the enhanced rigidity of the tail).

- The risk of contamination of the threads is low.

- Common applications: Electronic enclosures, hydraulic equipment, clean assembly areas.

How to Test Rivet Nut Pull Out Strength: Standards and Methods

a. Testing Standards

The following standards are internationally recognized or recommended within the industry for evaluating the pull-out performance of rivet nuts:

| Standard Code | Title | Applicability |

|---|---|---|

| ISO 14589 | Mechanical testing of blind rivet nuts | Specifies methods for pull-out and torque testing |

| ASTM F2282 | Blind threaded inserts performance standard | Common in the North American market; defines specimen preparation, test speed, and evaluation criteria |

| DIN 73378 | German standard detailing nut structure, strength, and testing | Suitable for European markets or automotive-grade suppliers |

| GB/T 26763 | Chinese national standard providing guidelines for mechanical testing of blind fasteners | Common in domestic use and applicable for export inspections |

b. Testing Equipment

- Universal Testing Machine (UTM)

- Brand examples: Instron, MTS, SANS, Shimadzu

- Key features: Constant loading rate control, real-time curve recording, maximum load detection

- Specialized Pulling Tooling

- Upper fixture fixing screw rod

- Lower fixture fixing base sample to maintain parallelism and prevent slippage

c. Standard Testing Procedures

1. Sample Preparation

- Select the target rivet nut and install it on the specified material (such as 1.5mm Q235 steel plate)

- Ensure that the hole diameter, tolerance, and installation method are consistent with the actual usage (manual/automatic)

- It is recommended to take the average value of 5 samples in each group

2. Install the Sample in the Fixture

- Install the base material on the fixed platform smoothly

- The pull force axis should be perpendicular to the installation surface to avoid eccentric load

3. Set the Test Parameters

- Pull-out rate: 5 mm/min (ASTM recommendation) or 2 mm/min (ISO recommendation)

- Recording unit: Maximum load (N or kN)

4. Perform the Pull-off Test

- Continuously load until the nut is completely detached from the base material or damaged

- At the same time, record the “failure mode”: base material fracture, nut pull fracture, internal thread slippage, etc.

5. Data Analysis

- Output results: Maximum pull-off load, load-displacement curve

- Can be compared with design values or standard values (such as ISO recommends M6 ≥ 5.5 kN)

Pull Out Strength vs Spin-Out Resistance: What’s the Difference?

✅ Pull Out Strength: The ability to resist being pulled out

The pull-off strength refers to the ability of a rivet nut to resist being pulled out from the substrate when subjected to an axial tensile force (perpendicular to the installation surface).

- Typical scenario: For example, in the fixation of car body parts or the outer shell of an electronic control box, the rivet nuts need to withstand prolonged tension.

- Testing method: Using a tensile testing machine, continuous axial tension is applied until the nut comes off.

- Influencing factors: The strength of the base material, the shape and structure of the rivet nut (such as ribbed or hexagonal), and the installation integrity.

🔄 Spin-Out Resistance: The ability to resist rotation

The rotational release force is a measure of the ability of the rivet nut to resist itself from slipping or rotating within the hole when the bolt is being tightened or loosened.

- Typical Scenario: Situations where electronic product shells and air conditioning panels need to be disassembled and reassembled frequently.

- Testing Method: Under a fixed installation condition, apply torque to test whether it rotates and comes off.

- Influencing Factors: The shape of the rivet nut (round or hexagonal), the accuracy of the hole type fit, and the installation pressure.

Why Are Both Important?

| Aspect | Insufficient Pull-Out Strength | Insufficient Torque-Out Resistance |

|---|---|---|

| Consequence | Rivet nut is pulled out, causing structural failure | Bolt cannot be tightened or removed, leading to maintenance issues |

| Risk | Safety hazards, structural failure | Installation failure, increased maintenance costs |

Rivet Nut Pull Out Strength Chart by Size and Material

Material distribution: Carbon steel / Stainless steel / Aluminum alloy

Base material default conditions: Steel plate Q235, thickness 1.5mm, standard hole diameter, pneumatic tool installation

| Thread Size (Spec) | Carbon Steel (Steel) | Stainless Steel | Aluminum Alloy (Aluminum) |

|---|---|---|---|

| M3 | 2.0–2.5 | 2.5–2.9 | 1.6–2.0 |

| M4 | 3.0–3.6 | 3.8–4.2 | 2.2–2.8 |

| M5 | 4.0–4.8 | 5.0–5.6 | 3.0–3.5 |

| M6 | 5.5–6.5 | 7.0–8.5 | 4.2–5.0 |

| M8 | 7.0–8.5 | 9.0–10.5 | 5.0–6.5 |

| M10 | 9.0–11.0 | 12.0–14.0 | 6.5–8.0 |

| M12 | 11.0–13.5 | 14.0–17.0 | 8.0–10.0 |

📌 Note:

- The tensile strength is the measured average maximum value, which may vary due to installation quality, hole tolerance, and material differences;

- Stainless steel nuts generally have higher strength than carbon steel and aluminum alloys, but it should be noted that their installation deformation resistance is greater;

- Aluminum alloys are suitable for light-load and high-corrosion-resistant environments, but their structural strength is relatively the lowest.

Design Selection Suggestions:

- Carbon steel or stainless steel nuts should be preferred for structural load-bearing components;

- Aluminum nuts are suitable for lightweight or soft substrate installations (such as aluminum shells, plastics);

- If the installation space permits, choosing a larger size can significantly increase the strength margin;

- When the plate thickness is less than 1.0mm, special attention should be paid to the clamping range and the supporting force of the hole wall.

Common Mistakes That Weaken Pull Out Strength

- Choosing the wrong material for the rivet nuts

For instance, using aluminum rivet nuts in steel structures can easily lead to a mismatch in material strength, resulting in pull-off when subjected to force. - Ignoring the matching of plate thickness and the clamping range of the rivet nut

If the thickness of the sheet material is less than the minimum clamping range of the rivet nut, the riveting will result in insufficient deformation and the part is likely to be pulled out. - Excessive or insufficient pre-drilled holes

An excessively large hole diameter will reduce the clamping force of the rivet nut, while a hole diameter that is too small is prone to damaging the substrate or the rivet nut itself. - Failure to use the recommended installation tool or improper application force

Using manual tools to randomly apply riveting force or not following the recommended settings for applying force may result in the rivet nut not fully deformed, and the connection not being secure. - Ignore the treatment of surface oil stains / coatings

If there is grease, oxide film or coating on the riveted surface, it will reduce the friction and bonding force, thereby affecting the tensile separation performance. - Reinstallation or Misinstallation Reinstalling rivet nuts or eccentric rivets in the already damaged holes will damage the wall structure of the holes, making them more prone to being pulled out.

Do You Have Any Questions?

Let Us Solve Your Problem

Work With a Reliable Rivet Nut Manufacturer to Ensure Strength

In the process of striving for connection strength and structural reliability, it is crucial to choose a rivet nut manufacturer with rich experience and a complete testing and quality control system. Rivetfix possesses advanced detachment strength testing equipment, a professional engineering team, and extensive industry application experience. It can provide customized nut selection and installation solutions based on your material type, usage environment, and load requirements. Whether it’s high-strength structural connections or anti-loosening designs under complex conditions, we can help you achieve a stable, safe, and long-lasting assembly effect.

📩 Contact Rivetfix immediately to obtain technical support and free samples!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.