Is a Heli-Coil a Permanent Fix?

Leading Threaded Insert Manufacturer and Supplier in China

Heli-Coil is a common thread repair tool, widely used to fix damaged metal threaded holes. It is usually made of stainless steel wire and has a spiral shape. It can be embedded in the original hole to re-establish a standard-sized threaded structure. This design can effectively restore the function of the thread and avoid replacing the entire part or component. In mechanical maintenance, aviation manufacturing, and the automotive industry, Heli-Coil is regarded as an economical and efficient repair method. Therefore, many engineers wonder: “Is a Heli-Coil a permanent fix?” This is precisely the core issue that this article will explore in depth.

In practical applications, Heli-Coil is favored for its ease of installation, relatively low cost, and the ability to enhance the tensile strength of threads. Especially in soft materials such as aluminum and magnesium, once the original threads are worn or stripped, Heli-Coil can provide a more durable internal thread, extending the service life of the workpiece. However, a question arises: How long can this “repair” last? Is it equivalent to a permanent solution? The following content will analyze from the perspectives of structural characteristics, usage environment, and industry cases whether Heli-Coil can truly be a permanent repair solution.

Table of Contents

Why Thread Damage Happens?

Thread damage is extremely common in mechanical maintenance. The causes are diverse, mainly including over-tightening, frequent disassembly and assembly, corrosion erosion, and material fatigue. When a bolt is subjected to excessive torque, the internal thread is prone to being scratched or peeling off. Especially on soft metals such as aluminum, thread slippage or cracking is more likely to occur.

Apart from operational issues, environmental factors should also not be overlooked. Metal components in high-humidity or salt-spray environments are prone to oxidation and corrosion, resulting in a decrease in thread strength. In working conditions with high-frequency vibration or high-temperature loads, such as in aircraft engines or heavy equipment, material fatigue can cause the threads to gradually loosen or even break.

These issues are widespread in fields such as automotive repair, aerospace manufacturing, and industrial equipment maintenance. Once the threads are damaged, not only will the assembly accuracy be affected, but there may also be safety hazards. And Heli-Coil demonstrates extremely high application value in such scenarios. It not only can quickly restore the function of the threads, but also can enhance the strength of the threads to a certain extent, providing a secondary guarantee for critical components. This also provides an important background for the discussion in the following paragraphs about whether it is a permanent solution.

How Does a Heli-Coil Work?

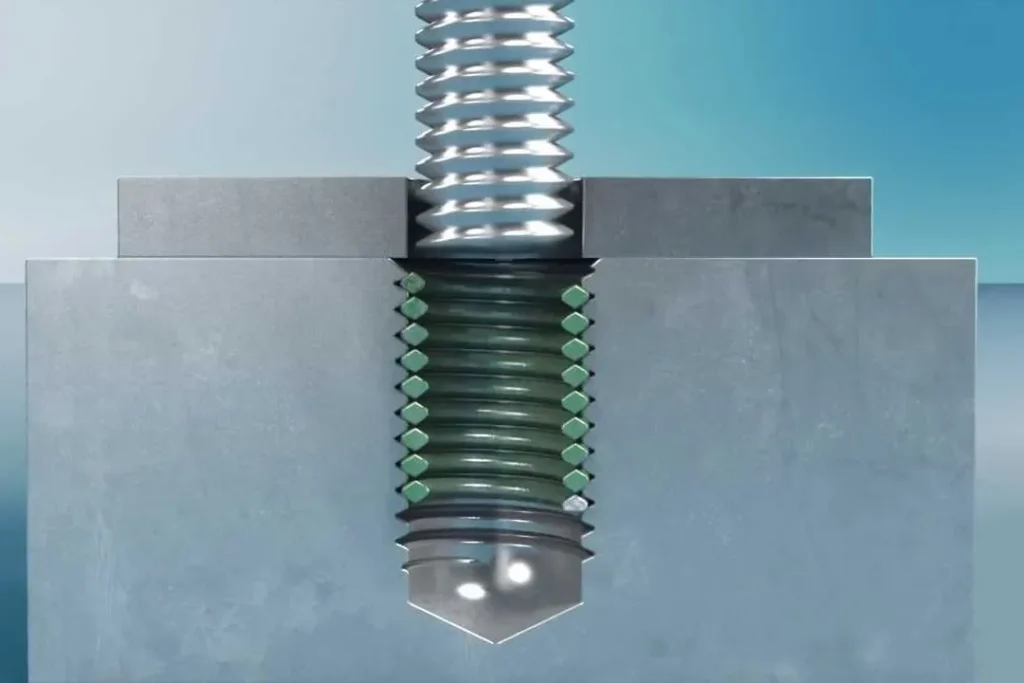

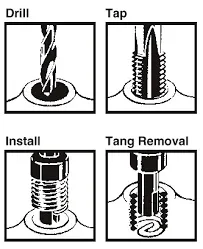

The essence of Heli-Coil is a threaded sleeve (Thread Insert), usually made of high-strength stainless steel wire. Its shape resembles a precise spring, but each layer has a complete threaded shape. During installation, a special tap must be used to re-drill the damaged hole to create standard threads, and then the Heli-Coil sleeve is screwed in to form a new internal thread. After installation, the originally worn-out threaded hole can be restored to its original size.

This process can be compared to embedding an additional “inner thread” on the originally “flaked” threaded wall. The newly formed threaded surface is made of high-strength steel and can effectively enhance the load-bearing capacity and durability of the connection component. Especially in soft materials such as aluminum and magnesium, the rigidity advantage of Heli-Coil is more pronounced, significantly reducing the risk of the thread loosening again.

Furthermore, the design of Heli-Coil features a radial tension difference between the “free state” and the “installation state”. This tension enables it to securely lock into the hole after installation and not easily loosen, thereby enhancing the overall connection stability. Many industrial standards even recommend using the threaded sleeve solution in high-stress environments.

The Advantages of Using a Heli-Coil

The use of Heli-Coil threaded inserts offers several significant advantages, especially in industries that have high requirements for structural strength and maintenance efficiency. Here are its main benefits:

- High Durability: Heli-Coil is mostly made of stainless steel, which can maintain stability in high-load, high-vibration and high-temperature environments. Even in extreme conditions such as aircraft engines and military equipment, it can maintain the reliability of threaded connections.

- High Cost Efficiency: Compared to replacing entire parts or shells, using Heli-Coil to repair threads can significantly reduce maintenance costs. Especially in large equipment and structural components, the economic value is more prominent.

- Easy Installation: The installation process can be completed with only standard screw tapping tools and a dedicated installer. The repair process is fast, controllable, and suitable for on-site operations, requiring no complex training.

- Wide Applicable Industries: It is widely used in multiple fields such as automobile repair, aviation manufacturing, military assembly, mold repair, industrial equipment maintenance. Its versatility and compatibility make it the preferred solution for many engineering technicians.

The Limitations and Risks

Although Heli-Coil has wide application value, it is not suitable for all scenarios. Under certain conditions, its use also has certain limitations and potential risks:

Not a Universal Fix Solution

In cases where the structure is severely damaged, the screw holes are misaligned, or the metal substrate is cracked, Heli-Coil is difficult to function effectively. Especially in high-security areas (such as the connection points of aircraft wings, heavy-duty bearing seats, etc.), engineering specifications often do not recommend using threaded sleeves as a permanent repair method.

Installation involves operational risks

If the tapping is not perpendicular or the installation depth of the sleeve is incorrect, it is likely to cause the sleeve to shift or come loose. Some common mistakes made by novice technicians during installation include over-tightening, failure to clean the screw holes, and not installing at the specified depth, all of which will reduce the service life.

Fatigue failure may occur under extreme conditions

In environments where components are exposed to prolonged heat or vibration (such as the engine block of a racing car), the threaded sleeves may experience loosening risks due to micro-movement wear or material fatigue. Therefore, under extreme conditions, professional assessment should be conducted and higher-grade locking sleeves (such as locking Heli-Coil) or alternative solutions should be selected.

Real Case Warning

In a car repair case, the technician used Heli-Coil to repair the spark plug threads of the engine cylinder. It functioned well for a short period of time. However, because the high-temperature-specific model was not used, the protective sleeve loosened after a few months, causing cylinder compression leakage and ultimately resulting in engine damage. This incident indicates that even effective repair methods must be used in the appropriate location and under the appropriate conditions.

Is a Heli-Coil a Permanent Fix?

a. From a Technical Perspective

Heli-Coil is designed with a technical principle that is suitable for long-term use. It is embedded into the base material using stainless steel or high-strength alloy wires. This allows for the restoration and even enhancement of the strength of the threads. After proper installation, its wear resistance and corrosion resistance are typically superior to those of the original threads.

For instance, in the aviation and military industries, Heli-Coil has been in use for over 50 years, being applied in engines, aircraft structures, and precision equipment. Industry standards (such as NASM33537) clearly stipulate the installation and inspection methods of Heli-Coil. This indicates that it is recognized as a reliable long-term solution in professional fields.

b. Judgment of Application Scenarios

Not in all cases can Heli-Coil be regarded as “permanent”.

For general mechanical equipment, automotive repair, molds or electronic devices with threaded holes, Heli-Coil can be considered a permanent repair. After the repair, the load-bearing capacity can even be higher than the original thread.

However, in scenarios involving critical safety components, such as engine blocks of aircraft, nuclear power plant equipment, and medical implants, Heli-Coil is usually used as a transitional solution. Because these fields have extremely high requirements for reliability and traceability, any repair is regarded as a potential risk. In such applications, it is recommended to replace the entire component or use more advanced threaded repair systems (such as Time-Sert or Keensert).

c. Long-term Reliability Data

The actual tests and industry experience indicate that Heli-Coil performs stably in most applications.

- Automotive industry: In the repair of engine cylinder heads and spark plug holes, Heli-Coil has been widely used. Many users report that the lifespan after repair can exceed 10 years, equivalent to the lifespan of the parts.

- Aviation industry: The maintenance manuals of Boeing and Airbus models both include Heli-Coil as an approved repair method. Long-term operation data prove that it can withstand high vibration, high temperature and repeated disassembly.

- Industrial equipment: In high-torque environments, Heli-Coil provides a stable locking torque. Compared with the original threads, its stripping risk is lower.

Technically speaking, Heli-Coil is not a “temporary fix”. In most non-critical applications, it is a long-term or even permanent solution.

’However, in highly secure fields, it is more suitable for emergency repairs rather than as a definitive solution. The correct selection of application scenarios is the key to determining its “permanence”.

Alternatives to Heli-Coil

1. Time-Sert (Solid Threaded Insert)

Time-Sert is a solid metal threaded sleeve. Unlike the spring structure of Heli-Coil, it uses a machined steel sleeve or alloy sleeve. After installation, it forms a more stable contact surface with the base material.

- Advantage: The structure is sturdy and, after installation, it is almost identical to the original thread. It is suitable for high-load and high-safety scenarios.

- Application: Widely used for repairing engine cylinder blocks and spark plug holes. It can withstand more repeated disassembly and assembly compared to Heli-Coil.

- Limitation: The cost is higher and installation requires special tools.

2. Keensert (Locking Thread Insert)

Keensert also belongs to the solid thread repair system, but it incorporates a “locking pin” structure. After installation, it is fixed by the locking pin to prevent loosening.

- Advantage: Extremely high vibration resistance. Suitable for the aerospace, military and heavy machinery industries.

- Application: It is often specified for use by OEMs (Original Equipment Manufacturers) in critical and highly reliable areas.

- Limitation: Installation is more complex. Once installed, it cannot be reversed and usually requires disposal after removal.

3. Replace the entire part or reprocess it

In some cases, replacing the entire part is safer than using Heli-Coil. This is especially true for critical safety components or parts that are subjected to high torque.

- Advantage: Completely eliminates risks and complies with industry certification requirements.

- Application: Aviation engines, nuclear power equipment, medical devices. Any scenario where failure could have serious consequences.

- Limitations: High cost and long cycle. May require production suspension or equipment shutdown.

4. Criteria for Selection: When to Use Heli-Coil and When to Implement Upgrade Solutions?

- Suitable scenarios for Heli-Coil: Daily maintenance, automotive parts, molds, and light industrial equipment. Its advantages include economy, speed, and reliability.

- More suitable scenarios for Time-Sert/Keensert: Components with high safety standards, equipment that withstands repeated stress and high vibration.

- Scenarios requiring replacement or reprocessing: Components related to life safety or those subject to industry mandatory standards.

Best Practices for Long-Lasting Repairs

① Choose the appropriate size and material

The first step in the repair process is to select the correct Heli-Coil size. An incorrect diameter or length will result in an uneven load distribution. This could lead to re-striking or loosening of the threads.

The material is also very important. Common materials include stainless steel, phosphor bronze, and Inconel alloy. For general mechanical maintenance, stainless steel is sufficient. However, in high-temperature environments such as engines or turbines, Inconel or nickel-based alloys are recommended.

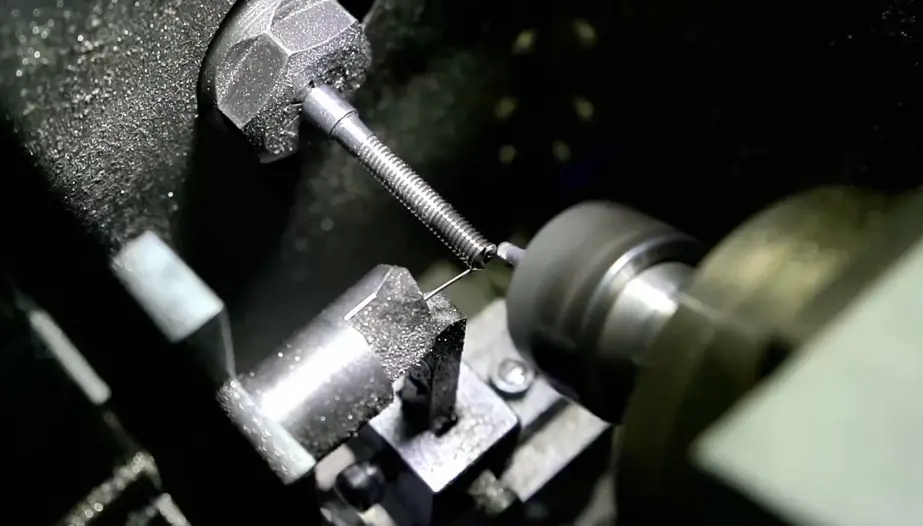

② Ensure that the installation tools and torque control are correct

During the installation process, only the matching specialized tools should be used. Using substitutes at will may cause the thread sheath to deform or break. At the same time, torque control is very important. If the tightening torque is too small, it will reduce the load-bearing capacity. If it is too large, it may damage the base material. Follow the torque standards provided by ISO 898-1 or the equipment manufacturer to execute, which can significantly improve the repair lifespan.

③ Regularly check the repair status in key applications

For non-critical components, Heli-Coil can be used for a long time without frequent inspections. However, in aviation, military, or high-stress equipment, regular inspections are necessary. The inspection contents include: whether there is looseness, whether the sheath is rotating, and whether there are cracks in the threaded holes.

Some industry standards (such as FAA AC 43.13-1B) recommend that during each major overhaul or disassembly inspection, the status of the repair points should be carefully confirmed.

④ Professional advice from technicians/mechanics

Experienced technicians can determine whether a repair is truly “permanent”. For instance, in the repair of spark plug holes, many seasoned automotive technicians recommend using the extended Heli-Coil to reduce the impact of thermal expansion and contraction.

In industrial equipment, mechanics usually perform torque calibration after repairs to ensure that subsequent maintenance personnel can reassemble the equipment according to the standards.

Conclusion: Is It Permanent or Temporary?

Heli-Coil is not merely an “emergency measure”. In most applications, it can be regarded as a long-term or even permanent repair method. After proper installation, the strength is often no less than that of the original threads. Long-term experience in automotive repair and industrial equipment also proves its reliability.

However, in high-security and critical components, Heli-Coil is more suitable for use as a temporary transition solution. For instance, in scenarios such as aircraft engines, nuclear power equipment, and medical devices. Industry standards typically require the replacement of entire parts when conditions permit to ensure the highest level of safety.

Therefore, Is a Heli-Coil a Permanent Solution? The answer depends on the specific circumstances.

- For routine maintenance and non-critical components → This can be regarded as a permanent solution.

- For areas related to life safety or strictly certified ones → It is recommended to use it only as a temporary fix.

The final judgment should take into account the type of equipment, usage conditions and industry standards. If one can consult experienced mechanics or technicians before making the choice, it is often possible to make a more reliable decision.

FAQs

Q1: Can a Heli-Coil last forever?

Heli-Coil does not have a fixed lifespan. Once installed correctly, it can be used for a long time and even beyond the natural lifespan of the components. Data from the automotive and aerospace industries show that Heli-Coil can be regarded as a permanent repair in most scenarios. However, in extremely high-temperature or high-stress environments, regular checks are still recommended.

Q2: Is a Heli-Coil stronger than original threads?

In many cases, the threads repaired with Heli-Coil are stronger. This is because the sheath material is usually high-strength stainless steel, which can distribute stress and enhance wear resistance. Tests show that the load-bearing capacity of Heli-Coil is increased by approximately 10% – 20% compared to the original threads. However, this is only true when the installation specifications are followed and the torque is controlled correctly.

Q3: Where should you not use a Heli-Coil?

It is not recommended to use Heli-Coil in critical safety components. For instance, main components of aircraft engines, medical implants, and nuclear power equipment. These applications have extremely high reliability requirements and usually mandate the replacement of the entire part. In these scenarios, Heli-Coil can only be used as a temporary repair.

Q4: How much does it cost to install a Heli-Coil?

The cost is relatively low. The price of a standard Heli-Coil kit is approximately $20 – $50, including the sleeve and installation tools. The repair cost for a single hole is usually less than $10. If operated by a maintenance technician, the labor cost varies significantly depending on the region. Compared to replacing the entire part, the cost savings can reach over 70%.

Q5: Are there better alternatives than Heli-Coil?

Yes. In some high-load or high-safety applications, Time-Sert and Keensert are considered to be more reliable. They are solid metal threaded sleeves with higher strength and better vibration resistance. However, they are more expensive and the installation process is more complicated. For most routine maintenance, Heli-Coil is already sufficiently reliable.

Do You Have Any Questions?

Let Us Solve Your Problem

Ready to Make Your Repair Permanent

If you are looking for a reliable, cost-effective and industry-proven solution for thread repair, Heli-Coil is the best choice. It not only restores the original strength but also achieves higher durability in most applications. Whether you are a professional in automotive repair, industrial maintenance, or mechanical processing, choosing high-quality Heli-Coil means reducing downtime, lowering costs, and ensuring long-term reliable performance.

👉 Contact us immediately to obtain the original Heli-Coil products and professional technical support, ensuring that every repair becomes a long-term solution.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.