How To Choose Threaded Inserts For Sheet Metal?

Leading Rivet Nut Manufacturer and Supplier in China

When working with metal enclosures, panels, or structural components, selecting the right threaded inserts for sheet metal is critical to ensure strength, durability, and long-term performance. Unlike solid materials, thin metal sheets require specialized insert types and installation techniques to handle repeated fastening, vibration, and corrosion exposure. In this guide, we’ll explore how to choose the most suitable insert based on your application’s material, thickness, and load requirements—ensuring every connection is both secure and serviceable.

Table of Contents

Why Use Threaded Inserts Instead of Tapped Holes in Sheet Metal?

In sheet metal parts, the traditional practice is usually to tap directly after pre-drilling to form internal threads for fastening bolts or screws. However, when the sheet metal thickness is thin or when there are higher requirements on the strength and durability of the connection, direct tapping has various limitations, while threaded inserts provide a more reliable and professional solution.

The following is a key comparison and analysis of the advantages and disadvantages of the two:

I. Limited plate thickness

In conventional tapping, the number of effective threads in a hole is limited by the thickness of the plate. Usually at least 1.5 times the thickness of the pitch is required to ensure the basic tightening torque. For example, an M4 thread with a standard pitch of 0.7mm should have a minimum plate thickness of ≥1.05mm, otherwise the thread length will be insufficient and it will be easy to slip or fail.

In contrast, threaded inserts are specially designed for thin plates, and some self-locking or pressure riveting type inserts can be applied to plates only 0.5 mm thick, relying on their structural design (e.g. knurling, locking teeth, flanges, etc.) to provide high-strength threads, completely solving the problem of tapping difficulties in thin plates.

II. Strength and Load Capacity

The threads formed by tapping depend directly on the strength of the base material, especially in soft metals such as aluminum and copper, which have limited tensile and shear resistance, and are prone to stripping the threads once they are subjected to excessive external forces.

Threaded inserts are often made of high-strength materials, such as carbon steel, stainless steel, combined with crimping, riveting, welding and other fixing methods, and the substrate to form a solid combination. Take compression rivet nut as an example, its tensile force can reach 5.5-8.9 kN (M4-M6), much higher than the same size tapped holes, which significantly improves the overall structural load-bearing capacity and reliability.

III. Repeated assembly and disassembly and thread life

Frequent assembly and disassembly operations are likely to cause wear or deformation of tapped holes, especially under the action of multiple tightening torque, the metal surface threads gradually fail, resulting in screw loosening or even falling off.

Inserts are usually made of wear-resistant materials with longer thread life and higher repeatability, which is suitable for electrical equipment, machine housings, electronic assemblies and other applications that require multiple maintenance.

IV. Installation efficiency and consistency

Tapping operations usually require additional equipment, such as tapping machines or CNC systems, which is not only time-consuming and inefficient, but also relies on operator experience for processing quality, resulting in poor consistency of the finished product.

Threaded inserts, on the other hand, are installed using standardized processes, such as pressure riveting, pull riveting, and injection molding pre-embedding, making the installation process fast and stable. For example, the assembly time for a rivet nut is usually less than 1 second, making it ideal for automated production lines and significantly improving efficiency and yield.

V. Adaptable to a wide range of materials

Direct tapping on soft materials (e.g. aluminum alloy or thin stainless steel) results in threads with poor tensile and shear resistance, which are highly susceptible to damage. And threaded inserts according to the base material can be flexible choice of materials and structural forms:

- For aluminum plate, stainless steel rivet nut can be used;

- For steel plate, you can use carbon steel welding nut or rivet nut;

- For corrosion protection, zinc-plated or stainless steel inserts can be used.

What Are the Common Threaded Inserts Used in Sheet Metal?

- Structural Principle: A special embossed ring or locking groove is designed at the bottom of the insert, and when pressed into the pre-fabricated hole by pressure, the metal sheet will “flow” and embed into the locking groove, forming a permanent occlusion;

- Recommended plate thickness: 0.8mm-2.5mm;

- Common use: server chassis, control panels, electrical cabinet door panels and other thin plate need to be fixed on both sides of the threaded occasions;

- Advantages:

- Fast installation and accurate positioning;

- Strong anti-rotation and anti-pulling ability;

- Suitable for large-volume automated press fitting;

- Precautions: only for metal materials with good ductility (such as mild steel, aluminum alloy), high hard materials are not applicable.

2. Self-Clinching Studs

- Structural Principle: Similar to pressure riveting nuts, the body of the insert is a column with exposed threads, which is fixed on a thin plate by riveting;

- Recommended plate thickness: ≥1.0mm;

- Common use: need to install brackets, cable clamps, PCB boards from the outside of the board fixed support pieces;

- Advantages:

- Convenient for external parts screws to be screwed in directly;

- Simple shape and high assembly strength;

- Precautions: The embedded area needs to be flat enough to avoid eccentric pressure riveting.

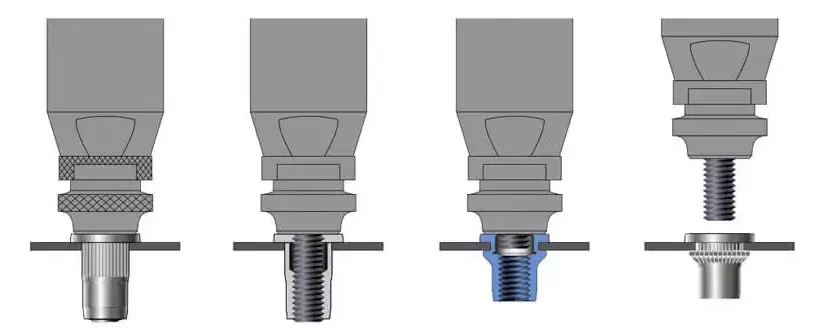

- Structural Principle: The nut is stretched and deformed from the hole by manual or pneumatic rivet gun to form a flap locking on the back side, which is suitable for structures where the back side cannot be accessed;

- Recommended plate thickness: 0.5mm-3.0mm;

- Common Uses: closed enclosures, sheet metal housings, equipment mounting brackets, and other single-side accessible workstations;

- Advantages:

- Flexible installation, not limited by back structure;

- Wide range of thread sizes (M3-M10);

- Cautions:

- Easy to pull apart when the board thickness is too thin, need to use models optimized for thin boards;

- The mounting holes need to be pre-tensioned and positioned to prevent slippage and rotation.

4. Weld Nuts / Weld Studs

- Principle of construction: Inserts are permanently fused to the sheet metal by means of a resistance or arc welding process;

- Recommended plate thickness: ≥1.2mm;

- Common Uses: body panels with high structural strength requirements, power boxes, industrial equipment frames;

- Advantages:

- Extremely high strength, can meet the structural stress threaded connections;

- Not easily loosened and resistant to high temperatures;

- Cautions:

- Thermal influence on the base material, the welding area needs to be clean and free of paint;

- Surfaces that are coated or plated need to be removed from the weld area beforehand.

5. Press-fit Inserts for Sheet Metal

- Structural Principle: By means of interference fit, metal sleeves with barbs or knurling are pressed into the holes of sheet metal;

- Recommended plate thickness: 0.8mm-1.8mm;

- Common use: precision structural parts, electronic radiator shell, aluminum profile sealing plate and other occasions with high visual requirements;

- Advantages:

- No damage to the board coating;

- Can be embedded on both sides;

- Cautions:

- Pre-hole precision needs to be controlled to avoid press-in eccentricity;

- Not suitable for connections with high loads or strong vibrations.

Table: Comparison of Threaded Insert Types for Sheet Metal

| Insert Type | Installation Method | Recommended Sheet Thickness | Advantages | Considerations |

|---|---|---|---|---|

| Self-Clinching Nut | Press-fit (stamping) | 0.8–2.5 mm | Dual-sided threads, high anti-rotation/pull strength, automation-friendly | Requires ductile materials like mild steel or aluminum alloys |

| Self-Clinching Stud | Press-fit (stamping) | ≥1.0 mm | Strong load support, easy external fastening, compact structure | Requires flatness control; misalignment can affect fit |

| Rivet Nut (Rivnut) | Rivet deformation locking | 0.5–3.0 mm | Blind installation, versatile specs, adaptable to many structures | Risk of spin-out in thin sheets; pull strength must be controlled |

| Welded Nut/Stud | Resistance or arc welding | ≥1.2 mm | High strength, permanent joint, heat-resistant | Base material must be clean; coating removal and heat distortion possible |

| Press-Fit Sleeve | Mechanical pressing | 0.8–1.8 mm | Clean appearance, double-sided access, ideal for compact areas | Not suitable for high-load applications; tight hole tolerance required |

How to Select the Right Insert For Sheet Metal?

A. Selection of Insert Type according to Sheet Thickness

The thickness of a sheet metal, due to its structural constraints, directly determines the type of insert and locking method. The following are recommended inserts for common thickness ranges:

| Sheet Thickness Range | Recommended Insert Type | Application Notes |

|---|---|---|

| < 1.0 mm | Self-clinching Nuts / Rivet Nuts | Thin sheets cannot support studs; use deformation-lock types. Thin-wall knurling preferred to avoid cracking. |

| 1.0–2.0 mm | Clinch Nuts / Clinch Studs | Ideal range for clinch inserts, balancing retention strength and positioning accuracy. |

| > 2.0 mm | Weld Nuts / Heavy-duty Clinch Inserts | Sufficient thickness for welding or high-load inserts. Suitable for structural/frame applications. |

Selection Notes:

- ≤1.0 mm: Prioritize rivet nuts or self-gripping inserts to avoid deformation or punching through.

- 1.0–2.0 mm: Use standard clinch series to achieve optimal strength and manufacturability.

- >2.0 mm: Consider high-strength structural inserts like weld studs or deep-groove clinch nuts.

B. Material Matching & Corrosion Prevention

The material of the base material (sheet metal) will directly affect the selection of threaded inserts and the corrosion prevention strategy, the following are the common matching and precautions:

1. Mild steel sheet (e.g. SPCC, Q235)

- SPCC (Cold Rolled Carbon Steel Plate)** and Q235 (Hot Rolled Carbon Steel) are the most commonly used structural materials in sheet metal processing, with good ductility, processability and welding properties;

- Widely used in:

- Electronic control box body, appliance enclosure;

- Industrial panels, bracket parts;

- Automation equipment sheet metal chassis, connecting skeleton.

1.1. Recommended insert material:

- Preferred: Galvanized carbon steel inserts

- Low cost and matched mechanical strength;

- Typically protected by electro galvanized (Zn) or Dacromet (Zn-Al);

- Mid- to high-end option: Stainless steel inserts (A2/304)

- Provides higher corrosion resistance and torque carrying capacity;

- Suitable for outdoor or high humidity working environment.

1.2. Recommended Insert Construction Types:

- Pressure Rivet Nuts / Studs (Self-Clinching Nuts/Studs):

- Utilizing the ductility of mild steel, the outer teeth of the nut “bite” securely into the plate;

- Suitable for plate thicknesses of ≥0.8 mm, they provide excellent resistance to rotation and pullout (M4 inserts typically have a pullout force of ≥5,000 N);

- Weld Nuts/Studs:

- For structural plates with a thickness of ≥1.5 mm, suitable for high-strength fastening;

- Commonly used in automotive chassis, power equipment, and heavy-duty skeleton structures.

1.3. Cautions

- Dissimilar metal contact (e.g., carbon steel plate + stainless steel inserts) creates a proto-cell effect that accelerates corrosion in humid/electrolytic environments;

- Galvanic Potential Difference (Galvanic Potential):

- Galvanic Potential: Carbon Steel vs. 304 Stainless Steel has a potential difference of approximately 0.5-0.6V;

- If the surface is untreated or there is a liquid film (e.g., condensation), the corrosion rate can increase to 5-10 times that of conventional environments;

- Typical failure case:

- Stainless steel rivets without isolation treatment cause “ring corrosion” or chalking and paint removal in sprayed housings.

2. Stainless Steel Plate (SUS304 / SUS430)

- SUS304 is austenitic stainless steel, with good comprehensive mechanical properties, widely used in indoor and outdoor structures, electrical equipment shells, medical devices and so on;

- SUS430 is ferritic stainless steel, magnetic, corrosion resistance is slightly inferior, but cost-effective;

- The common point of the two is high hardness, low ductility (HB ≈ 180-210), making the insert pressure riveting more difficult than ordinary carbon steel plate.

2.1. Recommended insert material:

- Preferred material: A2 (304) or A4 (316) grade stainless steel inserts.

- Work with the same grade of material as the plate to avoid electro-coupling corrosion (see below for details);

- Provides consistent coefficient of thermal expansion and surface potential to prevent stress loosening or structural peeling;

- Particularly suitable for: medical equipment, food machinery, outdoor electrical housings, and other high corrosion resistance scenarios.

- Carbon steel or galvanized inserts are not recommended:

- Stainless steel is the anode material, carbon steel is the cathode material, the potential difference between the two is about 0.6-0.7V, in the humid or electrolyte environment to form a microcell, the insert will corrode rapidly;

- In the actual test, in the salt spray environment, the combined structure may appear corrosion failure within 72 hours (far lower than the industrial 240-480h requirement);

2.2. Recommended Insert Types:

- Strong Self-Clinching Nuts/Studs

- Designed for high hardness plates, inserts with multiple knurling or composite bite structure;

- Recommended insert hardness ≥ HRB 88 to counteract the high resilience of the stainless steel base material;

- It is necessary to apply constant pressure during the riveting process and to control the positioning depth with limit fixtures.

- Specialized Rivet Nuts **Specialized Rivet Nuts

- Stainless steel rivet inserts are used when only one side can be operated;

- It is recommended to choose hexagonal stop-rotation structure or non-slip knurling type to improve the rotational resistance;

- Specialized rivet guns are required to control the deformation of the pressure ring without damaging the surface coating.

2.3. Corrosion Prevention and Process Precautions

| Risk Point | Mitigation Strategy |

|---|---|

| Galvanic corrosion between dissimilar metals | Use matching material grades (A2:A2 / A4:A4); avoid mixing carbon steel components |

| Iron debris contaminating stainless surfaces | Use dedicated stainless steel clinching tools or titanium heads to prevent rust |

| Pitting or intergranular corrosion after assembly | Use acid-passivated inserts and ensure no residual cold-working stress on sheet |

| Decorative parts using standard inserts | Add fluororubber sealing rings or coated sealing washers to block moisture-induced corrosion |

3. Aluminum alloy sheet (e.g. 5052, 6061)

- 5052: medium strength, good corrosion resistance, widely used in automotive skins, electrical boxes, structural panels;

- 6061: high-strength heat-treatable aluminum alloy, commonly used in mechanical frames, aviation brackets, profile structures;

- Aluminum alloy as a whole presents:

- Low hardness (Brinell hardness HB ≈ 60-95);

- good ductility but low thread bearing capacity;

- susceptible to galvanic corrosion with dissimilar metals, especially in humid or salt spray environments.

3.1. Recommended materials for inserts:

| Insert Material | Suitable Applications | Key Characteristics |

|---|---|---|

| Aluminum Inserts | Light loads, strong galvanic corrosion resistance | Matches thermal expansion of base material; excellent thermal stability after installation |

| Nickel-Plated Brass Inserts | Indoor/dry environments, cost-sensitive structures | Low cost, easy press-fit; not ideal for corrosive or high-vibration conditions |

| Stainless Steel Inserts | Medium to high loads, vibration-prone or repeat-assembly structures | High mechanical strength and wear resistance; galvanic isolation required with aluminum |

3.2. Recommended Insert Construction Types:

- Pressure riveting nuts (Aluminum or Stainless Self-Clinching Nuts)

- Suitable for aluminum plate thickness ≥1.0 mm, pressure riveting method to form a strong connection;

- It is recommended to use knurled structure + outer ring limit shoulder design to prevent assembly offset;

- Should be used with pressure limiting equipment to prevent overpressure and deformation of the aluminum plate.

- Pulled Rivet Nuts (Blind Rivet Nuts)

- Ideal for structures where the backside cannot be accessed, such as profiles, closed slot housings;

- Aluminum or stainless steel material can be selected according to corrosion resistance and strength requirements;

- Hexagonal head/knurled stop design is recommended for vibration conditions (e.g. vehicle/industrial control housings).

3.3. Galvanic Corrosion Risk Control and Protection Recommendations:

- Aluminum is an anodic material and tends to suffer galvanic corrosion when paired with stainless steel, leading to localized pitting.

- Reference potential difference: Aluminum (–0.80V) vs. 304 Stainless Steel (–0.35V); ∆V ≈ 0.45V.

- Without proper protection, visible pitting may occur within 240 hours under salt spray or humid conditions.

- Recommended Anti-Corrosion Strategies:

| Protection Level | Recommended Measures |

|---|---|

| Standard Level | Use anodized aluminum sheet + nickel-plated brass inserts (corrosion resistance ≈ 250h) |

| Intermediate Level | Use passivated stainless steel inserts + apply anti-corrosion grease (e.g., Molykote) |

| High Level (Outdoor) | Stainless steel inserts + sealing washers + isolation bushings or sealing gaskets |

4. Summary Recommendations:

| Sheet Material | Recommended Insert Material | Recommended Insert Type | Corrosion Protection Advice |

|---|---|---|---|

| Mild Steel | Zinc-plated Steel / Stainless Steel | Weld Nuts / Self-Clinching Nuts | Apply surface coatings; be cautious of bimetallic corrosion |

| Stainless Steel | 304 / 316 Stainless Steel | Self-Clinching Studs / Reinforced Nuts | Use matching materials to prevent corrosion; use stainless-compatible tools |

| Aluminum Alloy | Brass / Stainless Steel | Rivet Nuts / Self-Clinching Nuts | Avoid direct contact with dissimilar metals; use anodizing and anti-corrosion grease |

What Are the Common Installation Methods for Threaded Inserts in Sheet Metal?

1. Press-Fit / Clinching

- Applicable Inserts: Self-Clinching Nut, Stud, Press-Fit Nut Post;

- Principle of the process: Through the stamping pressure to make the insert external bite or groove and plate plastic flow, so as to form a permanent mechanical locking;

- Applicable plates: SPCC, 5052, SUS304 and other materials with good ductility;

- Advantages:

- Fast installation, high strength, suitable for automation;

- Strong resistance to rotation;

- Cautions:

- Precision positioning holes need to be prefabricated, and the tolerance of hole diameter is recommended ±0.05mm;

- Plate thickness is usually ≥0.8 mm;

- Not suitable for high hardness plates or brittle metals.

2. Blind riveting

- Applicable inserts: Rivet Nut / Rivnut, Rivet Stud;

- Principle of the process: through the rivet gun will be inserted in the hole stretching, back flap deformation, to achieve clamping fixed;

- Applicable plates: aluminum alloy, stainless steel, cold rolled plate, especially suitable for the back inaccessible structure;

- Advantages:

- Single side assembly, no need for reverse space;

- A variety of head structures to suit different locking needs (hexagonal head, anti-spin knurling, etc.);

- Cautions:

- High requirements for matching plate thickness and rivet gun parameters;

- If not installed in place, it is easy to cause rotational slippage or pull off;

- Certain types (e.g. open type) have limited waterproof capability, it is recommended to add rubber ring.

3. Welding

- Applicable inserts: Weld Nut / Stud;

- Principle of the process: permanent connection of the threaded insert to the plate by resistance or arc welding;

- Applicable plates: mild steel, thick plate structural parts (≥1.5mm);

- Advantages:

- Extremely high structural strength, suitable for load connection;

- Non-loosenable after installation, high reliability;

- Cautions:

- High demands on the plate surface (coatings and grease must be removed);

- Heat-affected zone requires secondary treatment to avoid stress concentration or corrosion;

- Not suitable for aluminum alloys, coated plates or ultra-thin structures.

4. Heat Staking / Ultrasonic Insertion

(commonly used for plastics, but also used in some laminate/soft metal composite structures)

- Applicable Inserts: Heat Staking or Ultrasonic Insertion;

- Advantages: Suitable for structural implantation of metal inserts in locally reinforced areas;

- Limitations: not applicable to metal sheets with high rigidity and slow heat conduction.

Table: Installation Methods and Insert Type Compatibility

| Installation Method | Recommended Insert Type | Suitable Sheet Material | Blind Installation | Installation Strength | Automation Compatibility |

|---|---|---|---|---|---|

| Press-Fit / Clinching | Self-Clinching Nuts, Studs | SPCC / Aluminum Alloy | No | High | High |

| Riveting / Blind Rivet | Rivet Nuts, Rivet Studs | All Sheet Metals | ✅ | Moderate | Medium |

| Spot Welding / Arc Welding | Weld Nuts, Weld Studs | Carbon Steel / Thick Stainless Steel | No | Very High | Medium–Low |

| Heat Insertion / Ultrasonic | Heat-Installed Inserts | Plastics / Composite Sheets | ✅ | Medium | Medium |

1. Automotive Industry

- Applications: Instrument panel brackets, inner bumper supports, seat mounts, inner door panels, wire harness brackets;

- Typical inserts: pull rivet nuts (for closed structures), welded studs (for high strength structural connections), pressure riveted studs (for instrument supports);

- Process requirements:

- High vibration resistance;

- High corrosion resistance (need to pass 240-720 hours salt spray test);

- Case: A2 stainless steel rivet nuts are used in the internal structure of the hood of passenger cars to realize single-sided assembly + anti-drawing ≥7000N.

2. Aerospace & Defense

- Applications: Airborne equipment housings, aviation instrument panels, radar housings, lightweight brackets;

- Typical inserts: pressure rivet nuts, aluminum or titanium alloy rivet nuts;

- Process requirements: lightweight, precision mounting, long-term fatigue-resistant structures;

- Cautions:

- Galvanic coupling corrosion must be controlled when using aluminum/titanium plates;

- Inserts are required to pass aerospace grade fatigue testing and FOD (foreign object dislodgement) verification.

3. Industrial Control Systems

- Application parts: control cabinet door panels, breakout box housings, operator panel brackets;

- Typical inserts: pressure riveting studs, pressure riveting nuts;

- Process Requirements:

- High reliability threaded connection, anti-loosening structure;

- Repeatable disassembly;

- Common Problem Prevention:

- It is recommended to use anti-loosening washers/coated sealant to prevent loosening under vibration conditions;

- Use standardized pressure riveting equipment to ensure the perpendicularity and flatness of inserts.

4. Electronics & 3C Devices

- Application parts: laptop shells, set-top boxes, smart wearable devices, communication antenna structures;

- Typical inserts: miniature rivet studs, knurled press-in nuts, brass rivet nuts;

- Process requirements:

- Precision small structure, high assembly efficiency, strong aesthetic requirements;

- The surface can not appear indentation or pressure through the phenomenon;

- Selection focus:

- It is recommended to use non-rotating structure inserts and supporting pressure limiting device;

- For aluminum alloy plate structure, aluminum or electric insulation inserts should be used to prevent galvanic corrosion.

FAQ: Threaded Inserts in Sheet Metal

1. Which Insert Works Best for Thin Aluminum Sheets?

Thin Aluminum Sheets (≤1.2mm), due to the softness and low strength of the material, it is recommended to use either Aluminum Rivet Nuts or Self Clamping Pressure Rivet Nuts specifically designed for thin sheets. These inserts provide reliable tension and torque support without damaging the base material. For structures requiring one-sided assembly, open or half-hex head rivet nuts are particularly suitable. Care should be taken when selecting the type to ensure that the deformation zone of the rivet will not penetrate or damage the sheet material, and pre-testing of the assembly is recommended.

2. How Can I Avoid Deformation During Insert Installation?

Common causes of deformation include: excessive rivet pressure, pre-hole eccentricity, and insufficient sheet thickness. Ways to avoid these problems are:

- Use a torque/pressure controlled riveting machine or pneumatic rivet gun;

- Designing reinforcing bars or reinforcing shims in the riveting area;

- Control the accuracy of pre-hole within ±0.05mm to ensure uniform force on inserts;

- For thin plates (<1mm), it is recommended to use inserts with deformation-resistant structural design, such as those with flap washer type or thread locking groove type structure.

3. Can I Use Carbon Steel Inserts in Stainless or Aluminum Panels?

Not recommended. There is a significant potential difference between carbon steel and aluminum or stainless steel, which makes it very susceptible to galvanic coupling corrosion in wet or electrolytic environments, resulting in corrosion of inserts, failure of threads, and even perforation of the aluminum panels. If it must be used, the following measures should be taken:

- Use carbon steel inserts with surface nickel plating, Dacromet and other highly corrosion-resistant treatments;

- Add insulating gaskets or corrosion-resistant sealants (e.g. DOW Corning corrosion-resistant grease);

- It is preferred to recommend the use of inserts made of materials similar to the parent material, such as stainless steel + A2 nuts or aluminum + anodized inserts.

4. What's the Minimum Sheet Thickness for Threaded Inserts?

The recommended minimum sheet thickness for conventional rivet or pull rivet nuts is 0.8 mm. If the plate thickness is less than this, a miniature press-in nut or a construction specifically designed for ultra-thin plates must be used, for example:

Closed type small flange rivet nuts for applications down to 0.5 mm;

Laser-welded weld nuts (for thin plates with high structural continuity requirements);

The force capacity of the insert mounting area can also be enhanced by localized thickening design, within the limits of structural permits.

5. How Do I Improve Thread Strength in High-Load Areas?

For structures subjected to high pullout forces or vibration impacts, the following strategies should be used to improve threaded joint stability:

- Use reinforced compression rivet inserts, such as thick-walled nuts and triangular locking teeth;

- Choose high-strength material inserts (e.g. stainless steel or titanium alloy) and match with high-grade bolts (≥8.8 grade);

- Installation of anti-loosening devices, such as: elastic washers, stopping rubber rings, interference thread adhesive (such as Loctite 243);

- If space permits, it is recommended to design it as a double threaded load-bearing structure or to use the clamping prestressing technique to share the load.

Do You Have Any Questions?

Let Us Solve Your Problem

Why Choose Rivetfix for Sheet Metal Inserts?

Rivetfix is your reliable and professional partner in the field of sheet metal joining. We specialize in the design, manufacture and customization of high-performance threaded inserts, covering a full range of insert solutions such as compression riveting, riveting, welding, self-locking, etc., which are widely used in automotive, aerospace, industrial control, electronic housings and other industries.

- Technical Advantages: independent mold development, insert structure optimization, corrosion resistance level customization, to meet various types of high-intensity, high-precision working conditions.

- Non-standard customization ability: support processing according to the drawing, abnormal shape improvement, multi-material selection (aluminum, brass, stainless steel, alloy steel, etc.).

- Rapid delivery: sufficient stock of standard products, special specifications within 72 hours at the earliest sampling shipments.

- One-on-one engineering support: Provide customers with selection advice, structural fit analysis, installation torque parameter table to reduce the risk of assembly failure.

Whether it is a high-volume production line, or a small batch of trial assembly R&D projects, Rivetfix always insists on quality and service, to help you make every structural connection stronger and more efficient. Contact us for samples and technical support.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.