How to Choose Jack Nuts for Fiberglass?

Leading Rivet Nut Manufacturer and Supplier in China

When working with fiberglass, it is essential to choose the right jack nuts to ensure strong, secure, and long-lasting threaded connections. Jack nuts for fiberglass provide a non-destructive installation method, minimizing the risk of material damage while offering a reliable anchor for bolts and screws. Understanding the factors like material compatibility, thread size, expansion type, and corrosion resistance will help you select the best jack nuts for your fiberglass applications. In this guide, we’ll walk you through the key considerations for choosing jack nuts specifically designed for fiberglass, ensuring optimal performance and durability.

Table of Contents

What is Fiberglass?

Fiberglass is a composite material made from fine strands of glass, which are woven into a fabric or combined with resins to form a solid, durable, and lightweight structure. It is created by drawing molten glass through fine nozzles to produce fibers that are as thin as a human hair. These fibers are then processed into mats, woven fabrics, or rovings (continuous strands), and are typically used as reinforcement in a variety of composite materials.

Key Features of Fiberglass

- High Strength-to-Weight Ratio: Fiberglass is extremely strong yet lightweight, making it an ideal material for applications where both strength and weight are important considerations.

- Thermal Resistance: It can withstand high temperatures without losing its shape or strength. It has excellent heat resistance properties.

- Electrical Insulation: Fiberglass is a non-conductive material, making it ideal for electrical insulation purposes. It is commonly used in the electrical industry for components that need to resist electrical conductivity, such as circuit boards and cable insulation.

- Chemical Resistance: Fiberglass is resistant to many chemicals, including acids, alkalis, and salts. This makes it suitable for use in industrial environments where exposure to harsh substances is common.

- Versatility: Fiberglass can be molded into complex shapes, allowing it to be used in a wide range of applications, from construction to sports equipment, and even in artistic designs. It can also be used in both structural and aesthetic roles.

Applications of Fiberglass

Aerospace: Fiberglass is used for manufacturing aircraft components like wing structures, fuselages, and interiors due to its strength and lightweight properties.

Automotive: Many cars and trucks use fiberglass parts such as body panels, bumpers, and dashboards to reduce weight and improve fuel efficiency.

Marine: Fiberglass is widely used in boat and shipbuilding because of its corrosion resistance, durability, and ability to withstand harsh sea environments.

Construction: It is used in reinforced concrete, roofing materials, insulation, and siding, offering better strength and insulation than traditional materials.

Sports Equipment: Fiberglass is found in products like skis, snowboards, fishing rods, and even tennis rackets due to its combination of strength, flexibility, and lightweight characteristics.

Consumer Goods: Fiberglass is also used in the manufacturing of consumer goods such as bathtubs, swimming pools, and even furniture.

Why Use Jack Nuts for Fiberglass?

1. Preserving Material Integrity

Fiberglass, although strong, can be prone to cracking or damage when subjected to direct threading. Jack nuts provide a way to create strong, reliable threaded inserts without cutting into or weakening the material. This ensures that the integrity of the fiberglass remains intact, avoiding issues like cracks or deformations.

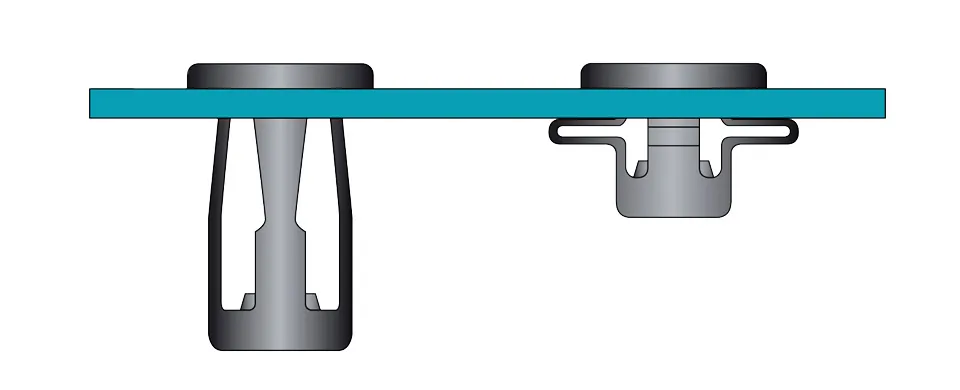

2. Non-Destructive Installation

Jack nuts are installed by expanding inside the fiberglass, which helps distribute the load evenly. This expansion process is non-destructive, unlike traditional threading, which can put stress on the material. By using jack nuts, you ensure a stable and secure connection without compromising the fiberglass.

Jack nuts eliminate the need for special tools or machining that might risk damaging the material. Their expansion mechanism is gentle on the fiberglass, ensuring a safe and efficient installation process.

3. Strong and Durable Connections

Jack nuts are relatively easy to install and don’t require specialized tools or machining. They can be installed quickly, even in thin or hard-to-reach areas of fiberglass products. This makes them a convenient and efficient solution, especially in high-volume manufacturing or repair tasks.

4. Ease of Installation

No Specialized Tools Required: Installing jack nuts requires fewer tools compared to other methods, such as tapping or threading, making the process simpler and more cost-effective.

Quick and Efficient: The expansion of the jack nut inside the fiberglass material is straightforward, reducing the time and effort needed to create secure, durable connections.

Minimal Training: The installation process of jack nuts is simple to learn, which makes them accessible even to operators with limited experience working with fiberglass materials.

How to Install Jack Nuts

The method of installing jack nuts is similar to that of rivet nuts. It is a straightforward process that can be done using manual, electric, or pneumatic tools.

- Prepare the Hole: Drill the correct size hole and deburr the edges.

- Insert the Jack Nut: Place the jack nut into the hole with the threaded side facing outward.

- Install the Tool: Choose the appropriate tool and set it to the correct tension.

- Expand the Jack Nut: Tighten the tool to expand the jack nut until fully secured.

- Check the Installation: Ensure the jack nut is securely expanded and threads are intact.

- Finish the Process: Remove the tool and clean the area for a smooth finish.

5. Prevention of Thread Stripping

Over time, screws or bolts can strip threads in softer materials like fiberglass. Jack nuts provide a reinforced threaded insert that prevents this issue, allowing for repeated removal and reinstallation of fasteners without damaging the material or causing thread wear.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Jack Nuts for Fiberglass?

1. Material Compatibility

Material compatibility is crucial to ensure long-lasting and reliable performance. Consider the following options:

Stainless Steel: Stainless steel jack nuts offer excellent corrosion resistance and strength. They are ideal for outdoor applications or environments where moisture is present, such as marine or industrial settings.

Aluminum: Aluminum jack nuts are lighter than stainless steel and offer good corrosion resistance. They are suitable for applications where weight is a concern, such as in aerospace or automotive industries.

Brass: Brass jack nuts are resistant to corrosion and are often chosen for electrical applications because they offer good conductivity and do not rust easily.

Coated or Galvanized Steel: Coated or galvanized jack nuts provide additional corrosion protection, making them suitable for environments with high humidity or exposure to chemicals.

2. Thread Size

Refers to dimensional parameters such as the diameter, pitch and thread type of the thread.

a. Thread Diameter:

- Common Sizes: Jack nuts come in various thread diameters, with common options including M3, M4, M5, M6, M8, M10, and M12 for metric threads. Imperial options typically include 1/4″-20, 5/16″-18, and 3/8″-16.

- Selecting the Right Diameter: The thread diameter should match the bolt or screw size that will be used in the application. Ensure the selected thread size provides adequate grip in the fiberglass without damaging the material.

b. Thread Pitch:

- Metric Threads: For metric threads, pitch is measured in millimeters between threads. For example, M6 x 1.0 means a 6mm diameter with a 1mm pitch.

- Imperial Threads: For imperial threads, pitch is typically measured in threads per inch (TPI). For example, 1/4″-20 means a 1/4-inch diameter with 20 threads per inch.

- Choosing the Pitch: A finer pitch (smaller number) creates a tighter fit, while a coarser pitch (larger number) may allow for easier installation and removal. Choose a pitch that balances ease of installation with the strength required for the application.

3. Load and Strength Capacity

When choosing jack nuts for fiberglass, consider the following key factors related to load and strength capacity with specific data:

a. Load Requirements:

- For static loads: Fiberglass materials typically have a tensile strength between 30 MPa to 130 MPa, depending on whether it’s general fiberglass or carbon fiber-reinforced. Choose jack nuts rated for tensile forces within the load limits of the fiberglass.

- For dynamic loads: In applications with vibration or impact, you may need jack nuts designed for higher shear resistance, typically between 500-1500 N depending on the nut size and type.

- M6 jack nuts in steel typically have a tensile strength of 8,000 to 10,000 N (Newtons), making them capable of withstanding significant pulling forces before failure.

- M8 jack nuts in steel may handle 10,000 to 15,000 N, providing better strength for larger applications.

c. Shear Strength of Jack Nuts:

| Material | M6 Size Load Capacity (N) | M8 Size Load Capacity (N) |

|---|---|---|

| Steel Jack Nuts | 2,000 to 3,500 N | 3,000 to 5,000 N |

| Stainless Steel Jack Nuts | 2,500 to 4,000 N | 4,000 to 6,000 N |

| Aluminum Jack Nuts | 1,500 to 2,000 N | 2,000 to 3,000 N |

| Brass Jack Nuts | 1,500 to 2,500 N | 2,500 to 4,000 N |

d. Fiberglass Compatibility:

Standard fiberglass typically has a shear strength of 45-70 MPa, while carbon fiber composites can go up to 300 MPa. Ensure the jack nut selected does not exceed the shear strength of the fiberglass material to avoid failure.

Problems of Jack Nuts for Fiberglass

Although Jack Nuts is very suitable for composite materials, there are still some problems that can occur in its use.

1. Thread Stripping

- Problem: Fiberglass, while strong, is brittle and susceptible to thread damage, especially under high torque or improper installation.

- Data: Fiberglass has a tensile strength typically around 70-140 MPa (Megapascals), depending on the specific type. Over-tightening jack nuts can exceed the material’s shear strength, leading to thread stripping.

- Solution: Select jack nuts with smaller thread pitches (e.g., M6 or M8), and use torque control tools to limit the applied force to 5-10 Nm (Newton meters), preventing thread stripping. Also, using jack nuts with a larger base helps distribute the load more evenly and reduces stress on individual threads.

2. Material Cracking

- Problem: Jack nuts expand by deforming, which can cause cracks or fractures in brittle materials like fiberglass.

- Data: The expansion force of a typical jack nut ranges from 500 N to 3,000 N (depending on size and material), which may cause cracking if applied too quickly or unevenly on brittle fiberglass.

- Solution: For fiberglass, use jack nuts that are designed for low expansion forces (such as aluminum or brass jack nuts) and install them at a controlled rate using tools with adjustable force settings. For instance, limiting the tool pressure to 100-200 psi can reduce the risk of cracking.

3. Corrosion Issues

- Problem: Jack nuts made from lower-quality materials can corrode when exposed to moisture, salt, or chemicals, weakening the connection in fiberglass applications.

- Data: Stainless steel has a corrosion resistance rating of up to 85-90% compared to carbon steel, which may corrode within 6-12 months if exposed to moisture or salty air.

- Solution: Use stainless steel or zinc-coated jack nuts, which are more corrosion-resistant. Stainless steel has a typical tensile strength of 600-850 MPa, offering durability and resistance to environmental factors. This ensures long-lasting, secure connections, especially in marine or outdoor environments.

4. Inconsistent Expansion

- Problem: Uneven expansion of the jack nut can result in poor engagement with the material or ineffective fastening, reducing the overall strength.

- Data: The expansion of a jack nut typically occurs by deforming the base, with expansion force ranging from 500 N to 2,500 N depending on size. Misalignment during installation can lead to inconsistent results, weakening the connection.

- Solution: Use a calibrated installation tool with adjustable pressure to control the expansion force. Tools should apply an even, consistent force within the 300-2,000 N range to ensure uniform expansion, maintaining strong connections.

5. Reduced Load-Bearing Capacity

- Problem: Jack nuts in fiberglass may not handle heavy loads, as the material’s tensile strength is much lower compared to metals. For instance, fiberglass typically has 70-140 MPa tensile strength, much weaker than metals like steel (400-700 MPa).

- Solution: For heavy-duty applications, use larger jack nuts (e.g., M12 or M16 size) with higher shear and tensile strength ratings (up to 8,000 N for steel). Additionally, reinforce the fiberglass by using thicker layers or integrating additional fasteners for improved load distribution.

6. Installation Difficulties

- Problem: Fiberglass is a sensitive material, and if the material is too thin (below 5 mm) or improperly supported during installation, jack nuts may cause deformation or damage.

- Data: Fiberglass with a thickness of less than 5 mm may not provide adequate support for jack nuts, which require proper backing to prevent material compression or failure.

- Solution: Ensure that the fiberglass is at least 6-8 mm thick for optimal jack nut installation. Use a pilot hole of appropriate diameter, around 1-2 mm larger than the jack nut’s outer diameter, to ensure smooth installation without material compression. Additionally, use low-expansion force jack nuts (e.g., aluminum) for thinner fiberglass applications.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Jack Nuts Solutions for Fiberglass

Rivetfix offers specialized jack nut solutions tailored for fiberglass applications, ensuring strong, secure, and non-destructive threaded connections. With expertise in providing custom solutions, we focus on delivering high-quality jack nuts. Choose Rivetfix for customized jack nut solutions that optimize the strength and longevity of your fiberglass products.

Discover Rivetfix: Transforming Your Projects with Premium Rivet Nuts Solutions

Rivetfix is your trusted partner for premium rivet nut solutions, offering a wide range of high-quality fasteners designed to elevate your projects. Whether you’re working with sheet metal, plastic, or other materials, our rivet nuts provide durable, reliable, and easy-to-install threaded connections.

We offer a comprehensive range of fasteners tailored to meet the unique requirements of your projects. With our customization services, we can design and deliver the ideal solution to suit your specific fastening needs. Committed to quality and customer satisfaction, we ensure that every product we provide enhances the security, efficiency, and durability of your projects, making them built to last.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.