How Reliable Are Rivnuts?

Leading Rivet Nut Manufacturer and Supplier in China

When it comes to securing components in thin materials or blind holes, rivet nuts—commonly known as rivnuts—are a popular fastening solution. But how reliable are rivnuts in real-world applications? Their performance depends on multiple factors including material strength, installation quality, vibration resistance, and environmental conditions. In this article, we’ll explore the key aspects that determine rivnut reliability and examine how they perform across various industries such as automotive, electronics, and appliances.

Table of Contents

A rivet nut, also known as a rivet insert nut or blind rivet nut, is a type of fastener that creates a threaded connection in thin sheets or hollow structures. It was originally invented by Chrysler in the United States during the 1930s for aircraft manufacturing. Due to its convenient, strong, and single-sided installation features, it has gradually been widely used across various industrial applications.

Working Principle

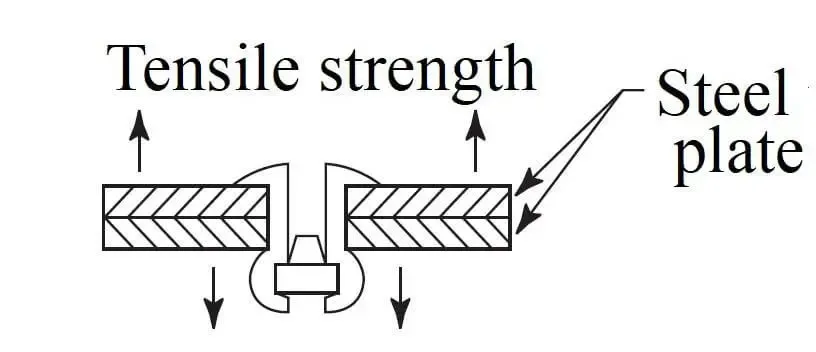

The core working mechanism of a rivet nut relies on installation tools (such as a rivet nut gun) pulling the threaded portion outward, causing the tail end to plastically deform and expand behind the sheet metal, thereby firmly clamping the base material. This process is similar to a combination of “flanging and pressing,” enabling a reliable threaded connection even in structures accessible from only one side.

Sheet Metal Assembly: Forms internal threads in thin sheet structures such as automotive panels, metal cabinets, furniture, and machine housings.

Automotive Manufacturing: Widely used in vehicle body structures, interior parts, seat brackets, and electrical system installations.

Electrical Equipment: Provides mounting threads for air conditioners, electrical boxes, and control panels.

Aerospace and Rail Transit: Applied in high-strength lightweight connections, facilitating maintenance and replacement.

New Energy and Industrial Equipment: Used in complex or enclosed structures such as solar panel mounts, battery enclosures, and control cabinets.

How Reliable Are Rivnuts?

Tensile strength refers to the maximum axial pulling force a rivet nut can withstand before being pulled out. It is a key indicator of whether the rivet nut can maintain a secure connection under load. For example, a standard M6 steel open-end round rivet nut, when properly installed, can achieve a maximum tensile strength of 4,000–6,000 N, with stainless steel variants typically having even higher strength.

Key factors affecting tensile strength include:

a. Material Strength:

The base material of the rivet nut directly determines its tensile strength: stainless steel (such as 304, 316) > carbon steel > aluminum alloy.

Stainless Steel (e.g., 304, 316): High strength and good ductility, suitable for higher loads and corrosive environments. 304 stainless steel usually has a tensile strength of 500–700 MPa, with 316 stainless steel being even stronger.

Carbon Steel: Common and cost-effective with high strength but lower corrosion resistance. Heat-treated carbon steel rivet nuts can exceed 800 MPa tensile strength.

Aluminum Alloy: Lightweight and easy to process but the lowest strength, suitable for light-duty structures. Typical tensile strength is around 200–300 MPa.

b. Wall Thickness and Structure:

The size and wall thickness of the rivet nut significantly influence its tensile capacity.

Heavy Duty (Thick Wall) Types: Thicker shells deform more robustly, ideal for high-load applications.

Long Grip Rivet Nuts: Longer deformation zones create larger contact areas, improving load distribution.

Closed-End or Reinforced Designs: Enhance overall structural strength and reduce risk of pull-out failure.

c. Installation Quality:

Hole size fit and proper installation stroke greatly impact final strength.

Stroke Control: Insufficient stroke causes incomplete deformation and uneven load transfer; excessive stroke may damage the base material or cause rivet nut cracking.

Hole Size Fit: The pre-drilled hole must match the rivet nut’s outer diameter closely; too loose leads to shifting during deformation, too tight causes insertion issues or jamming.

Tool Selection: Pneumatic, electric, or manual rivet nut tools provide different force outputs. Proper tool matching ensures consistent force and full deformation.

The tensile strength of the rivet nut also depends on the substrate (base material):

If the base material is too thin, it may not provide sufficient backing force during deformation, leading to tearing or installation failure.

For low-strength materials (e.g., plastics, thin aluminum), backing washers or long-grip nuts may be needed to increase load-bearing area.

In high-strength steel plates, the rivet nut design strength can be fully realized.

2. Shear Strength

Shear strength refers to the maximum stress a material or joint can withstand when forces are applied parallel to the connection surface without failure.

In rivet nut applications, shear strength represents:

The ability of the screw and base material interface to resist lateral sliding when pushed sideways;

The rivet nut’s own resistance to being “sheared off” or torn out under lateral load.

Factors influencing shear strength include:

The material strength of the rivet nut (stainless steel is stronger than aluminum alloy);

The tightness of the rivet nut’s fit with the base material;

The thickness and strength of the base material;

Whether the deformation during installation is sufficient and properly aligned.

3. Spin-Out Resistance

Spin-out resistance is the rivet nut’s ability to resist rotational forces caused by tightening or loosening screws after installation, preventing the rivet nut itself from spinning within the base material.

Why is spin-out resistance important?

Since rivet nuts are plastically deformed to fix onto the base material, they should remain firmly in place like a welded nut. If they cannot resist screw torque, problems include:

Inability to properly tighten screws or continuous screw slippage;

Damage or failure of internal threads;

Overall joint failure, affecting maintenance and reassembly.

Key factors affecting spin-out resistance:

a. Rivet Nut Body Design:

Smooth Round Body: Lowest spin resistance, relies only on friction, suitable for low torque conditions.

Knurled Body: External knurls bite into hole walls, increasing friction and grip.

Hex Body: Inserts into hexagonal holes for mechanical locking; strongest anti-spin performance, recommended for high torque applications.

Serrated (Toothed) Flange: Teeth on the flange increase friction with the base material, preventing rotation.

b. Base Material Hole Design:

Standard round holes used with smooth or knurled bodies rely mainly on friction;

Special hexagonal holes paired with hex rivet nuts provide positive mechanical lock, greatly improving anti-spin.

c. Base Material Thickness and Hardness:

Thinner or softer sheets provide weaker support, increasing spin risk;

Hard steel or reinforced plates offer stronger anti-spin backing.

d. Installation Process:

Proper deformation and precise alignment determine locking effectiveness;

Insufficient or excessive deformation may cause loose or spinning nuts.

4. Vibration Resistance

In environments with frequent vibration (such as transportation, heavy machinery, or power generation), screws connected via rivet nuts can loosen due to micro-movements over time. Methods to improve vibration resistance include:

Using nylon lock nuts or locking washers;

Applying thread-locking adhesives (e.g., Loctite);

Choosing rivet nuts with anti-spin tooth designs;

Using double nuts or spring washers to increase friction locking.

These measures significantly enhance the reliability of rivet nut assemblies under dynamic conditions.

5. Fatigue Durability

For applications requiring repeated disassembly or long-term exposure to cyclic loading (e.g., electrical cabinets, vehicle chassis, automation equipment), fatigue life is crucial.

Stainless steel rivet nuts have high fatigue strength and ductility;

Installation force should be controlled to avoid over-deformation damage;

Thicker base materials with stable backing improve fatigue life;

Selecting rivet nuts with reinforced threads or serrated features reduces loosening and cracking risks.

High-quality rivet nuts can withstand over a million load cycles under high-frequency vibration conditions.

6. Corrosion Resistance

Rivet nut materials behave differently under humid, salty, acidic, or alkaline environments:

304 Stainless Steel: Suitable for most industrial and outdoor environments; resistant to moisture and mild acids/alkalis.

316 Stainless Steel: Superior corrosion resistance; ideal for coastal, chemical plants, and highly corrosive environments.

Zinc-Plated Carbon Steel: Cost-effective for indoor or low-corrosion settings but unsuitable for prolonged exposure to moisture.

Aluminum Alloy: Good rust resistance but lower tensile and shear strength; suitable for light-duty structures.

Proper material selection combined with anti-corrosion treatments (coatings, rust inhibitors) is key to ensuring long-term rivet nut durability.

How Does Installation Method Affect Rivet Nut Reliability?

The reliability of rivet nuts depends not only on their design and material but also critically on the quality of their installation. Rivet nuts are secured by creating plastic deformation at their tail end using a pulling tool. Improper installation directly compromises the connection strength and service life.

| Tool Type | Max Pull Force (N) | Application Scenario | Pros & Cons |

| Hand Rivet Nut Tool | 500 – 1500 | Small batches, light materials | Simple to operate, low efficiency, difficult to maintain uniform pull force |

| Pneumatic Rivet Nut Gun | 1500 – 5000 | Medium to large production lines, hard materials | Stable force, high efficiency, ideal for continuous operations |

| Electric Rivet Nut Gun | 1000 – 4500 | On-site installation, flexible use | Strong power, portable, controllable force, higher cost |

Notes:

- Manual rivet nut guns are suitable for small-scale or lightweight installations. However, for hard materials or larger rivet nuts, they may not provide sufficient force, resulting in under-deformation or uneven compression.

- Pneumatic rivet nut guns use compressed air to deliver stable and strong pull force, ideal for high-volume production with consistent installation quality.

- Electric rivet nut guns combine portability and power, offering precise force control, making them ideal for on-site or varied installation needs.

Choosing the right tool ensures that the rivet nut undergoes sufficient plastic deformation to generate optimal clamping force. Insufficient or uneven pulling can cause loose connections or failure.

2. Installation Process and Best Practices

Hole Diameter Fit: +0.05 mm ~ -0.00 mm

The hole size must precisely match the rivet nut specification. Oversized holes can cause looseness, while undersized ones may hinder insertion and affect the joint quality.

Installation Alignment: ≤ 2°

The rivet nut must be inserted perpendicular to the hole to ensure uniform deformation and prevent stress concentration, cracks, or loosening.

Pull Force Control: 80% ~ 100% of design pull force

Insufficient force leads to inadequate deformation and poor clamping; excessive force may tear the base material or over-deform the rivet nut, weakening the structure.

Stroke Limitation: Adjust based on rivet nut specifications

The tool stroke should be properly set to avoid over-pulling or breakage of the rivet nut.

Cleaning & Lubrication:

The hole and rivet nut should be clean before installation. Use appropriate lubricants when needed to reduce friction and ensure smooth deformation.

3. Consequences of Improper Installation

- Weak Fastening: Incomplete deformation results in loose joints, leading to thread loosening or detachment.

- Spin-Out Failure: Poor wall engagement or uneven deformation can cause the rivet nut to spin under torque, compromising the joint.

- Base Material Damage: Excessive pulling or mismatched hole size can tear or deform the parent material, affecting structural integrity.

- Reduced Lifespan: Poor installation accelerates fatigue and corrosion, shortening service life.

4. Conclusion – How Does Installation Method Affect Rivet Nut Reliability?

Installation quality directly affects a rivet nut’s tensile strength, shear resistance, and long-term durability. By choosing appropriate tools, controlling key parameters (hole size, pull force, alignment, etc.), and strictly following installation procedures, the reliability and safety of the rivet nut connection can be maximized.

How Reliable Are Rivet Nuts in Real-World Applications?

Rivet nuts are widely used across various industries due to their ease of installation, stable load-bearing performance, and broad applicability. The following industry-specific case studies illustrate how rivet nuts perform reliably in practical working environments.

Automotive Industry: Securing Vehicle Body Panels

In automotive manufacturing, rivet nuts are commonly used to fasten body panels made of thin steel or aluminum sheets. By creating a secure grip through deformation on the blind side, rivet nuts eliminate the need for welding, thereby avoiding heat distortion and stress concentration issues.

During long-term vehicle operation, vibrations and impacts pose high demands on the rivet nut’s resistance to loosening.

Typical design lifespan: Over 10 years

Performance: Proven to withstand prolonged vibration and environmental fluctuations.

Telecommunications Equipment: Threaded Connections in Metal Enclosures

Metal enclosures of telecommunications devices often rely on rivet nuts to form threaded connections, ensuring ease of assembly/disassembly and reliable sealing. These devices are used in both indoor and outdoor environments, requiring rivet nuts with strong corrosion resistance and mechanical stability.

By using 316 stainless steel rivet nuts and incorporating anti-loosening designs, the enclosures can maintain tight threads even after multiple maintenance cycles.

Typical design lifespan: 5–8 years

Performance: Reliable through repeated installation and removal without thread failure.

Home Appliance Industry: Sheet Metal Enclosure Assembly

For household appliances such as washing machines and refrigerators, rivet nuts are widely used to join inner and outer sheet metal panels and to attach internal components. Rivet nuts allow for fast installation and strong connections on thin metal sheets, making them ideal for high-volume production.

After extensive vibration and temperature cycling tests, rivet nut joints maintain structural integrity and fastening strength.

Typical household lifespan: 8–12 years

Performance: Consistently secure clamping force, ensuring long-term panel stability.

a. Match Grip Range with Material Thickness

The grip range of the rivet nut must correspond to the thickness of the base material. If the material is too thin or too thick, it can compromise the fastening strength and installation quality. Always refer to the manufacturer’s specified grip range to ensure the material falls within the recommended limits and to prevent insecure fastening or damage to the base material.

b. Select Material Based on the Environment

Choose the rivet nut material according to the environmental conditions such as corrosion levels, temperature, and mechanical loads. For example, use 316 stainless steel in marine or high-humidity environments, carbon steel or aluminum for indoor applications, and alloy steel for high-strength requirements.

c. Choose Anti-Rotation and Anti-Loosening Designs

For soft materials or applications prone to loosening, opt for large flange rivet nuts to increase load-bearing surface. Hexagonal, knurled, or serrated body rivet nuts provide excellent resistance to spinning. Additional features like thread-locking adhesives or locking washers can enhance vibration resistance and prevent loosening.

d. Pay Attention to Testing and Certification

For applications with strict performance requirements, select rivet nuts that have passed tests such as salt spray (corrosion resistance) or tensile/shear load testing. Certified products ensure reliable performance and reduce the risk of failure due to poor materials or manufacturing defects.

Conclusion

Rivet nuts, as an efficient fastening solution, demonstrate exceptional reliability across multiple critical performance aspects—such as structural strength, anti-rotation, resistance to loosening, and corrosion protection—thanks to their unique structural design and installation mechanism. By selecting high-quality materials like stainless steel or galvanized steel, rivet nuts can perform reliably in a variety of harsh environments, ensuring long-term stability without corrosion damage at the connection points.

Various anti-rotation designs (such as hexagonal or knurled shapes) and anti-loosening features effectively prevent failures caused by vibration or load fluctuations, thus enhancing the safety and durability of assemblies.

Do You Have Any Questions?

Let Us Solve Your Problem

Why Choose Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.