How Many Times Can a Heli-Coil Be Used?

Leading Threaded Inserts Manufacturer and Supplier in China

In the field of fastener repair and maintenance, many people are concerned about how many times a heli-coil can be used. Generally speaking, under the condition of correct installation, Helicoil can be reused along with the repeated disassembly and assembly of the bolt. The strength of its internal thread can usually be maintained for dozens or even hundreds of cycles in most cases. However, the actual number of times it can be used is affected by multiple factors such as type (Free-Running or Screw-Lock), base material hardness and thickness, applied torque and lubrication conditions, working environment and installation quality. Therefore, whether to continue using Helicoil should be based on on-site inspection results and manufacturer or industry standards.

Table of Contents

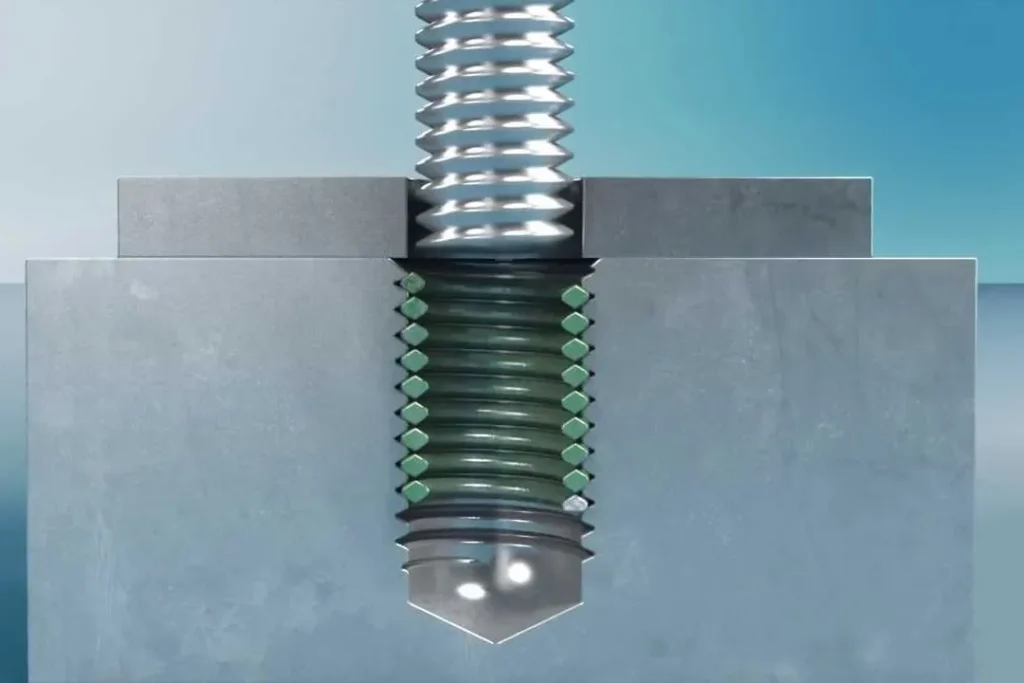

Helicoil is a threaded insert made of high-strength stainless steel wire wound into a spring-like shape. Its cross-section is usually rhombic. During installation, it is screwed into a pre-drilled hole with threads. It forms a new set of precise internal threads in the base material. This design repairs damaged threads or enhances load-bearing capacity in soft metals. It improves wear resistance for threads in aluminum, magnesium, and similar materials.

“Repeated use” means multiple bolt disassembly and reassembly, not the Helicoil itself. A correctly installed Helicoil, under proper torque and lubrication, remains reliable. It can support tens or hundreds of bolt cycles while maintaining safe thread strength. Helicoil is economical, efficient, and reliable for thread repair and reinforcement. It is ideal for mechanical structures requiring frequent maintenance.

How We Define “Reusability”

When assessing the reusability of Helicoils (how many times a heli-coil can be used), the industry does not have a single fixed number. Instead, it determines the “availability” based on a series of quantifiable performance indicators to ensure that the requirements are still met. The core assessment criteria include:

Cycle Count for Assembly and Disassembly

It refers to the number of times a specific Helicoil internal thread can withstand the repeated insertion and removal of bolts within the specified torque range. Different types of Helicoils (Free-Running vs Screw-Lock) have significantly different cycle lifetimes under the same conditions.

Preload Retention - Maintaining Stability

After multiple cycles, the preload force during the locking of the bolt should remain within the allowable range specified by the design. If the preload force significantly decreases, even if the thread shape is intact, it should be regarded as having failed or being close to failure.

Internal Thread Wear Degree

Check the tooth profile of the thread by visual inspection, using gauge blocks or thread projection instruments to see if there is any obvious wear, chamfered cracks or metal shedding. Excessive wear will reduce the thread meshing quality and increase the risk of failure.

Pull-Out Strength

The bonding between the Helicoil and the base material should maintain sufficient pull-out strength. If it falls below the design or specification requirements (usually measured in kN or lbf) during actual pull-out tests, it is not recommended to continue using it.

Overall, the true meaning of “reusability” is not merely counting the number of times a bolt is disassembled and reassembled. Instead, it is to ensure that throughout the entire usage period, Helicoil can consistently provide the required mechanical performance and connection reliability. This is why in safety-critical industries such as aviation and automobiles, the reusability of Helicoil is ultimately determined based on the combined results of inspections and manufacturer/industry standards.

Insert Types: Free-Running vs Screw-Lock

When discussing “how many times a heli-coil can be used”, the type of the heli-coil is one of the important factors determining its repeatable service life. Common heli-coils are classified by function into two types: Free-Running and Screw-Lock. They differ significantly in their cyclic disassembly and assembly performance as well as their applicable scenarios.

Free-Running

Structural Feature: The internal thread size is compatible with standard bolts, without additional locking resistance.

Service Life: Under correct torque, appropriate lubrication, and proper installation conditions, the free-insertion type Helicoil can typically withstand several tens to hundreds of bolt cycle disassembly and reassembly, while maintaining stable thread accuracy and preload force.

Application Scenarios: Suitable for frequent maintenance and repair operations or for parts that require quick installation and disassembly, such as mold installation holes, mechanical maintenance contacts, etc.

Screw-Lock

Application scenarios: Suitable for connection positions with frequent vibration and impact or where it is inconvenient to use chemical thread locking agents. Examples include aviation structural components, engine covers, vibration mechanical fixation points, etc.

Structural features: A compression zone is formed at the end of the coil, applying additional radial clamping force to the bolt to achieve mechanical locking functionality.

Service life: The anti-vibration effect of the self-locking type is superior to that of the free insertion type. However, due to the gradual attenuation of the self-locking torque over multiple cycles, its effective service life is typically in the range of single-digit to low double-digit cycles. When the self-locking torque drops below the design value, it is considered as failure and replacement is required.

Engineering Suggestions

- If you focus on the number of cycles and the ease of maintenance, the Free-Running type is more economical and durable.

- If you focus on vibration resistance and anti-loosening, the Screw-Lock type should be chosen, but self-locking torque testing should be conducted after the predetermined number of cycles. Replacement is necessary if required.

- In safety-critical connections, the replacement cycle should be determined based on actual load, environmental conditions, and industry standards, rather than relying solely on empirical values.

Key Factors That Drive Cycle Life

In engineering practice, the cycle life of Heli-Coil (thread protection sleeve) is not a fixed value but is influenced by multiple factors. The following six core factors will directly determine the number of times it can be used during the disassembly and assembly of bolts and its stability of use.

①. Material hardness and thickness

- Hardness: If the base material is a low-hardness metal such as aluminum or magnesium, repeated assembly and disassembly can cause wear or plastic deformation at the material’s orifice, thereby reducing the fixation force of the sheath; while steel or high-strength alloy base materials can provide higher support and durability.

- Thickness: Insufficient thickness of the base material cannot provide sufficient screw insertion length for Heli-Coil, making it prone to failure under high torque or frequent use.

②. Bolt Material and Grade

- Material: Stainless steel bolts are prone to galling with stainless steel Heli-Coil under dry friction conditions, which directly causes damage to the sheath or the bolt.

- Grade: High-grade bolts (such as 12.9 grade) generate higher axial loads during tightening. If the base material or the sheath is of poor quality, the lifespan will be significantly shortened.

③. Torque and Pre-tightening Force Control

- Excessive Torque: Exceeding the recommended torque value will cause the protective sleeve threads to undergo plastic deformation or scratching, significantly reducing the number of usable cycles.

- Stability of Pre-tightening Force: Unstable or excessively high pre-tightening force will accelerate fatigue damage during cyclic loading.

④. Lubricants, Anti-clogging Agents and Surface Treatment

- Lubrication: Appropriate lubrication can reduce the friction coefficient, minimize thread wear, and significantly extend the cycle life.

- Anti-sticking agent: Especially suitable for high-temperature or stainless steel compatible environments, it prevents cold welding and sticking.

- Surface treatment: Nickel plating, solid lubrication coating, etc. can improve corrosion resistance and wear resistance.

⑤. Operating Environment

- Temperature: High temperature will reduce the mechanical properties of the base material and the sheath, and may also damage the protective film of the lubricant.

- Corrosion: In marine and chemical environments, corrosion will accelerate the wear and fatigue of the threads.

- Vibration and Impact: Continuous vibration will cause the bolts to loosen and the sheath to come out. Self-locking Heli-Coil or additional anti-loosening measures need to be used.

⑥. Installation Quality

- Drilling: Poor accuracy of the hole diameter and cylindricality can result in uneven assembly clearance of the sleeve, thereby reducing the load-bearing capacity.

- Tapping quality: Incomplete thread profile will affect the bonding strength between the sleeve and the base material.

- Embedding depth: Installation that is too shallow will reduce the number of load-bearing threads, while installation that is too deep may interfere with the internal structure of the workpiece.

- Alignment: Eccentric installation will cause uneven force distribution, accelerating local wear.

If installed on high-strength base materials, with the use of appropriate grade bolts, torque is strictly controlled and lubrication and protection measures are taken, Heli-Coil can easily achieve several tens to several hundreds of reliable assembly and disassembly cycles in industrial applications. On the contrary, in low-hardness base materials, without lubrication and in a highly corrosive environment, the cycle life may drop to single digits.

Typical Ranges You Can Expect

When evaluating the reusable times of Heli-Coil (thread protection sleeve), the actual working conditions test and OEM specifications should be taken as the reference. The following data are only the reference ranges based on engineering experience.

Free-Running Type

- Features: No additional locking structure. The bolts can be smoothly screwed in and out. The friction resistance mainly comes from the thread fit and the lubrication state.

- Cycle Life Estimation:

- Under the condition of correct torque control (not exceeding the recommended value) and using the appropriate lubricant,

- With medium to high hardness base materials (such as steel or high-strength aluminum alloys),

- Generally, reliable assembly and disassembly cycles of several tens to several hundreds can be achieved, while the thread accuracy and tightening force remain within an acceptable range.

Reference data: Under the conditions of M8 Free-Running Heli-Coil + 7075 aluminum base material, after 90 cycles, the thread engagement strength decreased by less than 10%.

Screw-Lock Type

- Feature: A self-locking ring with local deformation integrated within the thread, achieving anti-loosening through frictional resistance.

- Cycle Life Estimation:

- The self-locking torque will gradually decrease with the increase in assembly and disassembly cycles.

- In most applications, after a few single-digit to low double-digit cycles (approximately 5 to 15 times), the self-locking function may fall below the design requirements, and torque re-testing or replacement of the protective sleeve may be necessary.

In industries with high safety standards such as aviation and racing, it is usually required that Screw-Lock type components be replaced after being used 5 to 10 times.

Inspection Before Reuse

Before deciding whether Heli-Coil (thread protection sleeve) can continue to be used, a systematic inspection must be conducted to ensure the safety and reliability of the fastening connection. The following is the recommended engineering inspection process:

Visual inspection of appearance

- Inspection Contents:

- Are there any burrs, indentations or scratches on the thread profile?

- Is there any corrosion, discoloration, pitting or cracks on the surface?

- Has there been any metal peeling or deformation at the thread root?

- Judgment Principles: If there are obvious damages or corrosion, it should be replaced immediately to avoid failure under high load.

Internal thread accuracy inspection

- Tool: Go/No-Go Gauges that comply with ISO or ASME standards.

- Method:

- The “go gauge” should be able to be smoothly inserted to the specified depth;

- The “no-go gauge” should not be inserted beyond the specified number of turns.

- Significance: Ensure that the internal thread still meets the original design’s accuracy grade (such as 6H, 2B, etc.).

Self-locking Torque Test (Applicable only to Screw-Lock Type)

- Tool: Ratchet Torque Wrench with scale.

- Method: Measure the initial self-locking torque when the bolt is screwed in, and compare it with the OEM standard or the requirements in the maintenance manual.

- Judgment: If the self-locking torque decreases to below the lower limit value (usually 70% – 80% of the new part), the sleeve should be replaced.

Installation stability and meshing length inspection

- Rotation/Torsion Detection: Ensure that the protective sleeve does not rotate, loosen, or undergo axial displacement within the base material hole.

- Effective Engagement Length: The actual engaged thread length should be no less than 1 to 1.5 times the diameter of the bolt (1.5D). If it is less, the bolt needs to be replaced or reinstalled.

Best Practices to Extend Life

In industrial applications, the lifespan of Heli-Coil (thread protection sleeve) is not only determined by its design quality, but also heavily relies on the management of installation, usage and maintenance processes. The following six engineering suggestions can significantly increase the reusable times and overall reliability of the sleeve.

Strictly control the depth of drilling, tapping and embedding

The drill hole diameter should be within the standard tolerance range (typically ±0.05 mm), with the tap thread being complete and without any broken threads; the embedding depth should reach 1 to 1.5 times the bolt diameter (1 – 1.5D). Ensure that the protective cover is closely adhered to the hole wall of the base material to reduce assembly gap and the risk of early loosening.

Use appropriate lubricants / anti-sticking agents

When the stainless steel bolt is combined with the stainless steel sleeve, a anti-sticking agent containing MoS₂ (molybdenum disulfide) or graphite should be used to prevent cold welding and sticking. This anti-sticking agent can reduce the risk of sticking in the stainless steel – stainless steel combination by more than 80%.

Use the torque-angle method or a calibrated torque tool

Use an annual-calibrated torque wrench or torque screwdriver to avoid over-tightening or under-tightening. The torque-angle method can provide more stable preload when the bolt lubrication condition fluctuates greatly.

For high-vibration operating conditions, it is recommended to use Screw-Lock

In high-vibration environments such as engine compartments, aircraft structures, and rail transportation systems, it is preferable to use Heli-Coil with self-locking function, or combine it with mechanical anti-loosening measures such as spring washers and locking nuts. This can reduce loosening caused by vibration and the degradation of service life.

Replace the bolts regularly

After completing a certain number of cycles, replace the mating bolts to prevent the old bolts’ threads from wearing out or causing burrs that damage the inner threads of the protective sleeve. In the aviation and racing fields, it is usually recommended to replace the bolts every 10 to 20 cycles.

In high-corrosive environments such as those in the marine and chemical industries, it is recommended to use 316 stainless steel or nickel-based alloys as the sheath material, and combine it with isolation coatings (such as epoxy, anodizing or nickel plating). This can reduce the corrosion rate by more than 50%, thereby delaying the fatigue and failure of the sheath.

FAQs

Is Heli-Coil a one-time product?

No.

When the installation is correct, the base material is in good condition, and the torque and lubrication are properly controlled, the Heli-Coil threaded sleeve can be used to repeatedly disassemble and assemble the bolts.

Reference for experience: The Free-Running type can achieve several tens to several hundreds of cycles under excellent working conditions; the Screw-Lock type usually requires re-testing of the self-locking function after single-digit to low double-digit cycles.

Can it be used in conjunction with thread locking adhesive?

Sure, but it needs to be carefully evaluated.

- When used in combination with the Free-Running type locking adhesive (such as Loctite), the anti-loosening ability can be enhanced. However, it is necessary to confirm the performance of the adhesive at the working temperature and avoid causing difficulties in disassembly after curing.

- When used in conjunction with the Screw-Lock type, special attention is required: The combined anti-loosening force of the two may lead to torque exceeding limits, and even damage the threads during disassembly.

- It is recommended to conduct chemical compatibility and torque verification before use to ensure that the curing agent does not affect the lifespan of the sheath due to erosion or changes in lubrication coefficient.

Will the Heli-Coil rotate out along with the bolt?

The following situations may occur:

- During installation, the protective cover did not fully extend to the required depth;

- The machining accuracy of the base material holes was poor, resulting in insufficient locking force;

- The threaded walls of the base material were corroded, worn, or underwent plastic deformation.

Troubleshooting and Repair Suggestions:

- Use the gauge block to confirm the accuracy of the base material’s thread.

- Check the installation depth and coaxiality of the sheath.

- If the hole wall is loose or severely worn, enlarge the hole diameter and re-tap the thread, then install the extended-type sheath.

Summary & Decision Flow

Reuse/Replacement Judgment Steps

- Visual Inspection → Check for burrs, deformation, corrosion, and thread breakage;

- If there are obvious damages → Replace.

- Gauge and Plug Inspection → Check if the internal thread accuracy is up to standard;

- If not → Replace.

- Self-locking Torque Test (Screw-Lock type) → Is it ≥ 70% – 80% of the new part’s standard?

- Below the lower limit → Replace.

- Insert Stability Check → Is it rotating with the bolt or loosening the hole wall;

- If there is loosening → Replace.

- Pre-tightening Force Stability → Is the fluctuation within ±10% at the same torque?

- If exceeding the standard fluctuation → Replace.

- All Pass the Above Inspections → Can be reused, and record the cycle times and conditions for tracking.

Do You Have Any Questions?

Let Us Solve Your Problem

Choose Rivetfix Heli-Coil Today

Whether you are aiming for higher assembly efficiency or seeking a durable and reliable threaded connection in harsh conditions, Rivetfix’s Heli-Coil can offer you an outstanding solution. We strictly select high-quality materials, strictly control manufacturing accuracy, and provide multiple specifications and anti-corrosion treatment options to ensure that each set of Heli-Coil can perform stably in your project, extend service life, and reduce maintenance costs.

Now choose Rivetfix and make your equipment connections stronger and more durable, giving you an edge in the competition.

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.