How Do You Remove a Jack Nut?

Leading Rivet Nut Manufacturer and Supplier in China

The Jack Nut achieves locking during installation through deformation and expansion, and it has the characteristic of irreversible structure. This means that in most applications, once installed, its structure undergoes permanent deformation and cannot be removed without damaging it. Therefore, the removal process of the Jack Nut usually requires destructive operations and cannot be reused. Regarding the common question “How do you remove a Jack Nut?”, the quick conclusion is as follows: Destructive removal methods such as drilling, cutting, or prying should be used to ensure that the substrate is not damaged while completing the removal. In actual operation, the integrity of the surrounding structure and the cost of removal should be considered, and the appropriate removal method should be selected based on the specific working conditions.

Table of Contents

Why Removing a Jack Nut Is Different from Regular Fasteners?

The Jack nut, as a structural fastener, features an irreversible expansion locking mechanism, which is both a design highlight and a challenge in disassembly. Compared to traditional fasteners that can be unscrewed, when selecting and maintaining it at the application end, one must consider the trade-offs between one-time installation, repairability, and cost.

Expansion Structure and the Irreversibility of "Flipping Locking"

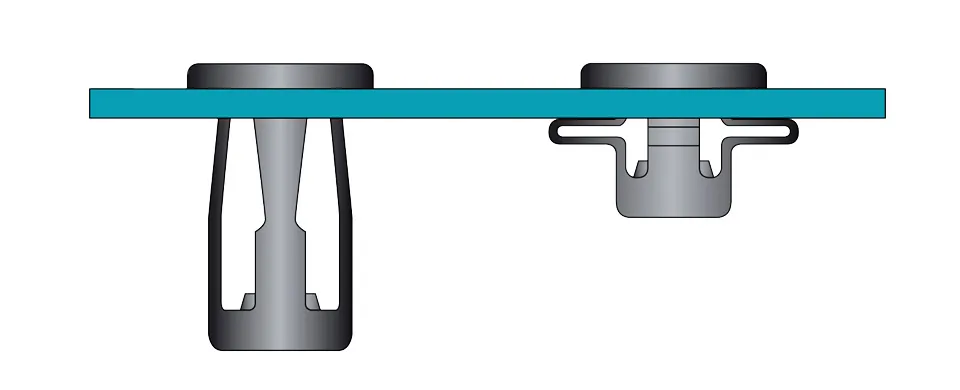

The Jack nut forms a conical structure by “flipping” its tail outward during the installation process, thereby clamping the base material. This process is similar to the expansion principle of a rivet, but the difference lies in that the Jack nut has internal threads, enabling the assembly of detachable screws.

- Once inflated and shaped, the tail structure undergoes permanent deformation and cannot be “unscrewed” and fully recovered like traditional bolts.

- If forcibly rotated in the opposite direction or pried out, it often damages the installation substrate or causes the hole to expand and deform.

- This type of structure belongs to a one-way locking mechanism, aiming to provide long-term reliable clamping force, at the expense of “reversibility”.

Objectives and Limitations of Structural Design

The core design intention of the Jack nut is to provide a reliable threaded installation point in situations where the back side cannot be used for tool support (such as in box bodies and thin-walled structures).

- Advantages:

- Suitable for blind hole installation.

- Provides strong clamping force, enhancing the structural integrity of components with insufficient base material strength.

- Quick installation, suitable for batch operations.

- Limitations:

- Once installation is completed, removal is difficult and usually requires destructive methods (such as drilling out or chiseling out).

- Not suitable for situations where frequent disassembly or maintenance is required.

Tools You'll Need to Remove a Jack Nut

The Jack nut has a “flipping deformation structure”, which means it cannot be simply unscrewed like a regular screw. Usually, destructive methods are required for its removal. By choosing the right tools and operation methods, the risk of damaging the base material can be reduced while ensuring safety.

Common Removal Tools

| Tool Type | Description and Use |

|---|---|

| Drill / Electric Drill | Used to destroy the center post of the Jack Nut from the front or enlarge the hole, causing loss of clamping force. Recommended to use high-speed steel (HSS) drill bits matching the nut’s outer diameter. |

| Slide Hammer | Suitable for pull-out removal, used with special screw kits to “pull” the Jack Nut out from the front. Ideal for high-strength materials or structures where drilling is not possible. |

| Cutting Tools (e.g., Pneumatic or Manual Shears) | For aluminum or soft metal Jack Nuts, cutting tools can cut off the flared parts, then remove the remaining pieces outward. |

| Chisel / Punch | Used with hammering to knock out the nut or clear residual parts. Requires precise direction control to avoid deformation of the base material. |

Manual vs. Power Tool Recommendations

| Operation Method | Recommended Scenarios | Features |

|---|---|---|

| Manual Tools (e.g., hand drill, impact screwdriver) | Suitable for single repairs or confined spaces | Low cost, high control, but lower efficiency |

| Power/Pneumatic Tools (e.g., electric drill, air shears) | Ideal for batch removal or hard base materials | Fast removal, compatible with various heads, requires professional handling and protection |

If it is a large-scale demolition, it is recommended to use an electric drill with a variable torque function, to prevent damage to the surrounding structures.

Safety Protection Suggestions

Since the removal of Jack nuts often involves high-speed cutting or forceful prying operations, the following safety measures must be implemented:

- Wear protective glasses and gloves to prevent metal debris from splashing and injuring people;

- The work area should be kept away from flammable materials and have good ventilation;

- If using electrical equipment, ensure good grounding and insulation to avoid electric shock;

- Mark or isolate the construction area to prevent unauthorised personnel from approaching;

- After dismantling, clean the debris inside the hole and assess the condition of the hole diameter to determine whether a larger model needs to be installed or a different tightening solution needs to be adopted.

Method 1: Drill Out the Jack Nut

“The drilling method” is the most common and reliable way to remove metal Jack nuts. Its core principle is to damage the expansion area of the nut, thereby eliminating its clamping force and achieving the removal.

Operation Steps

- Select the appropriate drill bit size

- Choose a drill bit that is slightly larger than the inner diameter of the nut (for example, use a Ø7-8mm drill bit for an M6 nut).

- It is recommended to use high-speed steel (HSS) or cobalt steel drill bits to handle metal structures.

2. Locate the drill hole at the center of the nut

- Use a center punch or a cone to mark the position, to prevent the drill bit from slipping.

- Ensure a vertical entry to avoid deviation and injury to the sheet material.

3. Drill slowly to break the core and the folding structure

- Maintain a medium-low speed and stable pressure drilling, gradually cutting into the expanded area.

- As the expanded part breaks, the Jack nut will loosen or rotate.

4. Remove the remaining components

- If the nut is still stuck in the hole, use a punch to strike or a pliers to pull out the debris.

Sheet Material Protection Techniques

- Backplate: Place a metal pad or wooden block behind the nut to prevent the drill from penetrating and damaging the equipment or workpiece.

- Drill head limiter: Install a depth limit device to prevent the drill bit from penetrating the base material and causing damage.

- Tape for positioning: Apply tape on the drilling area to prevent slipping and also to catch the chips.

Table: Application Scope & Recommendations

| Item | Description |

|---|---|

| Applicable Nut Type | Metal Jack Nuts (Aluminum, Stainless Steel, Carbon Steel) |

| Suitable Base Materials | Steel plates, aluminum plates, equipment enclosures, and other medium-to-high hardness structures |

| Advantages | Controlled operation, suitable for on-site repairs, no special fixtures required |

| Precautions | Not suitable for non-metallic (e.g., plastic) or fragile substrates; avoid excessive heat to prevent annealing or deformation |

Method 2: Use a Puller or Slide Hammer

Using pulling-type tools (such as a slapper) is a relatively non-destructive demolition method, suitable for situations where axial pulling force can be applied within the structural limits. The core principle is to pull the nut out of the installation hole as a whole under tension, rather than damaging the structure.

I. Tool Principles and Operating Procedures

Tool Composition:

- Slide Hammer: A type of impact pulling tool with a sliding counterweight, commonly used in auto repair and the disassembly of structural fasteners.

- Threaded Connection Head: A threaded part that can be screwed into the inner thread of the Jack nut, serving as a load-bearing point for pulling force.

- Locking Nut / Extension Kit (depending on model): Used to enhance the clamping force and prevent disengagement during the pulling process.

Operation Steps:

- Insert the screw into the interior of the Jack nut

- Use a pulling rod that matches the thread of the Jack nut (for example, an M6 screw for an M6 Jack nut), ensuring a perfect fit.

- Connect the lever or pulling device

- Connect the screw to the body of the lever to ensure a secure and stable structure.

- Apply intermittent axial pulling force

- The operator holds the lever and pulls outward to generate impact force, relying on inertia to overcome the clamping resistance of the Jack nut.

- Repeat the pulling several times until the nut loosens and is pulled out of the hole as a whole.

II. Applicable Conditions and Advantage Analysis

Applicable Scenarios:

| Item | Description |

|---|---|

| Base material allows tensile load transfer | Such as equipment housings, pipe connectors, sheet metal structures, and other non-enclosed surfaces |

| Jack nut material is relatively soft | Suitable for softer materials like aluminum alloys or medium-grade stainless steel to avoid cracking from excessive hammering |

| Structural integrity needs to be preserved | Ideal for high-end equipment or serviceable parts where damage to the parent material is not acceptable |

Technical Advantages:

- Non-destructive operation: Avoid permanent damage caused by drilling and cutting;

- Convenient for subsequent reuse or replacement: Especially suitable for equipment maintenance and quality control rework processes;

- Suitable for batch processing: Combined with pneumatic pulling tools, it can enhance operational efficiency.

Notes:

- If the Jack nut has suffered corrosion or severe adhesion, the pulling force may be too high, causing damage to the base material;

- It is necessary to ensure that the pulling axis is perpendicular to avoid causing elliptical deformation or cracking of the hole wall;

- When operating the slip hammer, protective gloves and safety glasses must be worn to prevent injury from rebounding.

Method 3: Access from the Back Side (If Possible)

In cases where the installation structure allows for contact with the back of the Jack nut, a cutting tool can be used to directly damage the folded part, thereby safely and efficiently removing the fastener. This method is applicable to maintenance windows, box openings, or modular structures, etc.

Application Scenarios

| Condition | Description |

|---|---|

| Backside is visible and accessible | For example, areas reachable through inspection ports, electrical cabinet back panels, or machine compartments |

| No need to retain the jack nut body | The goal is to replace or remove the fastener rather than reuse it |

| Prepared for hole repair afterward | The removal process may cause minor damage to the original hole, requiring follow-up treatment |

Recommended Cutting Methods and Tool Selection

①. Manual cutting tools (scissors/cleaver)

- Suitable for soft metal Jack nuts (such as aluminum alloy).

- Simple to operate, suitable for small-scale on-site removal.

- V-shaped or notched cutting edges are available, facilitating the engagement of the folded parts.

②. Pneumatic Shears / Hydraulic Shears

- Suitable for large-scale removal or for hard materials such as stainless steel nuts.

- Provides stable shear force, reducing the labor intensity of the operator.

- The shear force range can reach 10 to 15 kN, sufficient to break the flanges of most Jack nuts.

③. Procedure for the Cut Operation:

- Hold the flanging area from the back

- Identify the extended part of the Jack nut tail and locate the clamping point.

- Avoid shearing near the root of the base material to prevent structural tearing.

- Cut the flange radially

- It is recommended to cut in two stages to avoid severe shearing that causes material deformation.

- The main body of the front side nut can be removed by gentle pushing from the front or using a clamp after removal.

3. Clean the hole positions

- Use a file or grinding wheel to polish the remaining burrs.

- If necessary, measure the change in hole diameter and decide whether to replace the model or install a bushing for repair.

Tips to Avoid Damaging the Base Material

Jack nuts are usually installed on sheet metal, electrical control boxes, composite materials or structural panels. These substrates are mostly of medium-thin structure and are prone to deformation, cracking or failure due to tool impact or thermal influence. Therefore, scientificly controlling the forces, heat and mechanical interference during the removal process is crucial for protecting the base materials.

1. Controlling the Force of Tools

- Avoid excessive force: It is recommended to use a torque-adjustable electric drill for power tools, and avoid drilling at high speeds to prevent the material from being penetrated or the hole wall from being abraded.

- Adopt the “step-by-step dismantling” strategy: Especially when using a sliding hammer or a cutting tool, adopting the “gradual loading and intermittent operation” method can effectively reduce the reactive impact on the base material.

- Data Reference The yield strength of thin-walled sheet metal (with a thickness of 1.0mm) in the out-of-plane direction is usually less than 150 MPa. Excessive instantaneous force can easily cause plastic deformation. The single impact force should be controlled to be below 3 kN.

2. Techniques for Using Washers or Backing Plates

| Technique | Function Description |

|---|---|

| Front-side washer (e.g., rubber ring, plastic spacer) | Prevents scratches on panel surface from drill or impact tools; absorbs part of the vibration. |

| Backside isolation plate (e.g., wood piece or metal shield) | Prevents drill-through or impact force from damaging internal components, cables, or rear surfaces. |

| Guiding fixture or jig | Used in mass production or maintenance to ensure precise alignment and reduce tool drift, minimizing the risk of accidental damage. |

3. Prioritize the handling of plastic or aluminum Jack nuts

- Low resistance during removal

Plastics and aluminium materials have relatively low hardness. Usually, their folding structures can be easily broken using manual tools, without the need for high torque or high impact operations. - Reduce the risk of thermal/thermal impact

Compared with stainless steel or carbon steel Jack nuts, soft materials are easier to be cut or drilled through, and the counteracting force transmitted to the base material is significantly lower. - Recommended Application Scenarios

The plastic Jack nuts are suitable for non-structural load-bearing applications, such as plastic enclosures and panel modules. The aluminum Jack nuts are suitable for light-load electrical/electromechanical equipment.

What to Do After Removal – Replace or Reinforce

Once the Jack nut is removed, there are often problems such as deformation, uneven wear, enlarged hole diameter or residual burrs at the installation holes. These issues must be evaluated and the subsequent handling method determined. The judgment criteria are usually based on three dimensions: the hole position condition, the load level and the maintenance purpose.

Should You Enlarge the Hole?

| Situation | Recommendation |

|---|---|

| Original hole is intact with no visible deformation | You can install the same-size replacement rivet nut or one with a similar outer diameter. |

| Hole slightly enlarged (<0.5mm) | Consider using adhesive-coated threaded inserts or expansion-type rivet nuts to avoid further drilling. |

| Hole wall damaged or severely oval-shaped | It’s recommended to re-drill and enlarge the hole, then reposition and install a new structural fastener. |

- For the metal base material, it is quite common to increase the hole diameter to the next larger standard size (e.g. from M6 to M8). Be aware of the risk of interference with the original component;

- If the structure cannot accept the enlargement of the hole, alternative solutions such as eccentric screw sleeves or nested bushings should be considered for restoration.

Recommended Alternative Fasteners

a. Threaded Insert (such as Helicoil)

- Applicable to situations where the threads are damaged but the base material is intact;

- After installation, the thread strength is superior to that of the original base material, and it is commonly used in aviation and precision equipment;

- Pre-drilled standard thread holes and installation of special tools are required.

b. Rivet Nut

- Similar to the Jack nut function, but with higher versatility of the installation tool;

- Offering standard, metric, hexagonal, anti-rotation, and other types;

- If the hole diameter is slightly larger, the “enlarged flange type” rivet nut can be selected to compensate for the tolerance.

c. Expansion Nut

- Suitable for situations where the rear of the repair hole cannot be fixed but the hole diameter does not match;

- Automatically expands and tightens during installation, adaptable to different hole diameters and base materials;

- Can provide repeatable installation performance.

Structural Assessment Points in Repair Scenarios

| Inspection Item | Description |

|---|---|

| Base material thickness and deformation level | For thickness <1.5mm, check for fatigue and avoid reusing the same rivet nut type repeatedly. |

| Presence of cracks or corrosion | Use a magnifier or penetrant inspection to check around the hole, especially stress concentration zones. |

| Load direction and strength requirement | For shear loads, prefer hexagonal rivet nuts or backing washer-reinforced types; for tensile loads, use expansion or large-flange types. |

FAQs About Jack Nut Removal

Could it be dismantled without causing any damage?

Jack nuts are generally designed for single-use and are difficult to remove without causing any damage. This is because they are clamped in the hole by a spring, and the clamped part is prone to deformation or damage during removal. If reusability is required, it is recommended to choose specially designed reusable inserts or to use other types of fasteners.

What is the maximum aperture size that can be used with Jack nuts?

The Jack nut is suitable for holes with diameters ranging from 3mm to 12mm. The specific dimensions may vary slightly depending on the model and manufacturer. The hole diameter must be within the clamping range of the nut; anything too large or too small will affect the installation effect and clamping force.

Are there any reusable models available?

Most standard Jack nuts are for single use and there are no dedicated reusable models. If the project requires multiple disassembly, it is recommended to consider self-locking nuts, riveted nuts or threaded inserts, which are more suitable for repeated use as tightening solutions.

Conclusion: How Do You Remove a Jack Nut

The key to safely removing the Jack nut lies in choosing the correct method and using the appropriate tools. Whether you are performing maintenance, modification, or component replacement, understanding “how do you remove a jack nut” can effectively prevent damage to the substrate and ensure structural safety. We offer professional disassembly solutions and high-quality Jack nut products, helping you complete the disassembly work easily and improving project efficiency and reliability. Welcome to contact Rivetfix to obtain more technical support and customized services, making your disassembly process safer and more efficient!

Do You Have Any Questions?

Let Us Solve Your Problem

Choose Rivetfix Jack Nuts for Reliable Performance

Choose Rivetfix’s Jack Nut, and you will have a high-quality, durable and easy-to-install fastening solution. Whether it’s for cars, furniture or mechanical equipment, Rivetfix Jack Nut can provide outstanding load-bearing capacity and reliability, ensuring a stable and secure connection without loosening. Contact us now and experience professional product support and customized services to make your project more efficient and safer. Rivetfix, your reliable supplier of Jack Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.