How do Rivet Nuts Work?

Leading Rivet Nut Manufacturer and Supplier in China

Rivet nuts are versatile fasteners used to create secure, permanent threaded connections in various materials, including metals, plastics, and composites. In this blog, we’ll explore how do rivet nuts work, including their installation process. Additionally, we will discuss how they provide strong, reliable connections that stand up to demanding applications. By understanding how rivet nuts work, you can make more informed decisions for your fastening needs, ensuring optimal performance and reliability for your projects.

Table of Contents

Rivet nut also known as a rivnut, is a fastener used to create strong threaded connections in thin-walled materials. Typically made of metal, it features both internal and external threads. During installation, the rivet nut expands or deforms to securely anchor itself in the material, providing a durable threaded connection for bolts or screws, which can be removed and replaced multiple times.

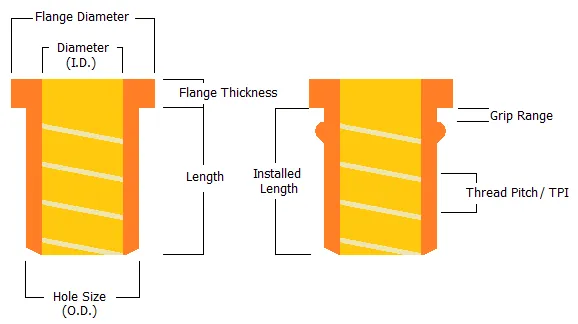

a. Structure

- Outer Shell: Usually made of metal (such as steel, stainless steel, or aluminum), it provides strength and corrosion resistance.

- Internal Threads: These threads allow for secure fastening with external bolts or screws, and common types include metric and imperial threads.

- Expansion Area: During installation, the rivet nut expands to secure itself within the material, creating a stable threaded connection.

b. Features

- High Strength: Rivet nuts can withstand high loads and torque.

- Versatility: They are suitable for a wide range of materials, including metals, plastics, and composites.

- Easy Installation: They can be installed using simple hand tools or pneumatic tools, reducing labor costs.

- Reusable: Once installed, bolts or screws can be removed and replaced multiple times.

Rivet nuts are widely used across industries such as automotive, aerospace, construction, electronics, and furniture, particularly for securing thin-walled metals or plastic materials. Common applications include:

- Automotive: Securing interior components, trim panels, or undercarriage parts.

- Aerospace: Fastening aircraft components, equipment, and instruments.

- Construction: Attaching metal components, brackets, and supports.

- Electronics: Fixing circuit boards, enclosures, and other electronic components.

How Do Rivet Nuts Work?

Rivet nuts create permanent threaded connections in materials through a process of mechanical expansion. As a result, they provide an efficient and reliable method for creating threaded connections in soft or thin materials. The installation process involves expanding the rivet nut to create a strong, secure, and permanent connection. Moreover, shear strengths and load capacities vary depending on the material and size, ensuring adaptability for different applications. This versatility makes rivet nuts a reliable solution for a wide range of industries.

1. Material Preparation and Hole Drilling

- A hole must be drilled into the base material for the rivet nut installation. The size of the hole depends on the outer diameter of the rivet nut. For example:

- M6 rivet nut: Requires a hole diameter of 6.5 mm to 6.7 mm.

- M8 rivet nut: Requires a hole diameter of 8.5 mm to 8.7 mm.

- M10 rivet nut: Requires a hole diameter of 10.5 mm to 10.7 mm.

- Drilling accuracy is crucial to ensure proper installation and secure attachment.

2. Insertion of Rivet Nut

The rivet nut is inserted into the pre-drilled hole with the threaded portion facing inward, and the unthreaded portion facing outward, flush with the material surface.

3. Compression and Expansion (Installation Process)

- Tools: A mandrel, hydraulic, pneumatic, or manual rivet nut tool is used to apply pressure to the rivet nut.

- As the tool compresses the rivet nut, the body of the nut expands, creating a strong mechanical grip inside the material.

- The expansion depends on the type of material and rivet nut used:

- Steel Rivet Nut: Expands up to 1.2 to 1.5 times its original diameter during installation.

- Aluminum Rivet Nut: Expands up to 1.3 to 1.6 times its original diameter, ensuring a strong, durable attachment.

The rivet nut typically deforms into a “bulged” shape within the material, creating a tight, secure connection.

4. Retention and Threading

Once the rivet nut is expanded, the threads inside remain intact. These threads are designed to withstand high shear forces and tensile loads. For example:

- M6 steel rivet nut: Can withstand shear strengths ranging from 2,000 to 3,500 N (Newtons).

- M8 steel rivet nut: Can withstand shear strengths ranging from 3,000 to 5,000 N.

- M10 steel rivet nut: Can withstand shear strengths ranging from 4,000 to 6,000 N.

The rivet nut now provides a permanent threaded connection that can hold bolts, screws, or fasteners securely.

5. Final Securing

The rivet nut is firmly fixed within the base material. The compression process creates a bulge that prevents the nut from pulling out or rotating, ensuring the rivet nut will stay in place under stress and load.

How do Rivet Nuts Provide Lasting Connections?

1. Material Expansion

- Expansion Mechanism: When a rivet nut is installed, the body of the nut expands as pressure is applied during installation. This creates a tight fit within the hole of the material.

- Deformation: The rivet nut deforms at the base and sides, providing a bulge that “locks” the nut in place. This prevents the rivet nut from rotating or pulling out under load.

- Customization for Materials: Different materials, such as steel, aluminum, and plastic, influence the expansion, ensuring a snug, secure fit for each application.

2. High Shear Strength

- Rivet nuts are designed to withstand significant shear forces, ensuring that they stay firmly anchored in place even when subjected to vibration or heavy loads. For example:

- M6 steel rivet nut: Can handle shear forces between 2,000 to 3,500 N.

- M8 steel rivet nut: Can handle shear forces ranging from 3,000 to 5,000 N.

- This load-bearing capacity ensures that rivet nuts remain stable and functional for a long time, even under high-stress conditions.

3. Reusability

- Unlike traditional welding or riveting methods, rivet nuts allow for multiple insertions and removals of bolts or screws without damaging the fastener threads or base material. This reusability is crucial in applications that require maintenance or assembly/disassembly.

- M6 and M8 rivet nuts can be installed and removed hundreds of times, depending on the material and application, making them ideal for maintenance-heavy industries such as aerospace, automotive, and electronics.

4. Versatility Across Industries

Rivet nuts are used in various industries where lasting, secure, and reusable threaded connections are needed. From automotive and aerospace to electronics and construction, rivet nuts are a trusted solution for providing lasting connections in demanding environments.

What is the Difference Between Blind Rivet and Rivet Nuts?

| Feature | Blind Rivet | Rivet Nut |

|---|---|---|

| Function | Joins two materials permanently without access to the rear side of the material. | Provides a threaded insert for bolted connections in materials that cannot support direct threading. |

| Use Case | Common in sheet metal, automotive, and construction industries. | Often used in automotive, electronics, furniture, and aerospace for creating threaded connections. |

| Strength | Provides strong, permanent connection but less flexibility than rivet nuts. | Provides a durable threaded connection that can bear significant loads and be reused multiple times. |

| Reusability | Not reusable; the rivet is deformed permanently during installation. | Reusable; bolts or screws can be inserted and removed repeatedly. |

| Applications | Widely used for non-load-bearing, permanent fastening in thin or medium-thickness materials. | Ideal for applications requiring removable, secure threaded connections in soft or thin materials. |

| Tool Requirements | Requires a rivet gun. | Requires a tool to install and expand the nut into the material. |

Summary:

- Blind Rivets are best suited for permanent, non-removable connections in materials that can withstand the deformation process. They are ideal when access is only available on one side of the material.

- Rivet Nuts offer a more versatile solution, providing reusable, threaded connections in materials like plastics and thin metals, and are typically used when fastening and unfastening components is necessary.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Maintain the Rivet Nut Connection?

Maintaining a rivet nut connection is crucial to ensure long-term performance and reliability. Here are some steps and tips to help you maintain rivet nut connections effectively:

1. Regular Inspection

- Frequency: Perform periodic checks to ensure the rivet nut is securely installed and has not become loose.

- Signs to Look For: Check for signs of corrosion, loosening, or damage to the material around the rivet nut.

2. Ensure Proper Torque

Applying the correct torque to a rivet nut ensures a secure, lasting connection and prevents damage to both the rivet nut and the material. Specifically, torque refers to the amount of rotational force used to tighten a fastener. Moreover, for rivet nuts, it is critical to follow the manufacturer’s torque specifications to ensure optimal performance and avoid over-tightening or under-tightening, which could compromise the connection.

Example Torque Values for Rivet Nuts:

- M6 Rivet Nut:

- Recommended Torque: Approximately 5–8 Nm (Newton-meters).

- Failure Torque: If over-torqued, it may fail at approximately 10–12 Nm.

- M8 Rivet Nut:

- Recommended Torque: Approximately 8–12 Nm.

- Failure Torque: Can fail if over-torqued at around 15–20 Nm.

- M10 Rivet Nut:

- Recommended Torque: Approximately 12–15 Nm.

- Failure Torque: Failure may occur above 20 Nm.

Key Points:

- Under-torquing: Results in a loose connection, reducing the holding strength.

- Over-torquing: Leads to thread stripping, deformation of the rivet nut, or material damage around the rivet nut.

3. Clean the Threaded Area

- Thread Cleaning: Dirt and debris can accumulate in the threads, preventing proper fastening. Clean the threads regularly using a brush or compressed air.

- Lubrication: Apply a light lubricant to the threads to ensure smooth and easy installation and removal of fasteners.

4. Prevent Corrosion

- Material Considerations: If the rivet nut is installed in a high-moisture or corrosive environment, use corrosion-resistant materials (e.g., stainless steel or coated rivet nuts).

- Protective Coatings: In extreme environments, consider adding protective coatings or sealants around the rivet nut to prevent moisture ingress.

5. Monitor Load and Vibration

- Vibration: In applications prone to vibration (e.g., automotive or machinery), ensure that the rivet nut remains securely fastened. Over time, vibration can cause fasteners to loosen.

- Check Load: Be mindful of the load placed on the rivet nut and ensure it doesn’t exceed the rated capacity, which could lead to failure.

6. Replace Damaged Rivet Nuts

- Signs of Damage: If a rivet nut becomes stripped, damaged, or corroded, replace it immediately to ensure the integrity of the connection.

- Check for Material Fatigue: Over time, the surrounding material may weaken. If cracks or deformations are visible, the rivet nut should be replaced or repositioned.

Why Choose Custom Rivet Nuts?

- Perfect Fit: Tailored to your unique material and strength requirements, ensuring compatibility and performance.

- Increased Efficiency: Reduce installation time and effort by using the perfect rivet nut for your application.

- Reliability: Custom rivet nuts are manufactured to strict quality standards, ensuring your projects meet safety and durability requirements.

Rivetfix offers custom rivet nut solutions for your project. Specifically, we provide customizable options in sizes, materials, and finishes. Additionally, our team of experts helps you select the right rivet nuts, taking into account factors like material compatibility, load-bearing requirements, and installation efficiency.

Furthermore, with Rivetfix, you can rely on fast delivery and consistent quality, ensuring your projects run smoothly and securely. Ultimately, let us be your trusted partner in creating lasting, secure connections for your application.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.