Choosing the Best PEM Studs for Sheet Metal Applications

Leading Self-Clinching Fasteners Manufacturer and Supplier in China

When selecting PEM studs for sheet metal applications, it’s essential to choose the right type and material to ensure a secure, long-lasting connection. Whether for automotive, electronics, or industrial uses, the correct PEM studs provide strength, reliability, and ease of installation, making them a crucial component in modern fastening solutions.

Table of Contents

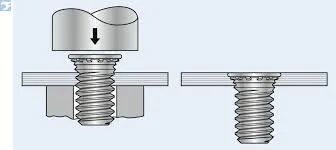

PEM Studs are self-clinching fasteners specifically designed for sheet metal, which can form a strong threaded connection within thin plates without the need for welding, nuts, or additional drilling. During installation, the stud is pressed into a pre-punched hole in the sheet metal, utilizing the metal’s cold flow deformation principle. This causes the sheet metal to flow into the annular grooves or barbed structures at the base of the stud, creating a secure mechanical lock.

Design Principles

- Self-Clinching Structure: The bottom of the stud is designed with annular teeth or grooves. When pressure is applied during insertion, the metal sheet is deformed and interlocks with the stud, ensuring a strong and secure fastening.

- No Thermal Deformation: The cold-press process avoids the heat stress or deformation (e.g., warping or oxidation) that may occur from high-temperature welding, making it ideal for thin plates or precision components.

Common Materials and Surface Treatments

PEM studs are typically made from the following materials to suit different environments:

- Stainless Steel (300 Series, 400 Series): Excellent corrosion resistance, suitable for humid, high-temperature, or chemically corrosive environments such as medical equipment, food processing, and shipbuilding.

- Carbon Steel: High strength and low cost, typically treated with galvanization, nickel plating, or other corrosion-resistant coatings. Commonly used in automotive, electronics, and electrical equipment industries.

- Aluminum Alloy: Lightweight and oxidation-resistant, ideal for aerospace, precision instruments, and electronics, reducing the overall weight of devices.

- Surface Treatments: Depending on the application environment, PEM studs can undergo galvanizing, nickel plating, phosphating, passivation, electroplating, or electropolishing to enhance corrosion resistance and aesthetics.

Key Advantages of PEM Studs

1. Fast Installation, Improving Production Efficiency

- Uses a simple clinching process that can be installed using pneumatic, hydraulic, or mechanical presses without welding or additional processing, significantly increasing production speed.

- Precise positioning makes it suitable for automated production lines, improving assembly quality.

2. High Pull-out Strength and Torque-out Resistance

- Forms a firm bond with the sheet metal using the cold flow deformation principle, making it resistant to loosening or detachment.

- Provides high pull-out strength and torque-out resistance, ensuring long-term stability in use.

3. Preserves Sheet Metal Integrity, Preventing Damage

- No welding design prevents sheet metal deformation or coating damage caused by high-temperature welding.

- Since the installation process doesn’t require tapping or additional drilling, it doesn’t weaken the structural strength of the sheet metal, making it ideal for thin plates and lightweight structures.

4. Wide Range of Applications Across Various Industries

- Electronics (server chassis, communication equipment, PCB boards, etc.).

- Automotive manufacturing (body sheet metal, dashboards, battery box fixation).

- Aerospace (aircraft structural components, lightweight fastening connections).

- Medical devices (stainless steel casings, precision instrument assemblies).

Form1: Comparison with Other Fastening Methods

| Criteria | PEM Studs | Weld Nuts | Rivet Nuts |

| Installation Speed | Fast (2-3 seconds per unit) | Slow (requires preheating and cooling) | Medium (requires rivet tool) |

| Risk of Thermal Deformation | None | High | None |

| Suitable for Thin Plates | Yes (≥0.5mm) | Limited (may burn through) | Yes (but rivet force may deform sheet metal) |

| Cost Structure | Medium-High (higher stud cost but labor-saving) | Low (cheaper nuts but high labor cost) | Medium |

How to Choose the Best PEM Studs for Sheet Metal ?

1. Material Compatibility

Different sheet metal materials require matching stud materials to prevent electrochemical corrosion (galvanic corrosion), which can affect the lifespan and strength of the fastener.

Matching Sheet Metal Materials:

- Aluminum Alloy Sheet Metal: It is recommended to use aluminum or stainless steel studs to avoid electrochemical reactions between carbon steel and aluminum.

- Stainless Steel Sheet Metal (SUS304/316): It is advisable to use the same or higher grade stainless steel PEM studs, such as SUS304/SUS316, to avoid corrosion-related fastener failure with carbon steel studs.

- Low Carbon Steel or Galvanized Sheet Metal: Carbon steel PEM studs can be used, but it is recommended to use galvanized or nickel-plated studs for improved corrosion resistance.

Environmental Requirements:

- High-Temperature Environments (>200°C): Materials such as SUS316 or nickel-based alloys should be chosen to prevent softening or loss of strength.

- High Humidity or Chemical Corrosion Environments: Stainless steel studs (SUS304/316) or carbon steel studs with surface nickel plating, phosphating, or passivation treatments are recommended for enhanced corrosion resistance.

Form2 : Surface Treatment Options

| Treatment | Characteristics | Suitable Applications |

| Galvanizing (Zn) | Low cost, general rust resistance | Indoor equipment, enclosures |

| Electroless Nickel (EN) | Uniform coating, wear and corrosion resistant | Medical devices, high-precision electronics |

| Black Oxide | Fingerprint resistant, aesthetic | Consumer electronics housings |

| Dacromet | Hydrogen embrittlement-resistant, high-temperature durability | Automotive engine compartments |

2. Stud Specifications

Thread Type and Size:

- Metric: Widely used in Europe and Asia. Common sizes include M2, M3, M4, M5, suitable for electronics, precision instruments, and similar industries.

- Unified Thread: For North American standards, sizes like #4-40, #6-32, #8-32 are used, typically in aerospace applications.

Stud Length:

- Ensure that the effective thread engagement length ≥ 1.5 times the thread diameter to ensure sufficient fastening strength.

- For example, the minimum effective engagement length for an M4 stud should be 6mm (4mm×1.5).

Head Design:

- Flange-style studs (Flush-head Studs): Suitable for high-strength connections, offering a larger contact area and increased load-bearing capacity.

- Low-profile or recessed studs (Flush-mounted Studs): Ideal for thin sheet structures or applications requiring an aesthetic finish, such as enclosures, electrical housings.

- Floating studs (Floating Studs): Suitable for assembly environments with large tolerances, capable of automatically adjusting for misalignment errors. Commonly found in server racks, electronic devices.

3. Load Requirements

The selection of PEM studs should take into account mechanical loads, including both static and dynamic loads, to ensure safety and long-term stability.

Static Load:

- Refers to the forces the stud will experience in normal working conditions, such as tightening torque and axial pull.

- When selecting studs, it is important to check the pull-out strength and torque-out strength to ensure the stud will not fail due to overload.

Dynamic Load (Vibration Environment):

- In high-vibration environments such as automotive, aerospace, and machinery, stronger materials (e.g., SUS316, hardened carbon steel) should be selected, and anti-loosening designs (e.g., adhesives, serrated studs) should be used to prevent loosening.

- For high-frequency vibration applications, it is recommended to use thicker flange studs or special locking structures to increase stability.

Safety Factor:

Basic Formula: Safety Factor = Ultimate Strength of Stud / Actual Working Load

For example, if the application environment requires the stud to bear a 10N tensile force, it is recommended to select a fastener with at least 15N pull-out strength to prevent failure from accidental overload.

Form3: Recommended Value of Safety Factor

| Scenario | Safety Factor | Example |

| Regular equipment fastening | 1.5–2 | Enclosure panels, display mounts |

| High vibration or shock load | 2.5–3 | Automotive suspension components, generator sets |

| Life safety-related applications | ≥4 | Spacecraft structures, medical equipment load-bearing components |

How Do Sheet Metal Characteristics Affect the Selection of PEM Studs?

When selecting PEM studs, the physical properties of the sheet metal directly impact the installation effectiveness, load-bearing capacity, and long-term stability of the fastener. The following are key considerations:

1. Sheet Metal Thickness Range

PEM studs are designed for specific thickness ranges of sheet metal. It is essential to ensure that the sheet metal thickness meets the fastener’s specifications.

Common Applicable Range:

PEM studs are typically suitable for 0.5mm to 6mm sheet metal. Extended-length studs can be used for thicker materials.

Matching Guidelines:

1. Ultra-thin Sheet Metal (<0.8mm)

- Challenge: Insufficient clinching force may cause material deformation or stud detachment.

- Solution:

- Use micro-design studs (e.g., PEM® MFH series, suitable for thickness ≥0.5mm).

- Increase clinching area (use studs with a larger flange diameter).

- Recommended material: Aluminum studs (lightweight and softer materials reduce localized stress).

2. Medium Thickness Sheet Metal (0.8–3.0mm)

- Typical Applications: Enclosures for electronic equipment, electrical control cabinets.

- Selection Advice:

- Standard flange-type studs can meet most needs.

- Stainless steel or carbon steel studs offer a balance of cost and performance.

3. Extra-thick Sheet Metal (>6mm)

- Challenge: Standard PEM stud length may not sufficiently fill the hole wall.

- Solution:

- Use extended-length studs (e.g., S-4004, with engagement length up to 8mm).

- Combine studs with reinforcing bushings (to improve pull-out strength).

- Recommended material: 17-4PH stainless steel (tensile strength ≥1000MPa).

2. Sheet Metal Hardness and Ductility

The hardness and ductility of the sheet metal affect the clinching quality of the stud. Overly hard materials may cause clinching failure or cracking, while overly soft materials may reduce fastening strength.

Hardness Level Matching:

- Soft Materials (HV ≤ 150):

- Examples: Aluminum (HV 50–80), annealed low carbon steel (HV 120–150). Standard carbon steel or stainless steel studs can be used directly.

- Medium-hard Materials (HV 150–300):

- Examples: Cold-rolled steel (HV 180–220), austenitic stainless steel (HV 200–250). Choose studs with sharp teeth (e.g., PEM® SA series) for better engagement.

- High Hardness Materials (HV > 300):

- Examples: Hardened steel (HV 400+), titanium alloys (HV 350–450). Requirements include:

- Local annealing of the material (reduce hardness in the clinching area to HV ≤ 250).

- Use more flexible stainless steel studs (e.g., 304 stainless steel) to avoid brittle fracture.

- Examples: Hardened steel (HV 400+), titanium alloys (HV 350–450). Requirements include:

How to Optimize Clinching:

- For harder sheet metals (e.g., stainless steel), it is recommended to reduce clinching pressure, using higher-strength stud materials, such as 304/316 stainless steel.

- For softer sheet metals (e.g., aluminum), use large flange design PEM studs to increase the bearing area and reduce the risk of sheet metal deformation.

Form4: Material Combination Recommendations

| Sheet Metal Type | Recommended PEM Material | Surface Treatment | Failure Case |

| Aluminum (6061-T6) | 5052 aluminum alloy studs | Electroless nickel plating | Carbon steel studs causing electrochemical corrosion |

| 304 Stainless Steel (HV220) | 316 stainless steel studs | Passivation | Carbon steel zinc-plated studs rusting and seizing |

| Hardened Steel (HV420) | Annealed stainless steel (HV ≤ 250) | Dacromet coating | Failure to anneal leads to clinching hole cracking |

Do You Have Any Questions?

Let Us Solve Your Problem

How Do I Install PEM Studs on Sheet Metal?

The quality of PEM stud installation directly impacts the fastening effectiveness, load-bearing capacity, and service life of the fastener. Correct tool selection and process steps ensure reliable fixation of the stud on sheet metal, preventing common installation issues.

Tool Selection

PEM studs are typically installed using press-fit methods, requiring appropriate tools to apply even pressure to ensure a strong bond between the stud and sheet metal.

Common Installation Tools:

- Hydraulic Press (ideal for mass production, offering high precision and stability).

- Pneumatic Press (suitable for medium-scale production, easy operation, and high efficiency).

- Manual Press Tool (for small batches or maintenance scenarios, low cost but relatively lower efficiency).

Tool Selection Recommendations:

- For hard materials (e.g., stainless steel) → Use a hydraulic press to provide stable pressure and reduce deformation during installation.

- For aluminum or low-carbon steel sheet metal → Either pneumatic press or manual tools can be used, as long as the pressure is applied evenly.

Installation Steps

1. Accurately Position the Hole:

- Ensure the stud installation hole diameter and tolerance meet the recommended values (usually ±0.05mm).

- Use laser cutting, stamping, or drilling to create the hole, avoiding burrs that may affect the clinching quality.

2. Apply Even Pressure (Avoid Tilting):

- Pressure Calculation Formula: Static pressing force (F) = stud cross-sectional area (A) × material yield strength (σ) × safety factor (1.2–1.5). For example:

- M4 stainless steel stud (SUS304, σ=205MPa): A = π×(4mm/2)^2 ≈ 12.56mm² → F ≈ 12.56 × 205 × 1.3 ≈ 3,356N (3.36kN).

- Step-by-Step Pressing Method (for hard or brittle materials):

- Pre-press Stage: Apply 30% pressure to position the stud, ensuring perpendicularity.

- Main Press Stage: Apply 100% pressure until the travel point is reached, maintaining pressure for 0.5 seconds.

- Pressure Relief Stage: Slowly release the pressure (rate ≤ 20kN/s) to prevent rebound.

3. Quality Verification:

- Visual Inspection:

- The stud flange should be flush with the sheet metal surface, with no visible gaps.

- Ensure the threads are free from damage or obstruction.

- Mechanical Testing:

- Pull Test: Use a digital torque wrench to apply standard torque (e.g., 20N·m for an M5 stud), checking for thread slippage.

- Tilt Angle Detection: Use a protractor to verify the stud’s perpendicularity error is ≤1°.

Form5: Common Problems and Solutions

| Problem | Possible Cause | Solution |

| Stud Deformation or Sheet Metal Dents | Excessive pressure, insufficient sheet metal thickness | Adjust pressure settings and select appropriate stud size |

| Stud Not Fully Inserted or Loose | Insufficient pressure, high material hardness | Increase pressure and use higher-strength installation tools |

| Thread Damage After Installation | Pressure not applied vertically, tool misalignment | Calibrate tool alignment and ensure perpendicular installation |

| Stud Rebound or Not Firmly Fixed | Hole diameter too large or tolerance exceeded | Ensure the hole diameter matches PEM’s recommended size and avoid tolerance exceedance |

How to Ensure the Compatibility of PEM Studs in Different Environments?

Testing Items

1. Tensile/Shear Strength Testing

- Reference Standards: ISO 898-1, ASTM F606, ASME B18.6.9

- Purpose: To verify the maximum load-bearing capacity of the stud under axial tension and lateral shear forces, ensuring that the fastener will not detach or break due to external forces.

- Testing Method:

- Install the stud into standard thickness sheet metal (e.g., 1.5mm SUS304).

- Apply axial tension using a universal material testing machine at a speed of 5mm/min and record the maximum load before fracture.

2. Salt Spray Test (Corrosion Resistance)

- Reference Standards: ASTM B117, ISO 9227

- Purpose: To assess the corrosion resistance of the stud in humid, corrosive environments (e.g., marine or high-humidity regions).

- Test Method:

- Place the sample in a salt spray test chamber to simulate prolonged exposure to corrosive environments and observe the surface oxidation.

- Standard Conditions: 5% NaCl solution, 35°C constant temperature, continuous spraying.

3. Vibration Fatigue Testing

- Reference Standards: ISO 16750, MIL-STD-810

- Purpose: To test the fatigue resistance of the stud under long-term vibration or mechanical shock, ensuring it does not loosen in high-vibration environments such as automotive or aerospace applications.

- Test Method:

- Use a vibration test bench to simulate various vibration frequencies and amplitudes, observing the fastener’s stability and potential wear.

Industry Certifications

NASM 25027

- Technical Requirements: Anti-loosening torque ≥ 70% of initial torque (after vibration)

- Application: Aerospace structural components

IATF 16949

- Technical Requirements: PPM (parts per million defective rate) < 50, SPC (Statistical Process Control)

- Application: Automotive supply chain

ISO 13485

- Technical Requirements: Biocompatibility report (e.g., nickel leaching in stainless steel < 0.1 μg/cm²)

- Application: Medical devices

UL Certification

- Technical Requirements: Flammability and electrical insulation testing (UL94 V-0 grade)

- Application: Electronic enclosures and distribution cabinets

Do You Have Any Questions?

Let Us Solve Your Problem

Application Scenarios and Cases

Consumer Electronics

- Material Selection: In consumer electronics products (such as smartphones, laptops, tablets), small-sized (M2-M3) stainless steel studs are typically used to secure lightweight sheet metal structures.

- Solution: Stainless steel PEM studs offer excellent corrosion resistance, ensuring secure fastening over long-term use. Additionally, due to their small size, PEM studs are particularly suited for lightweight consumer electronics, providing stable connections while effectively protecting delicate internal components from external pressure.

Automotive Chassis

- Material Selection: Automotive chassis need to withstand dynamic impacts and vibrations, so high-carbon steel PEM studs are used to meet these demanding environmental requirements.

- Solution: High-carbon steel PEM studs, known for their superior tensile strength and impact resistance, are ideal for structural connections in automotive chassis. These studs are capable of handling vibrations and dynamic loads generated during vehicle operation, ensuring the fastening and stability of various parts of the vehicle.

Medical Equipment

- Material Selection: Medical equipment, especially those that require frequent cleaning and disinfection, necessitate fasteners that are resistant to both corrosion and chemical erosion. Typically, stainless steel PEM studs are used, often with special anti-corrosion coatings.

- Solution: Stainless steel PEM studs with anti-corrosion coatings (such as nickel plating or passivation) or inherent corrosion resistance can withstand the effects of disinfection and chemical treatments. These studs help ensure the stability of medical equipment in high-demand environments, extend the lifespan of the equipment, and maintain hygiene and safety standards.

Common Mistakes and Solutions

Mistake 1: Ignoring the Hardness Difference Between Sheet Metal and Studs

Problem Description:

The difference in hardness between sheet metal and studs may lead to deformation, cracking, or insecure connections during the riveting process. Overly hard sheet metal can make it difficult for the stud to fully embed, or may cause damage.

Technical Reasons:

- If the sheet metal is too hard (e.g., HV > 300) and the stud material is brittle (e.g., high-carbon steel without annealing), cold pressing may result in cracks in the sheet due to insufficient plastic deformation.

- Extreme case: 1.8mm thick quenched steel (HV420) installed with M6 studs results in a hole penetration rate of 35%.

Solutions:

1. Form6: Material Hardness Matching:

| Sheet Metal Material | Recommended Stud Material | Max Allowed Sheet Metal Hardness (HV) |

| Aluminum (5xxx series) | 5052 Aluminum Alloy | ≤150 |

| Cold-Rolled Steel (DC04) | Austenitic Stainless Steel (A2-70) | ≤220 |

| Quenched Steel (22MnB5) | Annealed 304 Stainless Steel (HV ≤250) | Requires annealing to HV ≤250 |

2. Process Adjustments:

- Annealing: Perform local annealing of the riveting area (heat to 650°C, maintain for 10 minutes, then cool slowly).

- Step Pressure Application: Apply pressure in stages (e.g., pre-press 20% → hold pressure → main press 100%) to reduce instantaneous stress.

Mistake 2: Excessive Hole Diameter Tolerance

Problem Description:

Incorrect hole size can prevent proper stud installation or result in a weak connection after installation. Oversized holes may prevent the stud from being securely fixed, reducing the overall structural strength.

Technical Reasons:

- If the hole diameter exceeds the standard tolerance (e.g., M5 stud requires Φ5.05+0.05/-0.0mm, but the hole is processed to Φ5.15mm):

- Oversized holes → Stud will loosen after installation due to rebound (rebound force decreases >40%).

- Undersized holes → Excessive pressure results in stud fracture or sheet metal wrinkling.

Solutions:

1. Form7: Tolerance Control Specifications:

| Stud Size | Standard Hole Diameter (mm) | Allowable Tolerance (mm) |

| M3 | 3.05 | ±0.02 |

| M6 | 6.07 | ±0.03 |

| 1/4-20 (Imperial) | 6.35 (1/4 inch) | ±0.04 |

2. Process Optimization:

- Punching Technology: Prioritize laser cutting (precision ±0.02mm) over traditional punching machines.

- Inline Inspection: Use a CCD vision system for real-time hole diameter monitoring (frequency >50 parts/minute).

Mistake 3: Not Considering Subsequent Coating/Paint Thickness

Problem Description:

After coating or painting processes, the installation height of the stud may change, leading to unstable connections or the inability to secure the fastener properly.

Technical Reasons:

After stud installation, coatings or electrophoretic layers can have a thickness of 0.1–0.3mm, causing the following issues:

- Thread Blockage: Paint may enter the thread grooves, requiring additional tapping, which increases processing time by 30%.

- Insufficient Engagement: Effective thread length is reduced by >15%, lowering pull-out strength.

Solutions:

When selecting studs, consider the thickness of subsequent coatings or paint layers and adjust the stud installation height accordingly. This ensures that after coating, the stud still achieves the required installation depth and maintains its fastening performance.

With over 15 years of expertise in fastener manufacturing, Rivetfix has become a trusted global PEM fasteners supplier. Our team of 200+ skilled workers and 40+ sales professionals ensures reliable service and consistent supply.

Partnering with Rivetfix means access to top-quality fasteners, cost-saving solutions, and custom designs. We focus on boosting your efficiency, enhancing product durability, and providing on-time delivery. Count on our expert support and continuous innovation for your fastening needs. Choose Rivetfix for premium PEM fasteners and more!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.