Can You Use Rivet Nuts in Wood?

Leading Rivet Nut Manufacturer and Supplier in China

Rivet nuts are commonly used in metal and plastic applications, but can you use rivet nuts in wood? This question often arises when working with wood-based projects that require strong, durable, and reusable fastenings. In this post, we will explore how rivet nuts can be used in wood and the benefits they bring to woodworking applications.

Table of Contents

Can You Use Rivet Nuts in Wood?

The obvious answer is yes, rivet nuts are suitable for wood applications. They create secure, reusable threaded connections without splitting or damaging the wood.

Rivet nuts expand inside the material, distributing load evenly. This prevents cracking or pressure points from forming. They are ideal for projects requiring strong, durable fastening solutions.

Furniture, cabinetry, and DIY projects benefit from rivet nuts’ reliability. They offer a reliable alternative to screws or nails in wood-based projects. Rivet nuts provide a clean, professional finish with a strong grip.

Benefits of Using Rivet Nuts in Wood

Compared to traditional screws or gluing, rivet nuts provide stronger, more reliable connections in wood applications. They offer enhanced load distribution, prevent material damage, and ensure repeatable, secure fastening.

Stronger Connection

Rivet nuts create a secure threaded connection, offering superior strength compared to traditional screws. They provide a more durable bond that resists loosening over time, even under stress. This is especially beneficial in wood projects requiring long-term stability and reliability. Rivet nuts also distribute load evenly, preventing localized pressure that could damage the wood.

Reduced Wood Damage

Rivet nuts prevent wood from cracking or splitting by evenly distributing pressure during installation. Unlike screws, which can cause localized stress, rivet nuts expand inside the wood, reducing material damage. This feature is especially valuable when working with softer or thinner wood, where cracking is more likely. The installation process doesn’t compromise the integrity of the wood, ensuring a clean and secure connection.

Higher Load Capacity

Rivet nuts distribute load evenly, offering better resistance to tension, shear, and torque. This ensures stable connections in demanding applications. They support heavier loads compared to traditional screws, making them ideal for applications where high stress or heavy loads are expected, like furniture or cabinetry.

Do You Have Any Questions?

Let Us Solve Your Problem

Does Rivet Nuts Fit Securely on the Wood?

Choosing the appropriate rivet nut type and material is crucial for a secure fit. Especially for different wood types like hardwood or softwood.

Rivet Nuts in Hardwood:

- Stronger Connection: Hardwood, with a density of 600-900 kg/m³, provides a firm grip for rivet nuts.

- Higher Load Capacity: Hardwood can handle higher loads, supporting rivet nuts with tensile strength up to 40-60 MPa.

- Better Torque Retention: Due to the hardness, hardwood resists rotational movement, holding rivet nuts securely under torque up to 10-15 Nm.

- Lower Crack Risk: The structural integrity of hardwood reduces the chance of cracking when rivet nuts are installed correctly.

- Longer Durability: Hardwood’s dense structure leads to increased longevity, allowing rivet nuts to last over 10 years under proper conditions.

Rivet Nuts in Softwood:

- Weaker Connection: Softwood, with a density of 400-600 kg/m³, offers less grip, leading to weaker rivet nut connections.

- Lower Load Capacity: Softwood can only support moderate loads, with tensile strength averaging 30-45 MPa.

- Increased Risk of Loosening: The softness of the wood makes rivet nuts more prone to loosening under high torque (up to 5-10 Nm).

- Higher Risk of Cracking: Softwood may crack more easily due to lower resistance, especially when rivet nuts are over-tightened.

- Reduced Durability: The lower density of softwood leads to a shorter lifespan, typically around 5-7 years, compared to hardwood.

| Property | Hardwood | Softwood |

| Density | 600-900 kg/m³ | 400-600 kg/m³ |

| Strength | Stronger connection, higher load capacity | Weaker connection, lower load capacity |

| Torque Retention | Resists rotation, up to 10-15 Nm | Prone to loosening under high torque |

| Crack Risk | Lower risk of cracking | Higher risk of cracking |

| Durability | Longer durability, up to 10+ years | Shorter lifespan, typically 5-7 years |

| Tensile Strength | 40-60 MPa | 30-45 MPa |

What Kind of Rivet Nut is Suitable for Wood?

When selecting rivet nuts for wood, consider the material, shape and grip range. For wood, the rivet nut must provide a strong, secure connection without damaging the material.

1. Material

Aluminum rivet nuts and stainless steel rivet nuts are ideal for wood. They offer strength and corrosion resistance. Aluminum rivet nuts are lightweight, making them suitable for softer woods, while stainless steel is more durable for tougher applications.

2. Shape

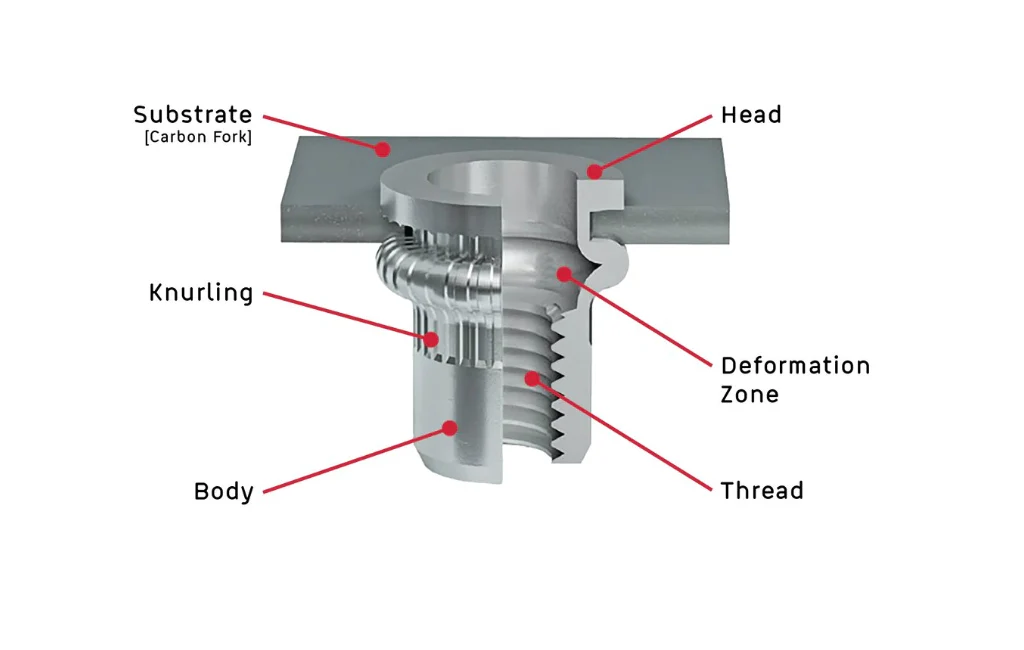

Round body rivet nuts are the most common and versatile design. They provide good load distribution and are easy to install. For higher torque resistance, hex body rivet nuts prevent rotation and ensure secure fittings.

Knurled body rivet nuts offer better grip in softer or thinner wood, improving installation and strength. The knurling helps prevent rotation and ensures better anchorage.

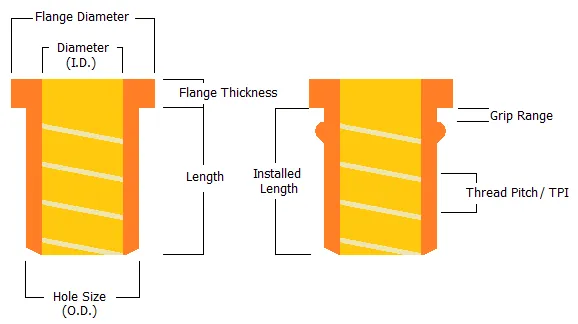

3. Grip Range

When selecting a rivet nut for wood, the rivet nut grip range is a critical factor. The grip range determines how much material thickness the rivet nut can securely fasten. Here’s how different grip ranges typically correspond to wood thickness:

- Narrow Grip Range: Suitable for materials with a thickness of 0.5mm to 2.5mm, ideal for thin wood such as plywood or softwoods.

- Medium Grip Range: Fits materials between 2.5mm to 6mm in thickness, offering a balance of strength and ease of installation for most standard wood applications.

- Wide Grip Range: Designed for materials from 6mm to 12mm thick, ideal for thicker wood or irregular surfaces where extra holding strength is needed.

How to Prevent Wood from Breaking During Installation?

1. Pre-drill Holes:

Drilling pilot holes before installing rivet nuts prevents splitting or cracking in the wood. The hole diameter should match the rivet nut’s body size for a snug and secure fit.

2. Select the Right Rivet Nut Size:

Ensure the rivet nut size fits the wood thickness to avoid excessive pressure. Refer to manufacturer specifications to ensure compatibility with the thickness and type of wood used.

3. Distribute Pressure Evenly:

To avoid concentrating stress on specific points, use washers or backing plates under rivet nuts. These components help spread the force evenly across the wood, reducing the risk of cracking or splitting.

4. Avoid Over-tightening:

Over-tightening rivet nuts or screws can lead to excessive pressure on the wood, causing cracks or splits. Tighten gently to prevent stress that could damage the wood while ensuring a secure, reliable connection. Using a torque wrench can help maintain consistent pressure and prevent over-tightening, protecting the integrity of the wood.

5. Choose Suitable Wood Types:

Select hardwoods, like oak or maple, for better strength and durability when using rivet nuts. Hardwoods provide better support, reducing the risk of damage during installation and ensuring a long-lasting connection. Avoid using softwoods like pine for high-stress applications, as they may not provide enough resistance to prevent damage.

How Improve the Durability of Rivet Nuts on Wood?

Use Quality Materials:

Materials like stainless steel or anodized aluminum offer superior corrosion resistance and strength. These materials prevent rusting and degradation over time, ensuring that the rivet nuts maintain their functionality in wood-based applications. Stainless steel, in particular, is known for its ability to withstand harsh environments, while anodized aluminum provides additional protection against wear and scratches.

Select Proper Grip Range:

Ensure the rivet nut’s grip range matches the wood’s thickness to avoid over-compression and ensure a secure fit. For thicker woods, choose rivet nuts with a wider grip range to ensure maximum stability and load distribution.

Opt for Knurled Rivet Nuts:

Knurled body rivet nuts have textured surfaces that provide better grip and anchorage in wood, especially in softer materials. The knurling increases friction between the rivet nut and the surrounding wood, preventing slipping or loosening over time. This feature is particularly useful in softwood or thin wood where traditional smooth rivet nuts might not hold as securely.

Apply Coatings:

Protective coatings like epoxy or powder coating help prevent corrosion, especially in moisture-prone or outdoor wood applications. These coatings create a barrier against rust and wear, ensuring that the rivet nut remains in good condition over time. Coatings also increase the rivet nut’s resistance to chemicals, reducing the risk of degradation in harsh environments.

Applications of Rivet Nuts in Wood

- Furniture Assembly: Rivet nuts securely connect wood furniture like chairs, tables, and cabinets. They attach hardware to kitchen and bathroom cabinets without damaging the wood.

- Woodworking Projects: Rivet nuts are perfect for DIY woodworking projects needing secure attachments without damaging the material. Carpenters use them for beams, frames, and panels.

- Automotive: In custom automotive projects, rivet nuts attach parts to wood panels in vehicle interiors.

- Displays and Shelving: Rivet nuts create sturdy connections for display racks, shelves, and storage units, especially in retail environments.

- Outdoor Structures: Rivet nuts secure fastenings in wood-based outdoor structures, withstanding weathering and heavy loads.

Do You Have Any Questions?

Let Us Solve Your Problem

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.