Can Rivnuts Be Used on Plastic?

Leading Rivet Nut Manufacturer and Supplier in China

When working with plastic components, especially in lightweight assemblies or electronics housings, a common question arises: can Rivnuts be used on plastic? While Rivnuts (riveted threaded inserts) are widely valued for creating strong threads in thin materials, their application on plastics is not as straightforward. Due to the relatively low strength and compressive resistance of many plastics, improper installation can lead to cracking, deformation, or long-term failure. In this article, we’ll explore the feasibility of using Rivnuts in plastic, potential risks, and best practices to ensure a secure and reliable fastening solution.

Table of Contents

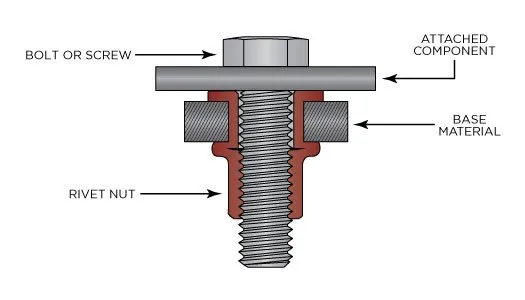

A Rivnut, also known as a rivet nut, is a single-use, plastic-deformation-based fastener specifically designed to solve the problem of creating threaded connections on thin-walled materials such as sheet metal or tubing, where traditional tapping is not feasible.

Its core working principle is to generate localized plastic deformation during installation, causing the tail end to expand and grip the base material, while forming a reliable internal thread for bolt fastening. The reliability of a Rivnut depends on its design, the mechanical properties of the base material, and the precision of the installation process. This is especially critical when used in low-strength materials like plastics, where support for the deformation zone and tensile/shear performance must be carefully considered.

a. Installation Process Explained

The installation of a Rivnut involves the following steps:

Drilling: A hole is drilled in the base material (such as plastic or metal) matching the outer diameter of the rivet nut.

Inserting the Rivnut: The rivet nut is inserted into the prepared hole, with the flange sitting flush against the surface.

Pulling the Mandrel: Using a rivet tool (manual, pneumatic, or electric), the threaded mandrel pulls on the internal thread, applying axial force.

Plastic Expansion: The tail end undergoes plastic deformation, bulging outward into a bell or bulge shape, gripping the backside of the material.

Installation Complete: The rivet nut is now firmly “locked” in place, offering a permanent internal thread for bolts or machine screws.

b. Core Principle: Plastic Deformation + Backside Clamping

Deformation Zone: The key deformation occurs at the cylindrical tail section, which expands and folds outward under axial tension, pressing against the backside of the base material.

Clamping Force: Created by the opposing pressure between the flanged head and the expanded tail, which sandwich the base material in between.

Three Key Factors for Secure Installation:

Strength of the Rivnut body (determines tensile and shear capacity);

Support strength of the base material (determines whether the load can be properly transferred);

Installation quality (including pull force control, hole size tolerance, perpendicularity, etc.).

3. Load Transfer Mechanism

Axial Load: For example, when a screw is tightened into the Rivnut, the axial load is transferred through the threads to the deformed tail, which disperses the force across the base material.

Shear Load: When lateral forces are applied, the shear resistance comes from the friction and interference fit between the Rivnut’s body and the base material.

Importance of Base Material:

Compressive Strength: Determines if the flange can be firmly seated without sinking.

Tensile Strength: Ensures the Rivnut won’t be pulled out under load.

Edge Support: Especially important for plastics and soft materials where weak edge support may lead to loosening or failure.

4. Compatibility with Different Materials

Metal Substrates: Offer strong support and grip, making them ideal for most Rivnut applications.

Plastic Substrates: Due to their softer nature and lower tensile/compressive strength, Rivnuts may become loose, rotate, or pull out over time unless specifically designed (e.g., knurled or anti-rotation types) or substituted with more suitable alternatives (e.g., threaded inserts).

What Are the Key Characteristics of Plastic Materials?

When considering the installation of Rivnuts (rivet nuts) into plastic materials, it is essential to understand the physical and mechanical properties of plastics. Compared to metals, plastics offer several notable advantages, but also have inherent weaknesses when it comes to structural fastening:

Advantages:

Lightweight

Plastics have much lower density than metals, making them ideal for lightweight product designs, such as in consumer electronics, household appliances, and automotive interiors.

High Design Flexibility

Plastics can be easily molded into complex geometries using injection molding and similar processes. This allows for integrated designs and greater flexibility in pre-positioning mounting inserts.

Excellent Electrical Insulation

Plastics are naturally non-conductive, making them suitable for electrical enclosures, PCB components, and other applications where insulation is critical.

Corrosion Resistance

Plastics naturally resist corrosion and do not rust, making them ideal for use in humid or outdoor environments where metal fasteners might degrade over time.

Weaknesses:

Low Compressive Strength

Compared to steel or aluminum, the compressive strength of plastics is only a fraction, making them prone to crushing or deformation under riveting forces.

Susceptibility to Deformation

Plastics deform more easily under localized pressure. During installation, this can result in permanent distortion that compromises the clamping force of the rivet nut.

Creep Behavior

Under continuous load, plastics tend to deform gradually over time — a phenomenon known as creep — which may eventually cause the Rivnut to loosen or fail.

High Thermal Expansion Coefficient

Plastics expand and contract significantly with temperature changes. If the Rivnut is constrained and there’s insufficient space for expansion, it may lead to stress concentration, cracking, or pull-out failure.

Can Rivnuts Be Used on Plastic?

Rivnuts (rivet nuts) can be used on plastic materials, but they are not an ideal solution. Due to the inherent limitations of plastic as a material, several structural problems and risks may arise during installation and long-term use of rivet nuts.

Potential Structural Risks:

1. Weak Clamping and High Risk of Pull-Out

Rivnuts rely on the plastic deformation of their metal tail to grip the base material. However, plastics — especially common thermoplastics like ABS and PP — are relatively soft and have low compressive strength, which can lead to:

Crushing or tearing of the plastic under the force of the rivet nut;

An inability to generate enough counterforce to secure the nut, resulting in installation failure or weak fastening.

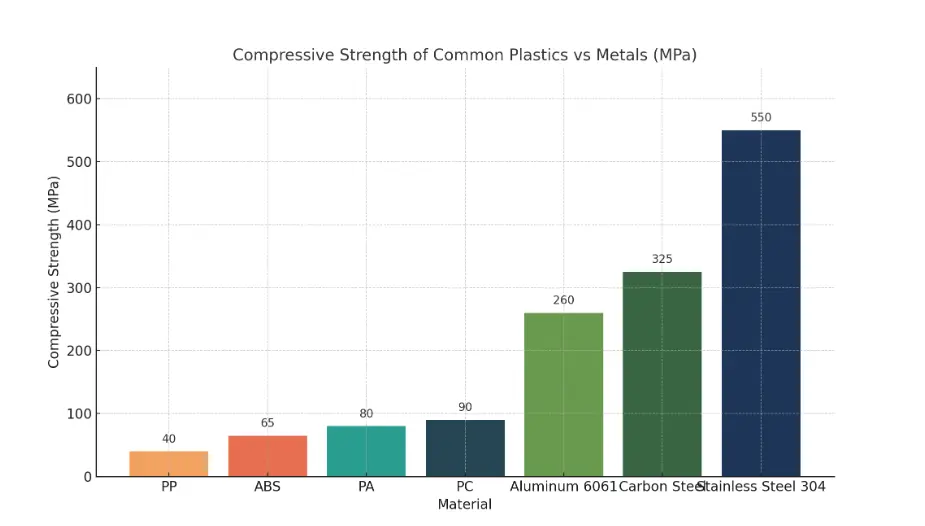

To better illustrate the softness and low compressive strength of plastics, we can compare the compressive strength of common plastics (e.g., ABS, PP) with that of metals (e.g., steel, aluminum). The following is a data overview with a comparison chart:

a. Compressive Strength Comparison of Common Materials (Unit: MPa)

| Material | Type | Compressive Strength Range (MPa) |

| ABS | Thermoplastic | 55 – 75 |

| PP (Polypropylene) | Thermoplastic | 30 – 50 |

| PA (Nylon) | Thermoplastic | 70 – 90 |

| PC (Polycarbonate) | Thermoplastic | 80 – 100 |

| Aluminum Alloy 6061 | Metal | 240 – 280 |

| Carbon Steel (AISI 1018) | Metal | 250 – 400 |

| Stainless Steel 304 | Metal | 500 – 600 |

b. Compressive Strength Comparison Chart (Plastic vs Metal)

c. Conclusion and Explanation

- PP and ABS have compressive strength of only 30–75 MPa, which is significantly lower than that of metals like aluminum and stainless steel (hundreds of MPa).

- Even relatively “hard” plastics like PC have a compressive strength that is only one-fifth to one-sixth that of metal.

- This explains why: under high loads or clamping forces, plastics are prone to localized compression, deformation, or even cracking.

- Therefore, using Rivnuts in plastic without structural reinforcement often results in insufficient clamping, loosening, or material damage.

2. Loosening or Pull-Out of Rivnuts

Under long-term exposure to vibration, sustained loads, or thermal cycling, the structural stability of plastics is significantly lower than that of metals. This can result in:

Relaxation or slippage in the riveted area;

The Rivnut rotating within the hole, leading to thread failure;

Complete pull-out of the Rivnut from the plastic base material.

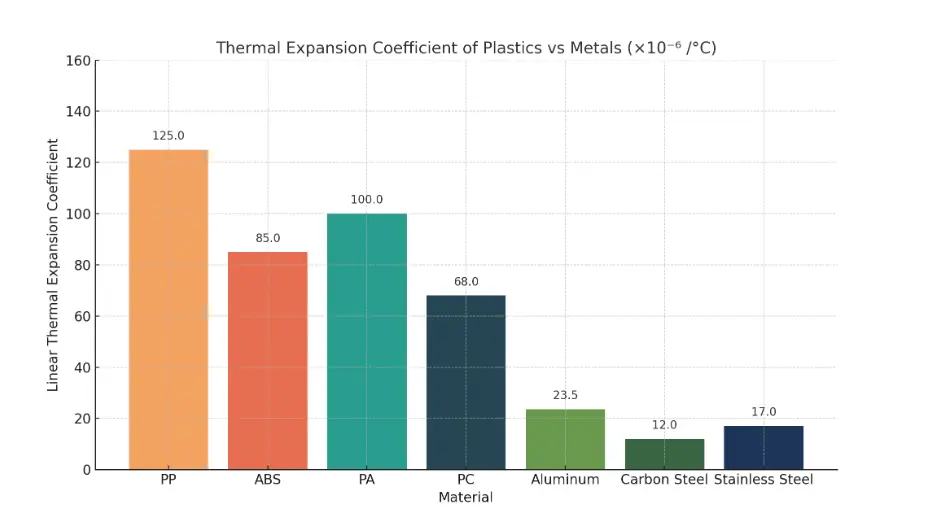

a. Thermal Expansion Comparison (Coefficient of Linear Thermal Expansion)

The Coefficient of Linear Thermal Expansion (CLTE) indicates how much a material expands or contracts per degree Celsius of temperature change, typically measured in ×10⁻⁶ /°C.

Chart: CLTE of Plastics vs. Metals

The chart clearly demonstrates that plastics (e.g., PP, ABS) have much higher CLTE than metals (e.g., stainless steel, aluminum). This means plastics are more prone to dimensional changes and structural instability under temperature fluctuations.

Plastic materials typically have a thermal expansion coefficient 3 to 10 times higher than that of metals. As a result, in environments with large temperature variations, plastic structures can expand or contract significantly, which can lead to loosening of the riveted joint or stress-induced cracking. This is one of the main reasons why plastic is not suitable as a base material for precision fastening in thermal cycling conditions.

b. Creep Behavior Comparison (Deformation Under Long-Term Load)

| Material | Type | Strain Over 1000 Hours at 23°C (%) |

| PP | Plastic | 1.5 – 3.0 |

| ABS | Plastic | 1.0 – 2.0 |

| PC | Plastic | 0.5 – 1.5 |

| Aluminum Alloy | Metal | < 0.1 |

| Steel | Metal | < 0.01 |

Plastics exhibit significant creep — gradual and permanent deformation — under sustained loads, especially in warm environments.

Creep is the time-dependent deformation of a material under constant stress or load. It is particularly common in plastics, rubbers, and high-temperature metals. Even if the initial fastening is firm, over time, molecular chain movement and internal relaxation in plastics lead to a loss of shape and dimensional integrity, causing gradual loosening of the joint.

Factors such as higher temperatures, greater loads, and longer durations accelerate this process — particularly in thermoplastics like PP, ABS, and PA.

Creep-related Rivnut failure risks:

- Initially, the Rivnut appears firmly secured as its deformed tail grips the plastic panel;

- Over time, micro-deformation occurs in the pressure zones around the Rivnut, reducing clamping force;

- After weeks or months, the joint loosens, the Rivnut may begin to rotate, shift, or even fall out;

- Additionally, localized stress concentration can result in fatigue cracking or structural failure.

Metals, by contrast, exhibit negligible creep, maintaining long-term structural stability.

c. Fatigue Life Comparison (Vibration Conditions)

- Plastic fatigue life: Typically 10⁴ to 10⁵ cycles, which drops significantly under high stress.

- Metal fatigue life (e.g., stainless steel, aluminum): Often 10⁷ to 10⁸ cycles or infinite below the fatigue limit.

Plastics are prone to developing micro-cracks under cyclic stress or vibration, giving them far lower fatigue resistance compared to metals. This presents serious reliability concerns in automotive, aerospace, and heavy industrial applications.

3. Panel Damage or Stress Cracking During Installation

When using a metal Rivnut on a plastic substrate, the installation process—relying on radial expansion and clamping force—can trigger several structural issues in the plastic component. These issues include:

a. Surface Indentation and Localized Compression Damage

Source of Installation Force: During installation, the Rivnut is pulled axially using a special tool, causing the tail to expand and clamp tightly against the material wall.

Limitations of Plastic: Thermoplastics like ABS and PP typically have compressive strength of only 30–75 MPa, while the installation force of metal Rivnuts can reach several hundred newtons, greatly exceeding the localized bearing capacity.

Consequences: At the contact surface (flange area) or in the expansion zone of the nut, the plastic may experience indentation, compressive yielding, or permanent deformation, affecting both structural accuracy and visual aesthetics.

b. Internal Stress Concentration Leading to Crack Propagation

Stress Concentration Mechanism: Plastics are more brittle than metals and tend to form stress concentration points at sharp edges, hole boundaries, and wall-thickness transitions.

Installation-Induced Disturbance: Improper installation—such as an undersized hole or excessive pulling force—can cause the Rivnut to tear into the hole wall, initiating microcracks.

Crack Development: These microcracks may propagate under thermal cycling, mechanical impact, vibration, or repetitive tightening/loosening, eventually leading to full structural failure. This is especially pronounced under creep or fatigue conditions.

Mechanical Behavior of Plastics During Rivnut Installation

| Material | Compressive Strength (MPa) | Installation Force (N) | Risk Assessment |

| ABS | 60 – 75 | 500 – 1000 | High force may cause dents or flange cracks |

| PP | 30 – 50 | 400 – 800 | Highly prone to indentation or installation failure |

| PC | 70 – 90 | 600 – 1200 | Risk of cracking without ribs or washers |

| Aluminum Alloy | 250+ | 600 – 1200 | No deformation or cracking; structurally stable |

Engineering Recommendations

- Use Rivnuts with larger flanges or add backing washers to distribute stress more evenly;

- Consider replacing metal Rivnuts with heat-set brass inserts or molded-in nuts for better compatibility with plastics;

- Chamfer hole edges, increase wall thickness, or add reinforcement ribs around the mounting area;

- Prefer glass fiber-reinforced plastics (e.g., GF30 PA) over standard ABS or PP to improve load-bearing performance.

Recommended Alternative Fastening Solutions

When working with plastics or other low-strength materials, directly using metal Rivnuts can lead to deformation, cracking, or loosening. Therefore, in structural design or mass production scenarios, the following fastening solutions are more suitable and highly recommended:

Threaded inserts are embedded metal fasteners with external features such as knurling, helical threads, or barbs that lock into the plastic via mechanical engagement. They are installed using either pressure or heat, forming a secure bond with the surrounding material and allowing for repeated screw insertions.

Installation Methods: Press-fit, Heat insertion, Ultrasonic welding

Advantages:

Strong mechanical anchoring with excellent pull-out and torque resistance

Durable and reusable for repeated assembly

High precision, suitable for structural alignment and positioning

Jack nuts are hollow, expandable fasteners. During installation, tightening the screw causes the rear metal legs to fold and flare out behind the panel, creating a broad grip surface and mechanical interlock.

Key Features:

Wide support area reduces localized stress on plastic

Suitable for thin or soft materials

Low tolerance requirements for hole accuracy

Advantages:

Less risk of damaging or cracking the plastic

Ideal for blind installations and easy maintenance

Can be installed on curved or uneven surfaces

Clinch nuts are pressed into pre-punched holes using a mechanical press. They rely on serrated edges or anti-rotation shoulders to form a strong mechanical lock with the base material.

Advantages:

No heat involved—ideal for heat-sensitive materials

High resistance to rotation and loosening

Flush, clean appearance after installation—suitable for aesthetic applications

Limitations:

Requires dedicated pressing equipment

Not suitable for very thin or soft materials

Conclusion: Can Rivnuts Be Used on Plastic?

Overall, it is not recommended to use metal Rivnuts directly in standard plastic materials, especially in applications involving high loads, frequent disassembly, or critical structural functions. This is due to the inherently low compressive strength of most plastics, which makes them prone to deformation, cracking, or creep under tension or localized pressure, resulting in poor long-term stability.

If the use of Rivnuts is absolutely necessary, you should ensure the plastic is a high-strength engineering material (such as PA6+GF30 or PC-GF20). Additionally, incorporate reinforcement structures like metal backing plates or washers, and apply design optimizations such as large-flange Rivnuts, slotted body designs, and controlled installation force to minimize stress and improve reliability.

However, from the perspective of reliability, reusability, and long service life, it is generally more advisable to select fastening solutions better suited for plastics—such as heat-set brass inserts, embedded threaded inserts, or jack nuts. These alternatives offer a safer and more durable connection, making them the preferable engineering solution in most plastic assembly applications.

What Are the Best Practices for Using Rivnuts on Plastic Materials?

Installing metal Rivnuts on low-strength substrates such as plastic is not entirely infeasible—but it requires specific structural optimizations and auxiliary techniques, otherwise failure is highly likely. Below are the key optimization strategies:

1. Choose Large Flange Type Rivnuts

Main Purpose:

Increase the contact surface area to reduce unit pressure, avoiding surface indentation or damage to the plastic material.

Technical Notes:

Large flange heads typically have 30%+ larger diameter than small flange or countersunk types;

The larger the flange, the lower the pressure per unit area, reducing the risk of sinking;

Effectively distributes axial load during installation, ideal for soft plastics like PP, ABS, or PE.

Recommended Use:

Use when there are no space restrictions behind the panel and no aesthetic requirements for flush surfaces.

2. Use Rivnuts Designed for Soft Materials (e.g., Slotted Body Types)

Optimized Designs:

Slotted body design: allows the tail to expand more easily radially, achieving sufficient clamping force at lower axial loads;

Knurled shank: improves friction and enhances resistance to rotation.

Advantages:

Slotted types are well-suited for ABS, PP, HDPE, providing gentler deformation;

Reduce direct compression on hole walls, lowering the risk of damaging hole edges;

Some models include barbs or grooved flanges to enhance pull-out resistance.

3. Add Backing Plate or Reinforcement Plate

Structural Strategy:

Add a metal washer or steel backing plate behind the Rivnut mounting hole;

Recommended thickness ≥ 1.0 mm; materials include stainless steel, galvanized steel, or aluminum;

Backing plates significantly improve clamping stiffness and prevent creep or collapse of the plastic under stress.

Additional Tips:

The plate should be aligned coaxially and flush against the plastic base;

When possible, use metal inserts or embedded frames for added support.

4. Control Installation Force to Prevent Overcompression

Main Risk:

Plastic yield strength is much lower than metal. Using standard torque during installation can easily cause:

Cracking around the hole;

Panel deformation;

Rivnut loosening or pull-out.

Recommended Practices:

Use a torque-controlled pneumatic Rivnut tool;

When using a manual tool, apply force gradually and observe flange seating;

First test on a scrap part to determine the optimal pull force range.

Do You Have Any Questions?

Let Us Solve Your Problem

Buy Rivet Nuts from Rivetfix

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world. We offers a wide range of rivet nuts and clinch nuts designed to meet the unique demands of your projects. Rivetfix ensures you have the right solution for every application. Choose Rivetfix for versatile, cost-effective, and durable fastening solutions tailored to your specific needs. In addition, we can also provide customized rivet nuts service and clinch nuts according to your requirements.

Contact us now for more information and customization options on Rivet Nuts!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.