Home » Knurled Rivet Nuts

Order Knurled Rivet Nuts from Rivet Nut Factory

Knurled rivet nuts provide high anti-rotation performance and stable clamping force due to their knurled pattern design. The knurled pattern on the outer wall creates a higher friction with the bore wall of the base material to ensure a reliable connection under high torque or vibration conditions.

Knurled body rivet nuts are available in steel, stainless steel, aluminum, and copper for a variety of strength requirements and environmental conditions.

If you need to buy knurled body rivnuts in bulk, please contact us!

Professional Rivet Nuts Manufacturer

Enhance Your Rivet Nuts Business

Rivetfix has received various certifications for its rivet nut products. We have not listed all certificates here, please contact us if you require more information on certifications or need a customized product certificate. We are committed to providing Rivet Nuts that meet IATF 16949, ISO 9001, RoHS, REACH and other standards. Buy rivet nuts Now!

Steps to Custom High Quality Rivet Nuts

01

Send Rivet Nut Inquiry

Contact us and send us your rivet nut sourcing requirements. Include type, quantity and requirements.

02

Samping and Sample Testing

You will receive a sample of the rivet nut within a week.

03

Confirmation and Production

Sample approval, production according to drawings

04

Delivery and Shipping

You need to pay the final payment of the order. Then we will ship your rivet nut order to your country.

FAQs About Knurled Body Rivet Nuts

What are Knurled Body Rivnuts ?

Rivnuts with knurled body are a type of rivet nut with a knurled pattern designed on the outer wall. This design allows the rivet nuts to prevent rotation by increasing friction within the round hole.The features of Knurled body rivnuts are as follows:

- The knurled pattern enhances the bite between the nut and the base material.

- Single side mounting for closed structures

Rivnuts with knurled body are ideal for use in applications where high spin stability is required.

What is the Difference Between Knurled Rivet Nut and Regular Rivet Nuts?

The main differences between Knurled body rivet nut and regular rivet nuts are as follows:

- Knurled design: rivnuts with knurled body have knurled pattern on the outer wall for better anti-rotation performance.

- Scenarios: knurled rivet nuts are suitable for high torque or applications that require stronger anti-rotation. And ordinary round body rivet nuts have weaker anti-rotation capability.

Types of Knurled Body Rivet Nuts

Knurled rivet nuts are categorized by head type and the common types are as follows.

- Flat Head: Can provide a large contact area.

- Reduced Head: Suitable for concealed installation.

- Countersunk Head: Suitable for scenarios where a flat surface is required.

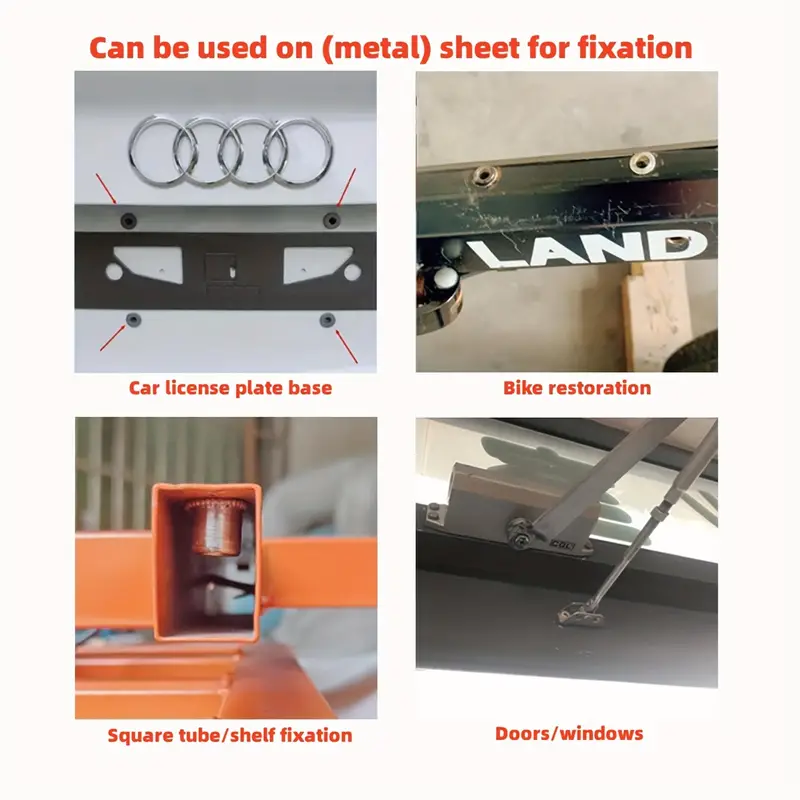

Applications of Knurled Body Rivnuts

Common application scenarios for rivnuts with knurled body are as follows.

- Automotive industry: door hinges, bracket fixing, connection of interior panels or light sheet metal parts.

- Industrial equipment: equipment frames, housing splices.

- Electronic equipment: plastic housings, metal bracket mounting.

- Construction industry: fixing of curtain walls, splicing of parapets.

- Furniture manufacturing: combination of wood and metal frames

Is it possible to use knurled rivnuts in a corrosive environment?

Knurled rivnuts can be made from stainless steel. Stainless steel knurled body rivnuts perform very well in corrosive environments!

Is it possible to use knurled rivnuts in high temperature scenarios?

Regarding whether knurled rivet nuts can be used in high-temperature applications, it largely depends on which material is used to produce the rivet nut.

- Stainless steel and steel rivet nuts are excellent for high temperatures.

- Aluminum and brass are suitable for low to medium temperatures.

Get a Free Quote Now!

We believe Rivetfix will be your best partner!

Please fill out the form with your contact details or contact our whatsapp, and we will get back to you within 24 hours.