Buy PEM Nuts Online: The Ultimate Guide to Reliable Industrial Fastening

Leading Self-Clinching Fasteners Manufacturer and Supplier in China

Buy pem nuts online (PEM® is a registered trademark of PennEngineering) delivers unmatched efficiency, cost control, and access to global suppliers—but only when you avoid compatibility pitfalls and quality risks. This ultimate guide decodes precision sourcing: explore expert insights on material selection, ISO-certified suppliers, installation best practices, and proactive maintenance strategies. Whether optimizing production lines or prototyping innovations, discover how to leverage PEM nuts’ vibration resistance and space-saving design while sidestepping costly errors.

Table of Contents

Definition

PEM nuts (also known as Self-Clinching Nuts) are specialized fasteners designed with integrated anti-loosening mechanisms (e.g., nylon inserts, serrated rings, or deformed threads). They are permanently embedded into thin metal sheets using a cold-forming clinching process. Once installed, the threaded portion protrudes from the opposite side of the sheet, enabling secure bolt or screw engagement for robust, vibration-resistant connections.

Design Features:

- Single-Sided Installation: Requires only one-side access, eliminating dual-side tooling.

- Anti-Vibration Locking: Mechanical deformation or friction-based locking mechanisms prevent loosening under shock or dynamic loads.

- Thin-Sheet Compatibility: Optimized for metal sheets ranging from 0.5mm to 6mm thick (aluminum, stainless steel, etc.).

Core Applications

PEM nuts solve critical challenges in thin-sheet assembly, ideal for high-stability, anti-vibration scenarios:

- Electronics: Securing PCBs, server chassis, and switch enclosures.

- Automotive: Sheet metal body panels, battery tray mounts, sensor brackets.

- Aerospace: Lightweight aluminum framing, avionics panel components.

- Industrial Machinery: Control cabinets, motor housings, robotic arm structures.

- Household Appliances: Drum assemblies in washing machines, compressor mounts in HVAC systems.

Key Industries: Electronics, automotive, medical devices, robotics, and renewable energy sectors demanding high stability and space efficiency.

Key Advantages

1. Superior Anti-Loosening Performance

- Vibration/Shock Resistance: Internal locking mechanisms ensure long-term stability, reducing equipment downtime.

- Fatigue Resistance: Maintains integrity under repetitive dynamic loads (e.g., high-frequency motor vibrations).

2. Optimized Assembly Time and Cost Efficiency

- Streamlined Process: One-step clinching eliminates welding, riveting, or secondary locking tools.

- Production Scalability: Enables automation integration, cutting assembly cycles by up to 40% (industry benchmarks).

3. Design Optimization

- Space-Saving Profile: Eliminates nut retention space, reducing component weight by 15–30% in lightweight designs.

- High-Strength Integration: Clinching bonds the nut with the host sheet, achieving 2–3x higher pull-out strength than standard nuts.

4. Reduced Lifecycle Costs

- Permanent Installation: Minimizes maintenance from loosening, extending equipment lifespan.

- Corrosion-Resistant Options: Stainless steel grades (304/316) or specialized coatings (zinc-nickel, Dacromet) for harsh environments.

| Traditional Nuts | PEM Nuts |

| Require dual-side access or welding | Single-sided clinching for rapid sheet embedding |

| Prone to vibration-induced loosening | Active anti-vibration locking for superior stability |

| Labor-intensive installation with tools | Automation-friendly process, cutting assembly time by 40%+ |

Why Buy PEM Nuts Online?

Buy PEM nuts online goes beyond conventional “e-commerce” practices, instead embodying the intellectualization of modern industrial procurement. Whether optimizing supply chains for large enterprises or meeting the agility demands of individual makers, online platforms effectively redefine efficiency and reliability in fastener sourcing. This is achieved through specialized services, data-driven precision, and adaptive supply networks, which together ensure a more streamlined and responsive procurement process.

Key Advantages

Buy PEM nuts online delivers professional-grade solutions while enhancing cost control and operational efficiency.

1. One-Stop Product Diversity

- Comprehensive Specifications: Platforms offer M2 to M12 thread sizes, materials (stainless steel, carbon steel, brass), and compatibility with sheet thicknesses (0.5mm to 6mm), enabling rapid demand matching.

- Specialized Variants: Select suppliers provide corrosion-resistant coatings (zinc-nickel, Dacromet®) and ultra-high-strength options (e.g., Class 12.9) tailored to niche applications.

2. Cost-Effective Procurement

- Transparent Pricing: Real-time catalogs display unit prices and volume discounts (e.g., 30% off orders ≥100 units), bypassing time-consuming offline negotiations.

- Logistics Flexibility: Options range from B2B bulk shipping for long-term inventory to expedited delivery for urgent replenishment.

3. Technical Support Accessibility

- Precision Filtering: Advanced search tools identify products compliant with ISO 9001, DIN, or other industry standards.

- Documentation Integration: Instant access to CAD drawings, 3D models, and installation guides ensures seamless collaboration with engineering teams.

4. Enhanced Decision-Making

- Peer Reviews: Authentic feedback from manufacturers (e.g., “excellent thermal resistance for motor enclosures”) aids quality assessment.

- Real-Time Inventory Visibility: Eliminate stockout delays with live inventory tracking, pre-order reservations, and cross-warehouse allocation.

5. Post-Pandemic Supply Chain Resilience

- Risk Mitigation: Multi-supplier redundancy reduces dependency on single-source disruptions.

- Global Sourcing: Cross-border platforms enable procurement of premium brands (e.g., German/Japanese suppliers), overcoming geographical constraints.

Target Audiences

1. Procurement Managers in Manufacturing

- Challenge: Rapid supplier comparison and guaranteed delivery timelines.

- Solution: Generate instant quotes and place bulk orders via industrial platforms (e.g., Misumi, Fasto), with real-time logistics tracking.

2. Mechanical Engineers & Designers

- Challenge: Validating nut-to-sheet compatibility to prevent design revisions.

- Solution: Download dimension templates and load capacity data for direct CAD integration.

3. SME Owners

- Challenge: Limited order quantities rejected by offline vendors or inflated pricing.

- Solution: Leverage small-order policies (e.g., 50-unit MOQ) to minimize inventory costs.

4. DIY Enthusiasts & Makers

- Challenge: Local shortages of specialized nuts (e.g., ultra-thin stainless steel variants).

- Solution: Source small batches through Amazon Industrial or eBay for prototyping.

5. Maintenance Teams

- Challenge: Urgent replacement of failed components with slow offline lead times.

- Solution: Utilize localized platforms (e.g., RS Components) offering same-/next-day delivery for rapid crisis response.

Key Considerations for Online Procurement of PEM Nuts

Material Selection

- Stainless Steel (e.g., Grade 316)

- Tensile strength: ≥515 MPa (ASTM A276 standard);

- Salt spray resistance: >500 hours (per ASTM B117), ideal for marine/chemical environments.

- Carbon Steel (Zinc-Plated)

- Cost: 30–50% lower than stainless steel;

- Corrosion resistance: Limited to 72-hour salt spray exposure, suitable for general industrial use.

- Aluminum Alloy (e.g., 6061-T6)

- Density: 2.7g/cm³ (65% lighter than steel), optimal for weight-critical applications (e.g., drones).

Specification Matching

- Thread Size

- Automotive: M6-M8 (supports 80–200N·m torque);

- Electronics: M2-M4 for compact assemblies.

- Sheet Thickness Compatibility

- Example: PEM® SJ-series nuts require 0.8–1.5mm sheet thickness;

- Deviation penalty: Exceeding range reduces tensile strength by ≥30% (manufacturer test data).

- Clinching Force

- Industry standard: 20–50kN (ISO 16582 compliant).

Certification Standards

- ISO 9001: Certified suppliers exhibit <0.2% defect rates vs. >1% for uncertified vendors (ASQ 2022 report).

- RoHS Compliance: Mandatory for EU markets: Hazardous substances restricted (e.g., Pb <0.1%, Cd <0.01%).

- IATF 16949: 75% of automotive buyers prioritize IATF-certified fastener suppliers (Deloitte Automotive Survey).

Supplier Qualifications

- Technical Support: Leading platforms (e.g., McMaster-Carr) provide 3D models for >90% of products.

- Customer Reviews: Suppliers rated 4.5/5+ achieve >95% on-time delivery (Thomasnet 2023 data).

- Warranty Policies: Top-tier vendors offer 30-day no-hassle returns and liability coverage for non-conforming products.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Select Reliable Suppliers?

Evaluation Metrics

1. Certifications & Quality Control

- Certification Coverage: Prioritize suppliers certified to ISO 9001 (15% improvement in yield rates) and IATF 16949 (mandatory for automotive applications).

- Testing Capabilities: Verify advanced equipment like spectrometers (material composition analysis with <0.01% error) or tensile testers (load accuracy ±1%).

2. Technical Documentation & Support

- 3D Model Availability: Leading suppliers (e.g., McMaster-Carr) provide downloadable CAD models for >95% of products.

- Response Efficiency: Top-tier vendors resolve technical queries within ≤2 hours, boosting customer satisfaction by 40% (Supply Chain Digest, 2023).

3. Customer Reviews & Delivery Performance

- Rating Authenticity: Select suppliers with ≥4.5/5 ratings (per Thomasnet) and >100 verified reviews.

- On-Time Delivery: Industry benchmark is ≥98% (e.g., Fasto achieves 99.2%).

- Stock Breadth: Major distributors (e.g., RS Components) maintain >100,000 SKUs for urgent order fulfillment.

4. Cost Efficiency & Flexibility

- MOQ Flexibility: SME-friendly platforms (e.g., AliExpress) allow trial orders of 1–50 units, vs. traditional B2B ≥1,000-unit MOQs.

- Price Stability: Long-term contracts with price-fluctuation clauses reduce procurement costs by 10–30% (steel market benchmark).

Global Supplier Recommendations

| Supplier Type | Recommended Brands/Platforms | Core Advantages | Ideal Use Cases |

| Comprehensive Industrial Supplier | McMaster-Carr (USA) | • 5.5M+ product catalog, 48-hour delivery across the US<br> • 100% PDF spec sheet coverage | Urgent orders in North America, multi-category procurement |

| Precision Standard Components Expert | Bossard (Switzerland) | • Local warehouses in 63 countries, full batch traceability to OEM standards<br> • Free torque calculation tools | Automotive, medical, and other high-compliance industries |

| Localized Asian Supplier | Rivetfix (China) | • 50% cost savings through domestic alternatives<br> • Diverse customization support (e.g., material, coating) | Cost optimization & rapid replenishment for Chinese manufacturing |

| Small-Batch/Maker-Friendly Platform | Amazon Industrial | • 1-unit MOQs, Prime logistics<br> • 3,000+ self-clinching nut models ranked by verified reviews | Prototyping, DIY projects, and low-volume R&D |

| High-End Custom Supplier | PEM® (USA) | • 3x longer corrosion resistance with nanocoating technology<br> • Free installation force simulation data | Military, aerospace, and mission-critical applications |

Pro Tip: Request free samples to validate material quality and compatibility (≥90% of qualified suppliers offer this service).

Common Buying Pitfalls & Avoidance Strategies

Error Cases & Solutions

1: Ignoring Environmental Compatibility

- Case Study: Carbon steel nuts corroded after 6 months in marine equipment due to salt spray exposure, causing joint failure.

- Solution: Use 316 stainless steel (>1,000-hour salt spray resistance per ASTM B117) or nickel-plated variants (720-hour resistance) for humid/chemical environments.

2: Overprioritizing Low Cost

- Case Study: Nuts purchased at ¥0.2/unit had tensile strength of 300N (below 800N GB/T 3098.2 requirement), risking structural collapse.

- Solution: Benchmark against market rates (e.g., ¥1.5–3/unit for 304 stainless M4 nuts) and reject prices 30% below industry averages.

3: Inaccurate Specification Matching

- Case Study: Nuts designed for 1.5mm sheets forced into 3mm sheets caused 40% drop in pull-out strength and sheet deformation.

- Solution: Adhere to supplier clinching force guidelines (e.g., PEM® specifies 15kN ±10% for M5 nuts).

4: Neglecting Technical Support

- Case Study: A 0.5mm CAD model discrepancy halted production for 48 hours.

- Solution: Source suppliers offering 3D downloads and free engineering support (e.g., YIHEDA with 98% response rate).

5: Underestimating Long-Term Demand

- Case Study: Unprotected steel price surges increased procurement costs by 25% post-order.

- Solution: Negotiate price fluctuation clauses (e.g., ±5% price locks) in bulk purchase agreements.

Quick Self-Checklist

- Material-Environment Match: Acidic → Stainless steel; Lightweight → Aluminum alloy.

- Sheet Thickness Validation: Confirm compatibility with nut specs (e.g., 0.5–6mm range).

- Third-Party Test Reports: Demand ISO/IEC 17025-certified lab results.

- Logistics Alignment: For urgent orders, prioritize local stock (e.g., Bossard EU hubs).

- Free Sample Testing: 80% of reputable suppliers offer trial samples (Thomasnet 2023).

Post-Purchase Installation & Maintenance Guidelines

Installation Steps

1. Tool Preparation:

- Use dedicated clinching presses (e.g., pneumatic presses) to avoid deformation from hammering.

- Clean installation surfaces to remove oil, debris, or burrs.

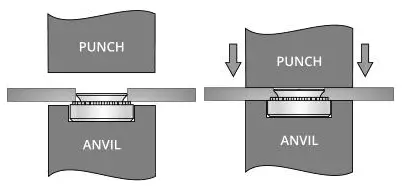

2. Positioning & Clinching:

- Precise Alignment: Vertically insert the nut into a pre-punched hole (hole diameter tolerance: ±0.05 mm).

- Force Calibration: Set clinching force per specifications (e.g., 12–15 kN for M4 stainless steel nuts).

- Single-Stroke Operation: Apply uniform pressure until the nut is flush with the sheet. No post-adjustments permitted.

Maintenance Best Practices

1. Inspection Intervals:

- High-Vibration Environments (e.g., motors): Inspect nuts quarterly for loosening.

- Static Load Applications (e.g., control cabinets): Annually audit 5–10% of installed nuts.

2. Maintenance Procedures:

- Corrosion Prevention: Apply molybdenum disulfide grease (-30°C to 300°C/-22°F to 572°F resistant) to threads in humid environments.

- Failure Response: Immediately replace nuts if sheet cracking or rotation occurs; reinforce damaged areas with backing plates.

Prohibited Actions:

- Welding or grinding installed nuts (compromises pre-load stress).

- Exceeding manufacturer-rated loads (e.g., applying 80kg to a 50kg-rated nut).

Common Issues & Emergency Solutions

| Issue | Potential Causes | Resolution |

| Post-installation nut loosening | Insufficient clinching force or oversize hole | Replace with larger nuts or re-clinch with +10% force (per ISO 16582). |

| Thread stripping/bolt misalignment | Over-torque or foreign particle ingress | Use thread repair kits (e.g., Heli-Coil®) or replace nuts. |

| Sheet deformation/cracking | Sheet thickness exceeds nut capacity | Upgrade to higher-strength nuts (e.g., Class 12.9) or increase sheet thickness. |

| Corrosion at contact surfaces | Material-environment mismatch (e.g., carbon steel in outdoor use) | Replace with 316 stainless steel nuts and apply anti-corrosion coatings. |

Do You Have Any Questions?

Let Us Solve Your Problem

With 15+ years of experience in fastener manufacturing, Rivetfix has grown into a trusted global supplier. Today, we have a dedicated team of 200+ skilled production workers and 40+ professional sales representatives, ensuring seamless service and reliable supply.

Our vision is simple yet powerful: to provide the highest-quality fasteners at competitive prices to customers worldwide. In doing so, we combine precision manufacturing, efficient operations, and exceptional customer support. As a result, we are committed to helping businesses build stronger, more cost-effective solutions. Through this approach, we aim to consistently exceed customer expectations and foster long-term partnerships.

Partnering with Rivetfix means stable supply, top-quality fasteners, and custom solutions. We help you cut costs, boost efficiency, and enhance durability. Expect on-time delivery, expert support, and innovation. Let’s grow together!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.