Home » Stainless Steel Jack Nuts

Buy Stainless Steel Jack Nuts - Bulk Jack Nuts Supply

Buy Stainless Steel Jack Nuts directly from the factory!

Stainless Steel Jack Nuts are high-strength fasteners specifically designed for soft or thin-walled materials. They are suitable for materials such as plastic, composite materials, and thin metal sheets, allowing for even load distribution during assembly, preventing material deformation or damage.

Made from 304 or 316 stainless steel, Stainless Steel Jack Nuts offer excellent corrosion resistance, making them particularly ideal for applications in environments requiring high corrosion resistance, such as outdoor and marine settings.

Product Features

- Material: Made of 304 or 316 stainless steel, providing superior corrosion resistance.

- Corrosion Resistance: Suitable for humid, high-temperature, or chemical environments, such as marine industries and outdoor equipment.

- High Strength: Offers excellent tensile and shear strength, making it suitable for high-load applications.

- Versatility: Compatible with metals, plastics, composite materials, and other base materials.

Purchasing and Customization Options

- Available in various sizes, materials, and bulk purchasing options.

- Custom products available to meet specific application requirements.

- Contact us for quotes and detailed technical support.

Professional Rivet Nuts Manufacturer

Enhance Your Rivet Nuts Business

Rivetfix has received various certifications for its rivet nut products. We have not listed all certificates here, please contact us if you require more information on certifications or need a customized product certificate. We are committed to providing Rivet Nuts that meet IATF 16949, ISO 9001, RoHS, REACH and other standards. Buy rivet nuts Now!

Steps to Custom High Quality Jack Nuts

01

Send Jack Nut Inquiry

Contact us and send us your jack nut sourcing requirements. Include type, quantity and requirements.

02

Samping and Sample Testing

You will receive a sample of the jack nut within a week.

03

Confirmation and Production

Sample approval, production according to drawings

04

Delivery and Shipping

You need to pay the final payment of the order. Then we will ship your rivet nut order to your country.

Industries and Applications of Stainless Steel Jack Nuts

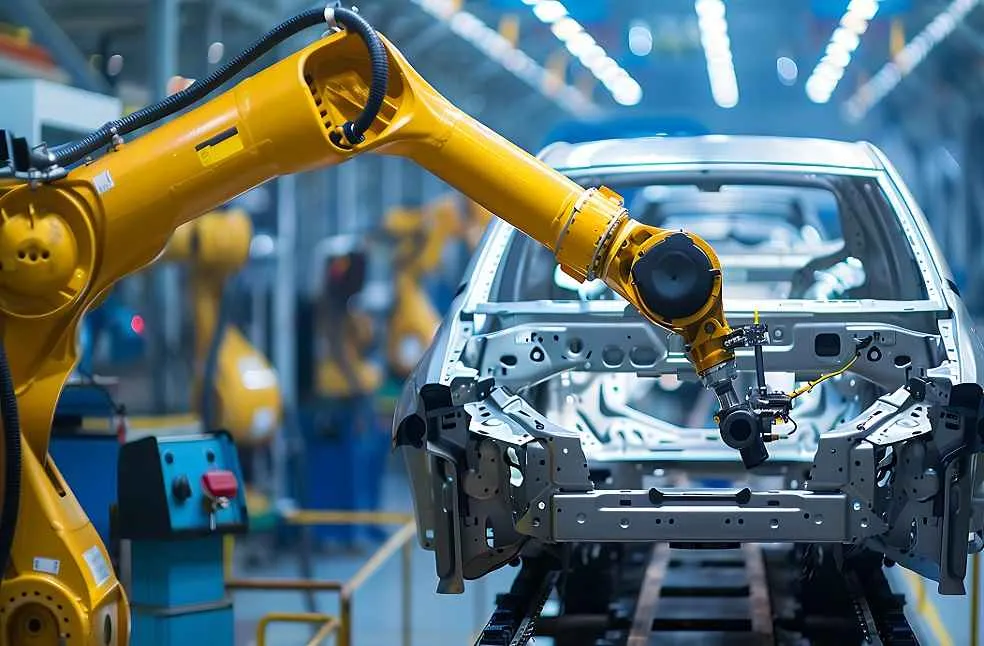

1. Automotive Industry

Used for the installation of car body panels, dashboards, and interior components, providing secure and durable threaded connections.

Application Examples: Door trims, dashboard brackets, seat armrest fastenings.

2. Marine and Shipping

Ideal for marine equipment, offshore platforms, and other water-based environments, ensuring fasteners can withstand the corrosion of moisture and saltwater.

Application Examples: Hull and deck component fastening, in-cabin equipment installation, offshore platform structural components.

3. Construction Industry

Stainless Steel Jack Nuts are widely used in outdoor railings, curtain wall systems, and other applications requiring high durability and strength, particularly in harsh weather conditions.

Application Examples: Metal frame structure fastening, building facade decoration, ventilation duct installations.

4. Electronics and Electrical

Used in high-end electrical equipment and industrial control enclosures to provide secure and reliable connections, ensuring equipment stability and long-term use in high-temperature, humid environments.

Application Examples: Electrical equipment chassis fastening, server rack installations, industrial control equipment securing.

FAQs About Stainless Steel Jack Nuts

1. What are the common size ranges for stainless steel jack nuts?

The size range of stainless steel jack nuts is typically available in various sizes to meet different application needs. Common sizes include:

- Outer Diameter: Typically ranges from 6mm to 20mm, with the specific outer diameter depending on the required hole size and material thickness.

- Length (Clamping Range): The length usually ranges from 8mm to 30mm, selected based on the material thickness and required fastening depth.

- Thread Sizes: Common thread sizes include M3, M4, M5, M6, M8, M10, M12, etc. Custom thread specifications are available for specific application needs.

2. The thread types of stainless steel jack nuts

Metric Thread

Metric thread is an internationally standardized thread type, widely used in most countries and industries. The thread size is determined by the outer diameter and pitch (distance between each thread). Metric threads are typically denoted by an “M” followed by a number, such as “M6”, which indicates a 6mm outer diameter.

Common Metric Thread Sizes: M3, M4, M5, M6, M8, M10, M12, etc.

Imperial Thread

The imperial thread is commonly used in the USA, the UK, and some other countries, with thread sizes defined in inches. Imperial thread specifications include fine thread (UNF) and coarse thread (UNC). The outer diameter and pitch are represented in inches, such as “1/4-20”, which indicates a 1/4-inch outer diameter and 20 threads per inch.

Common Imperial Thread Sizes: 1/4″-20, 3/8″-16, 1/2″-13, etc.

3. Common Clamping Ranges of Stainless Steel Jack Nuts

- M3 Thread: Suitable for clamping materials with a thickness of 2mm – 4mm.

- M4 Thread: Suitable for clamping materials with a thickness of 3mm – 6mm.

- M5 Thread: Suitable for clamping materials with a thickness of 4mm – 8mm.

- M6 Thread: Suitable for clamping materials with a thickness of 5mm – 10mm.

- M8 Thread: Suitable for clamping materials with a thickness of 6mm – 12mm.

- M10 Thread: Suitable for clamping materials with a thickness of 8mm – 16mm.

How to Choose the Right Clamping Range?

Selecting the appropriate clamping range is crucial to ensuring the stability of the installation. For optimal results, make sure:

- The material thickness falls within the clamping range of the nut.

- Before installation, ensure the hole diameter matches the outer diameter of the nut, allowing for even expansion during compression.

4. The load capacity of stainless steel jack nuts

The load capacity of stainless steel jack nuts is primarily measured by tensile strength and shear strength. Due to the excellent corrosion resistance and strength of stainless steel, it is suitable for use in harsh environments. The specific load capacity depends on the size, material type, and application environment of the nut.

Tensile Strength

Tensile strength refers to the maximum force the nut can withstand under tensile stress. In stainless steel jack nuts, the tensile strength typically ranges from 600MPa to 900MPa. This strength range allows them to withstand high tensile forces, ensuring a secure threaded connection.

Shear Strength

Shear strength refers to the nut’s ability to withstand lateral shear forces. In stainless steel jack nuts, the shear strength generally ranges from 500N/mm² to 700N/mm². It determines the nut’s ability to endure lateral loads without shearing or slipping.

Why Choose Stainless Steel Jack Nuts?

- Higher corrosion resistance compared to standard steel jack nuts, making them ideal for applications exposed to moisture or chemical environments over extended periods.

- Low maintenance costs, avoiding the need for replacement and maintenance due to rust or corrosion.

- Broad compatibility, suitable for various materials and environments, enhancing the reliability of installations.

Rivetfix - Buy Jack Nuts from Trusted Rivet Nut Manufacturer

Rivetfix is a top jack nut manufacturer in China. No matter whether your project has special requirements for jack nuts (special surface treatment, special head shape), our factory can provide you with products that can meet your requirements in terms of quality.

We manufacture jack nuts in multiple sizes and finishes, catering to applications in automotive, furniture, electronics, and construction. We offer custom solutions, fast delivery, and expert support to ensure your project is completed efficiently and effectively.If you would like to get samples for testing, please contact our engineers! Buy Jack Nuts Now!

Rivetfix, as part of Rivmate, can also supply high quality rivets and riveted parts. If you have a requirement, please contact us!

Get a Free Quote Now!

We believe Rivetfix will be your best partner!

Please fill out the form with your contact details or contact our whatsapp, and we will get back to you within 24 hours.