Where to Buy Jack Nuts?

Leading Rivet Nut Manufacturer and Supplier in China

The whole process of buying Jack Nuts is explained in another blog, The Ultimate Guide to buying Jack Nuts. When it comes to sourcing jack nuts, knowing where to buy jack nuts is crucial for ensuring both quality and cost-effectiveness. These fasteners are essential in various industries, from automotive to electronics, and selecting the right supplier can significantly impact the success of your projects. This guide will explore the best places to buy jack nuts and the factors to consider when choosing a supplier.

Table of Contents

Why Buy Jack Nuts?

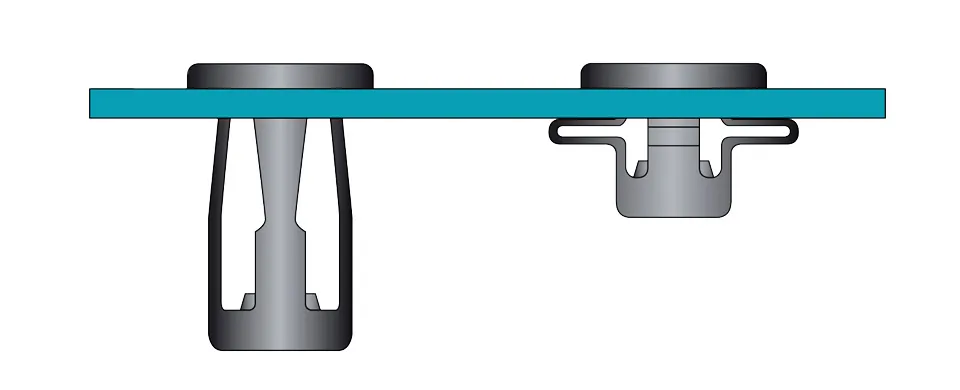

Jack nut is a threaded fastener for soft materials that is securely secured during installation by expansion or deformation, creating a reliable threaded connection. It is commonly used in plastics, thin metals and other materials to provide a stronger holding force than traditional threaded connections, while avoiding damage to the substrate.

1. Strong, Secure Connections

Jack nuts is designed to create long-lasting threaded inserts in soft or thin materials such as plastics, composites and thin metals. When they are installed by extension, they ensure a strong, reliable connection to the material.

Jack nuts provide stronger, long-lasting connections that can withstand high pressure, reuse and vibration without loosening. Their uniform expansion ensures a tight and uniform fit, making them ideal for applications requiring strength and security, ensuring that threaded connections remain stable under harsh conditions.

2. Prevents Material Damage

By means of expansion installation, avoid direct tapping or drilling damage to the material. Conventional tapping or insertion methods can cause cracks, flaking, or deformation of thin metal, plastic, or composite materials. But jack nuts distribute the pressure evenly through the expansion of its bottom when installed, thus reducing stress and damage to the surrounding material.

Especially when dealing with fragile or sensitive materials, jack nuts offers a non-destructive solution that ensures the integrity of the material, prolonging its service life and avoiding the common problems of stripping, cracking and so on.

3. Ease of Installation

The installation of Jack nuts is simple and efficient. Installation only needs to be completed by simple hand tools or pneumatic tools, and does not require complex equipment or professional technology. This convenient installation makes jack nuts ideal for efficient production and maintenance.

By placing the jack nut into a pre-prepared hole and applying the right amount of pressure, it can be easily expanded and securely secured inside the material for a fast, injection-free connection. Its easy installation features make it very popular in environments requiring mass production or high frequency maintenance.

Procedure for Installing Jack Nuts:

- Prepare the Material: Drill a hole in the material with the appropriate diameter for the jack nut, ensuring it matches the nut’s outer size.

- Insert the Jack Nut: Place the jack nut into the drilled hole, ensuring the nut sits flush with the material surface.

- Expand the Jack Nut: Using a manual or pneumatic tool, install the jack nut by tightening the tool to expand the nut, causing it to grip the material securely.

- Check Alignment: Ensure the jack nut is installed evenly and sits flush with the surface.

- Insert Bolt or Screw: Once installed, you can insert and tighten a bolt or screw into the jack nut, completing the secure connection.

4. Versatility

The versatility of Jack nuts makes it suitable for a variety of materials and scenarios:

soft material

Suitable for thin metals, plastics, composite materials, etc., which are easily damaged or cannot withstand stronger forces when connected with traditional threads.

Jack nuts provides a reliable and non-damaging connection method.

automobile industry

Automotive interior, body parts, decorative strips, light vehicle chassis, etc., where stable thread connections are needed.

aerospace industry

Aircraft internal components, instruments, electronic components, etc., which require high strength connections without damaging the base material.

electronics industry

For the assembly of electronic enclosures, control panels and internal components, jack nuts provides durable threaded connections to avoid material damage due to disassembly.

Furniture & appliances

Furniture and home appliances are assembled to ensure a solid connection on cork, density board and other materials to prevent thread slip or damage during use.

5. Cost-effective

Jack nuts is cost-effective in that it is easy to install and requires no special tools, resulting in significant savings in labor and equipment costs. In addition, the use of jack nuts on soft materials can avoid the damage and waste of traditional threaded connections, helping to improve material utilization and reduce waste. Thanks to its strong connection performance, jack nuts also reduces maintenance and replacement frequency, reducing maintenance costs in long-term operations.

In addition, the applicability of jack nuts is very broad, suitable for a variety of materials, can meet the needs of different application scenarios. By using jack nuts, companies can achieve more efficient production across multiple industries. At the same time, ensure the stability and security of the connection, and provide a higher cost performance for long-term use.

Where to Buy Jack Nuts?

When deciding where to buy jack nuts, it’s essential to weigh the pros and cons of each option to suit your specific needs.

1. Online Marketplaces

latforms like Amazon, eBay, or Alibaba offer a wide range of jack nuts in various sizes and materials. They often provide competitive pricing and fast shipping options.

Advantages

Online platforms such as Amazon, Alibaba, and eBay offer a vast selection of jack nuts in various sizes, materials, and grades. Shopping online allows you to compare prices easily and read customer reviews for insight into product quality. You can also purchase in small or large quantities based on your needs, and have the products shipped directly to your location.

Disadvantages

The main drawback is the potential variation in product quality, especially if the seller is not well-established. There is also a risk of delays in shipping, particularly if the supplier is overseas. Additionally, returns can be more complicated and time-consuming compared to buying from a physical store.

2. Offline Fastener Stores

Some local hardware or industrial supply stores may carry jack nuts in standard sizes for general use. This can be convenient for smaller orders or emergency needs.

Advantages

Purchasing jack nuts from a local store allows you to immediately access the product and inspect the quality before purchase. It’s ideal for urgent projects or when you need a small quantity of fasteners. Local stores may offer guidance on selecting the right type of jack nut for your needs.

Disadvantages

Local stores often have a more limited selection compared to online marketplaces. Prices can also be higher due to overhead costs such as rent and staff wages. Furthermore, specialized or custom-made jack nuts might not be readily available.

3. Specialized Fastener Suppliers

Companies like Rivetfix or other fastener suppliers offer jack nuts tailored for specific materials and applications. These suppliers often provide custom solutions and expert guidance.

Advantages

These suppliers focus on providing high-quality, reliable fasteners for industrial or commercial use. They often offer a wide range of sizes, materials (steel, stainless steel, aluminum), and even custom solutions for specialized applications. Purchasing from these suppliers ensures you’re getting high-performance products suited to your specific needs. Bulk orders often come with discounted pricing. Additionally, these suppliers typically provide expert advice and can help with selecting the right jack nut for your project.

Disadvantages

Specialized suppliers often require a minimum order quantity, which may not be ideal if you only need a small number of jack nuts. If you’re buying in bulk, shipping times could be longer, and prices may be slightly higher than those from local or online general stores.

Conclusion: Which purchase route is more suitable for you

- If you’re looking for convenience, online marketplaces are a good choice.

- If speed and personal service are more critical, offline fastener stores can meet your needs.

- For larger, more specific orders or customized solutions, specialized fastener suppliers like Rivetfix will provide the most tailored service and high-quality options.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Reilable Jack Nut Manufacturers?

Choosing a reliable jack nut manufacturer is crucial for ensuring that you receive high-quality products that meet your specific needs. Here’s a detailed guide on how to make the right choice:

1. Quality Certifications and Standards

- ISO Certifications: Look for manufacturers that hold rivet nut ISO certifications, which guarantee that they adhere to international quality standards. ISO 9001 is a common certification for manufacturers of high-quality fasteners.

- Industry-Specific Certifications: For industries like aerospace or automotive, ensure the manufacturer has certifications relevant to your sector, such as AS9100 (aerospace) or IATF 16949 (automotive).

2. Experience and Reputation

- Years of Experience: Manufacturers with years of experience in producing jack nuts are likely to have refined their processes and can offer reliable products. Look for companies with a long track record in the fastener industry.

- Client Testimonials: Check customer reviews, case studies, or testimonials to gauge the satisfaction level of other clients. Reputable manufacturers will have positive feedback and a proven record of delivering high-quality products.

- Industry Expertise: Manufacturers with expertise in your specific industry (e.g., automotive, aerospace, electronics) will understand the particular demands of your application and offer tailored solutions.

3. Custom Solutions and Flexibility

- Customization Options: Ensure that the manufacturer can customize jack nuts based on your unique requirements, such as size, thread type, material, or coating. A good manufacturer should be able to provide tailored solutions.

- Prototyping: Some manufacturers offer prototyping services that allow you to test a sample of your desired product before placing a large order. This can be an excellent way to confirm that the jack nuts will perform as expected.

- Order Flexibility: A reliable manufacturer should accommodate small or large orders and provide the flexibility to adjust to changes in order quantity or specifications if needed.

4. Production Capabilities

- Manufacturing Technology: Ensure that the manufacturer uses advanced equipment and technology to produce jack nuts. Automated production lines with CNC machines, precision tools, and high-tech quality control systems often result in more accurate and durable products.

- Lead Times and Capacity: A reputable manufacturer should provide clear lead times for production and delivery. Check if they have the capacity to handle your order volume within the desired timeline.

- Supply Chain and Logistics: Assess their supply chain capabilities, including sourcing of raw materials, inventory management, and shipping. Efficient logistics ensure timely delivery of your order.

5. Price Competitiveness

- Competitive Pricing: While price shouldn’t be the only consideration, a reliable manufacturer should offer competitive pricing based on the quality and quantity of the jack nuts. Request quotes from multiple manufacturers to compare prices.

- Bulk Discounts: Some manufacturers provide volume-based discounts for large orders, which can help reduce the overall cost per unit for your business.

Choose to Buy from a Jack Nut Manufacturer for Large Orders

For large orders, buying directly from a jack nut manufacturer provides significant cost savings, customization opportunities, and greater reliability, making it an ideal choice for businesses with high-volume or long-term needs.

Lower Costs for Bulk Orders

- Cost Savings: Manufacturers provide competitive pricing for large orders due to economies of scale. By bypassing distributors or middlemen, you can reduce the overall cost per unit.

- Volume Discounts: Manufacturers often offer volume-based discounts, making large orders more affordable.

- Reduced Shipping Costs: Buying in bulk can also lower shipping costs, as many manufacturers provide free or discounted shipping for large orders.

Customization Options

- Tailored Products: Manufacturers can customize jack nuts to meet specific requirements like size, thread type, material, or coating. This ensures that the fasteners suit your unique application perfectly.

- Specialized Materials: If you need jack nuts made from specific materials such as stainless steel, aluminum, or brass, manufacturers can provide these in large quantities.

- Specific Thread Patterns: For industries with specific threading needs, manufacturers can provide jack nuts with custom threading sizes and patterns that may not be available from standard retailers.

Reliable Quality Control

- Consistency and Uniformity: Manufacturers follow strict quality control processes to ensure that every jack nut meets the required specifications. This reduces the chances of defects and ensures consistency across all units.

- ISO Certifications: Many manufacturers have ISO certifications that guarantee adherence to internationally recognized quality standards. This is particularly crucial for industries where fastener integrity is vital, such as aerospace or automotive.

Consistent Supply

- Reliability: Establishing a direct relationship with a manufacturer ensures a steady, uninterrupted supply of jack nuts for large or recurring orders. You won’t have to worry about availability issues, especially for specialized or custom orders.

- Long-Term Partnerships: Purchasing in bulk from a manufacturer allows you to build a long-term relationship, potentially securing better pricing, faster delivery, and priority production.

- Supply Chain Control: Buying from the manufacturer allows you to have more control over the supply chain, which is particularly important for businesses with tight production schedules or high-volume demands.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs

1. What is the MOQ for Jack Nuts?

When purchasing jack nuts directly from manufacturers, the minimum order quantity (MOQ) is typically 50,000 units.

Purchasing large quantities significantly reduces the per-unit cost, making it a cost-effective option for high-volume projects. Manufacturers can provide a limited number of samples for testing, allowing buyers to assess the quality and suitability of the jack nuts before committing to the full order.

2. How to Ensure Jack Nuts Meet Industry Standards?

To ensure jack nuts meet industry standards, verify that they are made from high-quality materials like steel, stainless steel, or aluminum, and confirm they meet relevant jack nut standard such as ISO or ASTM.

Check the threading specifications to ensure compatibility with screws and bolts. Ensure proper finish and coating to resist corrosion, particularly for materials used in harsh environments. Additionally, perform load-bearing tests to verify tensile and shear strength, and check for dimensional accuracy to ensure the rivet nuts fit the required specifications.

It is important to work with reputable manufacturers and suppliers. They have strict products quality control and provide thoroughly tested product samples.

3. Are Jack nuts customizable?

Yes, excellent manufacturers offer custom Jack nut services to meet specific application needs.. They can tailor key features like material (steel, stainless steel, aluminum, brass), size (diameter, length, thread size), and thread type (metric or imperial) to ensure a perfect fit. These options allow jack nuts to be designed for optimal strength, corrosion resistance, and functionality.

Additionally, customizable coatings, such as zinc plating or anodizing, can be applied to improve durability and aesthetics. The head design can also be adapted (e.g., countersunk or flat), offering flexibility in meeting both technical and visual requirements.

4. Does it provide after-sales service?

Yes, many jack nut manufacturers provide after-sales service to ensure customer satisfaction. This includes technical support for installation and troubleshooting, as well as guidance on optimizing the use of jack nuts for specific applications.

In addition, if a defect is found, the return or replacement of the product is supported to ensure that the customer receives a functional and reliable product.

Why Buy Jack Nuts from China?

Competitive Pricing

China is known for its cost-efficient manufacturing processes. Jack nuts produced in China often come at lower prices compared to those from other countries. This is primarily due to lower labor costs and large-scale production capabilities.

High-Quality Standards

Many Chinese manufacturers produce jack nuts to meet international quality standards, such as ISO, DIN, and JIS. These manufacturers have improved their production techniques over the years and are capable of delivering reliable, high-performance products.

Efficient Supply Chain and Logistics

With established infrastructure and logistics networks, Chinese suppliers can ship jack nuts quickly and efficiently worldwide. Many suppliers also offer competitive shipping rates, reducing overall procurement costs. Whether you are importing in bulk or need smaller shipments, China’s robust logistics system ensures timely delivery.

If you want to know more about China’s outstanding rivet nut manufacturers, you can refer to the top 10 rivet nut manufacturers in China to help you make the right choice.

As a leading fastener manufacturer in China with more than 15 years in the industry, Rivetfix are committed to providing first-class quality fasteners and responsive services to the world.

Our factory manufactures 400 million pieces of structural rivets and automobile blind rivets, 1 billion standard blind rivets annually now. Choose Rivetfix for your next project and experience the difference that superior rivet nut solutions can make.

Contact us for project advice and the latest rivet nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.