What is a Jack Nut?

Leading Rivet Nut Manufacturer and Supplier in China

Jack nuts are commonly used in applications where the material cannot support a traditional threaded connection, such as plastics, composites, or thin metals. Their versatility, ease of installation, and ability to create threaded inserts without requiring access to both sides of the material make them popular in industries like automotive, aerospace, electronics, and construction. In this blog, we’ll explore “what is a Jack Nut”, how it works, and why it’s an essential component for many projects.

Table of Contents

What is a Jack Nut?

Jack Nut is a fastener designed to create internal threads in thin or difficult-to-tap materials like plastic, sheet metal, or composites. It provides a strong, threaded hole for screws or bolts, allowing secure, removable connections in applications where access to both sides is limited.

Commonly used in industries such as automotive, aerospace, and electronics, Jack Nuts are ideal for creating durable threads in lightweight or brittle materials. Unlike traditional rivets, they enable the use of standard screws for easy assembly and disassembly.

Installation is simple and can be done with manual or pneumatic tools. The Jack Nut expands inside the material, creating a strong, permanent connection. With their ability to distribute load evenly and prevent material damage, Jack Nuts offer a reliable and efficient solution for adding threaded connections to thin materials.

Key Features of Jack Nuts:

- Designed for Thin or Soft Materials: They work well in materials that are too thin or fragile to hold a traditional nut or bolt.

- Expansion-Based Installation: During installation, the jack nut expands within the material to create a secure anchor for fasteners.

- Corrosion Resistance: Many jack nuts are made from stainless steel or other corrosion-resistant materials to withstand harsh environments.

- Variety of Sizes and Types: Jack nuts come in a range of sizes and configurations, including flush, round, and low-profile designs, depending on the application.

The Pros and Cons of Jack Nuts

Jack nuts are a popular choice for creating strong threaded connections in materials that cannot support traditional fasteners. However, like any fastener, they come with both advantages and limitations. Here’s a breakdown of the pros and cons:

Pros of Jack Nuts:

Versatility in Material Use: Jack nuts are ideal for use in thin, soft, or brittle materials (such as plastic, composites, or thin metal sheets) that cannot support traditional threaded fasteners. They provide a secure and stable thread for applications where conventional methods would fail.

Easy to Install: Jack nuts are relatively easy to install using a specialized tool (manual, pneumatic, or hydraulic). The installation process involves expanding the nut inside the material, which creates a permanent, strong bond without the need for additional hardware or complex processes.

High Strength and Durability: Once installed, jack nuts provide a strong, durable threaded connection. They can handle a significant amount of torque, making them ideal for securing bolts and screws in high-stress applications.

Cost-Effective for Low to Medium Production Volumes: Jack nuts are often more cost-effective than welding or other methods of securing fasteners, especially in low to medium volume production.

Cons of Jack Nuts:

Limited Load Capacity: Although jack nuts provide a strong connection, they may not be suitable for very high-load applications. The load capacity depends on the material they are installed in, and in some cases, jack nuts may not offer the same strength as traditional nuts and bolts, especially in thick or high-strength materials.

Potential for Material Damage: The installation process involves expanding the jack nut inside the material, which can potentially damage the surrounding material if you do not install it properly or use excessive force. Over-tightening or incorrect tool calibration can deform or weaken the material.

Specialized Tools Required: Installing jack nuts requires a specific tool, which can add to the initial cost and complexity. While these tools are generally available, their need for proper maintenance and calibration might add extra operational costs over time.

What is a Jack Nut Used For?

1. Threaded Connections in Thin or Soft Materials

Jack nuts are ideal for applications where you need to create a strong threaded connection in materials that are too thin to support standard threads. This includes materials like plastics, aluminum, fiberglass, and thin sheet metal. For example, they are often used in aerospace, automotive, and electronics manufacturing where lightweight but strong connections are required.

2. Applications in Blind Holes

Jack nuts are particularly valuable when dealing with blind holes, where the back of the material cannot be accessed. Their design allows them to expand inside the material, creating a secure internal thread without the need for a back-side nut or a through hole. This makes them a perfect solution for parts like electrical enclosures, panel mounting, or any other application where a traditional nut and bolt would be difficult or impossible to use.

3. Structural Connections in Lightweight Applications

In industries such as automotive, aerospace, and marine, where weight reduction is crucial, jack nuts provide a lightweight solution for securing components without sacrificing strength. They allow for high-tensile strength connections while keeping the overall weight of the assembly low.

Composite materials such as fiberglass, carbon fiber, and other reinforced plastics are widely used across various industries for their high strength-to-weight ratio and excellent durability. However, creating secure threaded connections in composites presents a challenge, as these materials often crack or get damaged when subjected to direct threading. Jack nuts (also known as rivet nuts) offer a reliable solution by creating strong, permanent threaded inserts in these materials.

Why Jack Nuts Work Well for Composites

Jack nuts work by expanding inside the material during installation, forming a secure, firm grip without damaging the surrounding composite.

Unlike traditional tapping or threading methods, which can compromise the integrity of the composite material, jack nuts distribute pressure evenly, reducing the risk of cracking or delamination. Their ability to create a strong mechanical bond with the material makes them ideal for situations where threads need to hold heavy loads or frequent assembly and disassembly.

5. Maintenance and Repairs

You can use jack nuts in maintenance or repair applications to replace damaged or stripped threads in existing materials. They enable quick and easy re-threading of holes that have suffered damage over time, allowing components to be securely fastened without the need to replace the entire part.

Are Jack Nuts Removable?

Jack nuts remain permanent once installed and are not meant for removal. Their purpose is to create a secure, permanent threaded insert in materials like metals, plastics, or composites. Once expanded and secured, they provide a reliable and strong anchor point for bolts, screws, or other fasteners.

However, you can easily remove the bolts or screws threaded into the jack nut without damaging the jack nut or the surrounding material. This is one of the main advantages of using jack nuts—they allow you to remove and reinstall the bolted part repeatedly while keeping the insert (jack nut) intact.

Key Points:

- Once you install jack nuts, they remain permanent and cannot be removed.

- However, you can remove and replace the bolts or screws threaded into the jack nut as needed.

- The jack nut stays in place, providing a secure, reusable threaded insert in the material, while you can remove the fasteners without damaging the jack nut itself.

In this way, the jack nut offers a long-term threaded solution, while you can easily replace the fasteners that interact with it.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Jack Nuts for Your Project?

1. Material Compatibility

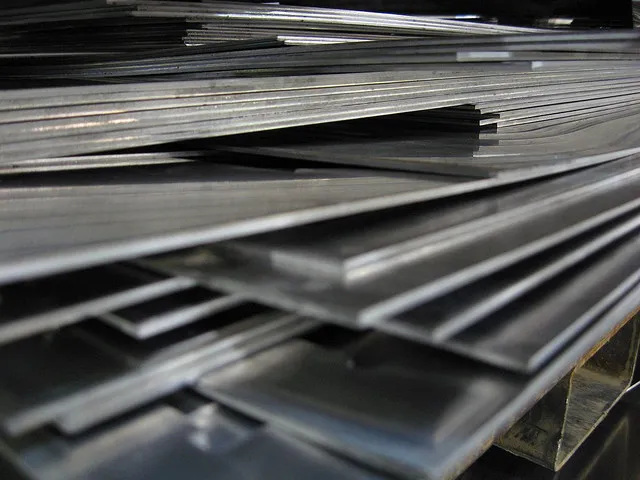

Metal Materials

- Steel:

For high-strength applications, steel jack nuts are often the best choice. They can be used in steel, aluminum, and other metal materials. Steel provides excellent tensile strength and shear resistance, making it ideal for heavy-duty applications.

For steel components, choose steel or stainless steel jack nuts to ensure strong, secure connections. Stainless steel provides additional resistance to rust and corrosion. - Aluminum:

Aluminum jack nuts are best suited for lightweight materials such as aluminum sheets or lightweight alloys used in automotive or aerospace industries.

Use aluminum jack nuts with aluminum base materials to avoid over-tightening or damaging the softer metal.

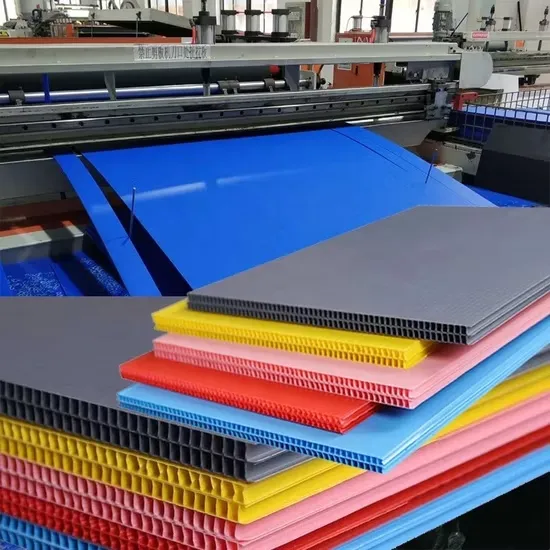

- Plastics:

When working with softer materials like plastic, PVC, or polycarbonate, it’s crucial to choose jack nuts designed to avoid damaging the material. Low-profile or soft-metal jack nuts are ideal for these applications.

Select jack nuts with a flanged design for plastic materials to help distribute the force evenly and prevent cracking or deformation of the plastic. - Composite Materials: Composite materials such as carbon fiber or fiberglass require special consideration. These materials are often strong but can be brittle or prone to damage under high force.

For composites, aluminum or stainless steel jack nuts with a low-profile design help ensure secure fastening without causing damage. The jack nuts should also have a larger contact surface area to evenly distribute stress.

2. Load Requirements

- Shear Strength:

Choose a jack nut that can handle the amount of shear force the joint will be subjected to. For high-load applications, high-strength materials such as steel or titanium are ideal. - Tensile Strength:

Consider the required tensile strength—jack nuts with a larger outer diameter or thicker walls provide stronger tensile pull-out resistance.

3. Thread Size and Compatibility

- Internal Thread Size:

Ensure the internal threads of the jack nut match the bolt size that will be used in your application. Common sizes are M6, M8, M10, or imperial sizes like 1/4″ or 5/16″. - External Diameter:

The external diameter should be slightly larger than the hole size in the base material to ensure a secure fit. - Thread Type:

Make sure the thread type of the jack nut matches your bolt. For example, use metric threads for metric bolts, or UNC/UNF threads for imperial bolts.

4. Size and Design of the Jack Nut

Length of the Jack Nut:

The length of the jack nut should be chosen based on the thickness of the material. If the material is thin, a shorter jack nut may suffice, but for thicker materials, a longer jack nut is necessary to ensure full expansion and a secure hold.

Type of Jack Nut:

- Standard: Used for general applications where high-load conditions are not a primary concern.

- Flanged: Offers more support and prevents the insert from pulling through, ideal for softer materials.

- Sealed: Used for applications that require leak-proof or water-resistant seals.

5. Installation Method

- Manual or Pneumatic Installation: Consider whether you’ll be using a hand tool or pneumatic tool for installation. For higher volume installations, pneumatic or hydraulic tools can speed up the process and ensure consistent installation pressure.

- Hole Size Compatibility: The hole size in the base material should match the specified hole size for the jack nut. This is critical to ensure proper expansion and secure seating of the jack nut.

What is the Difference Between Jack Nuts and Plus Nuts?

| Feature | Jack Nuts | Plus Nuts |

| Design | Cylindrical or flanged | Flanged, longer body |

| Expansion Mechanism | Split, compresses and locks | Aggressive flange, more pronounced expansion |

| Material Compatibility | Thin sheet metals, plastics, composites | Thicker materials, heavy-duty applications |

| Strength | Medium load capacity | High load capacity, higher strength |

| Applications | Automotive, aerospace, light machinery | Heavy machinery, construction, high-strength applications |

| Cost | Less expensive | More expensive |

Conclusion

The choice between jack nuts and plus nuts depends on your specific application requirements.

- If you’re working with thinner materials and need a compact, cost-effective solution, jack nuts are a great choice.

- For high-load applications or thicker materials, plus nuts provide superior performance due to their enhanced expansion and stronger holding capacity.

Always consider the material, load requirements, and installation method when selecting the appropriate threaded insert for your project.

Why Buy Jack Nuts from China?

China offers affordable, high-quality jack nuts with a wide range of options and reliable global shipping, making it an ideal choice for many businesses.

Cost-Effectiveness: China offers lower production costs and bulk order discounts, making it a budget-friendly option for businesses.

High Production Capacity: Chinese manufacturers can handle both small and large orders, ensuring quick turnaround times and reliable delivery.

Advanced Manufacturing: Many suppliers use modern technology to produce high-quality jack nuts, with options for custom designs and materials.

Wide Variety: Chinese suppliers provide a broad range of sizes, materials (steel, stainless steel, aluminum), and thread patterns to suit different applications.

Global Reach: With efficient logistics and competitive shipping costs, China can ship jack nuts worldwide, ensuring timely delivery at lower costs.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivetfix - Leading Jack Nut Supplier in China

Rivetfix, as a leading jack nut supplier in China, offers high-quality products designed to meet various industrial and commercial needs. With competitive pricing, reliable delivery, and a range of customizable options, Rivetfix is committed to providing efficient solutions for clients worldwide.

We are committed to providing first-class quality fasteners and responsive services to the world. We can select the most suitable fasteners according to your project needs, and provide product customization services.

Contact us for project advice and the latest jack nut quote!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.