What Is the Difference Between Keensert and Threaded Insert?

Leading Threaded Insert Manufacturer and Supplier in China

In high-demand engineering environments, the selection of appropriate threaded inserts directly affects the reliability and service life of products. Whether in aerospace, military equipment, or heavy industrial machinery and mold repair fields, Keensert and Threaded Insert are common and important fastening solutions. However, the difference between Keensert and Threaded Insert is not merely in appearance or price. They have significant differences in structural design, load-bearing capacity, vibration resistance, and installation methods. An incorrect choice may lead to thread failure and increased maintenance frequency.

Understanding the differences between these two types of inserts can help engineers and procurement personnel make more precise decisions at the design stage. For instance, in the maintenance of high-vibration and high-load aviation engines, the anti-rotation key design of Keensert can effectively prevent thread loosening. However, in scenarios that require rapid mass production or where cost is a concern, the installation efficiency and versatility of Threaded Insert offer more advantages. This article will systematically analyze the differences between the two in terms of structure, performance and application scenarios.

Table of Contents

What Is a Keensert?

Keensert is a high-strength metal threaded insert, with the key feature of having anti-rotation metal keys. This structure is not only used for repairing damaged threaded holes, but also for enhancing the thread load-bearing capacity in soft metal substrates such as aluminum and magnesium alloys. Compared with traditional threaded inserts, Keensert provides higher anti-loosening performance through mechanical locking, making it particularly suitable for high-load and high-vibration environments.

Structural Features

- External thread: Used for connection with the base material to ensure the overall stability and fixation.

- Internal thread: Provides a standard-sized threaded interface for convenient installation of bolts or screws.

- Anti-rotation keys: After installation, the keys will be pressed into the surface of the base material, forming a mechanical lock to prevent the insert from loosening in high-vibration or high-torque environments.

- High-precision manufacturing: Usually meets aviation and military standards (such as NAS1130/NAS1131).

Typical Application Scenarios

- Aerospace: Engine casings, wing connectors, which need to withstand high vibration and high temperatures.

- Military equipment: Critical parts of tanks, ships, missile launch systems, etc., which have extremely high reliability requirements.

- Heavy machinery: Key connection parts of mining machinery and engineering vehicles, which endure high impact and cyclic loads.

- Mold and equipment maintenance: Extending the service life of parts in the repair of damaged threaded holes.

Summary of Performance Advantages

- Outstanding anti-loosening performance: The mechanical locking design is superior to the anti-loosening method that solely relies on friction.

- High load-bearing capacity: Suitable for heavy-duty conditions, reducing the risk of thread slippage or failure.

- Strong durability: Resistant to corrosion and vibration, with a long service life.

- Standardized production: Matching in size and installation tools, facilitating global procurement and maintenance.

Threaded Insert is a metal or non-metal sleeve with internal threads, mainly used to enhance the strength of the threads or repair damaged thread holes. It not only extends the service life of the threads but also provides a stable fastening interface in soft metals, plastics, composite materials, etc. Compared with Keensert, Threaded Insert has a wider variety of types and a broader adaptability, and can be flexibly selected according to application requirements.

a. Helicoil (Spring Insert)

- It is made by winding high-strength stainless steel wire, and its shape is similar to a spring.

- After installation, it can restore the standard size of the threaded hole, and it is lightweight and occupies little space.

- It is suitable for medium and light load conditions with limited space.

b. Solid Inserts

- It is an overall metal solid sleeve with external and internal threads.

- The structure is more stable, and its load-bearing capacity is higher than that of Helicoil.

- It can be combined with locking structures (such as threaded lock glue, anti-loosening grooves) to enhance the anti-loosening performance.

Typical Application Scenarios

- Industrial Production: Increase the thread strength in soft base material (aluminum, plastic) parts during mass production.

- Mechanical Maintenance: Repair frayed threads in screw holes to extend the service life of the parts.

- Electronic Devices: Provide reliable metal threaded interfaces in plastic housings.

- Automotive and Home Appliance Industries: Enhance the stability and fatigue resistance of bolt connections.

Summary of Performance Advantages

- Wide applicability: Can be used for various materials and structures.

- Multiple installation methods: Screw-in type, press-in type, hot-melt type, ultrasonic welding type, etc.

- High cost-effectiveness: Most types have low costs and are suitable for mass production.

- Quick repair capability: Damaged threads can be quickly repaired on-site, reducing downtime.

Key Differences Between Keensert and Threaded Insert

| Feature | Keensert | Threaded Insert |

|---|---|---|

| Structure | Solid body with mechanical locking keys | Spring-type (Helicoil) or solid type without keys |

| Strength | Very high, suitable for heavy loads | Medium to high, depending on type and material |

| Vibration Resistance | Excellent due to key-lock design | Varies by type; generally lower for Helicoil |

| Installation Method | Requires drilling, tapping, and key slot milling | Screw-in, press-in, or coil insertion |

| Maintenance & Replacement | Easy to remove and replace | Some types are harder to remove |

| Cost | Higher unit cost | Lower cost, suitable for mass production |

① Significant structural differences

Keensert belongs to solid metal inserts, equipped with anti-rotation keys. After installation, the keys will be embedded into the base material, achieving mechanical locking, which can maintain stability in high-torque and high-vibration environments. Threaded Insert is divided into two major categories: Helicoil (spring type) and Solid Inserts (keyless solid type). The structure is relatively simple, and the anti-loosening performance depends on friction or additional locking measures.

② Different in terms of carrying capacity and application scope

Keensert’s load-bearing capacity and tensile strength are significantly higher than those of ordinary threaded inserts. It is suitable for heavy-duty applications in industries such as aviation, military, and heavy machinery. Industry data shows that the tensile strength of Keensert can be increased by more than 200% compared to the base material. While standard Helicoils typically increase by 40% to 90%, Threaded Insert can also enhance the threads, but its performance is slightly inferior in extreme load conditions.

③ Advantage of Anti-Vibration Performance

Keensert’s anti-vibration keys ensure stable performance in high-vibration environments (such as aircraft engines, tank chassis), with almost no risk of loosening. The anti-vibration capability of the Threaded Insert depends on the specific type – Helicoil may loosen under high vibration, while solid inserts combined with anti-loosening glue can achieve better results.

④ Installation Process Requirements

Keensert requires an additional process (milling out the keyway), and its installation time is longer than that of ordinary threaded inserts, but it comes with higher stability. Threaded Insert is easier to install; it can be screwed in or pressed in using a screw tool. It is suitable for mass production and quick on-site repairs.

⑤ Maintenance and Cost

Keensert is relatively easy to disassemble and assemble, and is convenient to maintain, but it has a high unit price; Threaded Insert has a lower unit price and is suitable for projects with budget constraints. However, for some types (such as Helicoil), it may damage the base material during disassembly and thus requires the replacement of the entire threaded hole structure.

Advantages and Disadvantages of Each

Keensert

Advantages

1. High-strength Bearing Capacity

- The solid structure combined with the anti-rotation key design significantly enhances its tensile strength and torque resistance compared to ordinary Threaded Insert.

- Data reference: In aviation maintenance tests, Keensert’s pulling force is 120% – 200% higher than that of the same-sized Helicoil, making it particularly suitable for heavy-load and high-safety-factor applications.

2. Outstanding Anti-loosening and Anti-vibration Performance

- The mechanical locking structure prevents loosening under high vibration or temperature changes, and is widely used in critical components such as engines and transmission systems.

- Aviation engine maintenance cases show that the service life of Keensert is 2 – 3 times longer than that of ordinary threaded inserts.

3. Durability and Reliability

- Utilizing high-performance materials such as stainless steel and nickel alloys, it can withstand high temperatures and corrosive environments, resulting in a longer maintenance cycle.

Disadvantages

1. High cost

- The unit price is usually 3 to 5 times that of Helicoil, making it unsuitable for projects with extremely tight budgets.

2. Complex installation process

- It requires drilling, tapping, and milling keyways, and the installation time is 30% to 50% longer than that of spring-type inserts.

Threaded Insert

Advantages

1. High cost-effectiveness

- Low cost, suitable for batch production and large-scale maintenance projects. The unit price of Helicoil is only 20% – 40% of that of Keensert.

2. Quick and easy installation

- No additional keyway processing required. Spiral or press-in installation methods are suitable for on-site maintenance or automated production.

- Can be used on various substrate materials such as metals, plastics, and composite materials. There are various types (Helicoil, solid type, hot-melt type, etc.).

Disadvantages

1. Unstable vibration resistance and anti-loosening performance

- Helicoil is prone to loosening in high-vibration environments and requires additional anti-loosening measures (such as locking glue, locking screws).

2. Relatively low load-bearing capacity

- The performance of the solid-type Threaded Insert can be comparable to Keensert, but the load-bearing capacity of Helicoil only increases the base material by approximately 40% to 90%, and is not suitable for extreme heavy-duty applications.

3. Some types are difficult to maintain

- The Helicoil inserts are difficult to remove and are prone to damaging the base material’s threaded holes.

How to Choose the Right Insert for Your Application?

In the field of fastening design and maintenance, choosing between Keensert and Threaded Insert is not a simple matter of cost or brand decision. Instead, it requires a comprehensive consideration of various factors such as load, installation conditions, material environment, and the total life cycle cost. Here are the selection ideas commonly used by professional engineers:

Based on Load Requirements (Heavy Duty vs. Light Duty)

Heavy Duty Conditions

- Applicable scenarios: Key structural components in aviation, military industry, heavy machinery, mining equipment, etc.

- Recommended solution: Keensert, as it features anti-rotation pins and a solid structure, can withstand higher tensile and shear loads.

- Data reference: Under the same thread specification, the pulling force of Keensert can reach 2 to 3 times that of ordinary aluminum-based threaded holes.

Light/Medium Duty Conditions

- Applicable scenarios: Electronic devices, household appliances, plastic products, light machinery.

- Recommended solution: Threaded Insert (Helicoil or solid type), with low cost and convenient installation.

Consider Installation Conditions (On-site Maintenance vs. Batch Production in Factory)

On-site Maintenance

- It is required to quickly restore the equipment operation and reduce downtime.

- Helicoil or keyless solid-threaded insert is more suitable because no additional milling grooves are needed and it can be installed quickly.

Factory Batch Production

- It allows for the addition of installation processes in exchange for higher connection reliability.

- Keensert can be combined with dedicated fixtures in batch production to enhance consistency and anti-loosening performance.

Materials and Corrosive Environments (Marine, Chemical, Indoor)

Marine environment / Chemical corrosion environment

- It is recommended to use stainless steel 316 or nickel alloy inserts. Keensert offers greater long-term stability in such environments.

Indoor or low corrosion environment

- Brass or aluminum alloy threaded inserts can be selected to reduce costs.

Comparison of Cost Budget and Long-Term Maintenance Costs

Unit Price

- The unit price of Keensert is approximately 3 to 5 times that of Helicoil.

Total Life Cycle Cost

- In high-value equipment, using Keensert can significantly reduce thread failure and maintenance frequency, and lower long-term maintenance costs.

Cost-sensitive Projects

- For short-term or one-time-use products, Threaded Insert is more economical.

If your application is in a scenario characterized by “critical security, high load, long-term operation and difficult maintenance”, you should opt for Keensert.

If it is a project with moderate to low load, mass production or budget-sensitive requirements, the Threaded Insert can be chosen, along with anti-loosening measures to enhance reliability.

Installation Best Practices

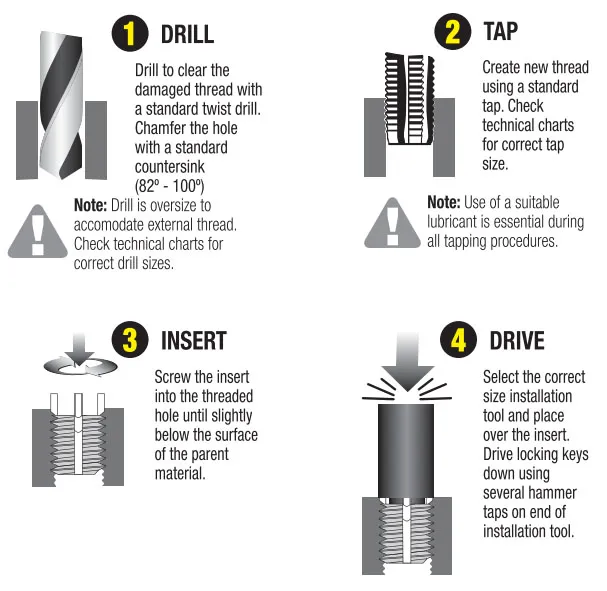

a. Key Steps for Keensert Installation

The installation of Keensert is rather strict and requires the following procedures to be followed:

1. Drilling

Process according to the drilling dimensions provided by the manufacturer, ensuring the accuracy of the hole diameter (±0.05mm) and the verticality.

2.Tapping

Use the tap that matches the external thread specification of Keensert for tapping, maintaining a complete and smooth thread.

3.Key Slot Milling

Process the key slot according to the position of the insert key to facilitate the insertion of the anti-rotation key after installation.

4. Screwing & Key Driving

Screw Keensert into the base material to the positioning position, and then use the dedicated punch to press the anti-rotation key into the key slot to achieve mechanical locking.

Note: In the aviation maintenance case, the Keensert installed in accordance with the specifications showed no loosening or disengagement during the 500-hour high-vibration test.

The Threaded Insert type is diverse (such as Helicoil, solid type, push-in type, etc.). Common installation points include:

1.Use the Correct Tools

Helicoil requires a dedicated installation wrench to prevent distortion during installation.

Solid inserts can be screwed in using an internal hexagonal wrench or a dedicated threaded insertion tool.

2.Torque Control

Control the insertion torque during installation.

3.Alignment Depth

Ensure the insert is flush with or slightly lower than the surface of the base material (0.1 – 0.2mm) to prevent interference from the assembly parts.

Note: The optimal installation torque for Helicoil on aluminum alloy parts is generally 1.2 to 1.5 times the recommended torque for the screws, which can effectively prevent loosening.

Common Installation Errors and Avoidance Methods

- Error 1: The hole diameter does not meet the specifications

- This affects the locking force of the insert and may even cause it to come loose. A calibrated drill bit should be used to avoid overly large or small hole diameters.

- Error 2: No debris in the hole was removed

- This can prevent the insert from fully adhering to the base material, reducing the load-bearing capacity. The threaded hole should be thoroughly cleaned before installation.

- Error 3: The anti-loosening measures were ignored

- For Threaded Insert in high-vibration conditions, it should be used in conjunction with thread lock glue or mechanical locking structures.

- Error 4: The installation torque was too large

- It may damage the base material or the threaded part of the insert. The operation should be carried out according to the recommended values by the manufacturer.

Conclusion: Making the Right Choice Improves Reliability and Cost-Efficiency

In the field of fastener and thread repair, it is crucial to understand the characteristics and application scenarios of different products. Various threaded inserts such as Keensert, thread sleeves, and Helicoil have significant differences in materials, installation methods, load-bearing capacity, and applicable environments. Making a reasonable choice not only ensures the long-term stability of the connection components but also effectively reduces maintenance and replacement costs.

It is recommended that enterprises and engineers conduct load testing and simulation analysis based on specific working conditions when making selection. If necessary, consult professional suppliers to ensure that the selected products achieve the optimal balance between performance and cost.

Action Suggestions:

- Clearly specify the environment, load conditions and disassembly frequency.

- Contact qualified suppliers to obtain technical support and sample testing.

- Conduct fatigue and corrosion resistance tests in conjunction with on-site applications to ensure long-term reliability.

Do You Have Any Questions?

Let Us Solve Your Problem

Upgrade Your Fastening Solutions with Rivetfix

Choose Rivetfix and make your fastening connections more reliable and efficient! We focus on the research and supply of high-quality Threaded Insert products, which are widely used in various industries such as aerospace, automotive manufacturing, and mechanical equipment.

Rivetfix not only offers a wide range of specifications, but also has a professional technical team providing full support throughout the process. This ensures that every threaded sleeve can perfectly meet your requirements.

Visit our official website https://rivetfix.com/ right now to get a personalized quote and technical consultation. Join hands to enhance the performance and competitiveness of your products! Choose Rivetfix, secure every connection, and achieve every remarkable project!

Get High Quality Rivet Nuts Quote!

Send Your Rivet Nut Request

For more than 20 years, Rivetfix has helped customers solve many rivet nuts sourcing needs and technical challenges.

Have a question? Contact us and we’ll provide you with the perfect solution.