Home » Custom Threaded Inserts

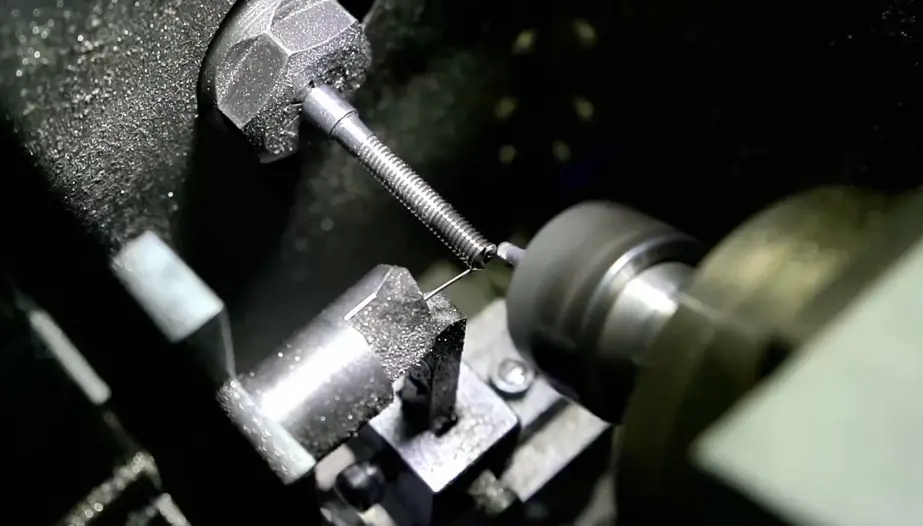

Custom Threaded Inserts For Your Project

Custom Threaded Inserts directly from Chinese factory!

Whether your project requires enhanced load strength, corrosion resistance, special dimensions, or adaptation to unique installation environments, Rivetfix offers fully customized threaded insert solutions tailored to your needs. We support a wide range of materials (stainless steel, carbon steel, aluminum, brass), structural types (tanged, tangless, self-locking), and non-standard size customization—ensuring every insert precisely fits your design and working conditions. Contact us today to explore our custom services—Rivetfix is here to safeguard your project with precision and reliability.

Rivetfix Thread Inserts Types

Material Options

Stainless Steel (304, 316)

Carbon Steel

Aluminum Alloy

Brass

Phosphor Bronze

Structure Types

Tanged / Tangless Inserts

Self-locking Inserts (with locking mechanism)

Open-end / Closed-end Inserts

One-way or Bi-directional installation types

Surface Treatments

Zinc Plating

Dacromet Coating

E-coating

Anodizing

Passivation

PTFE Coating

Professional Custom Threaded Manufacturer

Enhance Your Threaded Inserts Business

Rivetfix is a professional custom threaded insert manufacturer based in Suzhou, Jiangsu, China, dedicated to providing high-quality, on-demand thread reinforcement solutions for global customers. With advanced production equipment and a highly experienced engineering team, we offer multi-dimensional customization services—tailored to your drawings, performance needs, or special application scenarios.

Whether used in aerospace, automotive manufacturing, electronics assembly, or industrial equipment, Rivetfix delivers high-strength, highly reliable, and perfectly compatible threaded inserts to help your projects operate more stably, safely, and efficiently.

Custom Threaded Inserts Materials

Rivetfix offers all common wire thread inserts materials on the market. Including stainless steel (304/316), carbon steel, aluminum alloy, brass, and phosphor bronze—designed to meet various strength and environmental requirements.

- Stainless Steel (304, 316)

- Carbon Steel

- Aluminum Alloy

- Brass

- Phosphor Bronze

Custom Structure Types of Threaded Inserts

Custom structure types of threaded inserts are available to suit various installation and application needs:

Tanged / Tangless designs

Self-locking inserts

Open-end / Closed-end types

One-way / Two-way installation options

Floating inserts (to accommodate misaligned holes)

We also support non-standard structures customized according to your drawings or special application requirements.

Customized Threaded Inserts Surface Treatments

Customized surface treatments for threaded inserts are designed to enhance corrosion resistance, improve thread performance, or meet specific environmental requirements. You can choose the most suitable surface treatment based on your specific application needs.

Zinc plating

Nickel plating

Tin plating

Anodizing (for aluminum materials)

Coating treatments (such as PTFE coating, anti-corrosion coating)

Custom Threaded Inserts Solutions for You

Custom wire thread insert solutions tailored for you to meet diverse project needs and ensure strong, reliable connections:

Multiple material options (stainless steel, carbon steel, aluminum alloy, etc.)

Various structural types (tanged, tangless, self-locking, etc.)

Non-standard size customization to precisely match design requirements

Diverse surface treatments (zinc plating, nickel plating, anodizing, etc.)

Suitable for special installation environments (high temperature, corrosion, high vibration, etc.)

Steps to Custom High Quality Threaded Inserts

01

Send Threaded Inserts Inquiry

Contact us and send us your wire threaded inserts sourcing requirements. Include type, quantity and requirements.

02

Samping and Sample Testing

You will receive a sample of the threaded inserts within a week.

03

Confirmation and Production

Sample approval, production according to drawings

04

Delivery and Shipping

You need to pay the final payment of the order. Then we will ship your threaded inserts order to your country.

How to Choose Materials According to the Usage Scenario?

When selecting the material for threaded inserts, consider factors such as the working environment, load requirements, and budget:

- Stainless Steel Inserts: Ideal for humid, corrosive, or high-strength applications such as coastal areas, chemical equipment, and outdoor structures. 304 or 316 stainless steel is recommended.

- Carbon Steel Inserts: Cost-effective and suitable for general mechanical equipment or indoor structures. However, rust prevention (e.g., zinc plating) is necessary.

- Aluminum Inserts: Lightweight and suitable for applications requiring reduced weight, such as aerospace or electronic devices. However, due to lower strength, they are not recommended for high-load areas.

- Brass Inserts: Excellent corrosion resistance and electrical conductivity, commonly used in electrical equipment and precision instruments.

Will the Strength of the Customized Threaded Inserts Meet my Requirements?

Absolutely. When customizing wire thread inserts, we tailor the material (such as 304/316 stainless steel, carbon steel, aluminum alloy, etc.) and structural type (e.g., locking type, reinforced type) according to your specific application, load requirements, and base material. This ensures that the inserts provide sufficient tensile strength, shear strength, and wear resistance.

We also support non-standard dimensions and custom surface treatments to guarantee a secure fit and long-term performance after installation. If you have special strength requirements, simply provide your usage parameters, and our engineering team will conduct professional selection and design validation to ensure the final insert meets or even exceeds your expectations.

Can you Provide Samples of Threaded Inserts for Testing?

Absolutely. We offer samples for customers to test and evaluate. Simply let us know the required specifications, materials, structure types, and quantity, and we will arrange sample delivery based on stock availability. Common models can usually be shipped within 1–3 working days.

For customized models, we can also provide prototypes based on your drawings or specific requirements. Testing samples allows you to verify the fit, strength, and corrosion resistance in real-world applications, ensuring reliability and performance consistency before placing bulk orders. Feel free to contact us to request sample support.

Sample delivery lead time is usually 7-10 days.

Custom Threaded Inserts from Rivetfix

Rivetfix is a top China threaded inserts manufacturer and supplier. If you have a special demand for custom-made steel wire threaded inserts and need the supply of steel wire threaded inserts, we will fully meet your expectations!

Customize threaded inserts for your project now!

Get a Free Quote Now!

We believe Rivetfix will be your best partner!

Please fill out the form with your contact details or contact our whatsapp, and we will get back to you within 24 hours.