Home » Wholesale Wire Threaded Inserts From China

Wholesale Wire Threaded Inserts From China

If you’re looking for high-quality and competitively priced wire thread inserts, Rivetfix is your trusted partner. As a leading manufacturer in China, we operate modern production facilities, maintain strict quality control systems, and have extensive experience in global exports. Whether you’re sourcing in bulk, customizing for a specific project, or seeking OEM cooperation, Rivetfix offers high-strength, high-precision threaded inserts that meet international standards—ensuring more efficient and durable assemblies.

Contact Rivetfix today for a competitive quote!

Related Products

Get a Free Quote Now!

custom rivet and rivet nut manufacturer

1 4 20 Threaded Insert

5/16-24 Threaded Inserts

M3 Threaded Insert

3 8 Threaded Insert

M4 Threaded Insert

M5 Threaded Insert

M8 Threaded Insert

Applications of Wire Thread Inserts

Aerospace

Used in aircraft engines, airframes, and avionics systems to provide durable and lightweight threaded connections that withstand vibration and thermal stress.

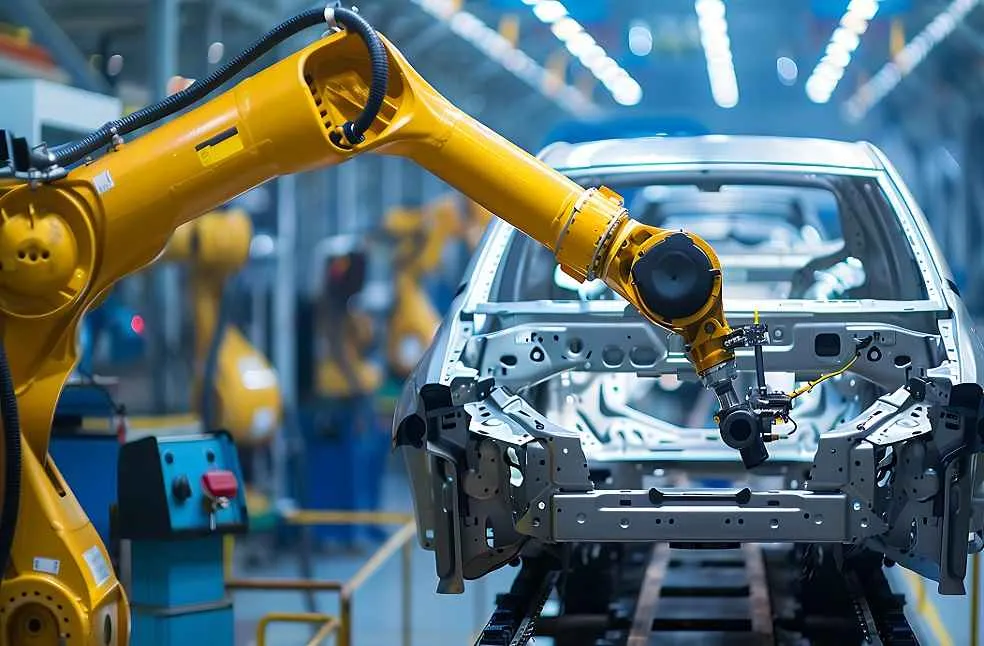

Automotive

Applied in engine blocks, gearboxes, and chassis components for reliable thread performance in high-temperature and high-vibration environments.

Electronics and Consumer Devices

Installed in lightweight enclosures and housings to prevent thread stripping in plastic or soft metal components.

Industrial Machinery

Ensures strong and reusable threads in castings, aluminum components, and equipment requiring frequent assembly/disassembly.

Marine and Shipbuilding

Utilized in high-corrosion environments for stainless steel thread reinforcement in structural and equipment installations.

Medical Devices

Supports reliable fastening in surgical equipment and diagnostic devices where hygiene and precision are essential.

Related Articles

What Is the Difference Between Keensert and Threaded Insert?

What Is the Differen

FAQs About Wire Threaded Inserts

1. What Are Wire Threaded Inserts?

Wire threaded inserts are helical coils made from stainless steel, installed into pre-tapped holes to create a high-strength, wear-resistant internal thread. They are used to enhance thread performance in soft materials or to repair damaged threads.

2. What Materials Are Wire Threaded Inserts Suitable For?

Wire inserts are especially suitable for soft or low-strength base materials such as:

Aluminum and its alloys

Magnesium alloys

Plastics

Wood (certain structures)

Cast iron or light alloy castings

They greatly improve thread strength and wear resistance in these materials.

3. What Are the Main Applications of Wire Inserts?

Reinforce threads in soft base materials

Repair stripped or damaged threads

Convert between metric and imperial thread systems

Improve resistance to loosening under vibration or frequent disassembly

Ensure long-term durability of thread connections

4. Are Wire Threaded Inserts Reusable?

The inserts themselves can be reused, but over-tightening the screw can damage the internal coil. If an insert loosens or fails, it must be replaced with a new one.

5. How Do I Choose the Correct Insert Size?

You should consider:

The external diameter and pitch of the mating screw

The diameter and depth of the tapped hole

Required load-bearing strength

Whether the purpose is thread repair, reinforcement, or conversion

Refer to standard sizing charts (e.g., ISO, UNC, UNF) for selection.

6. What Tools Are Needed for Installation?

Installation usually requires:

Insertion tools (manual or powered handles)

Drill bit (to prepare the hole)

Tap (to cut the threaded hole)

Tang break-off tool (for inserts with tangs)

Brands like Recoil and Heli-Coil offer complete installation kits.

7. What Types of Wire Inserts Are Available?

Common types include:

Tanged Inserts: Require tang removal after installation

Tangless Inserts: Used in applications where tang remnants are unacceptable

Self-locking Inserts: Designed for vibration resistance

Extended or fine-thread custom inserts

8. Are Wire Inserts Corrosion Resistant?

Most are made from stainless steel (304 or 316), offering good corrosion resistance. For marine or chemical environments, you can choose nickel-plated or 316L stainless steel for enhanced durability.

9. Can Wire Threaded Inserts Be Customized?

Yes. Rivetfix provides full customization options for material, size, structure (self-locking, knurled, etc.), and surface finish (e.g., phosphate, nickel-plated, color zinc) to suit specific project requirements.

10. What Is the Typical Service Life of Wire Inserts?

When properly installed and used, wire inserts can last through thousands of installation/removal cycles—far exceeding the durability of directly tapped threads in soft materials. Their lifespan depends on usage conditions and maintenance.